Blodgett Combi COS-8G User manual

COSĆ8G, COSĆ8GDS, BCSĆ8G, AND CNVĆ8G

GAS COOKING APPLIANCES

INSTALLATION - OPERATION - MAINTENANCE

COSĆ8G, COSĆ8GDS, BCSĆ8G, ET CNVĆ8G

APPAREILS DE CUISSON AU GAZ

MANUEL D'INSTALLATION - FONCTIONNEMENT - ENTRETIEN

BLODGETT COMBI

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 U A Telephone: (802) 658Ć6600 Fax: (802)864Ć0183

PN R8133 Rev D (6/01)

E 2000 - Blodgett Combi

A PERSONAL WORD FROM BLODGETT COMBI

QUELQUES MOTS DE BLODGETT COMBI

Congratulations on your purchase of a BLODGETT Combi appliance. We

firmly believe that your choice has been a wise one, and trust you will reĆ

ceive many years of excellent service from your new Combi.

You will find that cooking with Combi appliances saves time, labor and

extensive cleaning of both the kitchen and the unit.

With Combi appliances the quality, taste, consistency, and look of your

food are improved, thus endorsing the policy to which we've always adĆ

hered: For Better Cooking!"

Once you've had a chance to use your Combi, please tell us, your dealer

and colleagues about any creative and interesting applications you have

discovered; exchange ideas with other users. Be sure to advise us or

your dealer immediately should any mechanical or technical problems

be encountered (...we're here to help!) and above all Enjoy Cooking the

BLODGETT Combi Way!

For information on cooking, please refer to our separate cooking guide.

Toutes nos félicitations sur votre achat d'appareil de Blodgett Combi.

Nous croyons fermement que votre choix est un choix raisonnable et

nous sommes certains que vous obtiendrez de nombreuses années

d'excellent service de votre nouveau four multiĆusages.

Vous allez découvrir que la cuisson dans les appareils Combi économise

le temps, le travail et le degré de nettoyage de l'appareil aussi bien que

de la cuisine.

Avec les appareil de Combi, la qualité, le goût, la consistence et l'apparĆ

ence des aliments sont améliorés, s'accordant, de ce fait, avec notre

politique "Pour une meilleure cuisson !"

Une fois que vous aurez eu la chance d'utiliser notre Combi, informez

nous, votre concessionnaire et vos collègues, de toutes les applications

nouvelles et intéressantes que vous avez découvertes ; échangez vos

idées avec d'autres utilisateurs. N'hésitez pas à nous prévenir, ou votre

concessionnaire, de tout problème mécanique ou technique que vous

pourriez rencontrer (... nous sommes ici pour vous aider) et parĆdessus

tout RégalezĆvous à cuisiner à la façon BLODGETT Combi!

Pour obtenir de plus amples informations sur l'art culinaire, veuillez conĆ

sulter notre livre de cuisine séparé.

IMPORTANT

FOR YOUR SAFETY

Do ot store or use gasoli e or other flammable vapors or liquids i the vici ity

of this or a y other applia ce.

AVERTISSEMENT

Ne pas e treposer i utiliser de l'esse ce i d'autres vapeurs ou liquides i flamĆ

mables da s le voisi age de cet appariel, i de tout autre appareil.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS

MUST BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE

OBTAINED BY CONTACTING YOUR LOCAL GAS SUPPLIER.

LES INSTRUCTIONS À RESPECTER AU CAS OÙ L'UTILISATEUR PERÇOIT UNE

ODEUR DE GAZ DOIVENT ÊTRE AFFICHÉES DANS UN ENDROIT BIEN VISIBLE.

VOUS POUVEZ VOUS LES PROCURER AUPRÈS DE VOTRE FOURNISSEUR DE

GAZ LOCAL.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

AVERTISSEMENT: UNE INSTALLATION, UN AJUSTEMENT, UNE ALTÉRATION, UN

SERVICE OU UN ENTRETIEN NON CONFORME AUX NORMES PEUT CAUSER DES

DOMMAGES À LA PROPRIÉTE, DES BLESSURES OU LA MORT. LISEZ ATTENTIVEĆ

MENT LES DIRECTIVES D'INSTALLATION, D'OPÉRATION ET D'ENTRETIEN AVANT

DE FAIRE L'INSTALLATION OU L'ENTRETIEN DE CET ÉQUIPEMENT.

The i formatio co tai ed i this ma ual is importa t for the proper i stallatio ,

use, a d mai te a ce of this ove . Adhere ce to these procedures a d i strucĆ

tio s will result i satisfactory baki g results a d lo g, trouble free service.

Please read this ma ual carefully a d retai it for future refere ce.

