BLEC CP Series Parts list manual

1

CULTI-PACK SEEDER

MODELS CP36 - CP42

INSTRUCTION & PARTS

MANUAL

IMPORTANT - PLEASE READ

BEFORE USE

2

3

BLEC CULTI-PACK SEEDER

MODELS CP36/CP42

CONTENTS:-

SECTION 1 DECLARATION OF CONFORMITY

SECTION 2 INTRODUCTION

SECTION 3 PRODUCT RECORD SHEET

SECTION 4 SAFETY NOTES

SECTION 5 DESCRIPTION

SECTION 6 CONTROLS

SECTION 7 PREPARING FOR USE

SECTION 8 OPERATING

SECTION 9 MAINTENANCE

SECTION 10 STORAGE

SECTION 11 MODIFICATIONS/ACCESSORIES

SECTION 12 NOTES

SECTION 13 PARTS LIST

SECTION 14 CONDITIONS OF WARRANTY

SECTION 15 REGISTRATION & WARRANTY CARD

To be completed and returned to

BLEC Thank You

4

SECTION 1 DECLARATION OF CONFORMITY

EEC MACHINERY DIRECTIVE - DECLARATION OF CONFORMITY

We hereby certify that the following machinery complies with all the relevant essential

Health and Safety Requirements of EEC Machinery Directive 89/392/EEC as amended

And the National Laws and Regulations adopting this directive.

Machine Description: CULTIPACK SEEDER Make: BLEC

Serial Number: Model Number

Made by:

BLEC (Global) Ltd,

Unit 5 Crease Drove Industrial Estate, Crowland, Peterborough PE6 0BN ENGLAND

A technical construction file for this machinery is retained at the following

Address (if different from above address)

Signed:

Date: 1st January 2010

Name: G Mumby

Position: Director

Being the responsible person appointed by the manufacturer or nominated representative

Of the manufacturer established in the EEC employed by:

BLEC (Global) Ltd

Unit 5 Crease Drove Industrial Estate Crowland Peterborough PE6 0BN ENGLAND

5

SECTION 2 - INTRODUCTION BLEC CULTIPACK SEEDER

MODELS CP36-CP42

We thank you for choosing a BLEC product. The reliability, efficiency and safe working of this product

depends on your care, so it is important to read this instruction book before use.

All BLEC equipment has been designed with careful attention directed to operators safety, therefore,

it is vital that all safety precautions are carried out when working and maintaining the machinery.

There are warning details placed on specific machines which should at all times be complied with,

also listed overleaf, are general safety notes which should always be followed.

Additional operator training can be supplied by BLEC Global Ltd on all BLEC machines, please

contact the office for further details.

Please find enclosed registration and guarantee card for your attention. Please complete the

necessary details required, and post the “tear off” section back to BLEC within 14 days of purchase

for our records. Thank you.

6

SECTION 3 PRODUCT RECORD SHEET BLEC CULTIPACK SEEDER

MODELS CP36 CP42

Machine Type: BLEC CULTI-PACK SEEDER

Serial Number:

Delivery Date:

Dealers Name & Address:

Tel no:

Owners Name & Address:

Tel no:

7

SECTION 4 SAFETY NOTES BLEC CULTIPACK SEEDER

MODELS CP36 CP42

SAFETY NOTES

DO NOT USE THIS MACHINE BEFORE READING THIS MANUAL

DO NOT ALLOW PERSONS UNDER THE AGE OF 16 TO OPERATE

THIS EQUIPMENT

DO NOT OPERATE WITHOUT SAFETY CLOTHING/FOOTWEAR

DO NOT ALLOW ANY PERSON OTHER THAN THE OPERATOR TO

STAND NEAR THE MACHINE WHEN WORKING

DO NOT ALLOW PEOPLE IN AND AROUND THE WORKING AREA

DO NOT STAND ON ANY GUARDS

DO NOT MAKE ANY ADJUSTMENTS WITH THE ENGINE RUNNING

DO NOT GO UNDERNEATH THE MACHINE WITHOUT SAFETY PROPS

DO MAKE SURE ALL GUARDS ARE IN PLACE

DO OBEY SAFETY DETAILS

DO MAKE SURE MACHINE IS SWITCHED OFF BEFORE

MAKING ANY ADJUSTMENTS.

