Gas Boiler Wiring & Application Guide

U.S. Boiler Company

08/23/13

2

Table of Contents

1.0 Introduction ........................................................................................................................... 3

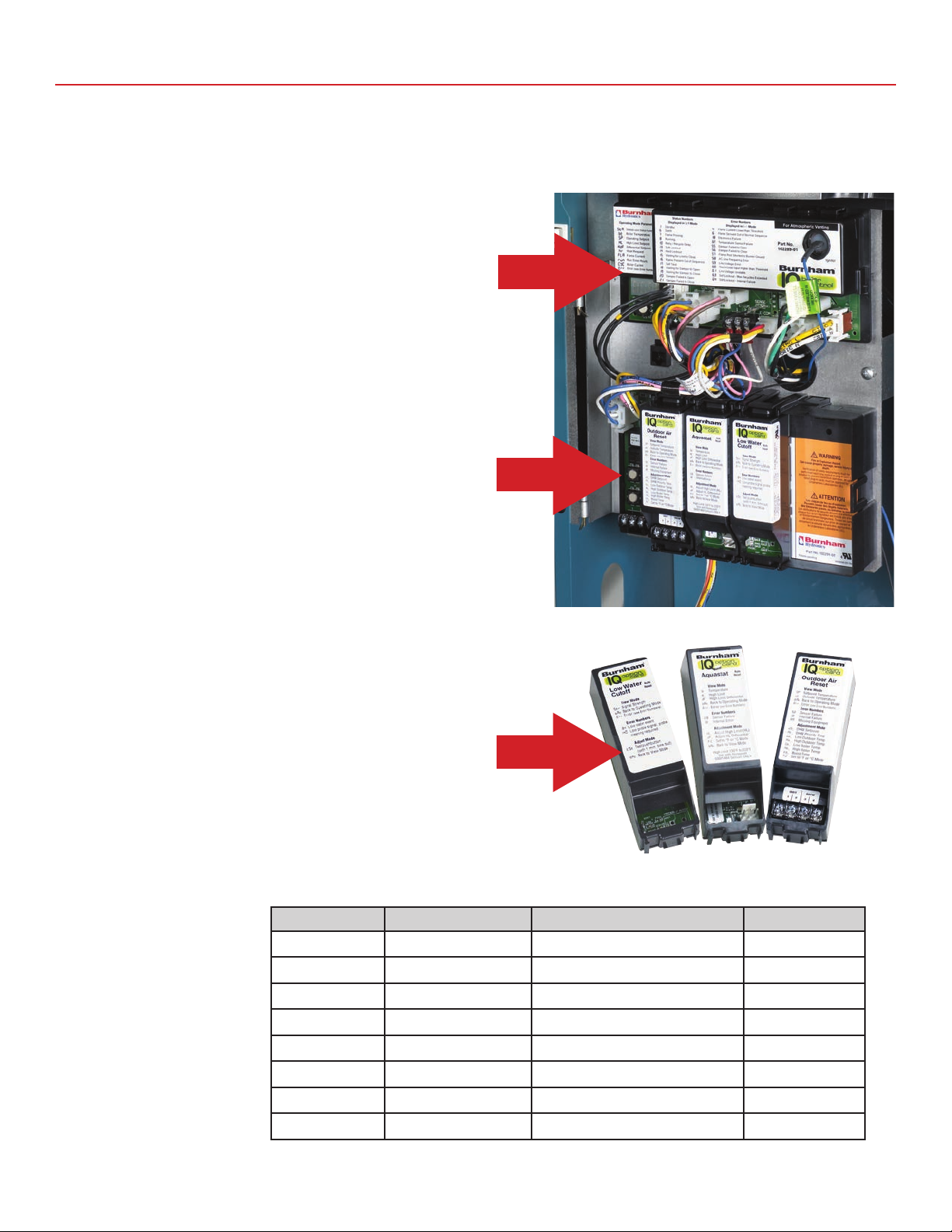

2.0 IQ Gas Boiler Control System .......................................................................................................................................... 4

