BLASTONE Mist Blaster Instruction manual

Mist Blaster™

www.BlastOne.com

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

2

MANUAL CONTENTS

Fill in your model and serial number in the blank spaces below. These can be used for reference whenever service

or maintenance is required.

Unit Serial Number

Date Of Issue

3 Safety Warnings

5 Rules For Safe Operationa

8 Description

10 How the System Works

9 How It Works

11 System Set Up

13 Operating Procedure

15 Maintenance

16 Fault Finding

18 Diagrams

21 Spare Parts & Accessories

3

SAFETY WARNINGS

Read all recommended safe procedures before attempting to use this equipment.

WARNING

• Depressurize unit before loading media or before any maintenance is performed.

• Do not use abrasives containing silica, lead, arsenic, copper, zinc or sharp glass particles - use

of abrasives containing these elements could result in serious injury or death.

• Furnish all personnel in the work area with hearing protection and approved respiratory

equipment.

• Do not modify or alter any equipment or controls without written consent from Blast One.

• Wear suitable eye protection when lling unit. There is a possibility that some abrasive may be

blown back as the pop-up valve seats.

• Always keep ngers well clear of the working area of the pop-up valve.

• Periodically check all hoses to see that they are in good condition. Repair any valves or hoses

that show any signs of wear or leakage.

• All blast operators must use approved respiratory protective equipment.

• The interior condition of the vessel should be inspected regularly for corrosion.

• All blast hose couplings and air hose couplings are provided with holes which must be safety

pinned or wired to prevent accidental disconnections.

• Any blast equipment without remote controls must have remote controls installed before

operating. Failure to do so is a violation of safety regulations and can cause serious injury

or death to personnel in the blasting area. The use of A-BEC, Clemco or a similar bleeder

type deadman can cause unintentional start-up without warning, which can result in serious

personal injury.

• Unrestricted air ow through a compressed air hose end will result in a whipping action which

can cause severe injury or death. Always attach a ball valve to each hose "at the source of supply

or branch line". Whip check hose restraints should be installed.

• Before operating any abrasive blasting equipment, READ ALL operating and maintenance

instructions. Personal protective equipment is REQUIRED when using this type of equipment.

Blasters MUST be equipped with heavy canvas or leather gloves, and blast overalls. Safety

shoes and hearing protection MUST be worn when required.

• Many coatings contain lead and other heavy metals that are toxic to humans and other life

forms. It is imperative when removing lead based coatings, that the operator be aware of the

standard industrial hygiene program as referenced in Australian Standard 4361.1. A thorough

understanding of all applicable regulations are necessary before operating this equipment.

4

SAFETY WARNINGS

When the unit is operating:

• DO NOT attempt to perform maintenance while the unit is under pressure or is even

capable of being pressurized. This means, at a minimum, the inlet valve should be closed

and ideally the air source be shut off or disconnected. Anytime the manual blow-down

valve (if tted) is closed it should be assumed the unit is under pressure.

• DO NOT aim the blast nozzle at any person or object indiscriminately;

• DO NOT remove, repair, or replace any parts while equipment is operating;

• DO NOT use worn or inferior quality hoses;

• DO NOT OVERFILL THE UNIT;

• DO NOT operate this machine without thorough knowledge of the machines’ operation;

• DO NOT exceed the recommended air pressure;

• DO NOT operate without safety locking clips and whip checks on the air hoses.

WARNING

The products described and illustrated in this manual are intended for experienced and

knowledgeable users of similar equipment used in the blasting industry. The important

safety instructions appearing in this manual cover normal conditions and situations.

Unusual, unforeseeable use may occur and in these situations, it must be understood that

common sense, caution and care are to be followed. These factors are not built into the

machine, but are supplied by the person(s) maintaining and operating it.

No representations are made or intended as to the useful life, maintenance cycles,

efciency or performance of this product or combination of products. It is the responsibility

of the user to ensure that proper and comprehensive training of operators has been

performed and all environmental and safety precautions observed.

CAUTION

WARNING LABELS

Listed below are the warning labels & the corresponding hazards encountered with the equipment.

7031-054 7031-007A

5

RULES FOR SAFE OPERATION

• Know your equipment. Do not operate this equipment in a manner other than its intended

application. Do not operate this equipment or any other equipment without following these

“Rules For Safer Operation” and all operating procedures and instructions. Learn the

applications and limitations as well as the specic potential hazards related to this machine.

Failure to do so could result in serious injury or death.

• Receive proper training. Do not operate this equipment unless you have received operational

maintenance training. Begin by thoroughly reading and understanding this operation and

maintenance manual and all included operation.

• Protect your feet. Do not operate this equipment without wearing approved foot protection.

Observe all local, state and federal safety regulations.

• Protect your eyes. Do not operate this equipment without wearing approved safety glasses.

Observe all local, state and federal safety regulations. When lling the abrasive blaster, there is

a possibility for some abrasive to be blown back.

• Protect your lungs. Do not operate this equipment without wearing approved respiratory

protection. Breathable silica may be generated by the use of this product. Silica can cause

severe and permanent lung damage, cancer and other serious diseases. Do not breathe the

dust. Do not rely on your sight or smell to determine if dust is in the air. Silica may be in the air

without a visible dust cloud. If air monitoring equipment for silica is not provided at the worksite,

then all personnel must wear appropriate respiratory protection when using or servicing this

equipment. Breathing air supplied to respirators must be of an acceptable quality.

• Protect bystanders. All blast equipment operators and personnel entering the vicinity of the

blast operation must use respiratory protective equipment that meets regulations.

• Protect your hearing. Do not operate this equipment without wearing approved hearing

protection. Observe all local, state and federal safety regulations. Loud noise is generated by

the blast nozzle and the blowdown operation of this equipment.

• Stay alert. Do not operate this equipment when you are tired or fatigued. Use caution and

common sense while operating and/or performing maintenance on this equipment.

• Do not use drugs, alcohol or medication. Do not operate this equipment while under the

inuence of drugs, alcohol or any medication.

• Keep children & visitors away. Do not let children or visitors contact this equipment or the

connecting hoses and cords. Keep children and visitors away from the work area.

• Avoid dangerous environments. Do not expose this equipment to rain. Do not use this

equipment in wet conditions. Keep work areas well lit. when working at an elevated location,

pay attention to equipment and personnel below.

• Fire damage notice. Do not operate if the vessel has been damaged by re. If damaged, take out

of service immediately and have it inspected and/or repaired at a qualied facility.