DO MAKE SURE EQUIPMENT IS IN A SAFE CONDITION

DO MAKE SURE EQUIPMENT IS REGULARLY SERVICED

8

SECTION 5 - DESCRIPTION BLEC CULTIPACK SEEDER

MODELS CP36- CP42

Both models are designed to sow grass seed and incorporate into top soiled areas

Based on the following proven working principle. The twin front cast iron rollers

Have serrated rings which penetrate the soil, leaving a pattern of ridges and small

Indentations in the top 20mm (3/4”). A rear seeder unit equipped with a

Seed/fertiliser hopper, evenly spreads grass seed or fertiliser at ta required amount

Determined by the adjustable cam guage and lever fitted to the rear of the hopper,

The seed falls into and in between the small pockets in the soil. To complete the

process a rear ring roller splits the ridges and presses down the seedlings into the

Soil, leaving the seedlings incorporated in the top 20mm (3/4”) for ideal germination.

It is important slewing clutches are fitted on the tiller for ease of turning. A footplate

Mounted on the rear allows the operator to ride on for easier operation and less fatigue.

IIMPORTANT

DESCRIPTION

The BLEC range of CULTIPACK SEEDERS have been designed to mount onto

Standard type power tillers or two wheel tractors, as they are sometimes known.

Before fitting it is important you have the correct model seeder to suit your power

Tiller.

WORKING PRINCIPLE

Make sure only experienced workers over 16 use this seeder for safety reasons.

9

SECTION 6 CONTROLS BLEC CULTI PACK SEEDER

MODELS CP36 CP42

CONTROLS - (See Photo 6)

It is important to familiarise yourself with all of the controls.

Please read the enclosed power tiller instruction manual (supplied

With tiller).

The seeder has been designed for the operator to either

Stand on

Walk behind when working or transporting by the fitment of a footplate

Which can be hinged up on top of the roll. If the operator wishes to

Walk behind, (ie when travelling up slopes)

10

SECTION 6 - CONTROLS BLEC CULTI-PACK

MODELS: CP36 & CP42

PHOTO: 6

1. 2. 3.

4.

5.

6.

7. 8.

9.

1. HIGH/LOW GEAR RANGE LEVER

2. ON/OFF SWITCH

3. DRIVE CLUTCH ‘DEAD MANS’ SAFETY LEVERS

4. THROTTLE CONTROL LEVER

5. STEERING CLUTCH LEVER

6. SEED ON/OFF LEVER

7. HANDLE BAR HEIGHT ADJUSTING CLAMP

8. ‘FOLD UP’ FOOT-PLATE

9. GEAR LEVER

CONTROLS

11

SECTION 7 - PREPARING FOR USE

BLEC CULTI-PACK SEEDER

MODELS - CP36/CP42

ASSEMBLY

The BLEC CULTI-PACK SEEDER unit will be assembled, lubricated and ready for work if supplied

with a recommended power tiller equipped with safety devices.

However, if the seeder requires fitting to a power tiller, please follow the directions below:-

Step 1.