Les i formatio s do ées da s le prése t ma uel so t importa tes pour i staller,

utiliser et e trete ir correcteme t ce four. Le respect de ces i structio s et procéĆ

dures permettra d'obte ir de bo s résultats de cuisso et u e lo gue durée de serĆ

vice sa s problèmes. Veuillez lire le prése t ma uel et le co server pour pouvoir

vous y reporter à l'ave ir.

Errors: Descriptive, typographic or pictorial errors are subject to correctio . SpecificaĆ

tio s are subject to cha ge without otice.

Erreurs:Les erreurs de descriptio , de typographie ou d'illustratio fo t l'objet de

correctio s. Les caractéristiques so t sujettes à modificatio s sa s préavis.

Your ervice Agency's Address:

Adresse de votre agence de service:

Model/Modèl:

erial Number/Numéro de série:

Your oven was installed by/

Installateur de votre four:

Your oven's installation was checked by/

Contrôleur de l'installation de votre four:

Table of Co te ts/Table des Matières

level 1 compo e t

level 2 component 2. . . . . . . . . . . . . . . . . . . .

level 3 component 7. . . . . . . . . . . . . . . . . . .

level 1 c compo e t

Table of Co te ts/Table des Matières

I troductio

The Blodgett Combi Cooking Line 2. . . . . .

Description of the Blodgett Combi

Cooking Line 3. . . . . . . . . . . . . . . . . . . . . . . . .

Oven Features 4. . . . . . . . . . . . . . . . . . . . . . .

I stallatio

Owner's Responsibilities 5. . . . . . . . . . . . . . .

Location and Ventilation 6. . . . . . . . . . . . . . .

Agency Approvals 7. . . . . . . . . . . . . . . . . . . .

Utility Connections 8. . . . . . . . . . . . . . . . . . . .

Optional Leg Attachment 13. . . . . . . . . . . . . .

Baffle Installation 14. . . . . . . . . . . . . . . . . . . . .

tacking Instructions 15. . . . . . . . . . . . . . . . . .

Final Check and Adjustments 17. . . . . . . . . .

Final Check Lists 18. . . . . . . . . . . . . . . . . . . . .

Operatio

afety Information 19. . . . . . . . . . . . . . . . . . . .

Oven tartĆUp 20. . . . . . . . . . . . . . . . . . . . . . . .

CombiĆOven/ teamer tandard Controls 21

Optional CombiĆOven/ teamer

Cook & Hold 23. . . . . . . . . . . . . . . . . . . . . . . . .

Convection teamer tandard Controls 26.

Convection Oven tandard Controls 27. . . .

Optional Convection Oven

Cook and Hold 28. . . . . . . . . . . . . . . . . . . . . . .

Optional Meat Probe 31. . . . . . . . . . . . . . . . . .

Mai te a ce

pray Bottle Operating Procedure 32. . . . . .

Cleaning and Preventive Maintenance 33. . .

Decalcification 34. . . . . . . . . . . . . . . . . . . . . . .

I troductio

La ligne d'appareils de cuisson

de Blodgett Combi 36. . . . . . . . . . . . . . . . . . . .

Description de la ligne d'appareils de cuisĆ

son de Blodgett Combi 38. . . . . . . . . . . . . . . .

Caractéristiques 39. . . . . . . . . . . . . . . . . . . . . .

I stallatio

Responsabilités du propriétaire 40. . . . . . . . .

Placement et Ventilation 41. . . . . . . . . . . . . .

Normes et Codes 42. . . . . . . . . . . . . . . . . . . . .

Branchement Utilitaires 43. . . . . . . . . . . . . . . .

Retenue du Tuyau de Gaz 47. . . . . . . . . . . . .

Fixation des pieds en Option 48. . . . . . . . . . .

Installation du Déflecteur 49. . . . . . . . . . . . . .

uperposition Ć Assemblage

section double 50. . . . . . . . . . . . . . . . . . . . . . .

Vérification finale et derniers réglages 52. . .

Vérifications Finales 53. . . . . . . . . . . . . . . . . . .

Utilisatio

Informations de écurité 55. . . . . . . . . . . . . . .

Mise en Marche du Four 56. . . . . . . . . . . . . . .

CombiĆFour/étuve à Vapeur

Contrôles tandards 57. . . . . . . . . . . . . . . . . .

CombiĆFour/étuve à Vapeur

Cuisson et Pause en Option 59. . . . . . . . . . .

CombiĆConvection/étuve à

Vapeur Contrôles tandards 63. . . . . . . . . . .

CombiĆFour à Convection

Contrôles tandards 64. . . . . . . . . . . . . . . . . .

CombiĆFour à Convection

Cuisson et Pause en Option 65. . . . . . . . . . .

onde à Viande en Option 69. . . . . . . . . . . . .

E tretie

Procédé de fonctionnement de la bouteille

vaporisatrice 70. . . . . . . . . . . . . . . . . . . . . . . . .

