11

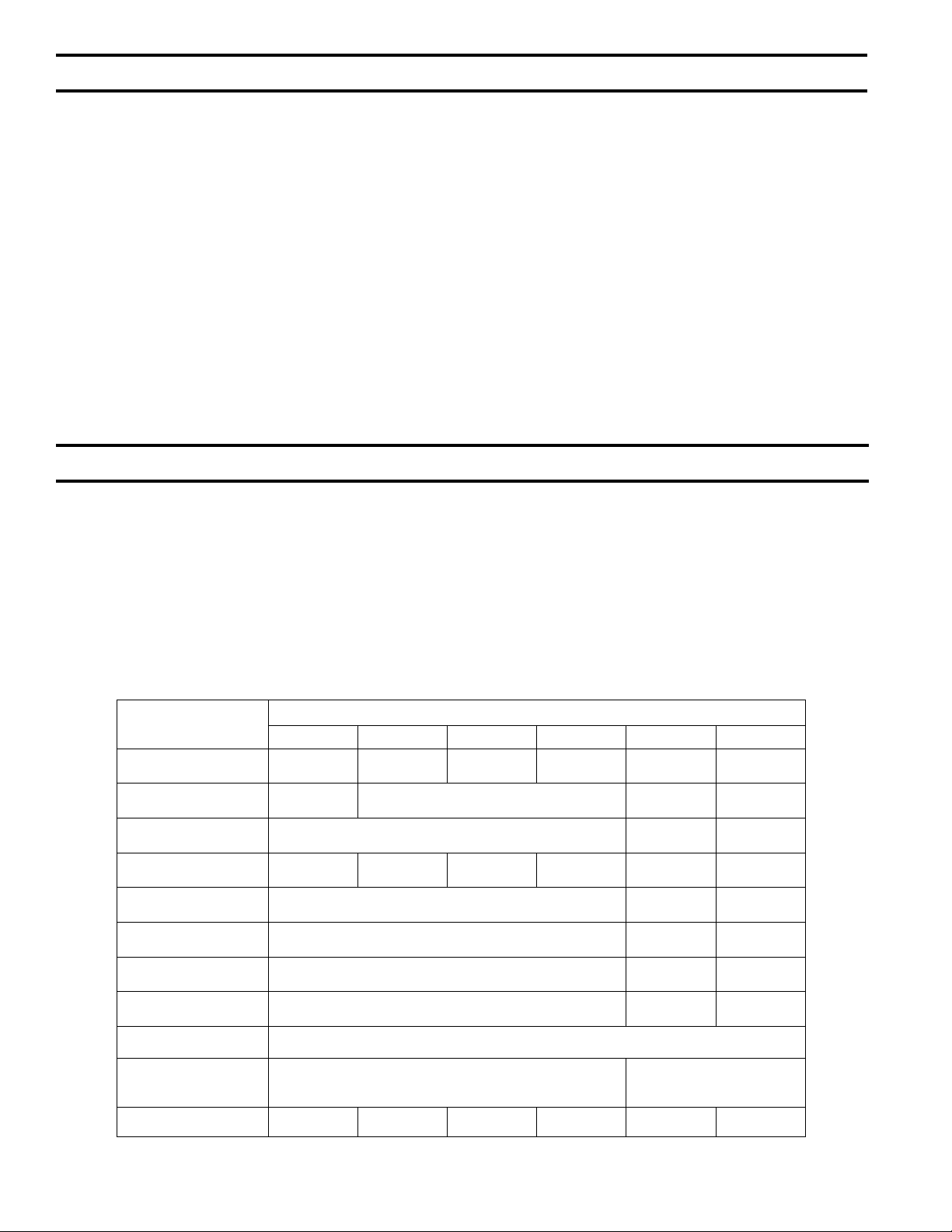

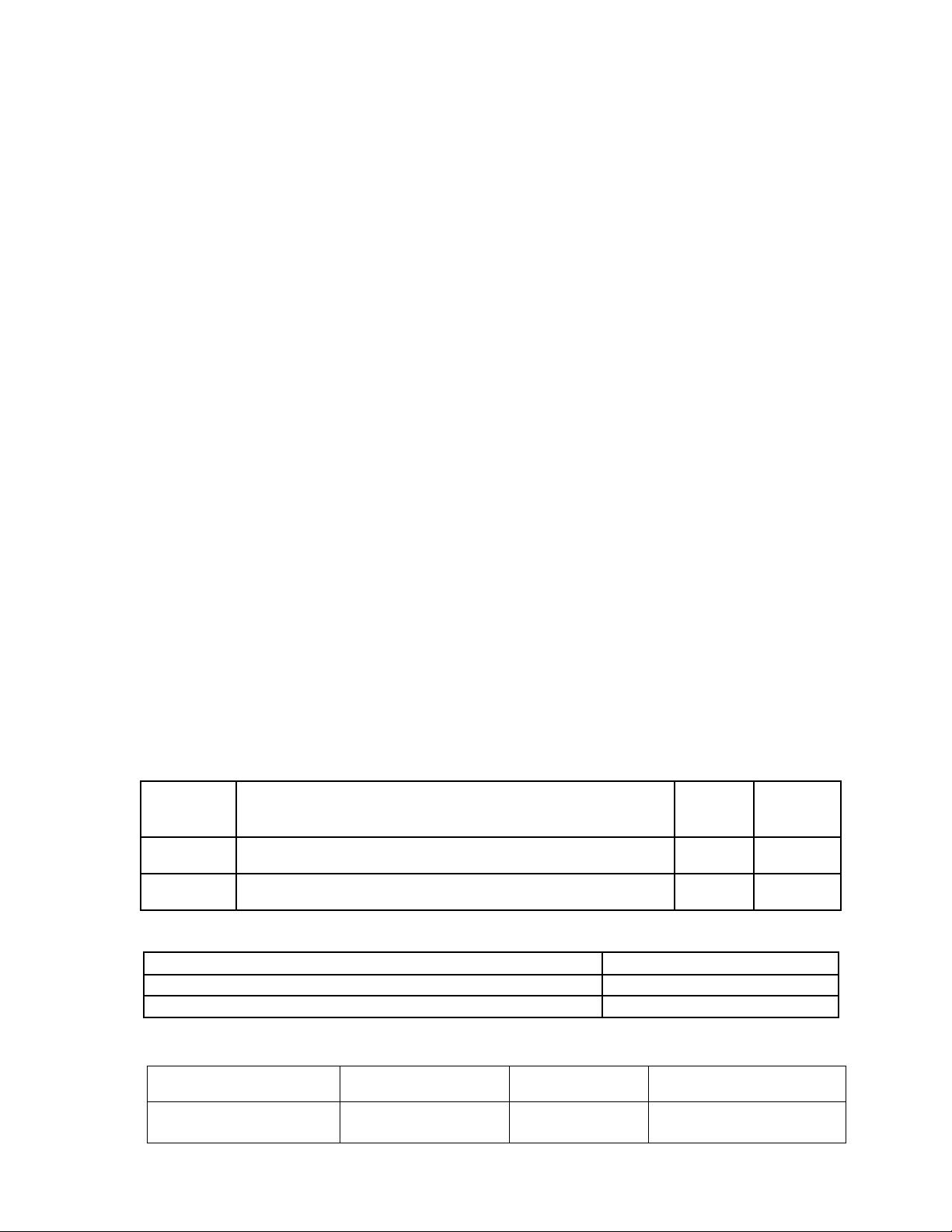

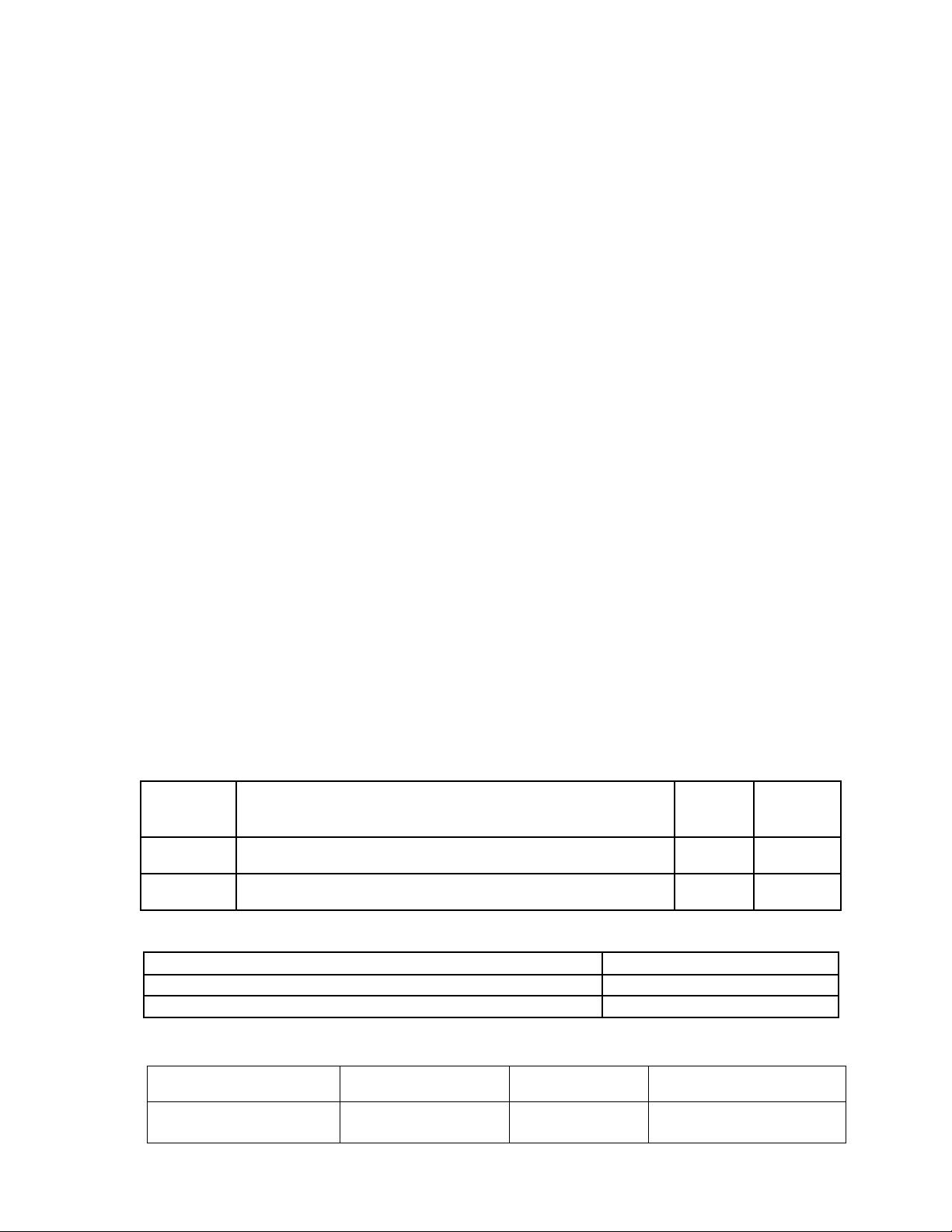

Vent Pipe Pipe Direction Enclosure Minimum Clearance To

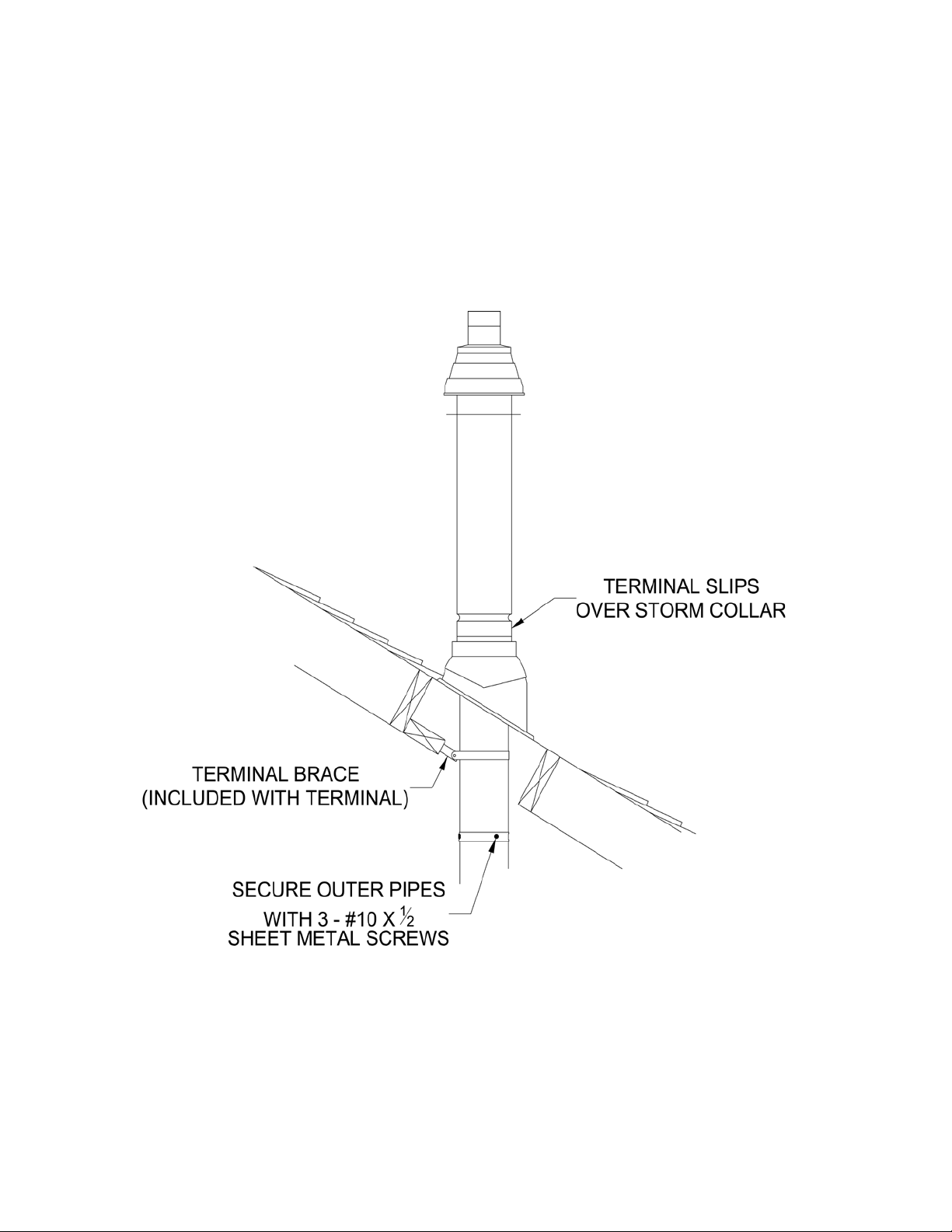

Combustible Material, Inches

