BMI IDP1010 User manual

Read safety and operating instructions carefully before operating the

saw for the fi rst time. Retain manual for future reference.

ATTENTION!

Owner’s Manual

Keep for your records

Optional

Saw Stand

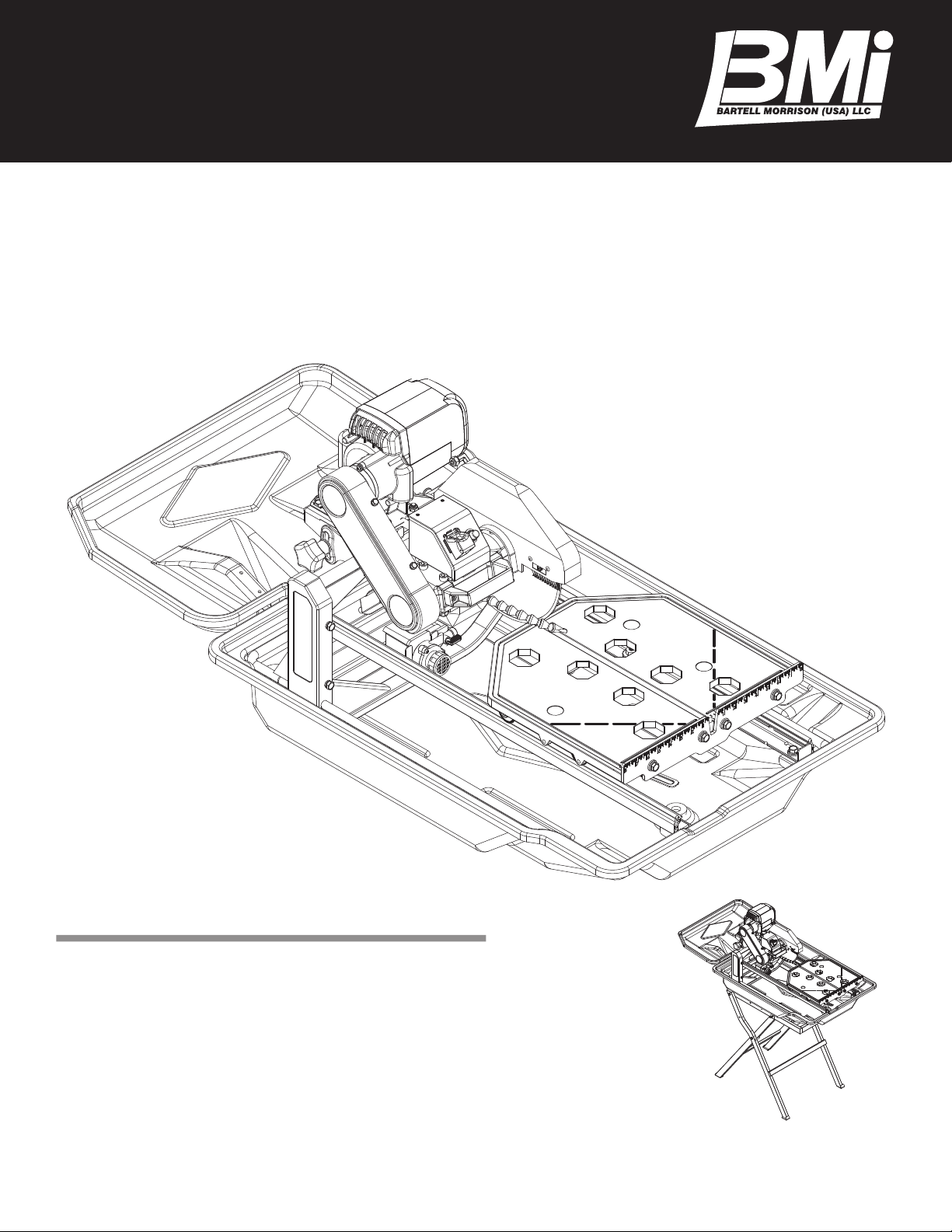

IDP1010

Wet Tile Saw

Contents

Contents 2

Safety Precautions 3

Health Warning 4

Unpacking 4

Set Up 4

Features 5

Specifications 5

Installation and Operation 6

Saw Stand Setup 6

Blade Installation 6

Water Pump Installation 6

Using the Cutting Table 7

Using the Rip Guide 7

Performing Diagonal Cuts 7

Performing Miter Cuts 7

Setting the Cutting Depth 7

Cleaning the Water Tray 7

Transporting the Saw 8

Proper Blade Use 9

Care And Maintenance 10

General Rules 10

Cleaning 10

Prolonged Period of Nonuse 10

Extreme Temperature 11

Water Pump Maintenance 11

Belt Replacement 11

Realignment 12

Leveling Adjustment 14

Electrical Specifications 15

Recommendations 15

Electrical Wiring Diagram 15

Extension Cord Chart 15

Troubleshooting 16

Replacement Parts List 19

Accessories 24

How to Order 25

Customer Service 25

Contact Us 26

Warranty 27

IDP1010 • Owner’s Manual

3

Safety Precautions

A. Saw blade should be inspected daily for excessive wear,

core cracks and arbor damage. Replace any blade that

shows signs of damage.

B. To mount the blade, clean the arbor and outer flanges,

and tighten the nut securely.

C. DO NOT place any portion of your body in line with the

blade while it is rotating.

D. Wet cutting blades MUST be used with water.

E. To reduce the risk of electrical shock, we recommend

the use of GFCI and to refer servicing to a qualified pro-

fessional.

F. When operating the saw, be sure to wear proper safety

gear, such as safety glasses, dust mask, and hearing

protection. A hard hat is also recommended.

G. Never use the machine improperly or work in an unsafe

manner.

H. Maintain alertness while operating the machine. Failure

to maintain attention, by the operator, may lead to seri-

ous injury.

I. Keep work area clean.

J. Before you start working, familiarize yourself with the

work site and its surroundings. Take notice of circum-

stances which may impede work or traffic, observe soil

conditions (good bearing or not) and take measures to

ensure safety (e.g. the shielding of roadworks from pub-

lic traffic).

K. Take measures to ensure that the machine is in a safe

and trouble-free condition prior to usage. Use the ma-

chine only when all protective devices (i.e. guards, noise

absorbers, emergency-off devices) are in place and in

working order.