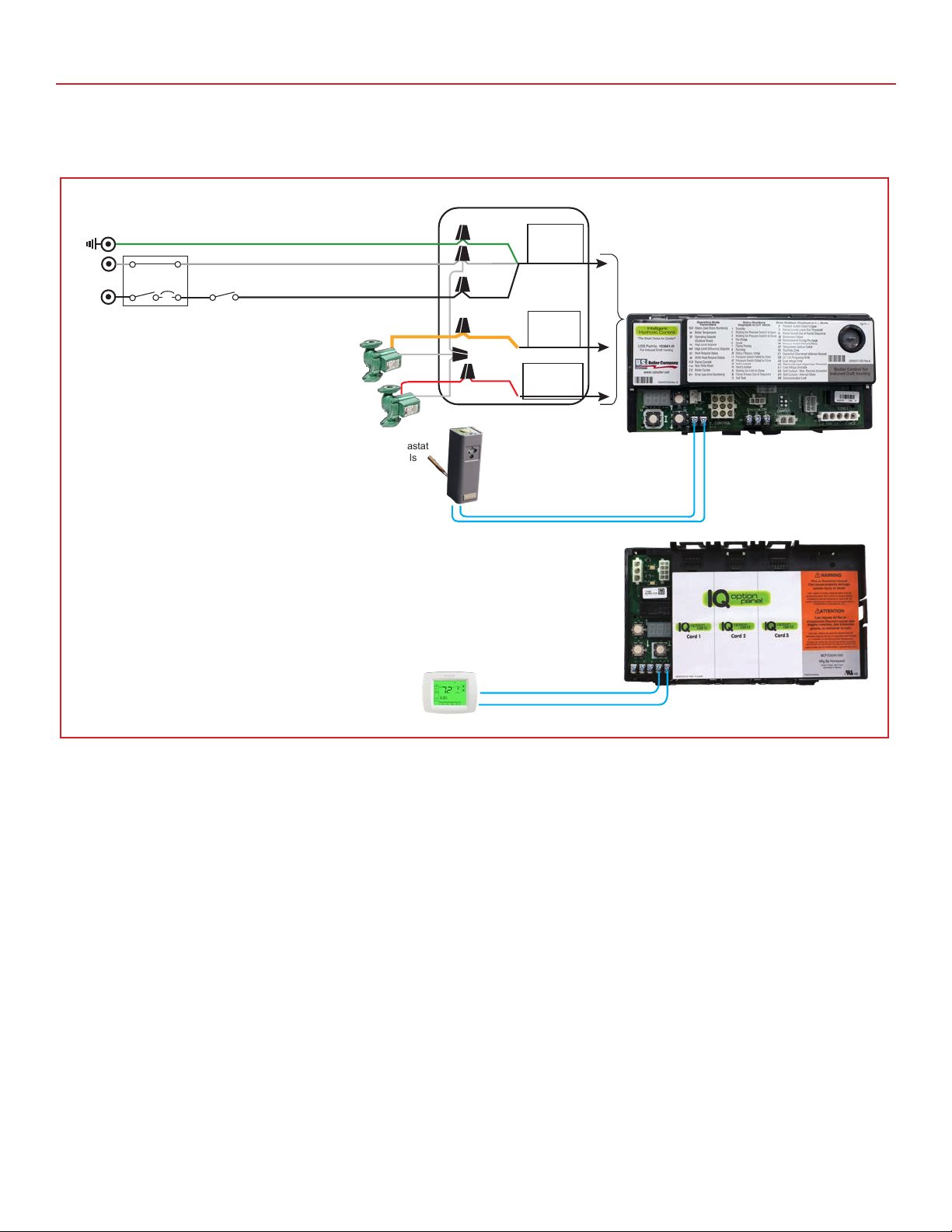

2.1 Single Zone Heating ............................................................................................................................................... 5

2.2 Single Zone Heating, Power Stealing Thermostat................................................................................................... 6