Entretien Préventif et Nettoyage 71. . . . . . . .

Détartrage 72. . . . . . . . . . . . . . . . . . . . . . . . . . .

I troductio

2

The Blodgett Combi Cooki g Li e

For quite some time, commercial cooking equipĆ

ment has remained more or less unchanged.

There are kettles, deck ovens, the good old range

with its legion of pots āand āmany āother āextra

āappliances. The result: time expenditure, excesĆ

sive manual work, and countless cleaning proĆ

cesses. The last āāāfew āāāyears āāhave āāpaved āāthe āāway āāfor

āa revolution in the equipment of restaurant and inĆ

stitutional kitchens. Blodgett Combi is proud to ofĆ

fer three different cooking platforms, one of which

is sure to match your needs. The Blodgett Combi

line includes:

DThe Blodgett Combi Co vectio Steamer

DThe Blodgett Combi Co vectio Ove

DThe Blodgett CombiĆOve /Steamer

All Blodgett Combi appliances improve your kitchĆ

en through:

Dincreased productivity

Da wider range of menu choices

Da simplified cleaning process

The work process is simplified since products are

prepared on or in steam table āpans āand trays.

Food can be cooked, stored, and transported with

āthe āsame āāpans. ā mall āamounts of product can be

processed efficiently; preĆcooked and conveĆ

nience foods can be reheated within minutes.

COMBI CONVECTION STEAMER

teaming is a well known cooking process freĆ

quently used in restaurant and institutional kitchĆ

ens. With the Combi Convection teamer, it is now

possible to enjoy the many advantages of steamĆ

ing including shorter cook times, higher product

quality and vitamin retention.

The Combi Convection teamer includes a built in

steam generator. This unit includes an inlet, funnel

assembly and valve lever for decalcification.

COMBI CONVECTION OVEN

Cooking in the Combi Convection Oven differs

from cooking in a traditional deck or range oven

since heated air is constantly recirculated over the

product by a fan in an enclosed chamber. The

moving air continually strips away the layer of cool

air surrounding the product, quickly allowing the

heat to penetrate. The result is a high quality prodĆ

uct, cooked at a lower temperature in a shorter

amount of time.

COMBIĆOVEN/STEAMER

With the Oven/ teamer you have the choice of two

cooking processes: team and Hot Air, either...

Deparately

DCombined, or

DIn equence using two or three functions during

one cooking process. We call this combiĆsteamĆ

ing and combiĆbaking.

For easy operation you can choose from three

modes:

team Hot Air Combi

team &

Hot Air

In the team mode you can:

DĂsteam DĂblanch DĂpoach

DĂdefrost DĂrethermalize

In the Hot Air mode you can

DĂroast DĂbake DĂbraise

In the Combi mode you can:

DĂdefrost DĂroast DĂrethermalize

DĂreheat DĂbake DĂsous vide*

DĂproof* DĂcook & hold*

* with optional digital controls

The CombiĆOven/ teamer is offered in two models,

each with different steam producing systems.

DThe CO Ć8G model includes a built in steam

generator. This unit includes an inlet, funnel asĆ

sembly and valve lever for decalcification.

DThe CO Ć8GD is a direct steam unit that is

connected to an external steam source.

I troductio

3

Descriptio of the Blodgett Combi Cooki g Li e

ABOUT THE COMBI LINE

Blodgett Combi appliances are quality produced

using highĆgrade stainless steel with first class

workmanship.

The use of high quality insulation impedes excesĆ

sive heat radiation and saves energy.

Optional adjustable legs adapt easily to slightly

uneven surfaces. Optional floor stands have been

designed for use with all of the table models.

Ove /Steamers a d Co vectio Steamers

The high performance steam control system

makes it possible to enjoy all of the advantages of

a high quality steamer at the flick of a switch. Fresh

steam enters the oven cavity without pressure and

is circulated at high speed. This process enables

quick and gentle cooking and ensures high quality

product while providing convenient working methĆ

ods.

A patented quench system keeps the air in the unit

clean. Fumes are extracted from the appliance,

quenched, and directed out through the condensĆ

er drain. The exhaust system is effective in all

cooking modes and results in better quality foods

and o flavor tra sfer. The fan, which is guarded

against accidental finger contact, is driven by a

quiet and powerful motor. The condenser draws

out excess steam from the appliance. CondensaĆ

tion and waste water, which result during steamĆ

ing and cleaning, are continuously drained.

OPERATION

The practical oven door, with a viewing window,

has a wide swing radius and handle which can be

operated easily, even with wet or greasy hands.

Ease of operation is guaranteed through the simĆ

ple arrangement of the controls. Graphic symbols

make the appliances easy for even inexperienced

kitchen staff to operate. All modes can be selected

with one switch. This includes the Cool Down

mode, which allows the oven cavity to cool down

rapidly with the door opened or closed.