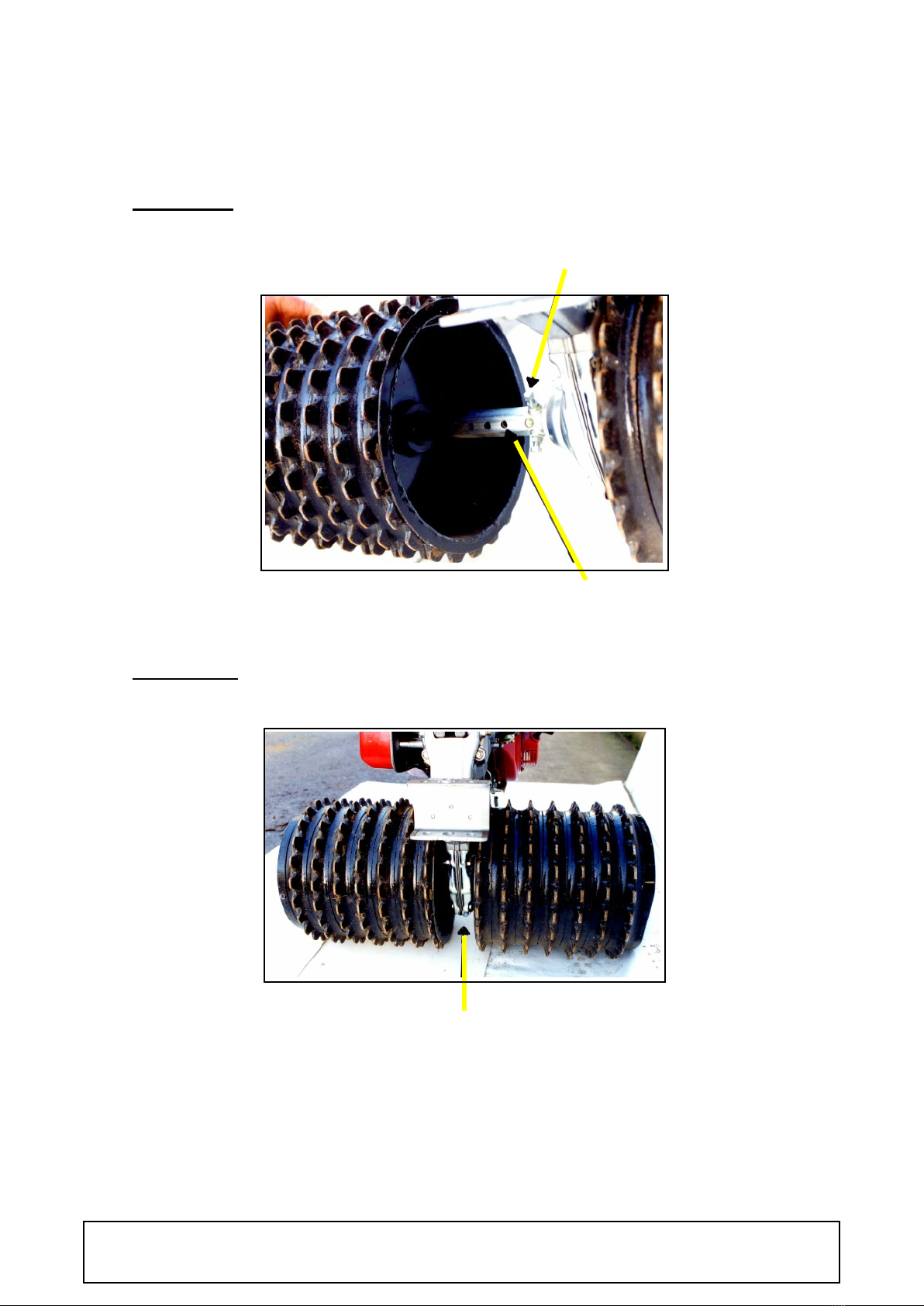

Fitment of cast ring roller drums to tiller axle. (See Photos 2A & 2B)

·This operation will require 2 people for safety.

·Please find level, hard surface. Stand the tiller on the wheels.

Remove the pin and clip on one side axle.

·Raise one side of the tiller to allow the wheel to be removed.

·(See Photo 2A).

·position the cast ring drums with welded lip side towards shaft.

·Rotate drum until the hole in the axle lines up with the hole in the drum.

·Then line up the axle with the tube and slide on until the edge of the drum is

close to the chain case and also to the nearest hole in the axle.

·Secure with the pin and clip.

·Repeat same process with opposite side drum.