6

RULES FOR SAFE OPERATION

• Depressurize vessel before performing maintenance. Do not remove, repair, or replace any

item on this equipment while it is pressurized. Do not attempt to perform maintenance or load

media while this equipment is pressurized or even capable of being pressurized. This means

at a minimum the inlet ball valve should be closed and ideally the air source be shut off or

disconnected. Any time the manual blowdown valve is closed it should be assumed that the

abrasive blast vessel is pressurized.

• Do not modify vessel. Do not modify or alter any abrasive blaster, blast equipment, or controls

thereof without the written consent of BlastOne. Do not weld, grind or sand the pressure vessel.

It will not be safe to operate. Non-authorized modications could lead to serious injury or death.

Non-authorized modications will void your warranty and the vessel’s pressure certication.

• Inspect vessel regularly. Do not operate if the vessel has been damaged. It is not safe. Inspect

the outside and inside of the pressure vessel regularly for corrosion and damage (i.e. dents,

gouges or bulges). If damaged, take out of service immediately and have it inspected and/or

repaired by a qualied facility.

• Check for leaks in vessel. Do not operate this equipment if there is a leak. If leaking, take out of

service immediately have it inspected and/or repaired by a qualied facility.

• Never operate over maximum working pressure. Do not operate this equipment above the

maximum allowable working pressure at the maximum operating temperature as marked on

the nameplate attached to the trailer.

• Never modify discharge. Do not connect the air discharge on this unit onto a common header

with any other unit of any description, or any other source of compressed air, without rst

making sure a check valve is used between the header and this unit. If this unit is used in

parallel with another unit of higher discharge and capacity, a safety hazard could occur in a back

ow condition.

• Always use remote controls. Do not sell, rent or operate abrasive blasters without remote

controls. Regulations require remote controls on all blast machine. All blast systems must be

equipped with automatic deadman type remote controls, either pneumatic or electric. Failure to

use remote controls can cause serious injury or death to the operator(s) or other personnel in

the blasting area.

• Check for damaged parts. Do not use this equipment with damaged components. Periodically

check all valves, hoses and ttings to see that they are in good condition. Repair any component

that shows any sign of wear or leakage.

• Always use safety pins on hose couplings. Do not use this equipment without safety pins in

place. All blast hose couplings and air hose couplings are provided with holes that must be

safety pinned to prevent accidental disconnections. Accidental hose disconnection can cause

serious injury or death.

• Always use correct replacement parts. Do not use replacement parts or accessories that

are not rated for pressures equal or higher than your abrasive blaster’s operating pressure.

Improper hoses and/or ttings used on, or connected to your abrasive blaster can rupture and

cause serious injury or death.

7

RULES FOR SAFE OPERATION

• Never aim nozzle towards any person. Do not aim the blast nozzle towards yourself or any

person. System malfunction can cause accidental start-up and result in injury to personnel.

• Never use media not intended for blast equipment. Do not use blast media containing free

silica. Silica can cause silicosis or other related respiratory damage. You must wear personal

protective equipment for all abrasive blasting operations.

• Check abrasive for foreign objects. Do not use blast media that contains trash or other foreign

objects. Trash or foreign objects can create a blockage and cause equipment malfunction.

Screen recycled media to remove trash.

• Use the provided kickstand when unit is stationary. Ensure that the kickstand is down and

locked in place using provided pin whenever the Mist Blaster™ is not being moved. The

kickstand can be locked in the up position using the same pin when the unit is to be moved.

• Stop operation immediately if any abnormality is detected. Do not operate this equipment if

any abnormalities are observed during operation. Stop operation immediately for inspection.

• Inspect pop-up valve assembly. Inspect the assembly and all other associated parts for proper

working condition.

• Maintain warning labels. Do not remove, cover, obstruct, deface or paint over any warnings,

cautions or instructional material attached. Warning labels (decals) must be provided,

maintained and conspicuously located with enough light for legibility.

• Save this operation and maintenance manual. Refer to this operation and maintenance manual

as well as any additional information included from other manufacturers as needed. Never

permit anyone to operate this equipment without having him/her rst read this manual and

receiving proper training. Provisions should be made to have this manual readily available

to the operating and maintenance personnel. If for any reason the manual becomes lost or

illegible, have it replaced immediately. This operation and maintenance manual should be read

periodically to maintain the highest skill level; it may prevent a serious accident.

WARNING

Keep ngers away from the pop up valve.

Whenever compressed air is applied to the unit,

there is the possibility that the valve may energize.