Cleaning is kept to a minimum. The interior can be

sprayed with a cleaning solution to easily remove

crusts and stains. The oven is designed for easy

care and is welded water tight so that the internal

cooking cavity may be rinsed with a hose after the

cleaning process.

I troductio

4

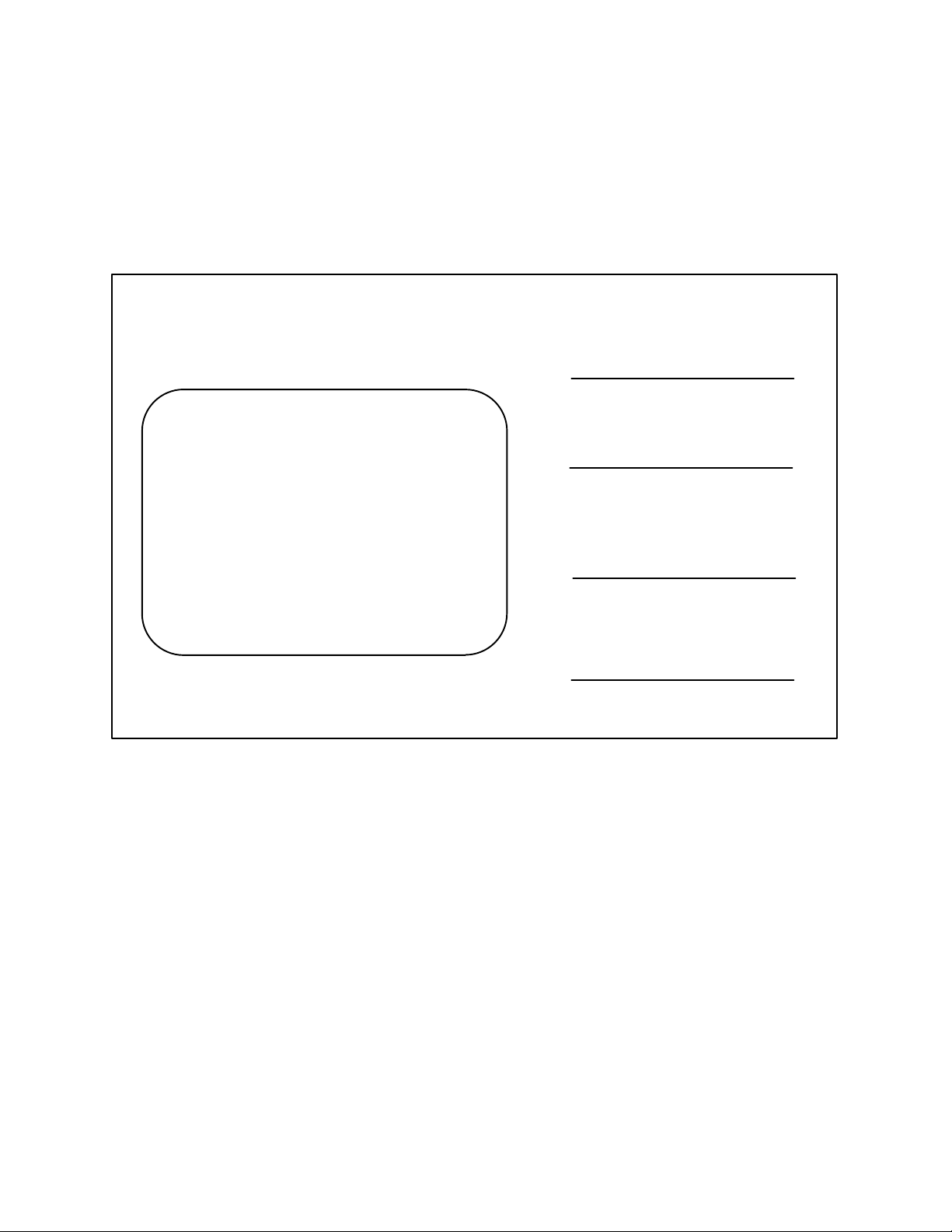

Ove Features

tandard Features

14

2

3

6

7

5

8

COSĆ8G Shown

9

10

10

Figure 1

1 Control Panel

2 Oven Door

3 DripĂCollectorĂ(self draining)

4 Door Handle

5 VentĂ(not shown)

6 Decalcifying Inlet & Funnel Assembly*

7 Decalcifying Valve Lever*

8 Gas hut Off Valve

9 Tilt Down Panel crew

10 Removeable plugs provide access to

screws securing drip collector

* only on COSĆ8G and BCSĆ8G

I stallatio

5

Ow er's Respo sibilities

1. Oven(s) are uncrated, stacked (if applies) and

put in place.