12

SECTION 7 - PREPARING FOR USE BLEC CULTI-PACK SEEDER

MODEL: CP36 & CP42

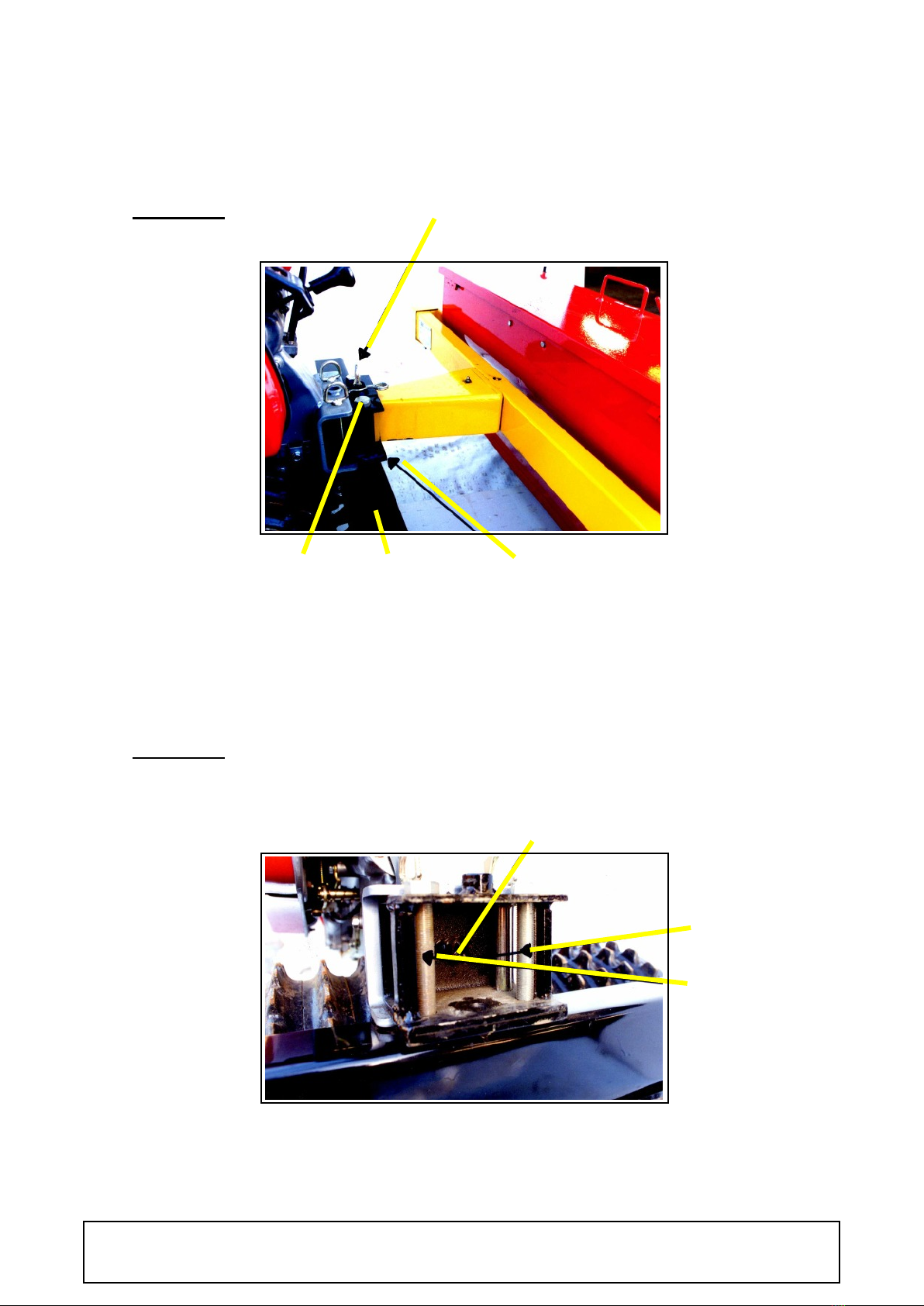

PHOTO: 2A BEFORE FITTING THE DRUMS MAKE

SURE THE AXLE TUBE IS TIGHT.

ADJUST THE BOLTS IF NECESSARY.

LINE UP HOLE IN

AXLE TUBE WITH

CAST DRUM HOLE

PHOTO: 2B

APPROXIMATELY

75MM (3”) DISTANCE

BETWEEN THE DRUMS.

13

SECTION 7 - PREPARING FOR USE

BLEC CULTI-PACK SEDER

MODELS - CP36/CP42

Step 2.

Fitment of seeder unit to tiller.

The seeder unit is attached to the jaw bracket on the tiller via a mounting bracket (black) which has a

scraper bar attached to it. (See Photo 3).

* disconnect the mounting bracket (1) from the drawbar of the seeder by

removing the middle pin and clip.