Severe personal injury can result

8

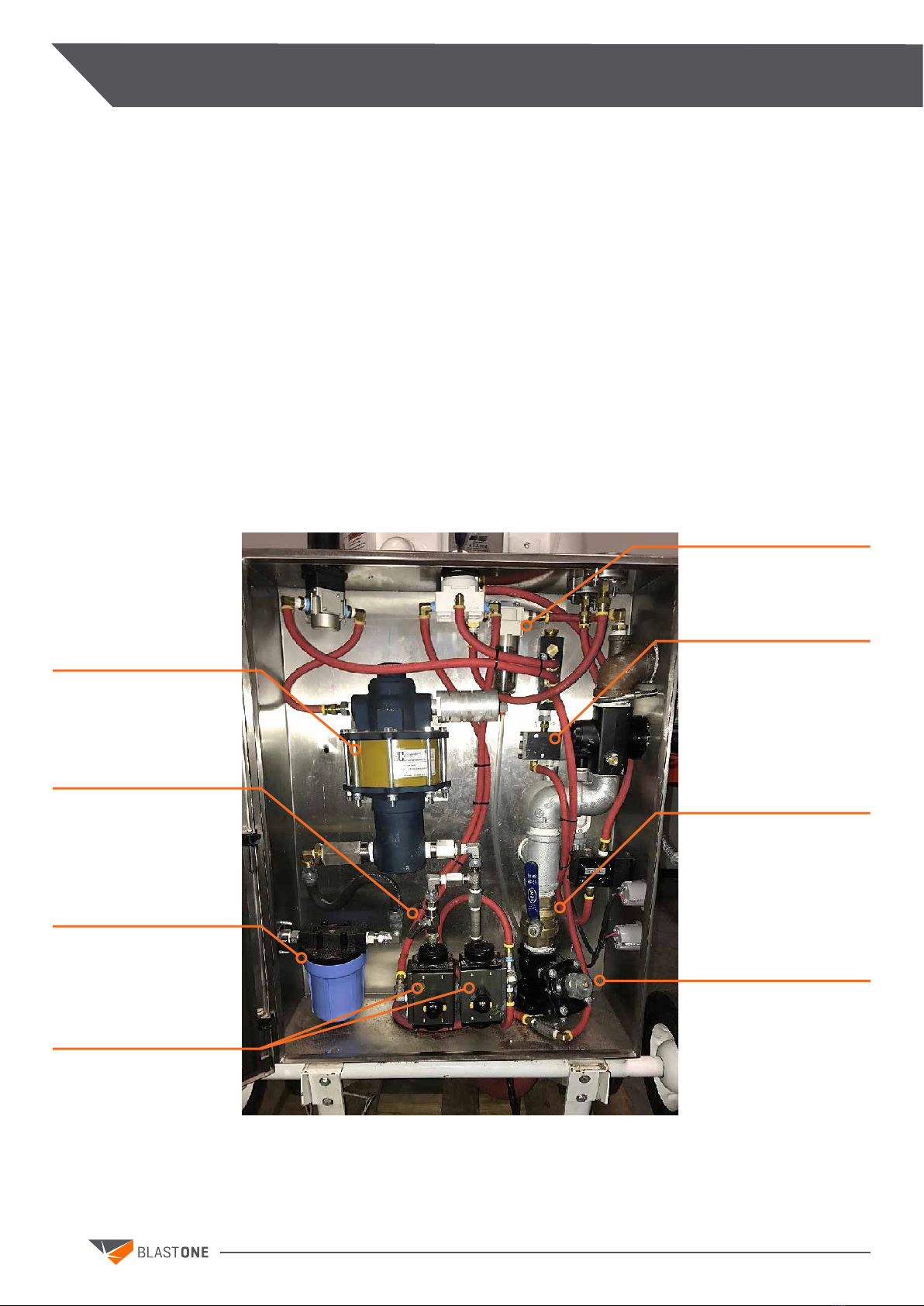

DESCRIPTION

The Mist Blaster™ is a blast machine with a cabinet mounted on a standard blast pot to allow

for mist blast, dry blast, and wash down functionality, consisting of the blast pot, an additional

mounting frame, injection block, and associated connecting hose.

The standard blast pot comprises a certied pressure vessel with internal pop-up valve, separate

electric pilot operated automatic air valve and Thompson abrasive metering valve, manually

operated exhaust valve, manually operated “choke” ball valve and associated pipe work

A three-way switch, pump regulator, blast air regulator, needle valve, and injection block are used

to allow for multifunctionality and to control each function. Both the water pressure and blast air

pressure may be adjusted using their dedicated regulators. The needle valve may be adjusted to

meter the amount of water introduced during the mist blasting.

Precautionary safety mechanisms are provided: a dead-man control and an emergency stop button.

If either the dead-man handle is released or the emergency stop is pressed, the entire system will

cease operation.

Air lter/

Moisture Separator

Deadman

control valve

Water pump

Needle valve

Water lter

Air actuated

valves

Manual

choke valve

Automatic

air valve

9

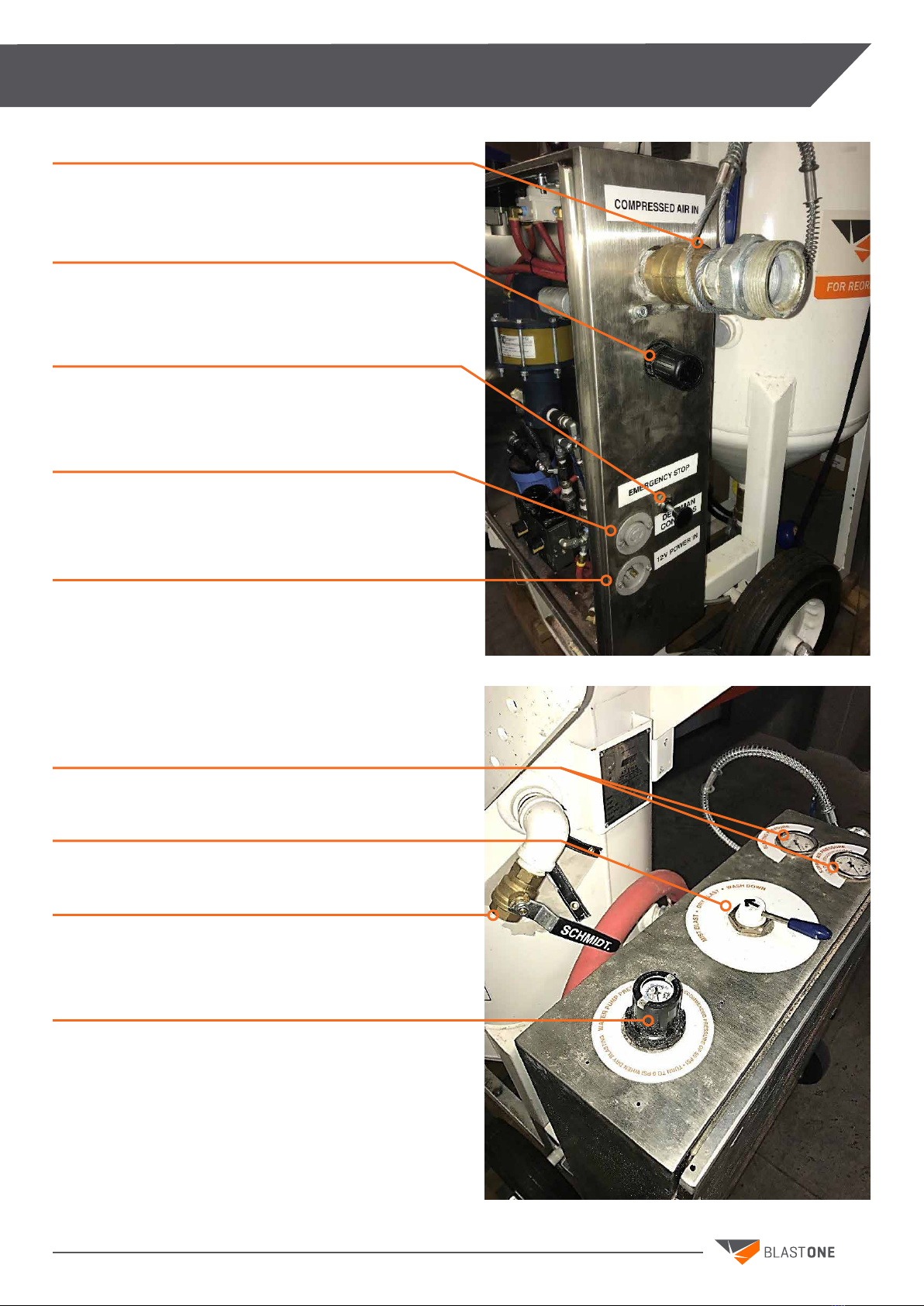

DESCRIPTION

Air inlet connection

Blast air pressure regulator

Emergency Stop Button

Deadman connection 3 pin twist lock plug

12 volt power in

Blasting pressure and supply pressure

3 way switch

Manual blow down exhaust valve

Water pump pressure regulator

10

HOW THE SYSTEM WORKS

With air supplied and with the manual exhaust (blow down) ball valve closed, the pot will be