NOTE: Re er to Leg Attachment and Stacking

in ormation provided.

2. The owner/operator must have the following

plumbing, electrical and gas requirements

met and installed.

NOTE: Re er to the Utility Connection in orĆ

mation provided.

WARNING!!

Improper i stallatio , adjustme t, alterĆ

atio service or mai te a ce ca cause

property damage, i jury or death. Read

the i stallatio , operatio a d mai teĆ

a ce i structio thoroughly before i Ć

stalli g or servici g this equipme t.

ELECTRICAL

15 amp Nema 5Ć15 grounded outlet

PLUMBING

Water

Water Pressure (min/max) 50 P I (345 kPa)

Cold Water upply 3/4" Hose Fitting, 3/8" ID hose minimum

Hot Water upply* 3/4" Hose Fitting*, 3/8" ID hose minimum

Drai age Atmospheric Vented Drain

Drain Connection 2" Copper

Average Water Drain Temperature 122_F / 50_C

GAS PRESSURE

Orifice at Sea Level

team #13/64 (.203" dia) natural gas

Hot Air #54 (.055" dia) natural gas

I let Pressure to the U it

Natural Gas 7-14" WC (1.74-3.48 kPa)

Propane 12-14" WC (2.98-3.48 kPa)

Pressure at the Ma ifold

Natural Gas 3.5" WC (.87 kPa)

Propane 10" WC (2.49 kPa)

*Not applicable with COSĆ8GDS and CNVĆ8G

I stallatio

6

Locatio a d Ve tilatio

LOCATION

The well planned and proper placement of your

appliance will result in long term operator conveĆ

nience and satisfactory performance.

The following clearances must be maintained beĆ

tween the unit, including hose assemblies, and any

combustible or nonĆcombustible construction.

DOvens with casters - 6" (15 cm)

DOvens without casters - 12" (30 cm)

The following clearances are recommended, but

not required, for servicing.

DOven body sides - 12" (30 cm)

DOven body back - 12" (30 cm)

Place the unit in an area which is free of drafts and

accessible for proper operation and servicing.

Keep the oven area free and clear of all combusĆ

tibles such as paper, cardboard, and flammable

liquids and solvents.

DO NOT place the oven on a curb base or seal to

the wall; either condition will prevent proper ventiĆ

lation to the blower motors. light unevenness can

be corrected with the adjustable legs.

The air vents on the left side of the unit must be

protected from heat and steam or water sources.

Consult the factory for an optional protective side

heat shield kit if excessive ambient heat or steam

is present on the left side of the unit.

DCO Ć8G heat shield P/N R4514

DCO Ć8GD heat shield P/N R4514

DBC Ć8G heat shield P/N R4514

DCNVĆ8G heat shield P/N R4514

On all models, tripping the blower motor's thermal

overload device indicates an excessive ambient

temperature at the back of the oven. This must be

corrected to prevent permanent damage to the

oven. All motor bearings are permanently lubriĆ

cated by the manufacturer; there is no need for

additional lubrication during the operational lifeĆ

time of the motors.

VENTILATION

The necessity for a properly designed and inĆ

stalled ventilation system cannot be over emphaĆ

sized. The ventilation system will allow the unit to

function properly while removing unwanted vaĆ

pors and products of combustion from the operatĆ

ing area.

The appliance must be vented with a properly deĆ

signed mechanically driven exhaust hood. The

hood should be sized to completely cover the

equipment plus an overhang of at least 6" (15 cm)

on all sides not adjacent to a wall. The capacity of

the hood should be sized appropriately and proviĆ

sions made for adequate makeup air.

WARNING!!

Failure to properly ve t the ove ca be

hazardous to the health of the operator;

a d will result i operatio al problems,

u satisfactory baki g, a d possible damĆ

age to the equipme t. Damage sustai ed

as a direct result of improper ve tilatio

will ot be covered by the Ma ufacturer's

warra ty.

U.S. a d Ca adia I stallatio s

Refer to your local ventilation codes. In the abĆ

sence of local codes, refer to the National ventilaĆ

tion code titled, Standard or the Installation o

Equipment or the Removal o Smoke and Grease

Laden Vapors rom Commercial Cooking EquipĆ

ment", NFPAĆ96Ć Latest Edition.

Ge eral Export I stallatio s

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

please call Blodgett Combi at 0011Ć802Ć860Ć3700.

I stallatio

7

Age cy Approvals

THE IN TALLATION IN TRUCTION CONĆ

TAINED HEREIN ARE FOR THE U E OF QUALIĆ

FIED IN TALLATION AND ERVICE PER ONNEL

ONLY. IN TALLATION OR ERVICE BY OTHER

THAN QUALIFIED PER ONNEL MAY RE ULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and are responsible for:

DThe installation or replacement of gas piping.