L. A visual check of the machine must be made at least

once a shift to ensure that visible damages or faults

are recognized. Any changes (including changes in

the performance or behavior of the machine) must be

reported to the supervisor. If necessary, stop the ma-

chine at once and secure it.

M. In the case of a malfunction, stop the machine imme-

diately and secure it. Fix the problem as soon as pos-

sible.

N. To stop and start the machine follow the operating in-

structions and observe any indicator lights.

O. Keep out of reach of children. Before operating ma-

chine, be sure the activated machine will be of no dan-

ger to anyone.

P. Be sure to connect the plug to a properly grounded re-

ceptacle to reduce the risk of electric shock.

Q. Wear proper apparel. Do not wear loose clothing or ac-

cessories. Keep hair and body parts away from open-

ings and moving parts.

R. If cord/plug is damaged do not operate.

S. Make sure power switch is in “off” position before plug-

ging in power cord to prevent any accidental activation.

T. When machine is plugged in do not leave it unattended.

Unplug prior to servicing, when changing accessories,

and when not in use.

U. Never carry machine by cord. Do not pull cord to un-

plug. Keep cord away from heat, sharp edges and oil.

V. Do not operate the machine when you are tired or while

under the influence of drugs, alcohol or any medica-

tion.

W. Never operate this unit when flammable materials or va-

pors are present. Electrical devices produce sparks or

arcs which can cause a fire or explosion.

X. When using an extension cord, make sure it is in good

condition and heavy enough to carry the current drawn

by the machine. Refer to the extension cord table in the

“Electrical Specifications” section for the correct gauge

depending on the desired cord length and the machine’s

horse power and voltage.

WARNING

4

Health Warning

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contain chemicals

known to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks, cement and other

masonry products, and

• Arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure

to these chemicals: Work in a well ventilated area, and

work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic

particles.

Unpacking

Open the container and carefully lift the saw by the foam packag-

ing and place it on a flat, level working area. Be sure that you

have the following items before you discard the container:

• Saw

• Plastic water tray

• Rear drip tray

• 10” saw blade

• Universal wrench

• Water pump

• Rip guide

• Owner’s manual

• Drain plug

See also page 23 for additional optional accessories.

Set Up

Proceed to the following section to complete the assembly

of the saw:

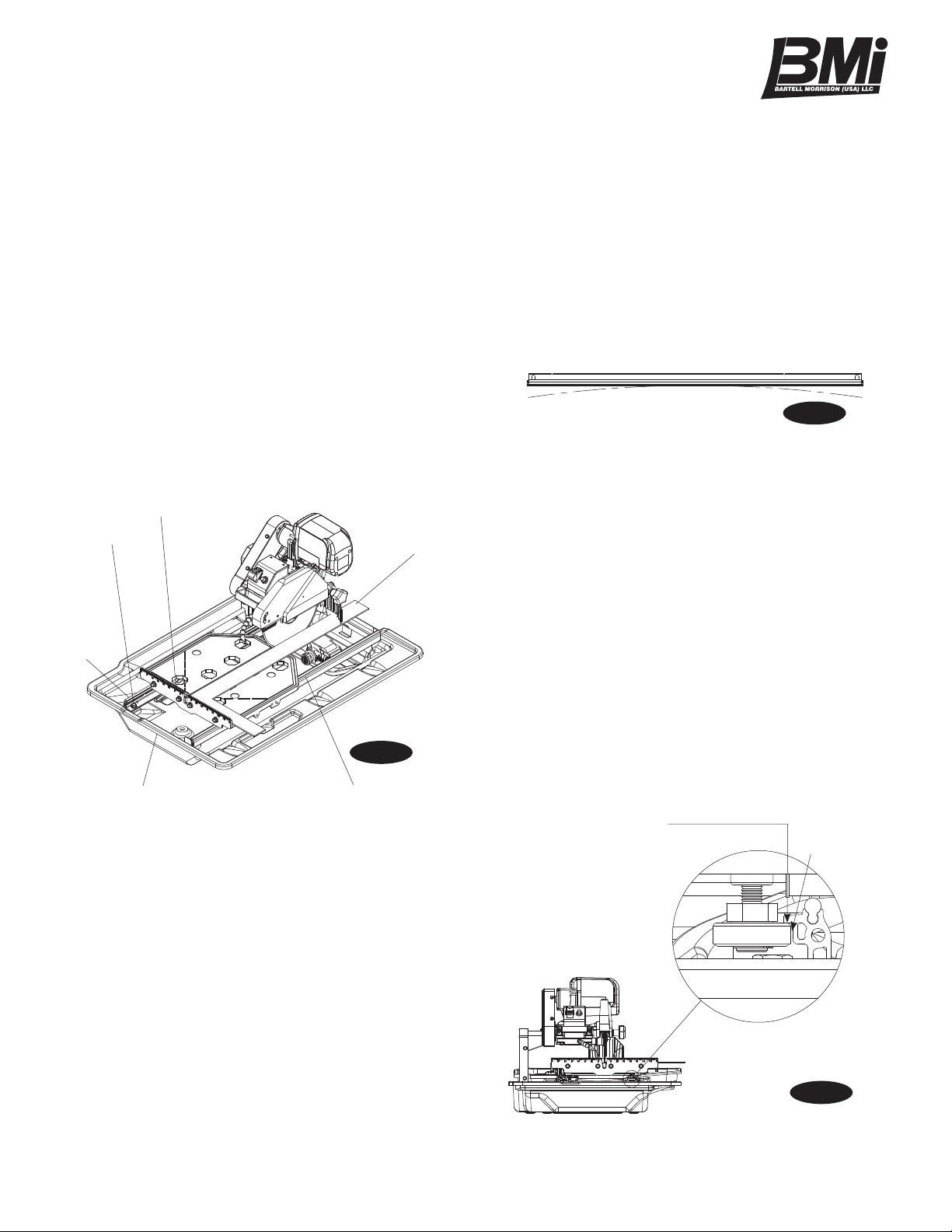

1. Slide water pump onto U-shaped bracket located at the

bottom of the frame. (see figure 1)

2. Slide cutting head onto the post. Secure cutting head

to the shaft using the provided flat washer, lock washer

and nut. Then attach cutting depth control knob and

washer to the cutting head through the slot located un-

derneath the belt guard.

3. Mount blade guard onto shaft protruding from the side

of the cutting head. Secure the blade guard in place

using the provided serrated washer and blade guard

knob.