Concentric Venting

80/125 mm, 100/150 mm Vertical Or Horizontal Enclosed at All Sides 0

Table 5: Clearances from Vent Piping to Combustible Material

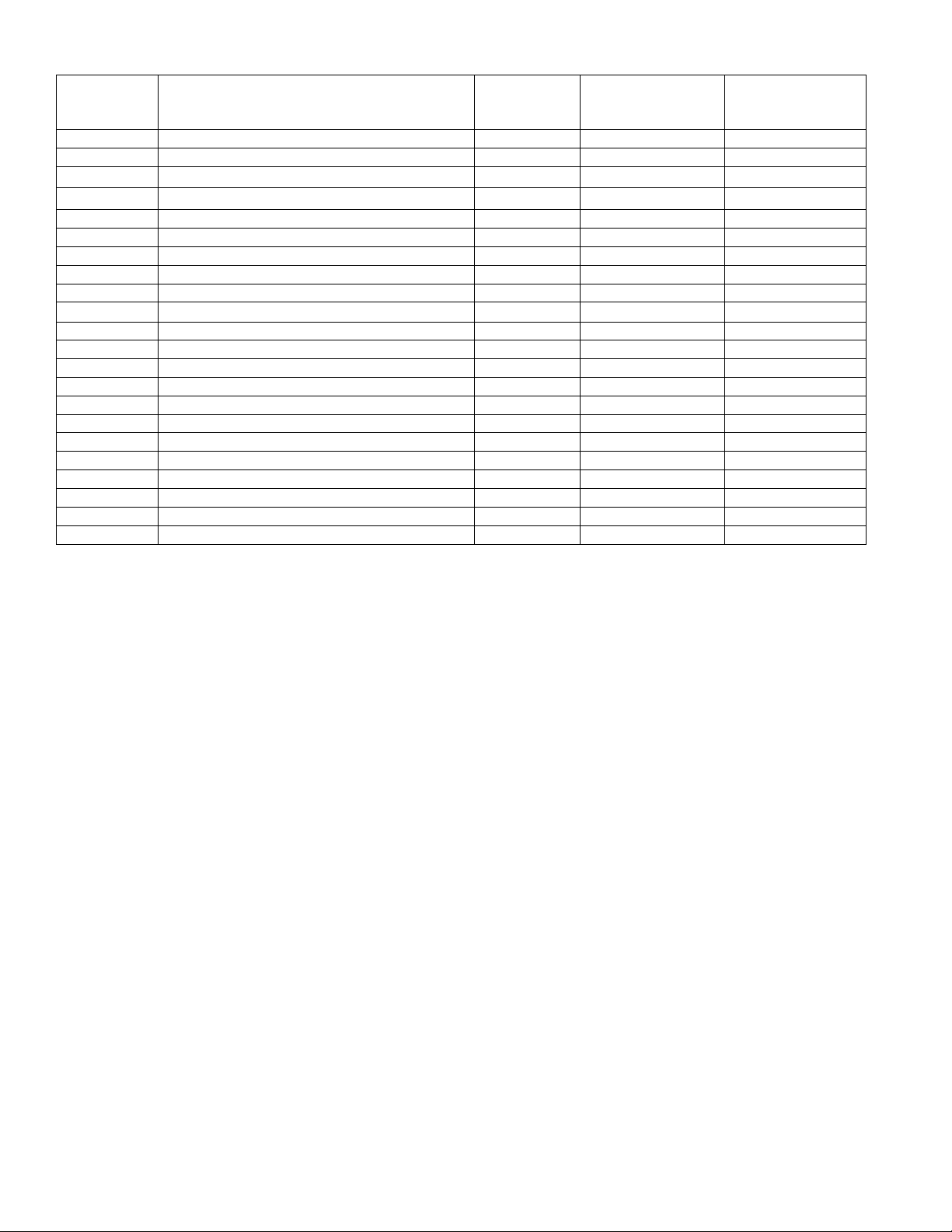

Table 3: Vent System Congurations

Table 4: Vent System Components Included with Boiler

Conguration Description Additional

Vent Kit

Required

Installation

Figure

1. Horizontal Direct Vent (sealed combustion) the concentric vent pipe terminates

horizontally (through a sidewall). No 4

2. Vertical Direct Vent (sealed combustion) the concentric vent pipe terminates vertically

(through the roof). Yes 5

Vent System Components Part Number

80/125mm Horizontal (Wall) Terminal (ALP080 thru ALP210) 101808-01

100/150mm Horizontal (Wall) Terminal (ALP285 thru ALP399) 101809-01

C. General Guidelines

1. Vent system installation must be in accordance

with National Fuel Gas Code, NFPA 54/ANSI

Z221.3 or applicable provisions of local building

codes. Contact local building or re ofcials about

restrictions and installation inspection in your area.

