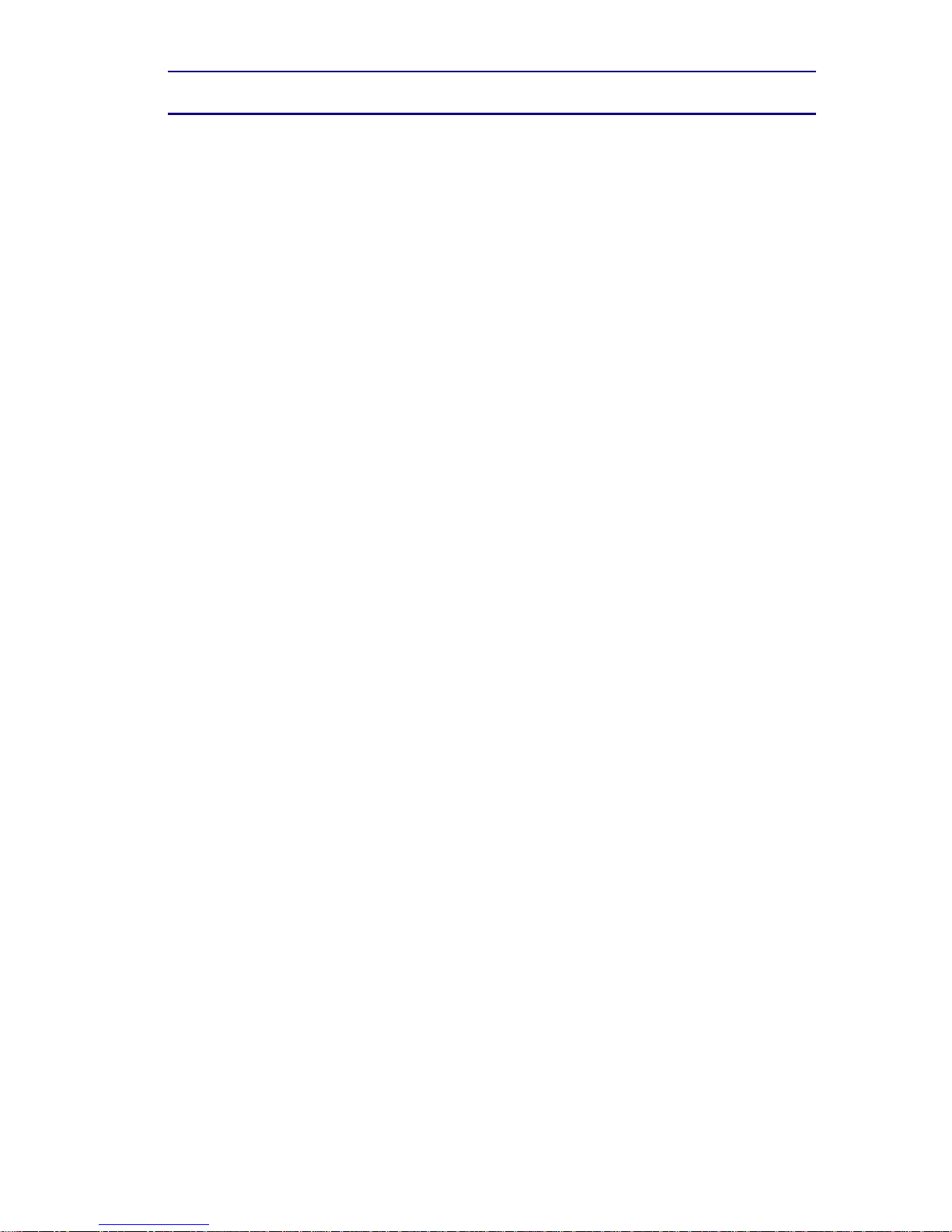

MICRO - BIRD

4

FORWARD

This Operator’s Manual provides some general, as well as

specific information regarding safe operation and maintenance of

your Blue Bird bus. It does not address all items or situations that

may arise and is not a substitute for proper driver and mechanic

training. The exercise of care, common sense, and good driver and

working practices are required for safe operation.

If specific questions or concerns arise that are not adequately

addressedinthismanualpleasecontactyourBlueBirddistributor.

The distributor will answer your questions or put you in contact

with the proper factory personnel. Throughout this guide, you

will find CAUTIONS and WARNINGS. WARNINGS remind

you to be especially careful to avoid personal injury. CAUTIONS

are given to prevent you from making an error which could

damage the vehicle and possibly cause personal injury.

Blue Bird Body Company offers many items as standard and

optional equipment to insure reliable and safe transportation of

passengers.

Some examples of this safety equipment are: stop arms,

crossing guards, warning lights, warning light monitors, mirrors,

first aid kits, fire extinguishers, warning reflectors, fusees, direc-

tional and brake lights, warning buzzers, vandal locks, emergency

exits, and seat belts.

It is the drivers responsibility to insure that the safety items

are in proper order. Equipment relating to should be checked for

operation on a daily basis. Safety equipment may vary due to state

and federal specifications.

In addition, the driver/operator must insure that the loading

areaaroundthebusisclearofpedestriansbeforestoppingandthat

all unloaded passengers are a safe distance away from the bus

before moving.

Blue Bird has mounted the bus body on the chassis you have

received. You should have also received an operator’s manual

with your vehicle from the chassis manufacturer. If you have

failed to receive such a manual, contact the chassis manufacturer’s

closest dealership to obtain one. Please read this manual and the

chassis manual carefully before operating or repairing your bus.