pressurized as soon as the inlet ball valve is opened.

When the three-way switch is set to the dry blasting position, the dead-man handle is pressed, and

the emergency stop has not been actuated, the auto air valve and Thompson valve are energized.

Air pressure will then pass to the automatic air valve, which will open, allowing air to pass down

through the choke valve, through the ‘pusher’ line to the Thompson valve, and through the blast

hose to the nozzle.

When the three-way switch is set to the mist blasting position, the dead-man handle is pressed,

and the emergency stop has not been actuated, the air actuated valve corresponding to mist

blasting will open and metered water will be introduced into the system at the water injection

block. This metered water will join the abrasive from the Thompson valve and both will be propelled

through the blast hose to the nozzle.

When the three-way switch is set to wash down position, the dead-man handle is pressed, and the

emergency stop has not been actuated, the air actuated valve corresponding to wash down will

open and unmetered water will be introduced into the system at the water injection block. In this

setting, the normally open Humphrey valve is actuated which in turn deenergizes the Thompson

valve, so no abrasive is added to the stream.

When the deadman is released or the emergency stop is actuated, the entire system is de-energized,

the air, water, and abrasive supply to the blast nozzle is stopped.

The pot is still pressurized, however. To release the pressure in the blast pot, close off the inlet

ball valve, then open the blow down ball valve. When the air is released, the pop-up valve will drop,

allowing abrasive to be added if required.

Depressurization is a noisy operation, so hearing protection for operators and persons in the

vicinity is mandatory.

This control system operates on 12 volts D.C. ONLY. Do not attempt to use any other power

supply or damage will result.

FAILURE TO HEED THIS WARNING COULD RESULT IN SERIOUS PERSONAL INJURY

AND DAMAGE TO THIS EQUIPMENT

WARNING

11

SYSTEM SET UP

Connect the blasting hose to the outlet coupling

on the water injection valve. A large whip check

and safety clips MUST be used, as shown

Connect air supply hose (minimum 2” I.D.)

to the inlet connection (using a large whip

check) and connect the 12 volt power supply

and deadman cable

Connect a water supply to the water inlet

12

SYSTEM SET UP

TO FILL

The inlet air supply MUST be turned off prior to lling. Close the inlet ball valve and open the blow

down ball valve. Allow any residual air pressure to be relieved, or the pop up valve may not drop to

allow abrasive to enter.

Dump abrasive into the screen (if supplied), where it will be sieved through into the top head dish.

Pieces of the bag, etc. will be prevented from entering the pot. The abrasive will ow into the pot

until full. An excessive amount of material piled on top of the pop-up valve after the unit is full may

prevent the pop-up valve from closing properly. If the lid is moved for any reason, be sure to keep

ngers clear of the pop-up valve.

OPERATION CHECK LIST

1. The alligator clips are connected to a fully charged automotive battery.

2. The deadman cable is connected to the plug.

3. The provided kickstand is down and locked in place with provided pin.

4. The blast hose is connected to the injection connection AND has a whip check and safety locking

pin inserted.

5. Ensure adequate c.f.m. for chosen nozzle is suppled; refer to air consumption chart on page 15.

6. Ensure system is connected to a dry air supply, as moisture inside the blast pot leads to

abrasive clumping; please consult a BlastOne sales representative for a moisture control

solution.

7. The supply air hose (minimum 2” I.D.) is connected to the inlet tting AND has a whip check a

safety locking pin inserted.

8. Abrasive has been added to the pot.

9. A water supply (either tap water or gravity feed tank, not siphon) is available and turned on;

for long distances, a transfer can be used. The transfer pump should be turned off when in dry

blast mode.

10. The manual needle valve is open at least one eighth of a turn and increase/decrease as needed.

11. CLOSE the exhaust air ball valve.

12. OPEN the supply air ball valve, and allow air to enter the system. Listen for any leaks on

connections and ttings.

Failure to install safety pins on all blast hose couplings could result in serious injury or

death.

WARNING

13

OPERATING PROCEDURE

DRY BLAST

To operate in dry blast mode, turn the three-way switch to dry blast and ensure that the pump

regulator is set to 0 PSI. If using a transfer pump with a water tank, ensure that the transfer pump

is off when dry blasting. With the nozzle pointed at the work, push the deadman handle. Air and

abrasive will ow into the blast hose, and blasting will commence.

The abrasive ow can be adjusted with the control knob on the abrasive metering valve. Turn

clockwise for less abrasive and counter clockwise for more abrasive. Due to the length of the blast

hose there will be a slight delay in control of the abrasive at the nozzle, so allow a few seconds

before adjusting further.

To stop the process, release the deadman handle. Note that the pot will not depressurize; only the

blasting process will stop. The pot is still under pressure.

MIST BLAST

To operate in mist blast mode, turn the three-way switch to mist blast and ensure that the pump

regulator is set to 50 PSI. With the nozzle pointed at the work, push the deadman handle. Air and

abrasive will ow into the blast hose, and blasting will commence. Water will also be introduced,

providing dust suppression. The amount of water may be adjusted using the needle valve. Turn

clockwise for less water and counter clockwise for more water. It is not recommended to adjust the

water ow by using the pump’s air regulator, as a minimum pressure is required to inject into the

blast hose.

The abrasive ow can be adjusted with the control knob on the abrasive metering valve. Turn

clockwise for less abrasive and counter clockwise for more abrasive. Due to the length of the blast

hose there will be a slight delay in control of the abrasive at the nozzle, so allow a few seconds

before adjusting further.