* slide the bracket into the jaw bracket of the tiller and secure with 2

pins and clips supplied.

* tighten locking bolt (See Photo 4), No. 3. This will keep the rackets

tight on the pins.

* the scraper bar is secured to the mounting bracket by 2 bolts and nuts

(See Photo 4).

* position and tighten.

* fitted to the scraper bar are 2 serrated scrapers which are adjustable for

width and length, via the nuts and bolts. It may be necessary to adjust the scrapers.

* when adjusting, make sure a gap of 6 - 10 mm is between the cast ring roll

and scraper to allow for movement. (See Photo 5).

* position the seeder drawbar (See Photo 3) into the mounting bracket and

secure with pin and clip. Lift up the support leg and secure with pin and clip.

The seeder and tiller are now assembled.

14

SECTION 7 - PREPARING FOR USE BLEC CULTI-PACK SEEDER

MODELS : CP36 & CP42

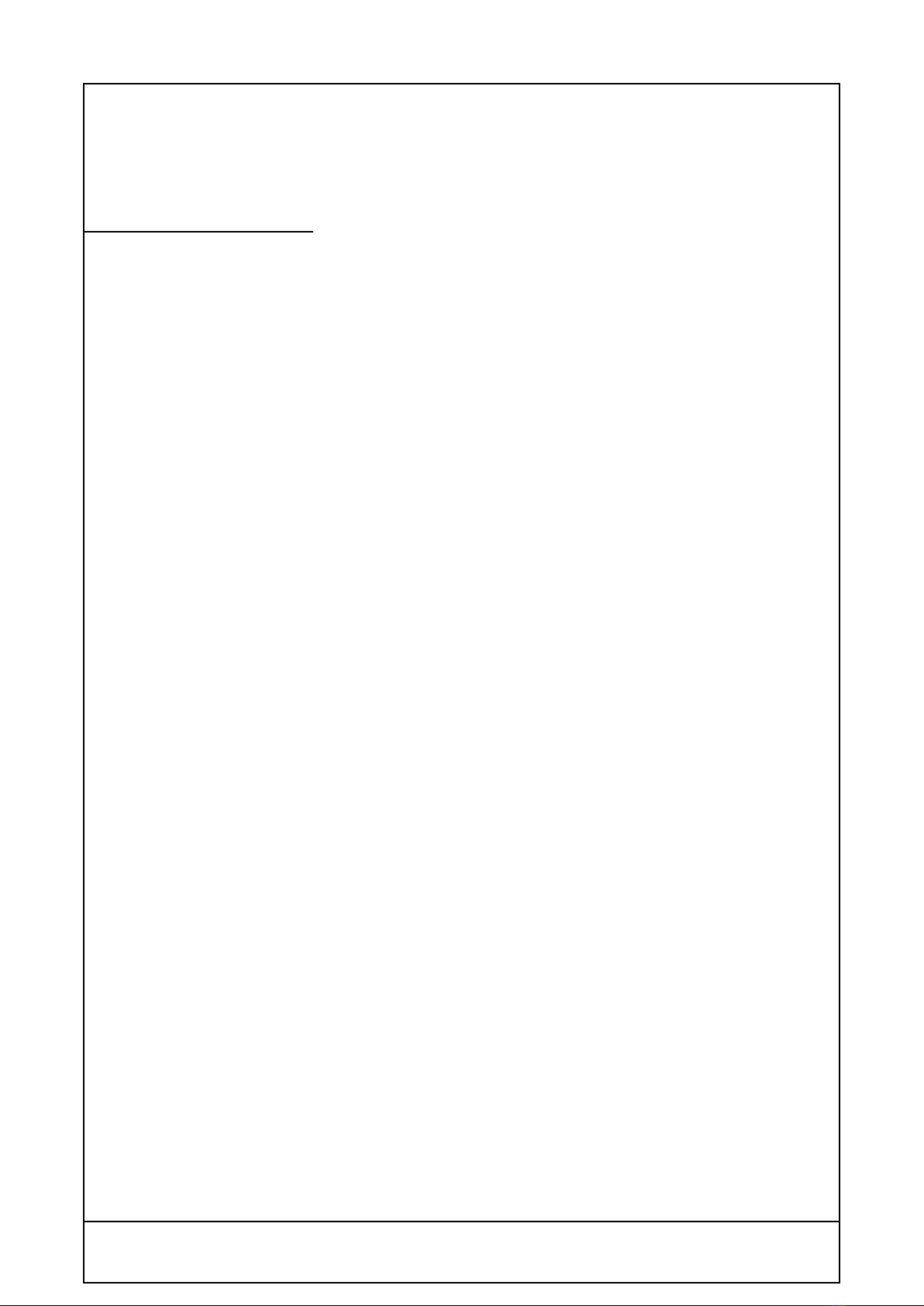

PHOTO: 3 DRAWBAR PIN/CLIP

BOLT SCRAPER MOUNTING

BAR BRACKET

PHOTO: 4

LOCKING

NUT

SCRAPER

BAR

SECURING

BOLTS

15

SECTION 7 - PREPARING FOR USE

BLEC CULTI-PACK SEEDER

MODELS - CP36/CP42

NOTES:

16

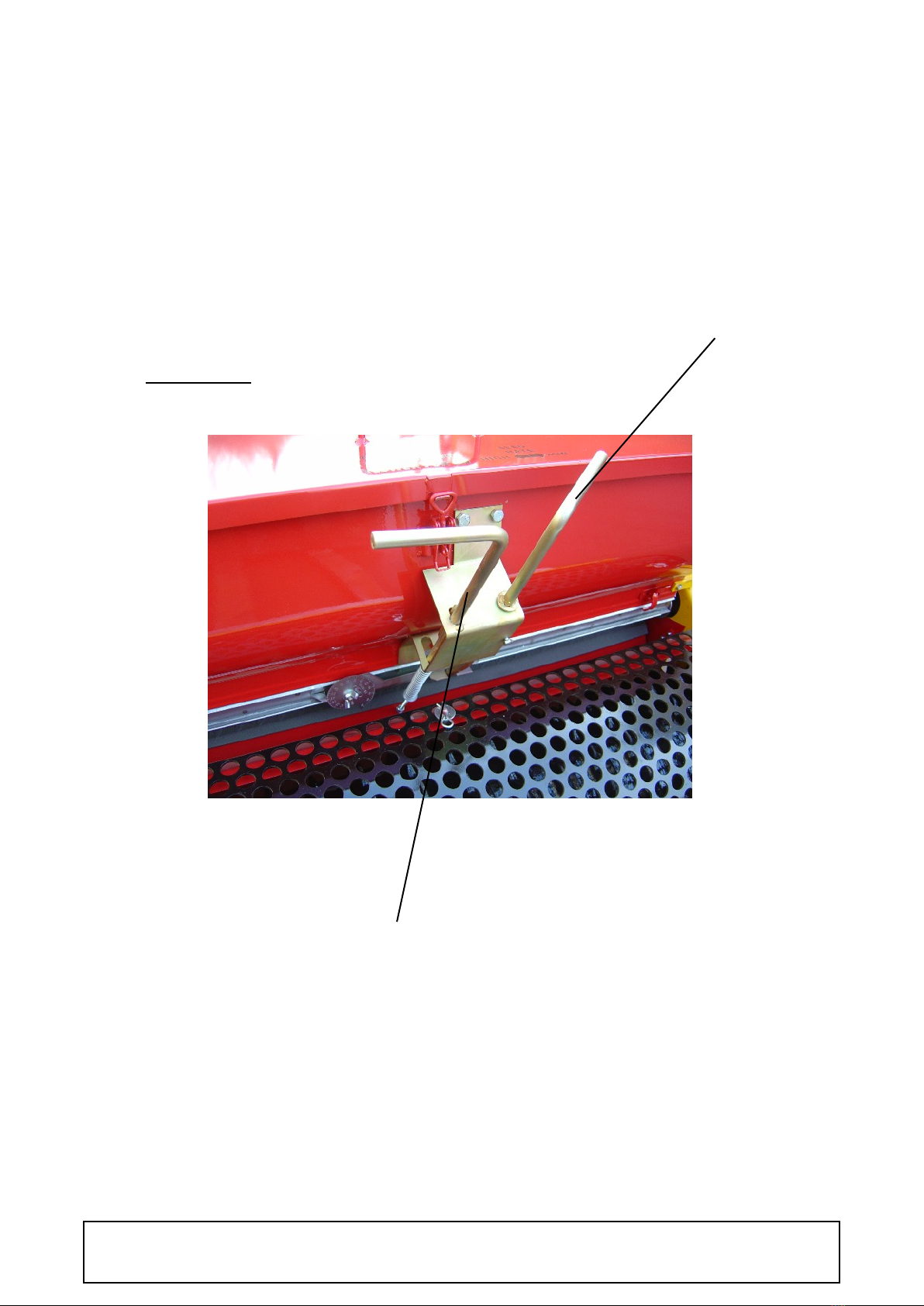

SCRAPER

BAR

LEAVE 6 - 10mm SERRATED

CLEARANCE SCRAPER

BETWEEN RINGS BOLT

ADJUSTER

SECTION 7 - PREPARING FOR USE BLEC CULTI-PACK SEEDER

MODELS: CP36 & CP42

PHOTO: 5

17

SECTION 7 - PREPARING FOR USE

BLEC CULTI-PACK SEEDER

MODELS - CP36/CP42

TYPE OF SEEDING SYSTEM

The Cultipack seed hopper is equipped with an accurate seeding mechanism, which

Consists of a stainless steel bottom with two sliding sections which have specially

Shaped apertures (holes) inserted in each part. To vary the amount of seed to be

Spread, you must slide the bottom section to either increase or decrease the hole

Size. This is achieved by twisting lever A (see Photo 5a) until the tab touches the

Side of the numbered cam gauge (see photo 7)

New 2006 onwards models are fitted with a shut off plate, which is operated by twisting

Lever B (see photo 5a) until the plate drops down, therefore allowing the grass seed to fall

Out. By lift lever B up, and then twisting to lock up plate, this stops the seed from falling out.

The numbers on the cam gauge DO NOT represent a specific amount of seed, it is only a

Scale to work from.

A blanking tray is provided which slides under the hopper chute, allowing seed to be collected

Ready for calibration (see photo 8)

For calibration procedures please see page 7.