4. Attach rear drip tray to the water tray.

figure 1

IDP1010 • Owner’s Manual

5

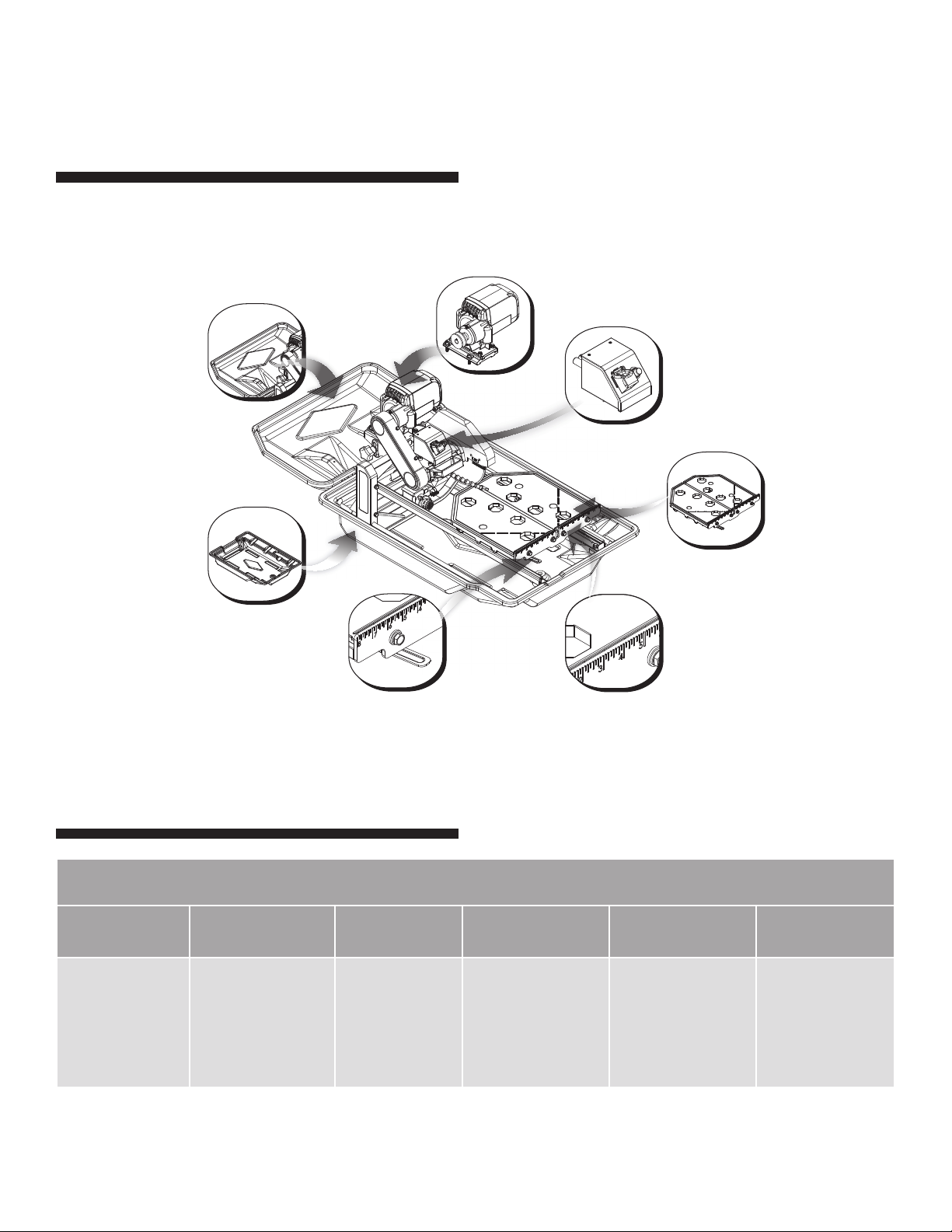

Carbon Brush Motor

Generates more torque and is physi-

cally smaller and lighter than similarly

rated induction motors.

Thermal Overload Protection

Prevents the motor from overheat-

ing and protects the saw from power

surges.

Cutting Table

Features an injection mold rubber

mat that provides a fi rm, durable

work surface while the ball bearing

wheels and rollers ensure smooth ef-

fortless movement.

Ruler Guide

The guide allows convenient mea-

surements and promotes precision

cuts.

Table Retention Device

The device secures the cutting table

when transporting the saw.

ABS Water Tray

ABS is a lightweight alternative to

stainless steel and offers excellent

durability.

Features

Specifi cations

Bartell Morrison IDP1010 TILE SAW

Motor Max. Blade

Capacity Cutting Length Cutting Depth Weight Dimensions

2 HP,

115 V/60 Hz,

3000 RPM

10” blade with 5⁄8”

arbor

24”,

Diagonally cut

16” tile

3½” 65 lbs

Length: 36.5”

Width: 26”

Height: 20.4”

Drip Tray

Rear drip tray increases the surface

area for collecting water and slurry to

prevent spillage.

* Dimensions do not include drip tray.