To stop the process, release the deadman handle. Note that the pot will not depressurize; only the

blasting process will stop. The pot is still under pressure.

WASH DOWN

To operate in wash down mode, turn the three-way switch to wash down and ensure that the pump

regulator is set to 50 PSI. With the nozzle pointed at the work, push the deadman handle. Air and

water will ow into the blast hose, and wash down will commence.

IMPORTANT: When switching from dry or mist blast to wash down, there will still be abrasive

in the blast line for a brief period of time. Always adhere to all safety protocol when operating

the Mist Blaster™.

To stop the process, release the deadman handle. Note that the pot will not depressurize; only the

blasting process will stop. The pot is still under pressure.

14

OPERATING PROCEDURE

PROPER SHUT DOWN PROCEDURE

It is recommended that when blasting has nished, the blast hose should be ushed free of all

abrasive and water. Shut the union ball valve and set the system to dry blast and activate the

deadman. This will only take 20 to 30 seconds, depending on the length of the blast hose. When the

white haze is not observed at the nozzle, the hose is clear.

This is an important procedure, especially when working at heights. This blow through

prevents any residual water in the hose running backwards and accumulating at the Thompson

valve, resulting in a clogged valve.

DEPRESSURIZING THE POT

To release the pressure in the blast pot, close off the inlet ball valve, then open the blow down

ball valve. When all the air is released, the pop-up valve will drop, allowing abrasive to be added if

required.

WATER SUPPLY

Water supply with a positive head is required for the Mist Blaster™. You can achieve this by

positioning the uid level of the reservoir above the water inlet of the pump or by providing a

pressurized uid supply.

One way to achieve a pressurized uid supply is with a water tank and 12V transfer pump. The

transfer pump should be connected to a fully charged 12V automotive or marine battery. When

operating in dry blast mode, ensure that the transfer pump is off. In addition, ensure that the

transfer pump is off when the Mist Blaster™ is not in use. Consult a BlastOne sales representative

about suitable water supply options.

WINTERIZING THE UNIT

When operating in near-freezing to freezing temperatures, it is vital that the necessary precautions

are taken to prevent any water freezing in the pipes of the Mist Blaster™. To prevent such freezing,

run windshield wiper uid through the unit in place of water until only the windshield wiper uid

exits the unit.

Airborne particles and loud noise hazard from exhaust air can cause serious injury and loss

of hearing. Stay clear of the blow down path. DO NOT place hands or other body parts in the

blow down air path. Make sure no personnel are in the blow down air path. Wear approved

eye and ear protection.

WARNING

15

MAINTENANCE

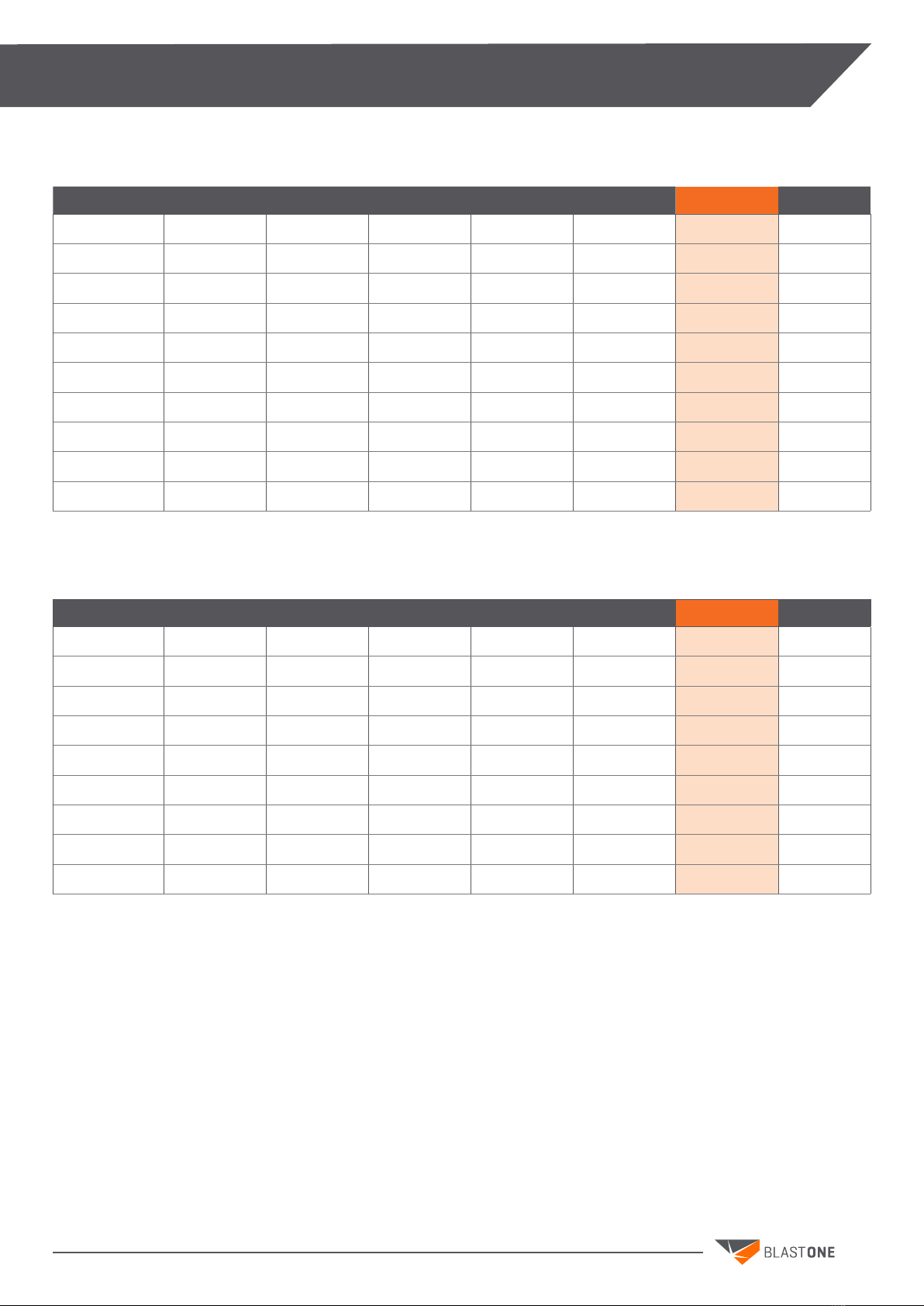

AIR CONSUMPTION (C.F.M.) PER BLAST NOZZLE

ABRASIVE CONSUMPTION (LBS PER HOUR) PER BLAST NOZZLE

NOZZLE SIZE 60 p.s.i. 70 p.s.i. i. 80 p.s.i. 90 p.s.i. 100 psi 120 p.s.i.