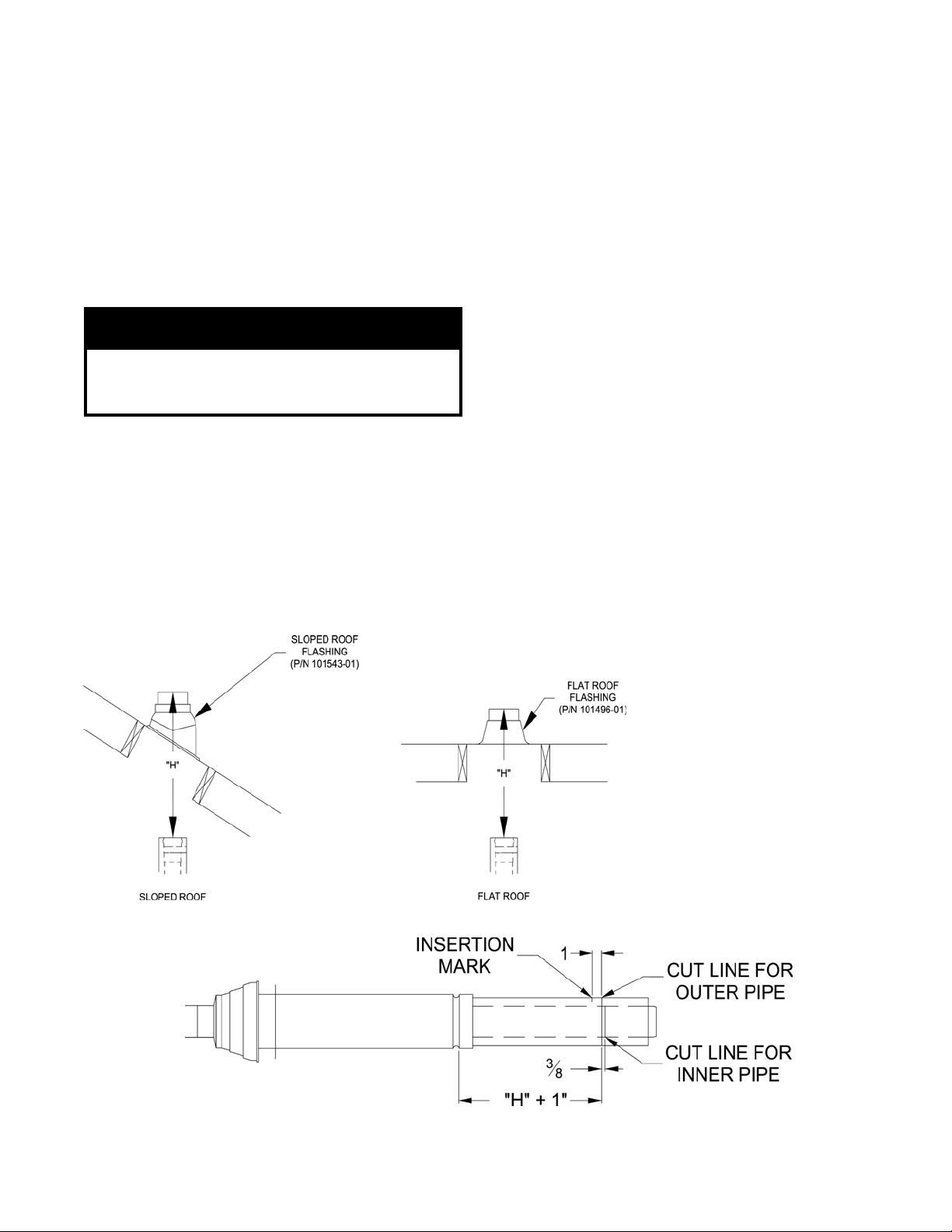

2. Refer to the appropriate drawings in this section of

this manual to determine the proper conguration of

venting system. See Table 3.

3. This appliance requires a special combination

Concentric Gas Vent / Air Inlet. Concentric vent

consists of inner re resistant polypropylene vent

pipe and outer steel pipe casing. The inner pipe

serves as conduit to expel products of combustion,

while outdoor fresh air for combustion is drawn

through the space between the inner and outer pipes.

4. Horizontal vent pipe must maintain a minimum ¼

inch per foot slope towards the boiler.

5. Use noncombustible ¾ inch pipe strap to support

horizontal runs and maintain vent location and

slope while preventing sags in pipe. Do not restrict

thermal expansion or movement of vent system.

Maximum support spacing is ve (5) feet. Do not

penetrate any part of the vent system with fasteners.

6. Vent length restrictions are based on equivalent

length of vent pipe i.e. total length of straight

pipe plus equivalent length of ttings. See Table

6 for specied vent length details. D not exceed

maximum vent length. Table 7 lists available

concentric vent components and includes equivalent

vent length for ttings. Do not include vent terminal

into total vent length calculations.

7. Provide and maintain vent pipe minimum clearances

to combustible material. See Figure 2B and Table 5

for details.