2.3 Single Zone Heating, IWH w/TPI Control................................................................................................................ 7

2.4 Single Zone Heating, IWH w/Aquastat Control ....................................................................................................... 8

2.5 Two Zone Heating .................................................................................................................................................. 9

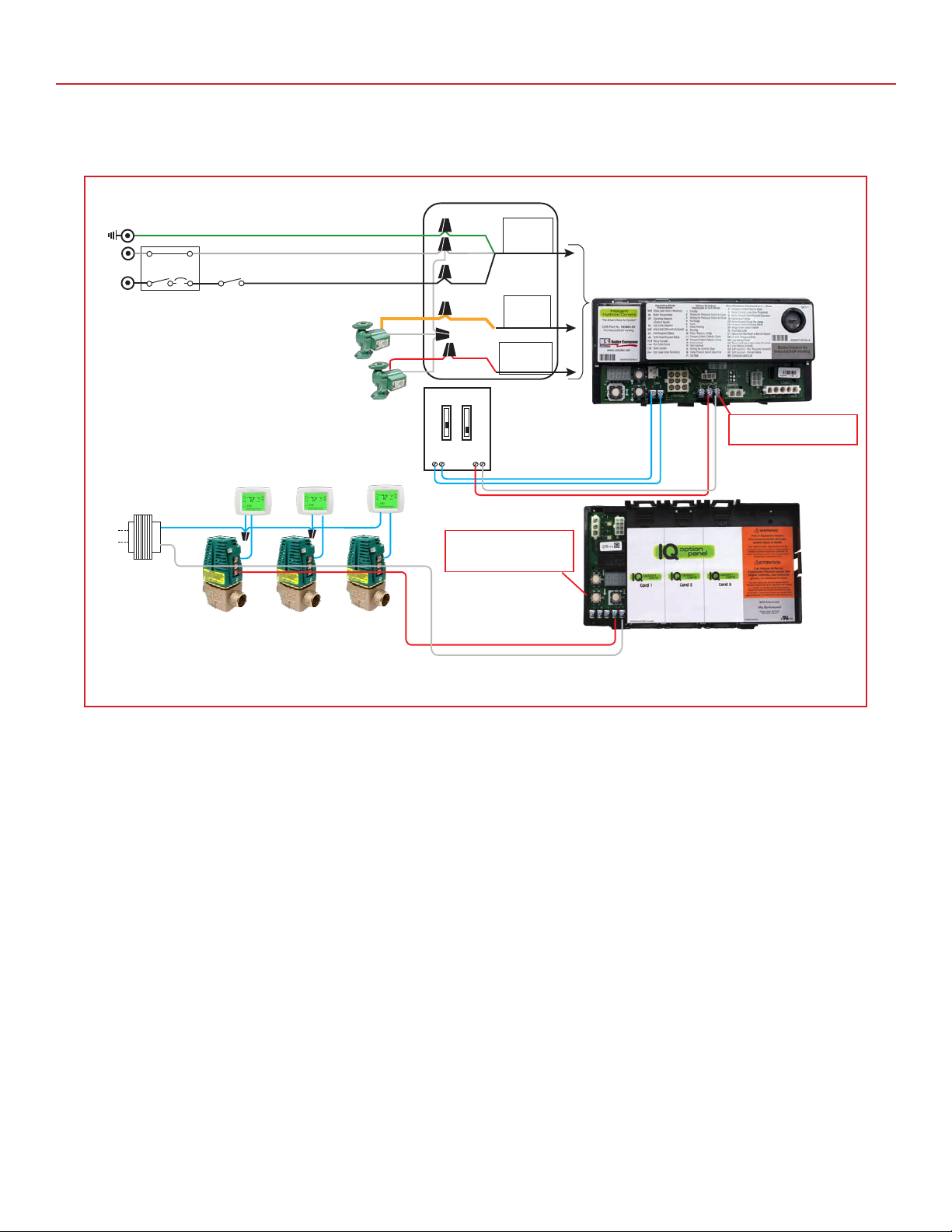

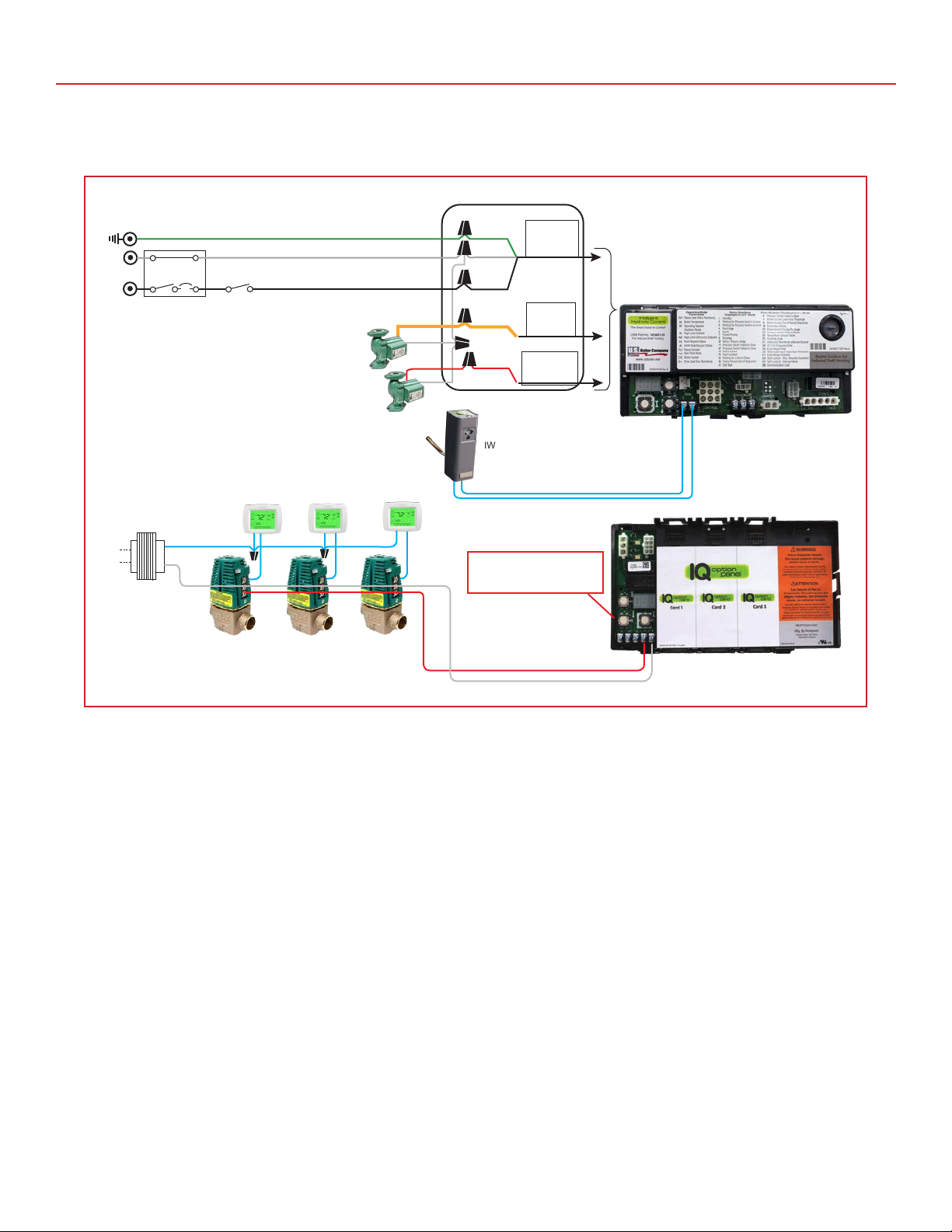

2.6 Zone Valves Heating............................................................................................................................................. 10