No. 2 1/8” 17 19 21 24 26 30

No. 3 3/16” 37 42 47 52 57 67

No. 4 ¼” 66 75 84 93 103 119

No. 5 5/16” 103 117 131 145 158 186

No. 6 3/8” 149 169 189 209 229 269

No. 7 7/16” 203 230 258 285 312 367

No. 8 ½” 265 300 336 371 407 478

No. 10 5/8” 412 468 524 580 632 744

No. 12 ¾” 596 676 756 836 916 1076

Efciency 55% 64% 74% 86% 100% 130%

NOZZLE SIZE 60 p.s.i. 70 p.s.i. i. 80 p.s.i. 90 p.s.i. 100 psi 120 p.s.i.

No. 2 1/8” 90 105 115 130 140 165

No. 3 3/16” 205 230 260 290 320 375

No. 4 ¼” 365 420 460 500 560 660

No. 5 5/16” 575 650 725 825 900 1050

No. 6 3/8” 840 945 1050 1155 1260 1475

No. 7 7/16” 1150 1300 1450 1600 1750 2050

No. 8 ½” 1460 1660 1850 2000 2250 2650

No. 10 5/8” 2290 2600 2900 3125 3520 4100

No. 12 ¾” 3300 3750 4180 4500 5060 5950

16

FAULT FINDING

SYMPTOM POSSIBLE PROBLEM REMEDY

Air Blast but No Abrasive

(with water ow)

The pot is empty Rell

Thompson valve isolation ball valve is

closed

Open

The abrasive in the pot is wet

(Moisture can enter in vapor form

with the compressed air - this is not

uncommon depending on air quality) *

Try closing the choke valve until some

abrasive is pumped out. Operating

the unit in the "choked" condition

will allow the use of media that

is too damp to ow properly, but

it greatly accelerates wear in the

metering valve. Continuous running

in the “choked" position also reduces

productivity and therefore should be

avoided

The remote abrasive control valve is

faulty

Inspect for dirt jamming the internal

shuttle valve

Foreign matter is plugging the

abrasive metering valve

Try closing the choke valve &

opening the abrasive metering valve

momentarily to see if that will blow

the obstruction out. If this does not

work then it will be necessary to

depressurize the pot & remove the

obstruction by hand

Pop up valve/handway leak - worn or

out of alignment with seal

Check and rectify

Air control line leak Ensure all ttings are tight and there

are no holes, cuts, kinks, or abrasions

in air lines

Worn out exhaust ball valve Check and rectify

Unit turns on

accidentally

The deadman is faulty Repair or replace

Deadman control valve is faulty Repair or replace

Air Blast with

Abrasive but no

Water

Water not turned on Turn on

Needle valve closed Open

Pump pressure regulator set too low Raise to 50 p.s.i. on gauge

Air actuated valve failure Check and rectify

Needle valve blocked Remove and clean

Water lter blocked Remove and replace

Pump failure Repair or replace

17

FAULT FINDING

SYMPTOM POSSIBLE PROBLEM REMEDY

Reduced Pressure

at the Nozzle

(with or without

abrasive ow)

Undersized air compressor (see air

requirements chart)

Use a larger compressor or a smaller

nozzle

Air hose is too small The air hose diameter should be at

least 3 times the nozzle diameter.

Abrasive adjustment open too far Start off with no abrasive (fully closed)