6

Installation and Operation

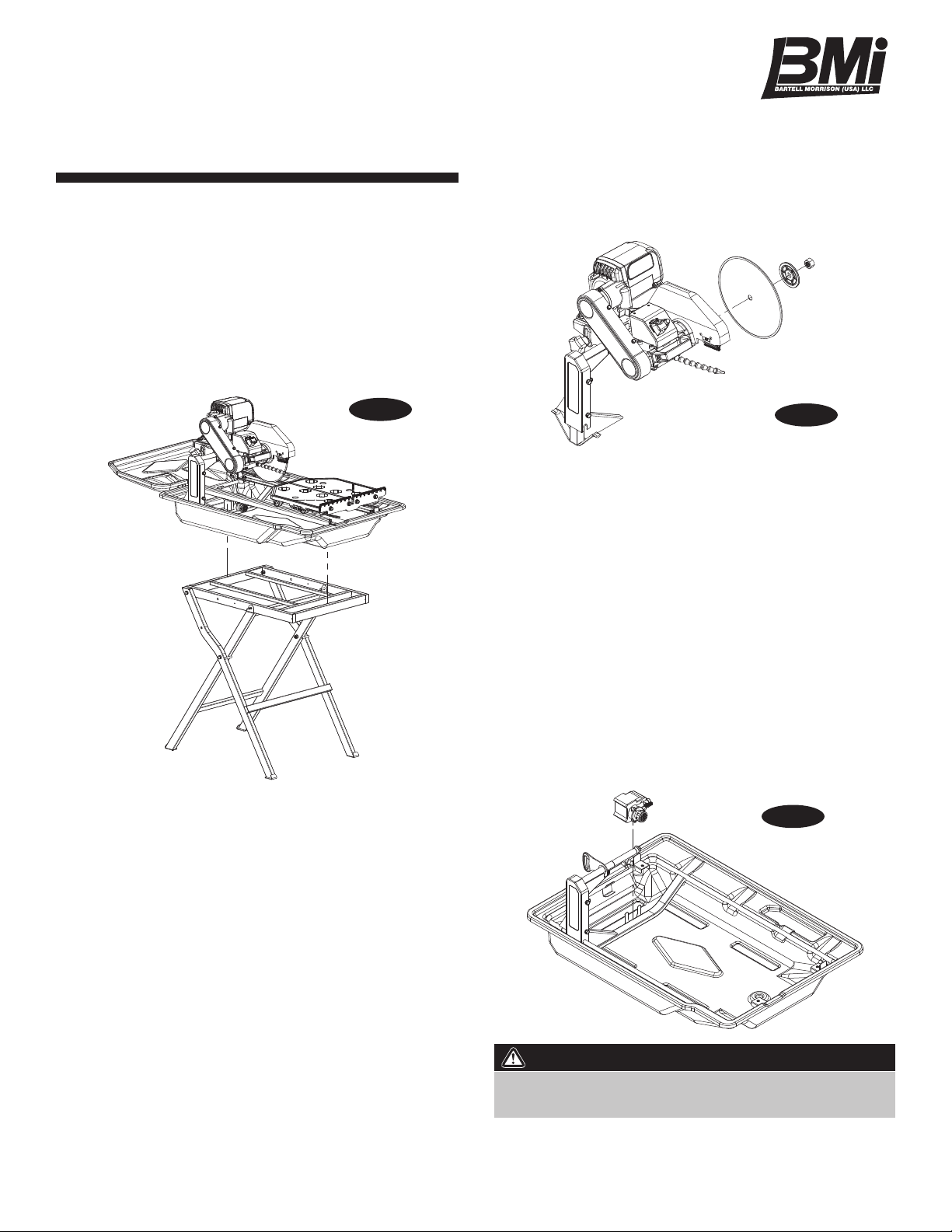

SAW STAND SETUP

1. Remove the folding stand from its box.

2. While holding the stand upright, spread both sets of legs

apart and swing the workbench over and on top of the

legs.

3. Seat the saw securely onto the stand. (see figure 2)

BLADE INSTALLATION

1. Loosen blade guard adjustment knob located at the rear

of the blade guard. Raise the blade guard to the highest

position and retighten the knob.

2. Remove the blade shaft nut and outer flange. (see fig-

ure 3) If a blade has been mounted, hold the blade with

one hand and use the other hand to loosen the nut with

the universal wrench. Remove existing blade.

3. Mount new blade, but make certain the arrow on the

blade coincides with the rotation direction of the shaft.

4. Attach outer flange and blade shaft nut. Hold the blade

with one hand and use the other hand to tighten the nut

with the universal wrench. Make certain the flanges are

pressed flush against the blade and that the nut is firmly

tightened, but do not over tighten.

5. Loosen blade guard adjustment knob, lower the blade

guard and retighten the knob.

WATER PUMP INSTALLATION

1. Remove the water pump from the box and check that it

is not damaged.

2. Slide the pump onto the U-shaped bracket located at

the bottom of the frame. The pump should be oriented

such that the water outlet is horizontal. (see figure 4)

3. Connect water hose from the bearing housing located

on the underside of the cutting head to the water pump.

Plug the pump’s power cord into the connector leading

from the switch box.

4. Fill the water tray so that the water intake is fully im-

mersed. Proper water level must be maintained at all

times during saw operation.

Disconnect the pump before attempting to handle the

pump. Never operate pump without water in the tray.

WARNING:

figure 3

figure 2

figure 4

IDP1010 • Owner’s Manual

7

USING THE CUTTING TABLE

• The ruler guide has inches marked along the top to al-

low convenient measurements and to promote preci-

sion cuts. (see figure 5)

• The table the table spans an area of 16” x 16”. With

the optional side extension table equipped, the cast alu-

minum cutting table spans an area of 25” x 16”, which

allows it to provide greater support for handling larger

materials.

• Cutting table is covered by a rubber mat that provides a

firm, durable work surface.

• A rip guide should be used together with the cutting ta-

ble to ensure precision while making cuts.

USING THE RIP GUIDE

1. Set the rip guide at the desired location on the ruler

guide and tighten the threaded knob. Make sure that

the rip guide is firmly tightened to avoid slippage. The

rip guide can be used for 45˚ and 90˚ cuts.

2. After the rip guide is positioned for the desired cut, place

material flat against the rip guide and the ruler guide.

3. Now you are ready to make your cut.

PERFORMING DIAGONAL CUTS

1. Remove threaded knob from the end of the rip guide

with the horizontal groove and insert it into the other end

with the diagonal groove.

2. Set the rip guide onto the ruler guide, such that the top

edge of the rip guide is aligned with the diagonal groove

to the left of the vertical channel in the cutting table.

Tighten threaded knob once in place.

3. Place one corner of the material being cut in the vertical

slot of the ruler guide and rest the adjoining edge flat

against the rip guide.

4. Now you are ready to make your cut.

PERFORMING MITER CUTS

To make miter cuts, an optional miter block must be pur-

chased.

1. Place the lip of the miter block on the ruler guide with the

threaded knob facing you.

2. Position the miter block such that a tile laying flat against

the block may rest its left-most edge within the vertical

channel of the cutting table. Tighten the threaded knob

to secure the miter block in place.

3. Place material onto miter block and you are ready to

cut.

SETTING THE CUTTING DEPTH

The recommended cutting depth is ¼” below the cutting

table surface. To adjust the cutting depth, loosen the cut-

ting depth control knob and set the cutting head such that

the lowest point of the blade is ¼” below the table surface.

CLEANING THE WATER TRAY

1. Remove the rear drip tray.

2. Lift the saw up from inside the water tray.

3. Remove the drain plug and drain any water left inside

the water tray.

