EN

10 | BL220 PERISTALTIC PUMPS

P2: This parameter allows to configure the working mode of level contact: 0 = NO (normally open,

standard configuration) 1 = NC (normally closed, fail-safe mode).

P3: This parameter allows to store the status of the ON/OFF button at the system shutdown: 0 = at

start-up the pump is always enabled 1 = at start-up the pump restores its status at shutdown.

P4: This parameter allows to set the pump working mode:

0 = OFF the pump is always off, independently from measured value: this option allowsto

monitor the measurement without intervening, for example during the plant start-up

1 = ON thethe pump is always on, independently from measured value: this option is used

to manually force the dosage, for example during the plant start-up or maintenance

2 = ON/OFF acid thethis option is typically used for acidification; the pump activates when

the measurement exceeds the “working threshold + ½ hysteresis” level, and deactivates when

the measurement falls below the “working threshold – ½ hysteresis” value

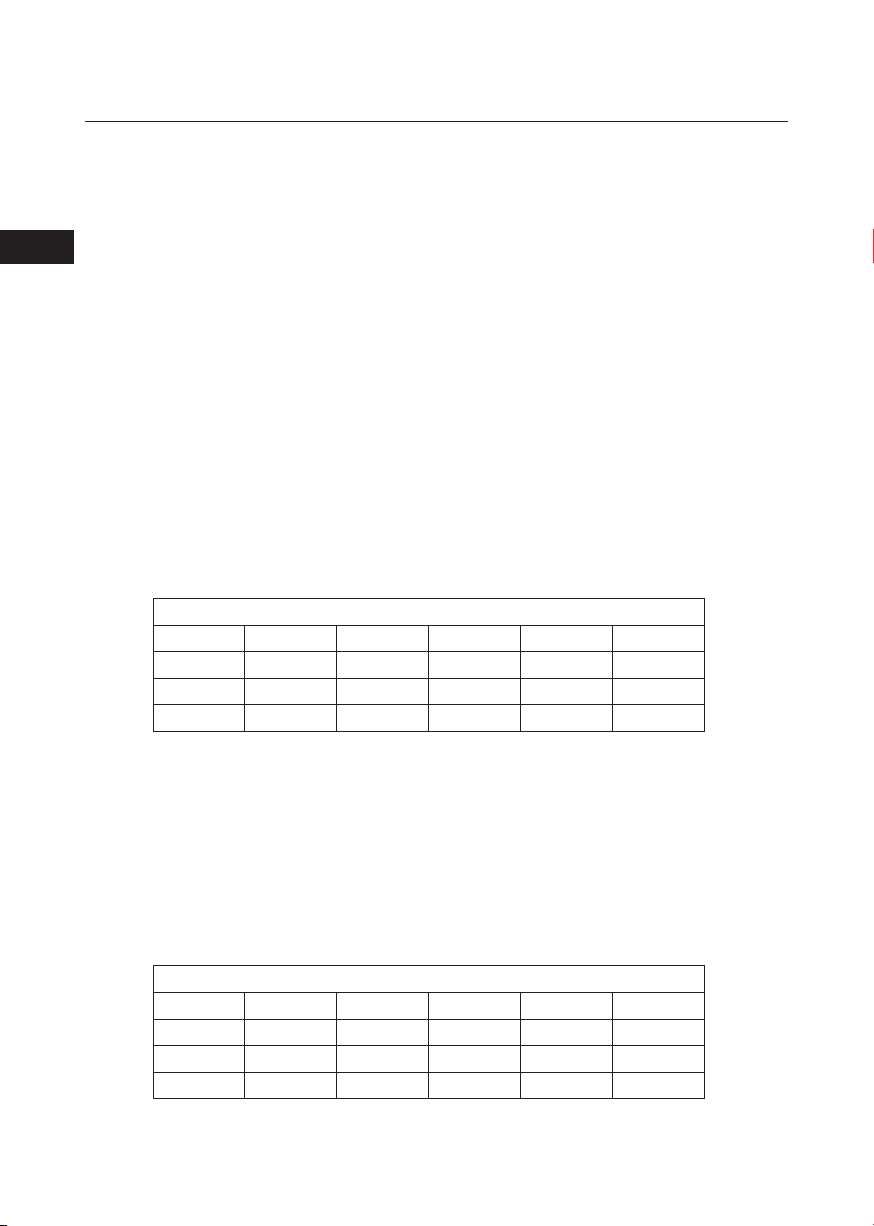

3 = Proportional acid the pump is definitely active when the measurement is greater than

the “working threshold + ½ hysteresis” level, and definitely off when measurement is lower

than the “working threshold – ½ hysteresis” value, while for measurements between these

limits, the operating time of the pump is proportional to the distance of measurement from

the limits. The time base is fixed (90 seconds) and operation follows the trend shown in the

table below:

Measurement = pH ; Working threshold = 7.20 pH ; Hysteresis = 0.40 pH

Measure <= 7.00 7.10 7.20 7.30 >= 7.40

% dosage 0 % 25 % 50 % 75 % 100 %

Pump ON never 23 seconds 45 seconds 67 seconds always

Pump OFF always 67 seconds 45 seconds 23 seconds never

4 = ON/OFF chlorinethis option is typically used for chloration or alkalinization; the pump

activates when the measurement is lower than the “working threshold – ½ hysteresis”

value, and deactivates when the measurement exceeds the “working threshold + ½

hysteresis” level

5 = Proportional chlorinethe pump is definitely active when the measurement is lower

than the “working threshold – ½ hysteresis” value, and definitely off when measurement is

greater than the “working threshold + ½ hysteresis” level, while for measurements between

these limits, the operating time of the pump is proportional to the distance of measurement

from the limits. The time base is fixed (90 seconds) and operation follows the trend shown

in the table below:

Measurement = Redox ; Working threshold = 680 mV ; Hysteresis = 20 mV

Measure <= 670 675 680 685 >= 690

% dosage 100 % 75 % 50 % 25 % 0 %

Pump ON always 67 seconds 45 seconds 23 seconds never

Pump OFF never 56 seconds 45 seconds 67 seconds always