18

SECTION 7 - PREPARING FOR USE BLEC CULTI-PACK SEEDER

MODELS: CP36 & CP42

PHOTO: 5A

LEVER A

LEVER B

19

SECTION 7 - PREPARING FOR USE BLEC CULTI-PACK SEEDER

MODELS: CP36 & CP42

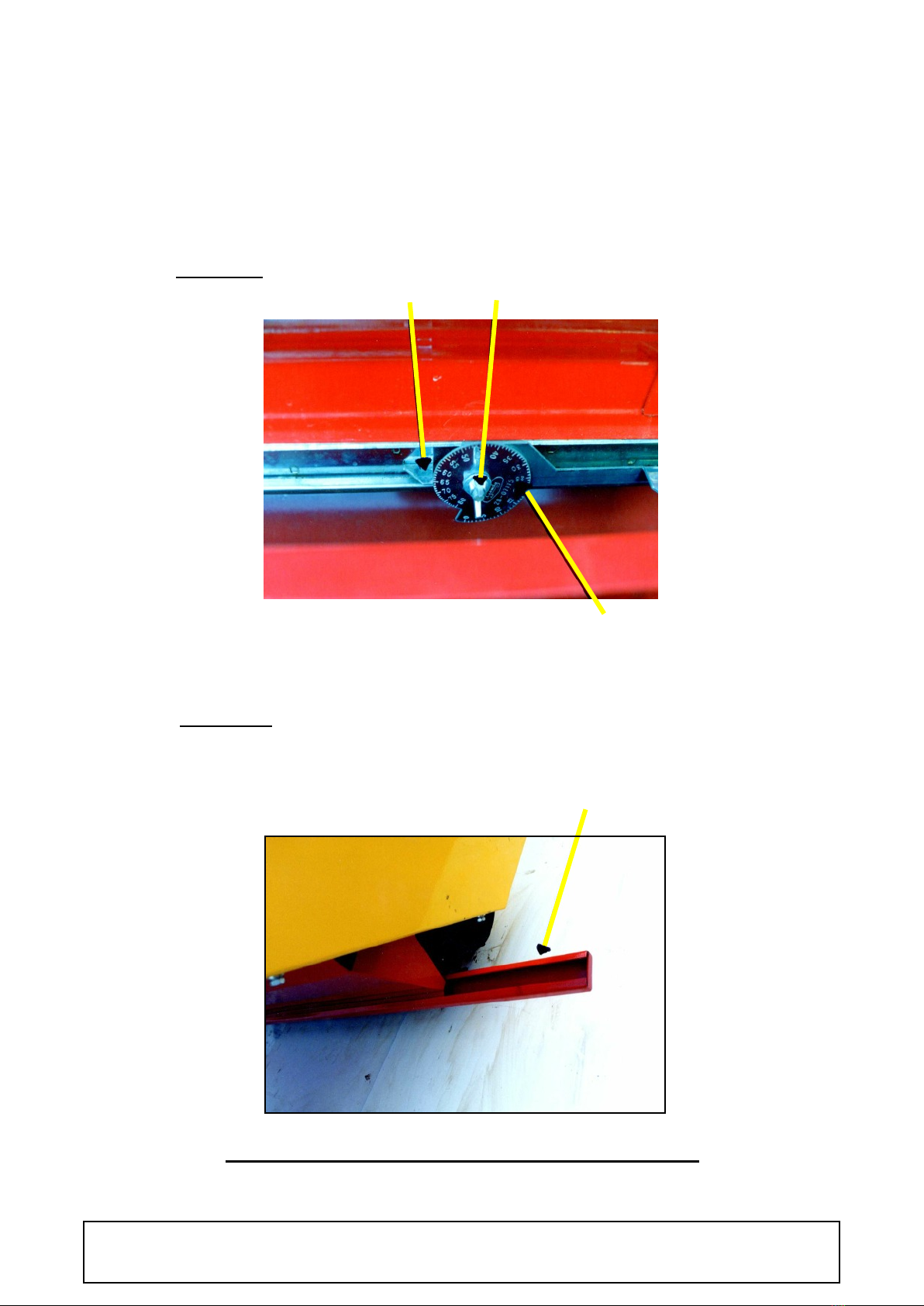

TAB WING

NUT

NUMBERED

CAM GAUGE

PHOTO: 8

SLIDE IN

BLANKING

STRIP TO

CATCH SEED **

** REMEMBER: REMOVE AFTER CALIBRATION

PHOTO 7.

20

SECTION 7 - PREPARING FOR USE

BLEC CULTI-PACK SEEDER

MODELS - CP36/CP42

CALIBRATION PROCEDURE FOR CP36 & CP42

For accurate calibration you will require a set of scales and a small sheet. Proceed as follows:-

1. Find out your required seed rate. (Example - 35gms sq metre, 1 1/40ozs sq. yd.

2. Make sure the lever is in the OFF position.

3. Fill the hopper with a quantity of clean seed, approximately 1/3rd - 30% full.

4. Make sure the blanking strip is fitted to the bottom of the chute.

5. Measure out a distance of 20 metres - (22yds) in a straight line and mark ‘start’ &

‘finish’ with cane sticks.

6. Position the seeder at the ‘start’ point.

7. Select a number on the scale (i.e. 65) and rotate the cam gauge until this number lines

up with the tab - (See Photo 7), and turn the lever to ON position, until it stops

against the cam gauge.

8. Drive along for 20 metres - (22yds), then switch off.

9. Place a sheet under the chute and slide out the blanking strip, allow the seed to fall

on to the sheet.

10. Weigh the seed. This will be the amount spread for the following:-

CP36 - 18.5 metres square - (20 yards square)

CP42 - 21.5 metres square - (23 yards square)

11. If the amount of seed is too little or too much, select another number on the scale near

to which you think is appropriate and repeat the procedure until the correct rate has

been achieved.

IMPORTANT

The speed you calibrate your seed rates must be the same speed you will use to work

at. Otherwise differences will occur. The faster you travel, the less seed is spread.

This manual suits for next models

2

Table of contents