4. Flush water into the tray while holding it upright to re-

move any sludge buildup.

Blade Diameter Cutting Depth

7” 1¾”

10” 3½”

figure 5

Setting the blade too low may damage the cutting table

and if set too high, the blade may grab the material being

cut, possibly causing injury to the operator and the saw.

WARNING:

8

5. Replace the saw back into the water tray.

6. Attach the rear drip tray. (see figure 6)

TRANSPORTING THE SAW

1. Ensure that the water tray is empty and dry.

2. Unplug the power cord and store it in the water tray.

3. Secure the cutting table to the front of the saw using the

table retention device.

4. Tighten the cutting depth control knob.

5. Optionally the rear drip tray may be removed and set in

the water tray for better handling.

figure 6

IDP1010 • Owner’s Manual

9

Proper Blade Use

Dos Don’ts

Wet Cut

Blades

• Inspect blades daily for cracks or uneven

wear.

• Always use appropriate blade for material be-

ing cut.

• Inspect arbor shaft for uneven wear before

mounting blade.

• Always use blades with the correct arbor

shaft size.

• Ensure that blade is mounted in the correct

direction.

• Use proper safety equipment when operating

the saw.

• Always have a continuous flow of water on

both sides of blade.

• Secure the blade to the arbor with a wrench.

• Do not operate the saw without safety guards

in position.

• Do not operate the saw with blades larger

than 10”.

• Do not cut dry with blades marked “Use

Wet”.

• Do not exceed manufacturer’s recommended

maximum RPM.

• Do not force blade into material. Let blade

cut at its own speed.

Dry Cut

Blades

• In addition to the following, always follow wet

recommendations.

• Use appropriate blade for material being cut.

• Inspect segment blades for segment cracking

or loss.

• Do not use damaged blades.

• Use proper safety equipment when operating

the saw.

• In addition to the following, always follow wet

recommendations.

• Do not make long cuts with dry blades. Allow

them to air cool.

• Do not use the edge or side of blade to cut or

grind.

• Do not attempt to cut a radius or curve.

• Do not cut too deep or too fast into the mate-

rial.

• Do not cut any material not recommended by

blade manufacturer.

10

Care and Maintenance

GENERAL RULES

• Always clean the machine before performing any main-

tenance/repair.

• Before performing any cleaning/maintenance/repair,

the machine must be switched off with the main power

switch.

Steps to Follow When Cleaning:

• Please do not use aggressive cleaners (i.e. containing

solvents). Do not use high-pressure water jets, aggres-

sive detergents or solutions and liquids with a tempera-

ture exceeding 86ºF! Use a fluff-free cloth only.

• Use a cloth which may be lightly moistened only for re-

moving dust and dirt. Hard packed dirt can be removed

with a soft brush.

• For the sake of safety, no water/cleaning liquid/vapor

may penetrate into the electric motor, connectors/plugs,

switches, etc. Therefore cover all apertures, holes in

the housing, connectors or plugs, etc. or seal them with

adhesive tape!

• Use a soft, low-pressure water jet and a brush to rinse

dirt and incrustations away. Be particularly careful when

near hazardous parts of the machine (e.g. switch, mo-

tor). Clean the motor and switches only by wiping with a

moist cloth.

• Do not “rinse” the bearings of the drive elements to pre-

vent them from running dry. The ball bearings of the ma-

chine are permanently lubricated.

• After cleaning, remove all covers and adhesive tape!

All screws/nuts which you may have loosened must be

tightened again!

• After wet cleaning, try the machine on a power outlet

which is equipped with a power breaker (i.e. fault cur-

rent circuit breaker). If the fault current circuit breaker

cuts the power supply, the machine must be inspected

by an authorized dealer prior to use!

CLEANING

After every use of the machine:

• Remove dirty water from container.

• Remove dirt and mud from the bottom of the container.

• Rinse the immersion pump with fresh water to prevent

the water pump from clogging with residual dirt.

After wet cleaning and before using the machine

again:

• Connect the machine to an electric power outlet equipped

with a “GFCI” safety power breaker. If the safety power

breaker cuts off the electrical power supply, do not try to

operate the machine but have it checked by an autho-

rized dealer first.

PROLONGED PERIOD OF NONUSE

Before not using the machine for a prolonged period

of time:

• Clean and lubricate all movable parts. However, do not

grease the guide rails.

After not using the machine for a prolonged period of

time:

• Check that the stand is safely fixed.

• Check that all screw joints and nuts are fixed.

• Check that the cutting table is seated properly on the

guide rails and that it moves easily along the entire

length of the rails.

• With the saw blade removed, switch on the motor for an

instant and switch it off again. If the motor does not run,

have the machine inspected by a qualified electrician.

• Check that the immersion pump works properly. Turn

on the cooling water tap and switch the machine on. If

the pump does not give any water or only a little, switch

the machine off at once. Clean the pump, or replace if

necessary.

For your safety, before performing any maintenance on

the saw turn OFF the power switch and UNPLUG the

power cord.

WARNING:

IDP1010 • Owner’s Manual

11

EXTREME TEMPERATURE

Ambient temperature below 32° F (Winter):

• To prevent the water in the pump and cooling system

from freezing, remove the water after using the machine

or when there will be a long break. Make sure that the

cooling system is entirely drained so that there is no wa-

ter left inside the pump and water hose!

WATER PUMP MAINTENANCE

When the machine has not been used for a long period

of time, hard packed dirt may begin to build up inside the

pump and block the pump wheel. If the machine is acti-

vated with the immersion pump blocked, the electric motor

of the pump will be damaged within a few minutes! Please

follow the steps listed below to clean the pump before op-

erating the saw:

1. Remove the immersion pump from the water container.

2. Clean the immersion pump.

3. Loosen the fixing screws of the pump lid.

4. Take the lid off the pump. Be careful not to damage or

lose the gasket underneath.

5. Clean the pump lid.

6. Remove all dirt and incrustations from the pump wheel.

7. Check whether the pump wheel can be easily turned.

8. Then reassemble the immersion pump correctly and

check whether it works properly.

BELT REPLACEMENT

1. Unplug the saw before proceeding any further.

2. Loosen and remove the four bolts located above and

below the belt guard and then remove the belt guard.