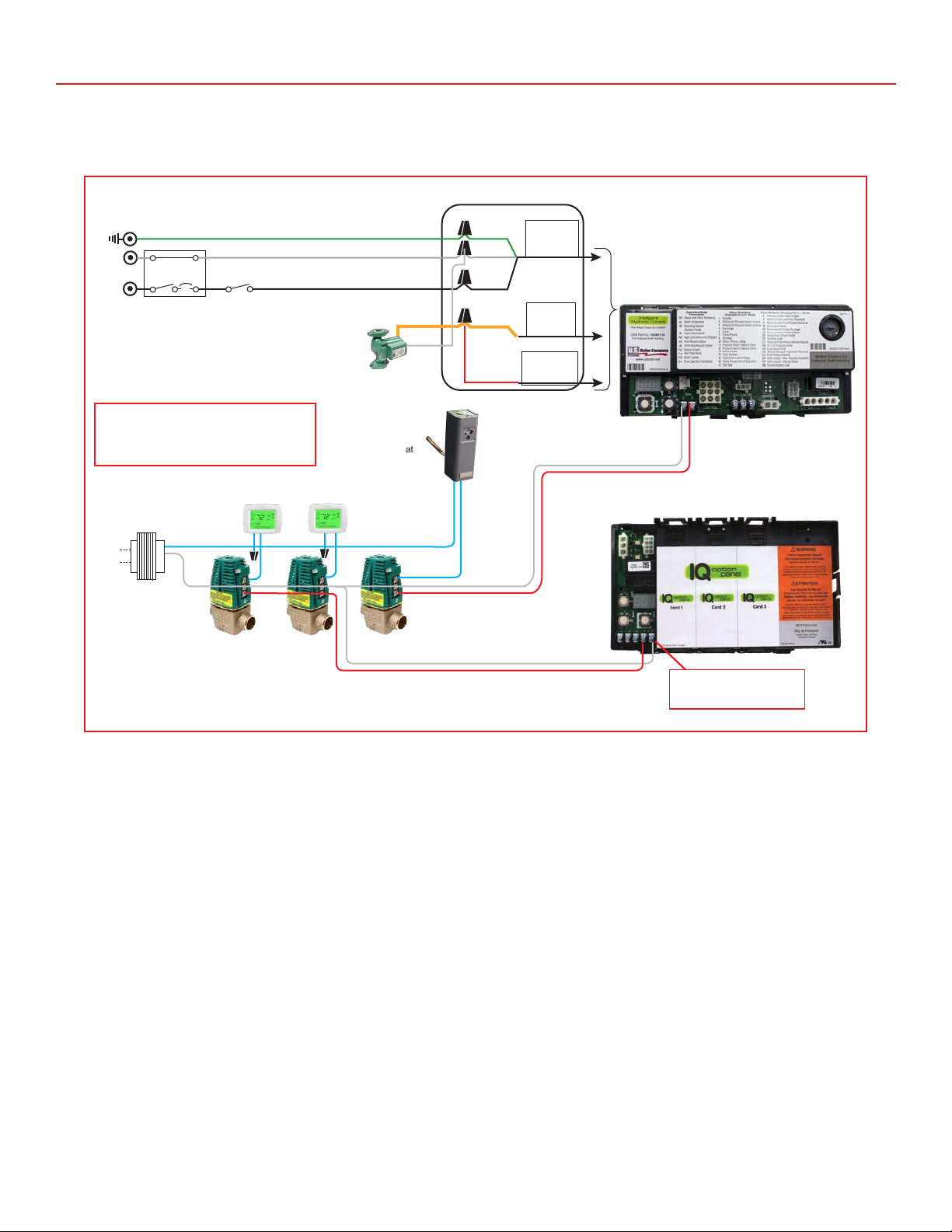

2.7 Zone Valves Heating, IWH w/TPI Control, 2 Circulators ....................................................................................... 11

2.8 Zone Valves Heating, IWH w/Aquastat Control, 2 Circulators............................................................................... 12

2.9 Zone Valves Heating, IWH w/TPI Control, 1 Circulators, No Priority .................................................................... 13