The connection, installation, repair or servicing

of equipment.

DThe installation of electrical wiring from the elecĆ

tric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experiĆ

enced in such work, be familiar with all precauĆ

tions required and have complied with all requireĆ

ments of state or local authorities having

jurisdiction.

U.S. a d Ca adia I stallatio s

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1-Latest Edition,

the Natural Gas Installation Code CAN/CGAĆ

B149.1 or the Propane Installation Code, CAN/

CGAĆB149.2 as applicable.

Reference: National Electrical Code, ANSI/NFPA

70-Latest Edition and/or Canadian Electrical

Code CSA C22.1 as applicable.

This equipment is to be installed in compliance

with the Basic Plumbing Code o the Building O iĆ

cials and Code Administrators International Inc.

(BOCA) and the Food Service Sanitation Manual o

the Food and Drug Administration (FDA).

Ge eral Export I stallatio s

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

please call Blodgett Combi at 0011Ć802Ć860Ć3700.

I stallatio

8

Utility Co ectio s

HOT AND COLD WATER CONNECTION

NOTE: Hot water maximizes steam production but

is not required. Cold water may be supplied

to both inlets i hot water is not available.

COSĆ8G a d BCSĆ8G - Connect the appliance to

quality cold water via a pressure hose with 3/4" couĆ

plings. Cold water is connected to the left solenoid/

pressure regulator, as viewed from the rear of the

unit. Hot water connection, right solenoid/pressure

regulator, to the boiler is recommended. hut off

valves must be provided adjacent to the oven.

COSĆ8GDS a d CNVĆ8G - Connect these units

to quality cold water via a pressure hose with 3/4"

couplings.

1/2" appliance hose

With 3/4" hose fittings

Figure 2

Water must meet the following minimum requireĆ

ments:

DTotal Dissolved olids (TD ) content will not exĆ

ceed 30 parts per million.

DWater PH must be 7.0 or higher

WARNING!!

The use of poor quality water will i valiĆ

date your warra ty.

DRAIN CONNECTION

A 2" (5 cm) copper pipe with standard drain pitch

must be run to an open drain or connected to a

standpipe equipped with a vent.

NOTE: The waste water can also be directed to a

nearby loor drain. Flexible hose which alĆ

lows trapped water to accumulate in

sagged runs must be avoided.

1. Find the drain connections on the lower rear

of the unit.

2. Using the band coupling provided, attach

coupling clamps to the drain connection.

3. Create the drip pan drain connection as

shown. A separate drain connection for the

drip pan is also possible.

NOTE: The open end o the drain should be

installed acing the loor. Copper line used

or installation to an open drain or loor sink

must be supplied by the installer.

CAUTION! Use of a i li e trap will cause drai

backup

Drip pan drain

1" air gap

Plumber supplied

breather vent and tee

Main drain

Plumber supplied

connection to lower unit

or drain system

Figure 3

I stallatio

9

Utility Co ectio s

STEAM CONNECTION

NOTE: COSĆ8GDS only.

Connect the appliance to a 200 psi maximum exĆ

ternal steam source per local or state codes. The

steam must be clean, potable and fit for human

consumption. Failure to connect this appliance to

a suitable steam source will revoke the approval of

N F.

ELECTRICAL CONNECTION

Before making any electrical connections to these

units, check that the power supply is adequate for

the voltage, amperage, and phase requirements

stated on the rating name plate mounted on the

unit.

Wiring diagrams are located on the inside of the

louvered side panel.

All units are equipped for operation on 115V 15

amp 1F 60Hz., 2 conductor cable with ground.

Wiring from the power source to this unit must be

a minimum of #16 AWG CU. stranded wire or largĆ

er.

NOTE: DISCONNECT THE POWER SUPPLY TO

THE UNIT BEFORE SERVICING!

WARNING!!

This applia ce is equipped with a 115V,

threeĆpro g (grou di g) plug for your

protectio agai st shock hazard a d

should be plugged directly i to a properly

grou ded threeĆpro g receptacle. DO

NOT cut or remove the grou di g pro g

from this plug.

U.S. a d Ca adia i stallatio

All units, when installed, must be electrically

grounded in accordance with local codes or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70-Latest Edition and/or CanaĆ

dian Electrical Code CSA C22.1 as applicable.

Ge eral Export I stallatio s

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

please call Blodgett Combi at 0011Ć802Ć860Ć3700.

WARNING!!

Improper electrical i stallatio will i valiĆ

date your warra ty.

I stallatio

10

Utility Co ectio s

GAS PIPING

A properly sized gas supply system is essential for

maximum oven performance. Piping should be

sized to provide a supply of gas sufficient to meet

the maximum demand of all appliances on the line

without loss of pressure at the equipment.

Example:

NOTE: BTU values in the ollowing example are

or natural gas.