(see figure 7)

3. Loosen the four bolts located at the base of the motor.

4. Use a hex wrench to access the socket hex bolt located

at the rear of the cutting head. Turn wrench to move the

motor forward, thus providing some slack in the belt.

5. Remove existing belt and replace with a new belt.

6. Perform steps 1 through 4 in reverse to tension the belt

and reinstall the belt guard. Make sure the belt is at the

proper tension before tightening the four bolts at the

base of the motor.

figure 7

12

REALIGNMENT

Method 1:

This procedure deals with the most common source of mis-

alignment that occurs when the guide rails are not parallel

with the blade.

1. Set the cutting depth such that the blade passes through

the table, not over.

2. Place a straight edge (i.e. carpenter’s square) on the

cutting table as shown in figure 8.

3. Loosen the left and right guide rails by loosening the

fasteners found at the ends of the rail. (see figure 8)

The left rail should be slightly loose, so there is not too

much play during adjustments, but the right rail should

move freely.

4. Make sure the short portion of the straight edge is placed

flush against the ruler guide. Adjust the left guide rail

so that the front and rear edges of the blade touch the

straight edge, although a tolerance of 0.1mm between

the front and rear edges is allowed. Perform this adjust-

ment along the entire length of the straight edge.

5. Position the table as close to the user as possible.

Place the straight edge flush against the ruler guide and

blade. Without holding onto the straight edge, gently

move the table towards the rear of the saw and then

back. Observe any gaps that may appear between the

straight edge and blade or between the straight edge

and ruler guide. A gap exceeding the allowed tolerance

Ruler Guide

Right Guide Rail

Fastener

Left Guide

Rail

Straight Edge

Front of the Saw

figure 8

means that the table is not moving parallel to the blade;

hence, further adjustments as outlined in step 4 will be

required. However, if scenario A or B described below

occurs, other adjustments may be required instead.

A. If the straight edge only touches the blade when

the table is positioned midway along the rail or

at the ends of the rail, then the rail may be de-

formed (i.e. bowed). (see figure 9) Perform test

cuts to determine if the rail should be replaced.

Typically a bowing displacement of up to 0.2mm

will not affect cutting accuracy.

B. If the straight edge touches both edges of the

blade intially, but shifts apart as the table travels

along the rail, proceed to method 2 below.

6. Tighten the fasteners at both ends of the left rail.

7. Adjust the right guide rail so that the horizontal rollers

underneath the table engage the rail as shown in figure

10. In most cases the rollers will not have to be verti-

cally adjusted. Spacing between rails must be equidis-

tant at all points to ensure that they are parallel. Once

adjustments are made, lightly tighten the fasteners on

the right rail and move the table back and forth. If the

table binds against the rail at any point, adjust spacing

accordingly until the table moves smoothly.

8. Tighten the fasteners at both ends of the right rail.

If alignment has been achieved do not proceed to method

2.

figure 9

Leave hairline gap

between rail and roller

Leave a 1⁄32″

(1mm) gap

figure 10

IDP1010 • Owner’s Manual

13

3. If the table shifts to the right as it travels away from the

user, a shim needs to be added to the guide roller fur-

thest from the ruler guide. On the other hand, if the

table shifts to the left, a shim needs to be added to the

guide roller closest to the ruler guide. Remove the ap-

propriate guide roller to insert a shim between the roller

and table, then reattach. (see figure 14) Depending on

the severity of the shift, more than one shim may be

required.

4. After adding shim(s), mount the table onto the guide rails

by reversing the instructions in step 2. Move the rails

toward each other to engage the horizontal rollers to the

right guide rail as shown in figure 10. Realign the table

to the blade using method 1. Check to see if any shifting

persists. A shift tolerance of 0.2mm is allowed. A shift

in excess of that will require further adjustment—repeat

step 3.

5. Once alignment is successful, replace saw back into the

water tray.

Method 2:

This procedure corrects another source of misalignment

that occurs when the table’s orientation is not parallel with

the guide rails.

1. Lift the saw up from within the water tray and place it on

a flat level surface. Use the universal wrench to loosen

(but not remove) the fasteners from either end of both

guide rails. Move each rail away from the other, so that

the horizontal rollers are clear of the right guide rail. (see

figure 11)

2. Remove rubber cap A on the left side of the table. Loos-

en the exposed lock nut using a 13mm socket wrench.

Use a flat screwdriver to turn the shaft of the roller clock-

wise to lower it by approximately 3/8”. (see figure 12)

Evenly lift up the table to disengage the guide rollers

from the left guide rail. Once the guide rollers are clear,

shift the table to the right to clear the left horizontal roller

of the rail. Remove the table from the guide rails. (see

figure 13)

Horizontal

Roller

Flat Roller

figure 14

Shim

Guide Roller

Rubber Cap B Flat Screw Driver

Size 13mm

Socket

Wrench

figure 12

Rubber Cap A Rubber Cap C

figure 11

Loosen Fasteners

Right Guide Rail

Clearance

Horizontal Roller

Guide Roller Horizontal Roller

figure 13

1

2

Left Guide Rail

14

LEVELING ADJUSTMENT

This procedure levels the table so that it is perpendicular to

the blade and flush against the rails.

1. Remove rubber caps B and C on the right side of the

table. Loosen the exposed lock nuts using a socket

wrench. Next, use a flat screwdriver to turn the shaft

of the rollers clockwise. (see figure 12) This will lower

the horizontal rollers to allow room for adjusting the flat

rollers.

2. Loosen the socket bolts on the flat roller plate so that the

roller can swing freely about one bolt. (see figure 15)

Do this for both flat roller plates.

3. Hold the table against the guide rails. The flat rollers

should reposition themselves to maintain contact with

the guide rails. If the table is not perpendicular to the

blade, lift the right side of the table instead to obtain the

proper angle. A square tool will be required to confirm

the angle. Tighten the socket bolts. Check the table for

play. Repeat step 2 if some play is still present.

4. Restore the horizontal rollers to their original positions

as shown in figure 10 by reversing the instructions in

step 1. Be sure to tighten the lock nuts and replace the

rubber caps.