2.10 Zone Valves Heating, IWH w/Aquastat Control, 1 Circulators, No Priority............................................................ 14

2.11 Zone Valve Control Heating, IWH w/TPI Control, 2 Circulator .............................................................................. 15

2.12 Zone Valve Control Heating, IWH w/Aquastat Control, 2 Circulator...................................................................... 16

2.13 Zone Valve Control Heating, IWH w/TPI Control, 1 Circulator .............................................................................. 17

2.14 Zone Valve Control Heating, IWH w/Aquastat Control, 1 Circulator...................................................................... 18

2.15 Zone Switching Relay Heating.............................................................................................................................. 19

2.16 Zone Switching Relay Heating, IWH w/TPI Control .............................................................................................. 20

2.17 Zone Switching Relay Heating, IWH w/Aquastat Control...................................................................................... 21

3.0 IQ Gas Boiler Control System, Outdoor Reset Card.................................................................................................22-24

3.1 Single Zone Heating ............................................................................................................................................. 25

3.2 Single Zone Heating, IWH w/TPI Control.............................................................................................................. 26

3.3 Single Zone Heating, IWH w/Aquastat Control ..................................................................................................... 27

3.4 Zone Valves Heating, IWH w/TPI Control, 2 Circulators ....................................................................................... 28

3.5 Zone Valves Heating, IWH w/Aquastat Control, 2 Circulators............................................................................... 29

3.6 Zone Valves Heating, IWH w/TPI Control, 1 Circulators, No Priority .................................................................... 30

3.7 Zone Valves Heating, IWH w/Aquastat Control, 1 Circulators, No Priority............................................................ 31

3.8 Zone Valve Control Heating, IWH w/TPI Control, 2 Circulator .............................................................................. 32

3.9 Zone Valve Control Heating, IWH w/Aquastat Control, 2 Circulator...................................................................... 33

3.10 Zone Valve Control Heating, IWH w/TPI Control, 1 Circulator .............................................................................. 34

3.11 Zone Valve Control Heating, IWH w/Aquastat Control, 1 Circulator ..................................................................... 35

3.12 Zone Switching Relay Heating, IWH w/TPI Control .............................................................................................. 36

3.13 Zone Switching Relay Heating, IWH w/Aquastat Control...................................................................................... 37

4.0 Intelligent Hydronic Control (IHC) Series 2 & PVG Boilers Only

4.1 Single Zone Heating ............................................................................................................................................. 38

4.2 Single Zone Heating, Power Stealing Thermostat................................................................................................. 38

4.3 Single Zone Heating, Indirect Water Heater (IWH) w/TPI Control......................................................................... 39

4.4 Single Zone Heating, IWH w/Aquastat Control ..................................................................................................... 40

4.5 Two Zones Heating............................................................................................................................................... 41

4.6 Zone Valves Heating............................................................................................................................................. 42

4.7 Zone Valves Heating, IWH w/TPI Control, 2 Circulators ....................................................................................... 43

4.8 Zone Valves Heating, IWH w/Aquastat Control, 2 Circulators............................................................................... 44

4.9 Zone Valves Heating, IWH w/TPI Control, 1 Circulators, No Priority .................................................................... 45

4.10 Zone Valves Heating, IWH w/Aquastat Control, 1 Circulators, No Priority............................................................ 46

4.11 Zone Valve Control Heating, IWH w/TPI Control, 2 Circulator .............................................................................. 47

4.12 Zone Valve Control Heating, IWH w/Aquastat Control, 2 Circulator...................................................................... 48

4.13 Zone Valve Control Heating, IWH w/TPI Control, 1 Circulator .............................................................................. 49

4.14 Zone Valve Control Heating, IWH w/Aquastat Control, 1 Circulator...................................................................... 50

4.15 Zone Switching Relay Heating.............................................................................................................................. 51

4.16 Zone Switching Relay Heating, IWH w/TPI Control .............................................................................................. 52

4.17 Zone Switching Relay Heating, IWH w/Aquastat Control...................................................................................... 53