then open slowly, whilst observing

air stream existing the nozzle, until a

slight color change can be seen

Pop-up not seating properly Check valve and “O”-ring seat

Choke valve partially closed Open fully

Nozzle is worn Inspect and replace

Unit is Slow to

Turn On or Will

Not Turn On

The control valve is faulty Inspect for dirt jamming the internal

shuttle valve

Control hoses are leaking Check and repair

Control hoses are plugged or kinked Repair as necessary

Breather vents clogged Inspect and replace

18

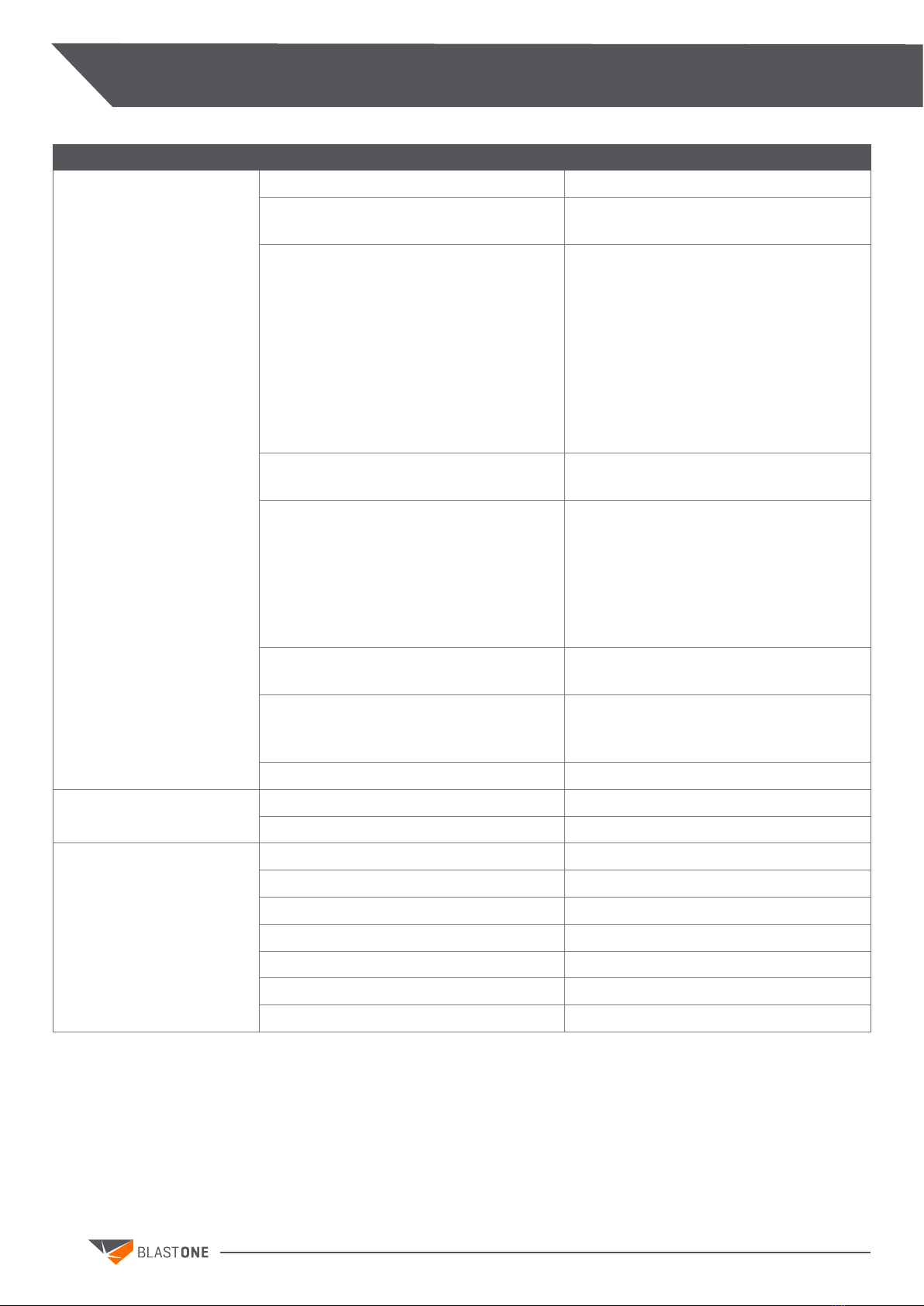

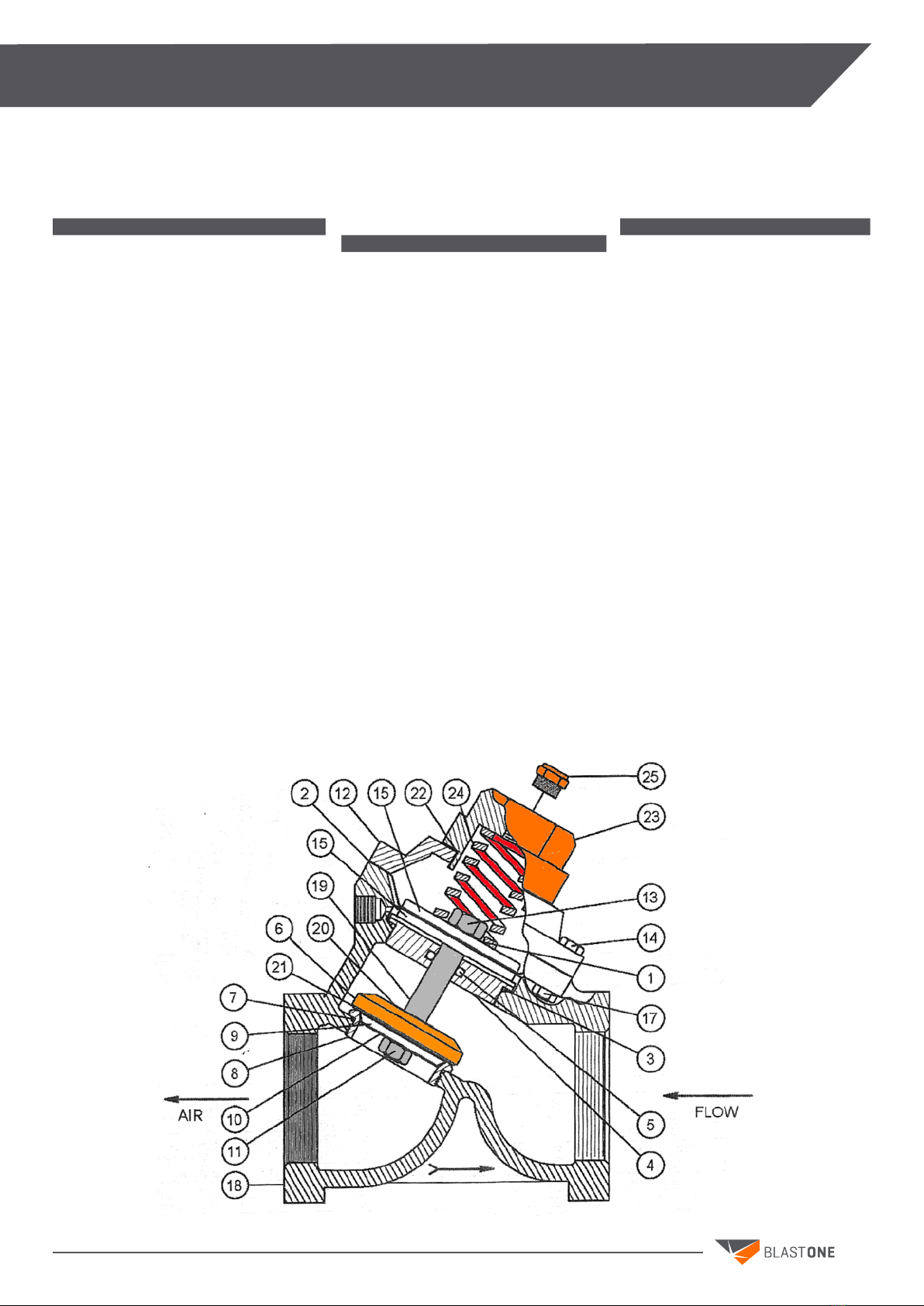

DIAGRAMS

NOTE: With spring closed valve air ow is in opposite direction from arrow on valve body.

2152-006 1" Valve With Tungsten Carbide Sleeve

2152-106 1" Valve With Urethane Sleeve

2152-007 1 1/4" Valve With Tungsten Carbide Sleeve

2152-107 1 1/4" Valve With Urethane Sleeve

2152-008 1 1/2" Valve With Tungsten Carbide Sleeve

2152-108 1 1/2" Valve With Urethan Sleeve

NO. PART NO. DESCRIPTION

2152-000-99 Repair Kit With Tungsten Carbide Sleeve

2152-100-99 Repair Kit With Urethan Sleeve

12152-000-01 Knob

22152-000-17 Breather Vent

32152-000-12 Spring Retainer

4*+ 2152-000-18 O-Ring

57027-503-02 Washer

67010-507-07 Hex Bolt, 3/8" UNC x 1-1/4" Lg.