Flat rollers rotate in this manner

figure 15

IDP1010 • Owner’s Manual

15

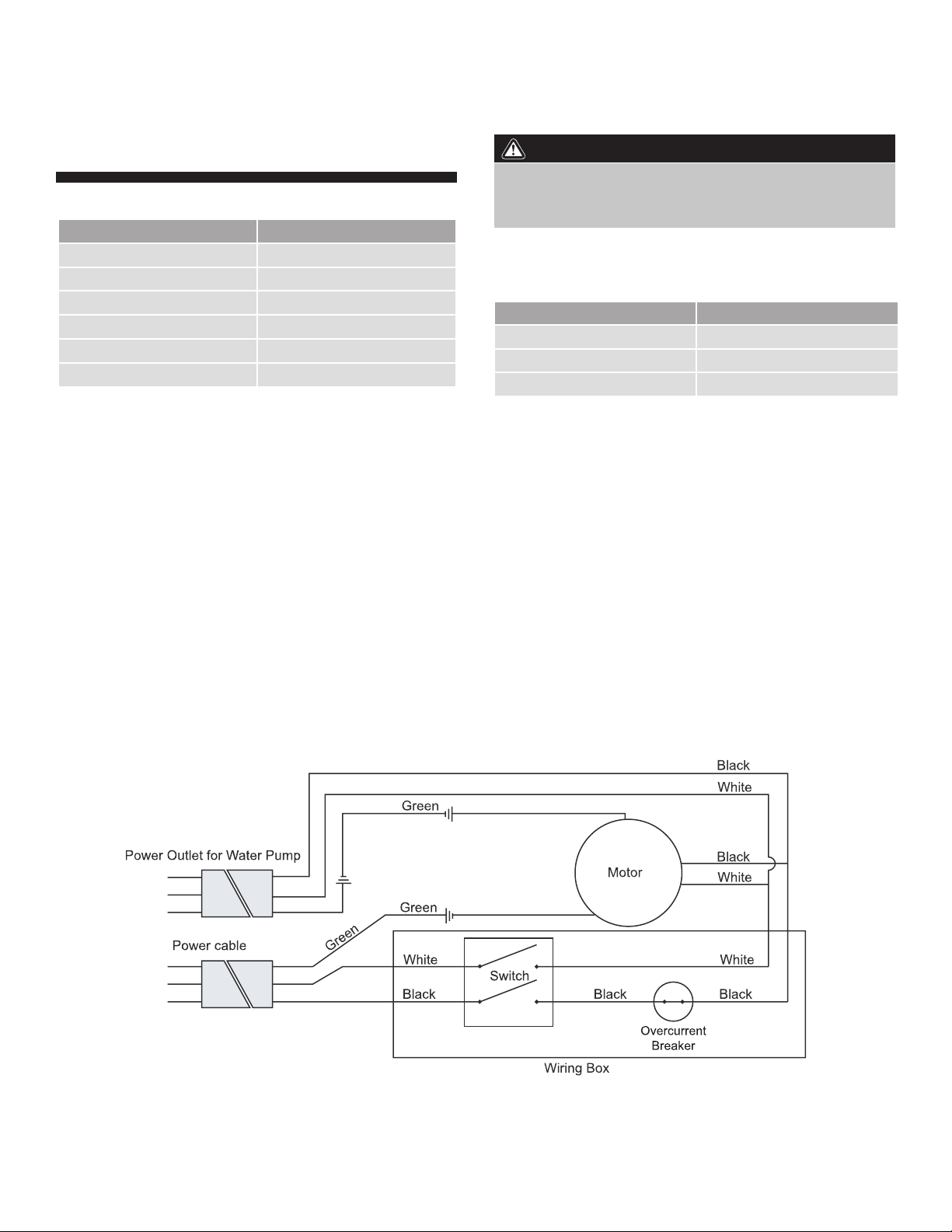

ELECTRICAL WIRING DIAGRAM

RECOMMENDATIONS

• It is recommended that a 15 amp circuit be used while

operating this saw. This will prevent any loss of power

or interruption.

• Always plug saw as close as possible to the power

source while operating. This will allow you to receive

optimum electricity.

EXTENSION CORD CHART

IDP1010

Power 2 HP

Volts 115 V

Amps 13 A

Motor RPM 3000 RPM

Cycle 60 Hz

Phase 1

Wire Gauge Length of Cord

No. 12 25’

No. 10 50’

No. 8 75’

Electrical Specifications

To avoid permanent motor damage you must use the cor-

rect extension cord. Never use more than one extension

at a time. Follow the chart below for proper size.

WARNING:

16

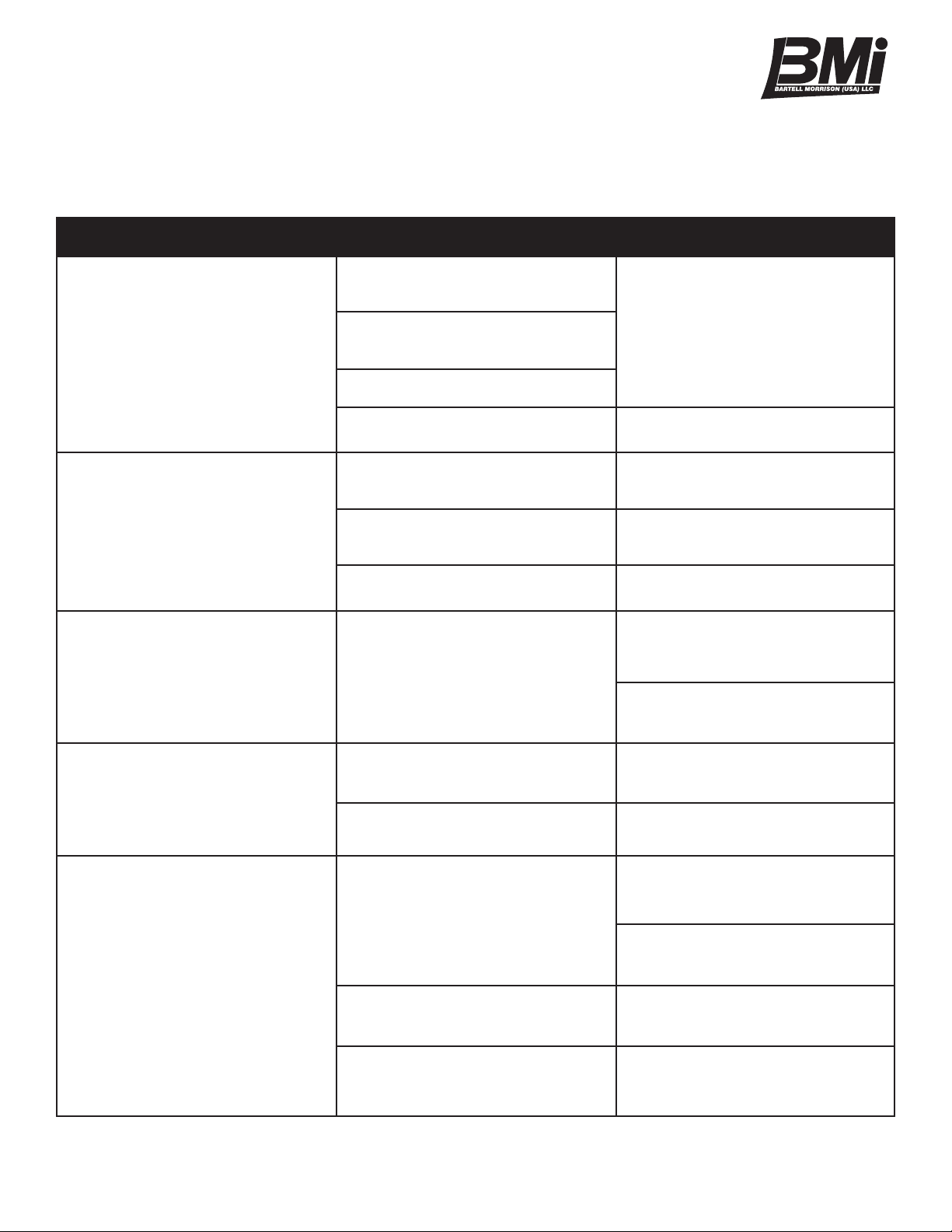

Troubleshooting

Problem Possible Cause Solution

Machine does not run when switched

on

Power cord not properly fixed/

plugged in

Check that the machine is properly

connected to the power supply

Power cord defective Have the power cord checked, re-

place if necessary

Main power switch defective Have the main power switch checked

and replace if necessary by a quali-

fied electrician

Loose electrical connection inside

the electric system

Have the whole electric system of

the machine checked by a qualified

electrician

Motor defective Have the motor checked and re-

placed if necessary by a qualified

technician

Motor stops (power cut out) Too much pressure exerted while

cutting

Exert less pressure when cutting

Incorrect specification for saw blade Use a saw blade which corresponds

to the material being cut

Saw has a defective electric system Have the electric system of the saw

checked by a qualified technician

Poor machine performance, little

power

Power cord/extension cable too long

or cable still wound up inside cable

drum

Use a power cord/extension cable of

the rated length, use a cable drum

with cable fully extended

Power network is insufficient Observe the electrical ratings of the

machine and connect it only to a

power network which complies with

these ratings

Drive motor no longer runs at rated

speed (RPM)

Have the motor checked by a quali-

fied electrician and have it replaced if

necessary

IDP1010 • Owner’s Manual

17

Problem Possible Cause Solution

Insufficient flow of cooling water or

no cooling water at all

The pump draws air Fill the container with water

Filter clogged Clean the filter of the pump

Pump wheel of the immersion pump

blocked by dirt

Disassemble the immersion pump

and clean

Irregular run of the saw blade Poor tension in the blade material Return the saw blade to the manu-

facturer

Saw blade wobbles when running Saw blade is damaged or bent Have the saw blade aligned /

flattened

Clean the receiving flange

Solder the diamond segments of the

old blade onto another saw blade or

use a new blade

Flange of the saw blade is damaged Replace the saw blade flange

Shaft of the motor is bent Replace the electric motor

Diamond segment becomes loose Overheating of the saw blade; cool-

ing water not sufficient

Have the diamond segment soldered

on the blade again; ensure optimum

flow of cooling water

Excessive wear Wrong type of saw blade Use harder saw blades

Shaft of motor causes wobbling Have bearings of the motor or the

motor replaced

Overheating Ensure optimum flow of cooling

water

Cracks in or near the diamond seg-

ment

Saw blade too hard Use a softer blade

Fixed flange is worn out Replace the fixed flange

Motor shaft bearing Replace the bearing of the motor

shaft

18

Problem Possible Cause Solution

Saw blade is blunt Saw blade type is unsuitable for the

material being cut

Use appropriate type of saw blade

Saw blade type is unsuitable for the

machine performance

Saw blade too hard

Diamond segments are blunt Sharpen the diamond saw blade

Appearance of cut is not optimal Poor tension in the blade material Return the saw blade to the manu-

facturer

Too much load placed on the saw

blade

Use a suitable saw blade

Diamond segments are blunt Sharpen the saw blade

The center hole in the saw blade has

become wider due to wear

The saw blade has slipped on the

motor shaft when running

The arbor of the saw blade must be

fitted with an appropriate adaptor

ring

Check the receiving flange and have

it replaced if necessary

Saw blade shows blooming colors Saw blade overheating due to a lack

of cooling water

Ensure an optimum flow of cooling

water

Lateral friction when cutting The material feed is too high; pro-

ceed more slowly

Grinding marks on the saw blade Material is not being fed parallel to

the saw blade

Ensure that the direction of feed is

absolutely parallel to the saw blade

Adjust the roller table or have it

adjusted

Poor tension in the blade material Have the saw blade tensioned

Too much load on the saw blade The material feed is too high, pro-

ceed more slowly

IDP1010 • Owner’s Manual

19

Replacement Parts List

MAIN ASSEMBLY

1. Frame assembly 100125

2. Cutting head assembly 100127

3. 10” Blade guard assembly 100129

4. 848L Left/Right rail 100131

5. 230 gal/hr Water pump 100132

6. TX02 Cutting table 100133

7. 10” (254mm) General purpose blade

8. Dia 5/8” (15.9mm) Universal flange 100136

9. 5/8”-11 UNC Nut 100137

10. M8 Spring washer 100080

11. M10 Spring washer 100138

12. M8 x 1.25 x 20L knob 100139

13. D30 Rubber plug 100140

14. M8 x 1.0 Nut 100086

15. M8 Narrow washer 100141

16. M8 x 1.25 x 16L Hex bolt 100109

17. M8 Regular washer 100142

18. ABS Water tray 100143

19. Rear drip tray 100144

DESCRIPTION PART NO DESCRIPTION PART NO

2 17 10

6

16

10

15

4

13

19

18

5

1

11

12

14 3 11 12 7 8 9

Table of contents

Other BMI Saw manuals