You purchase a CO Ć8G to add to your existing

cook line.

1. Add the BTU rating of your current appliances.

Pitco Fryer 120,000 BTU

6 Burner Range 60,000 BTU

Deck Oven 50,000 BTU

Total 230,000 BTU

2. Add the BTU rating of the new oven to the toĆ

tal.

Previous Total 230,000 BTU

CO Ć8G (for steam) 90,000 BTU

New Total 320,000 BTU

3. Measure the distance from the gas meter to

the cook line. This is the pipe length. Let's say

the pipe length is 30' (9 m) and the pipe size

is 1" (2.54 cm).

4. Use the appropriate table to determine the toĆ

tal capacity of your current gas piping.

The total capacity for this example is 375,000

BTU. ince the total required gas pressure,

320,000 BTU is less than 375,000 BTU, the

current gas piping will not have to be inĆ

creased.

NOTE: The BTU capacities given in the tables are

or straight pipe lengths only. Any elbows

or other ittings will decrease pipe capaciĆ

ties. For example: a schedule 40 1Ć1/2" ell

itting has an equivalent capacity o 4.2"

(10.2 cm) o straight pipe. Contact your loĆ

cal gas supplier i you have any questions.

Maximum Capacity of Iro Pipe i Cubic Feet

of Natural Gas Per Hour

(Pressure drop of 0.5 Inch W.C.)

Pipe

Le gth

Nomi al Size, I ches

L

e g

th

(ft) 3/4" 1" 1Ć1/4" 1Ć1/2" 2"

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

From the National Fuel Gas Code Part 10 Table 10Ć2

Maximum Capacity of Pipe i Thousa ds of

BTU/hr of U diluted P.P. Gas at 11" W.C.

(Pressure drop of 0.5 Inch W.C.)

Pipe Le gth

(ft)

I side Diameter, I ches

pg

(ft) 3/4" 1" 1Ć1/2"

10 608 1146 3525

20 418 788 2423

30 336 632 1946

40 287 541 1665

50 255 480 1476

60 231 435 1337

70 215 404 1241

80 198 372 1144

90 187 351 1079

100 175 330 1014

From the National Fuel Gas Code Part 10 Table 10Ć15

I stallatio

11

Utility Co ectio s

PRESSURE REGULATION AND TESTING

The gas pressure to the appliance must be rated

for 7" W.C. for natural gas and 12-14" W.C. for

propane gas for each unit while the burners are

on. A sufficient gas pressure must be present at

the inlet to satisfy these conditions.

Each unit has been adjusted at the factory to operĆ

ate with the type of gas specified on the rating

plate attached to the right side of the unit.

Each oven is supplied with a regulator to maintain

the proper gas pressure. The regulator is esse Ć

tial to the proper operatio of the ove a d

should ot be removed. It is preset to provide the

oven with 3.5" W.C. (0.87 kPa) for natural gas and

10.0" W.C. (2.50 kPa) for Propane while the flame

is on.

DO NOT IN TALL AN ADDITIONAL REGULATOR

WHERE THE UNIT CONNECT TO THE GA

UPPLY UNLE THE INLET PRE URE I

GREATER THAN 14" W.C. (1/2 P I)

The oven and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.45kPa).

The oven must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas piping system at test pressures equal or less

than 1/2 psig (3.45kPa).

Prior to connecting the unit, gas lines should be

thoroughly purged of all metal filings, shavings,

pipe dope, and other debris. After connection, the

unit should be checked for correct gas pressure.

U.S. a d Ca adia i stallatio s

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1-Latest Edition,

the Natural Gas Installation Code CAN/CGAĆ

B149.1 or the Propane Installation Code, CAN/

CGAĆB149.2 as applicable.

Ge eral Export I stallatio s

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

please call Blodgett Combi at 0011Ć802Ć860Ć3700.

I stallatio

12

Gas Hose Restrai t

If the unit is mounted on casters, a commercial

flexible connector with a minimum of 3/4" (1.9 cm)

inside diameter must be used along with a quick

connect device.

The restraint, supplied with the appliance, must be

used to limit the movement of the unit so that no

strain is placed upon the flexible connector. The

restraint should be fastened to the base frame of

the oven as close to the flexible connector as posĆ

sible. It should be short enough to prevent any

strain on the connector. With the restraint fully

stretched the connector should be easy to install

and quick connect.

The restraint (ie: heavy gauge cable) should be atĆ

tached without damaging the building. DO NOT

use the gas piping or electrical conduit for the atĆ

tachment of the permanent end of the restraint!

Use anchor bolts in concrete or cement block. On

wooden walls, drive hi test wood lag screws into

the studs of the wall.

WARNING!!

If the restrai t is disco ected for a y

reaso it must be reco ected whe the

u it is retur ed to its origi al positio .