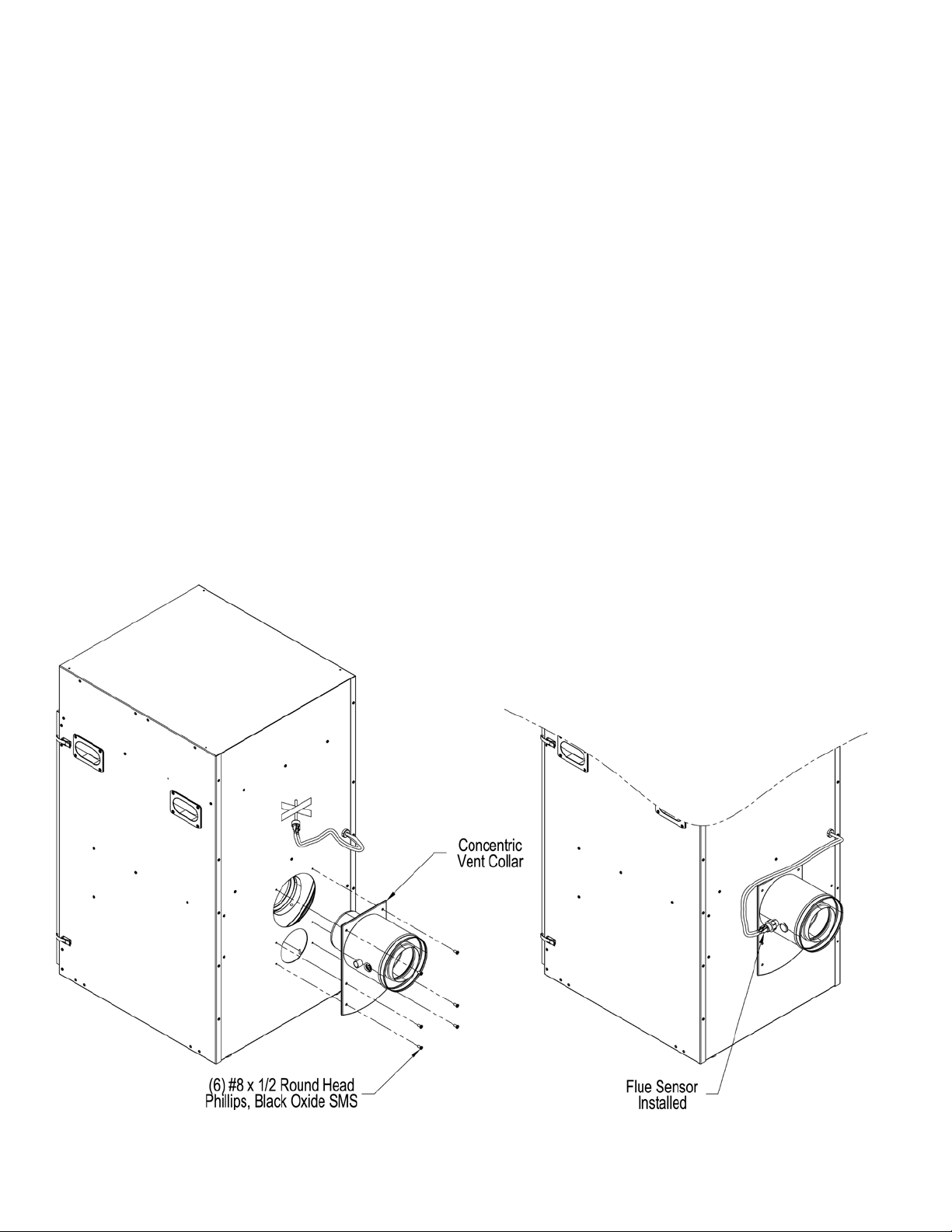

8. Provide minimum service clearance between boiler

back and concentric vent exiting through outside

wall, for concentric vent installation/replacement

and/or ue temperature sensor service/replacement,

as follows:

a. For horizontal venting where supplied

Concentric Vent Terminal is attached directly to

installed Boiler Concentric Vent Collar - 6 inches

b. For vertical venting where optional Concentric

Vent 90° long radius elbow is attached to

installed Boiler Concentric Vent Collar - 18

inches

9. Do not install venting system components on the

exterior wall of the building except as specically

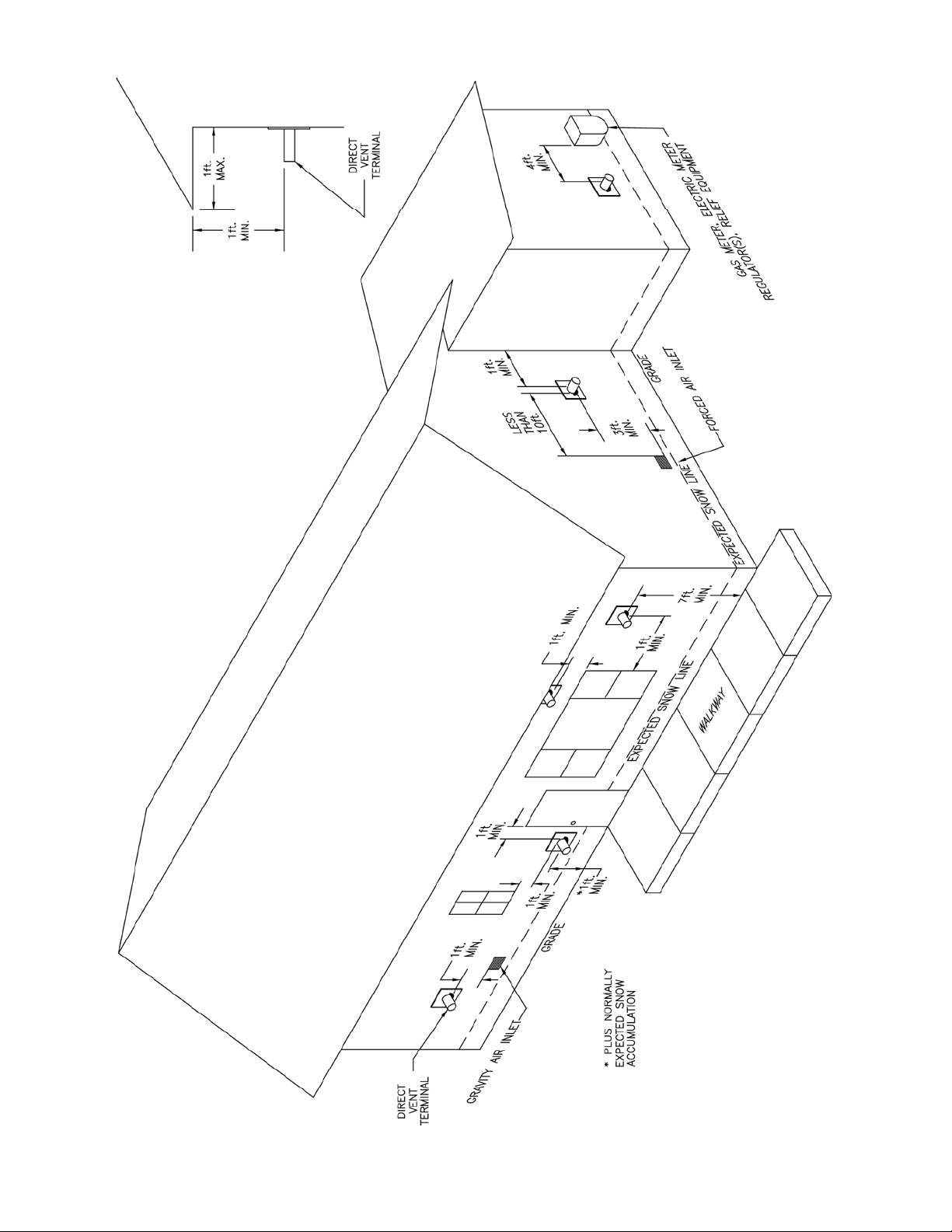

required by these instructions. Refer to Figure 3.

The direct vent termination location is restricted as

follows:

a. Minimum twelve (12) inches above grade plus

normally expected snow accumulation level, or

minimum seven (7) feet above grade, if direct

vent terminal is located adjacent to public

walkway. Do not install the terminal over public

walkway where local experience indicates that

appliance ue gas vapor or condensate creates a

nuisance or hazard.

b. Minimum three (3) feet above any forced air

inlet located within ten (10) feet.

c. Minimum four (4) feet horizontally from electric

meters, gas meters, regulators and relief valves.

This distance may be reduced if equipment is

protected from damage due to ue gas vapor or

condensation by enclosure, overhang, etc.

d. Minimum twelve (12) inches below, above or

horizontally from any air opening into a building

(window, door or gravity air inlet).

e. Minimum twelve (12) inches horizontally from a

building corner.