72152-000-02 Cap Plate

8*+ 2152-000-16 Cap Gasket

92149-000-19 Bump Ring

10 2152-000-25 Vibration Disc

11 2152-000-03 Spring

12 2149-000-08 Nut

13*+ 2149-000-04 Piston Seal

14 2152-000-05 Piston

15*+ 2152-000-07 Tungsten Carbide Plunger

16 2152-000-09 Cylinder

17*+ 2149-500-06 Plunger Seal (Molythane)

18*+ 2152-000-06 Plunger Seal (Urethane)

19 2152-000-14 Body

20+ 2152-100-13 Urethane Sleeve

21 2152-000-19

2152-000-15

2152-000-11

Base, 1" NPT

Base, 1 1/4" NPT

Base, 1 1/2" NPT

22 7010-507-95 Hex Bolt, 3/8" UNC x 4 3/4" Lg.

23 3014-106 Plug

24* 2152-000-21 O-Ring

25* 2152-000-13 Tungsten Carbide Sleeve

26* 2152-000-10 Seat

27 8403-000-54 Cleanout Ball Valve Adder

28 3006-106 Street Elbow 90°, 1" Galv.

29 3029-106-09 Nipple TBE, 1" x 2" Lg. Galv.

30 2401-506 Ball Valve, 1" Full Port

* Included in Repair Kit for Tungsten Carbide Sleeve

+ Included in Repair Kit for Urethane Sleeve

THOMPSON VALVE®II

19

DIAGRAMS

AUTOMATIC AIR VALVE (NORMALLY CLOSED)

2123-106 1" Valve

NO. PART NO. DESCRIPTION

2123-006-99 Repair Kit

1* 2123-006-01 Gasket

2* 2123-006-02 Diaphragm

3* 2123-006-03 O-ring

42123-006-04 Retainer Bushing

5* 2123-006-05 O-ring

62123-006-06 Disk Retainer

7* 2123-006-07 O-ring

82123-006-08 Seat

92123-006-09 Disc Plate

10 "Deleted" Lock Washer, Internal

11* 2123-006-11 Lock Nut

12 2123-106-12 Cap

13* 2123-006-13 Hex Nut (w/Locktite)

14 2123-006-14 Cap Screw

15 2123-006-15 Diaphragm Plate

17 2123-006-17 Lock Nut

18 2123-006-18 Body, 1"

19 2123-006-19 Shaft

20* 2123-006-20 Gasket

21* 2123-006-21 Disc

22 2123-106-22 O-ring

23 2123-106-23 Spring Retainer

24 2123-106-24 Spring

25 2014-300 Vent, 1/8"

(not included)

* Included in Repair Kit

2123-109 2" valve

NO. PART NO. DESCRIPTION

2123-009-99 Repair Kit

1* 2123-009-01 Gasket

2* 2123-009-02 Diaphragm

3* 2123-009-03 O-ring

42123-009-04 Retainer Bushing

5* 2123-009-05 O-ring

62123-009-06 Disk Retainer

7* 2123-009-07 O-ring

82123-009-08 Seat

92123-009-09 Disc Plate

10 "Deleted" Lock Washer,

Internal

11* 2123-009-11 Lock Nut

12 2123-109-12 Cap

13* 2123-009-13 Hex Nut

(w/Locktite)

14 2123-009-14 Cap Screw

15 2123-009-15 Diaphragm Plate

17 2123-009-17 lock Nut

18 2123-009-18 Body, 2"

19 2123-009-19 Shaft

20* 2123-009-20 Gasket

21* 2123-009-21 Disc

22 Not Needed

23 2123-109-23 Spring Retainer

24 2123-109-24 Spring

25 2014-300 Vent, 1/8"

(not included)

* Included in Repair Kit

2123-107 1 1/4" Valve

2123-108 1 1/2" Valve

NO. PART NO. DESCRIPTION

2123-007-99 Repair Kit

1* 2123-007-01 Gasket

2* 2123-007-02 Diaphragm

3* 2123-007-03 O-ring

42123-007-04 Retainer Bushing

5* 2123-007-05 O-ring

62123-007-06 Disk Retainer

7* 2123-007-07 O-ring

82123-007-08 Seat

92123-007-09 Disc Plate

10 "Deleted" Lock Washer, Internal

11* 2123-007-11 Lock Nut

12 2123-107-12 Cap

13* 2123-007-13 Hex Nut (w/Locktite)

14 2123-007-14 Cap Screw

15 2123-007-15 Diaphragm Plate

17 2123-007-17 Lock Nut

18 2123-007-18 Body, 1 1/4"

2123-008-18 Body, 1 1/2"

19 2123-007-19 Shaft

20* 2123-007-20 Gasket

21* 2123-007-21 Disc

22 2123-107-22 O-ring

23 2123-107-23 Spring Retainer

24 2123-107-24 Spring

25 2014-300 Vent, 1/8"

(not included)

* Included in Repair Kit

20

DIAGRAMS

CONTROL VALVE

2229-100 Electric Control Valve, 12 Volt D.C.

2229-101 Electric Control Valve, 12 Volt A.C.

2229-102 Electric Control Valve, 24 Volt D.C.

NO. PART NO. DESCRIPTION

2229-100-99 Replacement Parts Kit (Electric)

1Not Available Air Operator Cap

2*+ 2229-000-02 Plunger w/O-Rings

3Not Available Valve Body

4*+ 2229-000-04 Spring

5Not Available Spring Retainer

6*+ 2229-000-06 Filter Disk

8Not available Screw (8)

92229-000-09 Air Operator Assembly

10*+ 2229-000-10 O-Ring (2 ea)

11 Not Available Electric Operator Cap

12 Not Available Coil Cover Bottom

13 2229-100-03 Coil 12 Volt D.C.

2229-101-03 Coil 12 Volt A.C.

2229-102-03 Coil 24 Volt D.C.

2229-100-03 Coil 24 Volt A.C.

14 Not Available Coil Cover

15 Not Available Nut

16 2229-100-06 Solenoid Pilot Assembly, 12 Volt D.C.

2229-101-06 Solenoid Pilot Assembly, 12 Volt A.C.

2229-102-06 Solenoid pilot Assembly, 24 Volt D.C.

17+ 2229-100-07 Gasket (Electric Only)

+ Included in Replacement Parts Kit-Electric

Table of contents

Other BLASTONE Shot Blasting Machine manuals