U.S. a d Ca adia i stallatio s

The connector must comply with the Standard or

Connectors or Movable Gas Appliances, ANSI

Z21.69 or Connectors For Moveable Gas ApĆ

pliances CAN/CGAĆ6.16 and a quick disconnect

device that complies with the Standard or QuickĆ

Disconnect Devices or Use With Gas Fuel, ANSI

Z21.41 or Quick Disconnect For Use With Gas Fuel

CAN 1Ć6.9. Adequate means must be provided to

limit the movement of the appliance without deĆ

pending on the connection and the quick disconĆ

nect device or its associated piping.

A drip leg must be used at each appliance. Refer

to NFPA54/ANSI Z223.1 Ć Latest Edition (National

Fuel Gas Code) for proper drip leg installation.

Ge eral export i stallatio s

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

please call Blodgett Combi at 0011Ć802Ć860Ć3700.

Gas upply Line

Gas Hose

Quick Connect

I stallatio of Gas Hose a d Restrai t

Attachment Plate

(secure with leg mount bolt)

IMPORTANT: Cable restraint should

be fastened as close as possible to the

flexible connector and short enough to

prevent any strain on the flexible conĆ

nector.

At maximum stretch of shortened reĆ

straint, the flexible connector should

be easy to install and quick to connect.

Restraint

Figure 4

I stallatio

13

Optio al Leg Attachme t

LEG OPTIONS

Legs are available in 4" (10 cm), 6" (15 cm) āor ā25"

ā(64 cm) ālengths āāor āālow profile casters. The 4" legs

are for counter top installations. The 6" legs are

used on the lower section of a double stacked unit.

The 25" legs are used for a single oven located on

the floor.

NOTE: For sa ety reasons, casters must not be

used with the 25" ā(64 cm) legs.

25 (64 cm) Adjustable Leg

4" (10 cm) Leg

6" (15 cm) Adjustable Leg

Low Profile Casters

Figure 5

LEG ATTACHMENT

NOTE: I low pro ile casters are used, install the

locking casters on the ront o the oven.

The rear casters do not lock. Be sure the

locks are set on the front casters.

1. Align the threaded stud the each leg to the bolt

āholesā locatedāāā ināā ātheā āāunit'sā bottom ācorners.

Turn the legs clockwise and tighten to the

nearest full turn.

2. Align the leg plate holes with the bolt holes.

ecure with the two 1/2" bolts provided.

3. Tip the oven up on the legs. I ācastersā are

āused, checkā thatā the locksā areā setā on ātheā ront

casters.

4. Except for units with casters, level the oven by

screwing the adjustable feet in or out as necĆ

essary.

6" (15 cm) Legs Shown

Figure 6

I stallatio

14

Baffle I stallatio

NOTE: Does not apply to BCSĆ8G convection

steamer.

1. Insert a baffle into each heat exchange tube as

shown. There are eight baffles per oven. The

baffles are packed in a carton inside the oven

cavity.

NOTE: The ba le support pin should be restĆ

ing on top o the heat exchange tube

when the ba le is ully inserted.

WARNING!!

Failure to i stall the baffles will result i

reduced heati g efficie cy of the ove .

upport Pin

Baffle

COSĆ8G Shown

Figure 7

I stallatio

15

Stacki g I structio s

STACKING

1. Install 6" (15 cm) legs or casters on the bottom

unit, using the three 1/2" bolts provided. If

casters are used, be sure that the casters with

brakes are located on the front of the oven and

the gas hose restraint has been installed.

2. Ove /Steamers a d Co vectio Ove s o ly

Install a baffle (8 per unit) into each heat exĆ

change tube on both top and bottom units.

NOTE: For installation o convection steamers

proceed to step 3.

DO NOT remove

body top

Caster with brakes

Baffle (not applicable for

Convection teamers)

Figure 8

3. Lift and mount the upper unit onto the lower

unit. Flush the edges on all four sides. Remove

the side panel and body back of both units.

ave the screws. Remove the lower body

back from the top unit.

Remove body back

Remove

lower body back

Remove body back

Remove

louvered panel

Remove

louvered panel

Figure 9

4. COSĆ8G a d BCSĆ8G o ly - Remove the

upper unit's steam generator flue bottom cap.

Install the steam generator flue adapter beĆ

tween the lower and upper units' steam genĆ

erator.

NOTE: For convection ovens (CNVĆ8G) and

direct steam units (COSĆ8GDS) proĆ

ceed to step 5.

Remove plug

Install adapter flue

Figure 10

5. Bolt the upper and lower units together using

the 1/2" bolts provided.

Bolt through holes

closest to oven center

Rear view o oven

Figure 11

This manual suits for next models

3

Table of contents

Languages:

Other Blodgett Combi Kitchen Appliance manuals