BONIS ST535 Instruction Manual

User Handbook

Electric Top Loading Kilns For Ceramics

- Controller ST535 -

------------------------------------

TEL: 0030 210 6220520, 0030 210 6220521

Email. [email protected]

1

Dear Customer,

Thank you for choosing a kiln made by Bonis SA.

Your kiln is especially made for firing ceramics, it is a high

performance product made by high uality raw materials, sourced

from the best known European manufacturers.

It features high uality insulation for low power consumption.

This instruction manual includes all the important information and

guidelines you will need to start using you kiln as safe and simple

as possible.

Please read the instruction manual carefully, before the first

operation and become familiar with the features and functions of

the kiln and the controller.

Our team is always available to provide more information and help

you in operating your kiln.

Your Bonis Team

2

1. KILN SPECIFICATIONS.........................................................4

2. SAFETY INSTRUCTIONS.......................................................4

2.1 Sign recognition...........................................................4

2.2 KILN PLACEMENT..........................................................5

3. CONNECTION TO POWER SUPPLY..........................................5

4. ABOUT THE KILN................................................................7

4.1 Knowing your kiln.........................................................7

4.2 Transport of kiln.........................................................10

4.3 Kiln Operation............................................................10

4.4 Maintenance...............................................................11

4.5 Insulation..................................................................11

5. USING YOUR KILN.............................................................11

5.1 Kiln shelves................................................................11

5.2 Kiln loading................................................................13

5.3 Kiln Cooling................................................................14

5.4 Kiln unloading.............................................................14

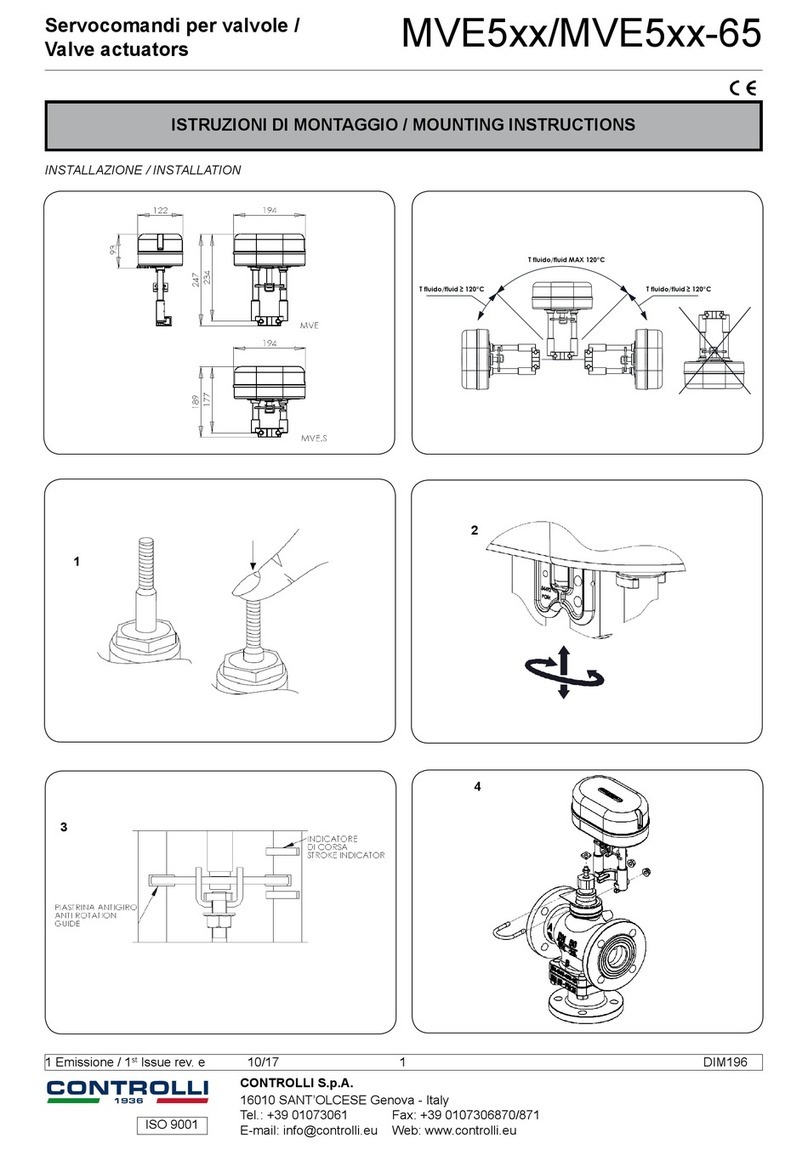

6. Controller ST 535..............................................................15

6.1 Controller ST215 Features............................................15

6.2 Controller overview.....................................................16

6.3 Turning On.................................................................16

6.4 Quick Start Guide........................................................17

6.5 Firing Program............................................................18

6.6 Program Samples........................................................19

6.6 Entering a program.....................................................19

6.7 Altering, Reviewing a program......................................22

6.8 Program Start.............................................................22

6.9 Indications during firing...............................................23

6.10 Functions during firing...............................................24

Program Pause Facility:.................................................25

6.11 Program STOP..........................................................25

6.12 Completion of firing...................................................26

6.13 Useful operations......................................................26

6.14 Error Messages.........................................................27

7. Kiln Drying – First firing.....................................................30

8. Pre installed Programs.......................................................31

9. My Programs....................................................................32

10. Notes............................................................................33

3

1. KILN SPECIFICATIONS

A label with all kiln specifications is placed on the kilns control

panel.

1. Year of manufacture

2. Type

3. Serial Number

4. Maximum temperature

5. Installed power - Kw

6. Amper (for single phase kilns)

7. Plug type / Power supply

8. Amper per phase (for three phase kilns)

2. SAFETY INSTRUCTIONS

2.1 Sign recognition

arning

HIGH VOLTAGE

arning

DANGER

arning

HOT SURFACE

arning

RISK OF FIRE

4

Declaration of Conformity

This kiln is manufactured in accordance with EC

directives

Copyright by BONIS SA

No responsibility is accepted for the correctness of this information.

We reserve the right to make technical alterations.

2.2 KILN PLACEMENT

• Do not place the kiln on a flammable table / floor

• Place the kiln on an even surface

• The distance to the walls should be at least 25 cm

• Do not place / store any flammable materials close to the kiln.

Always have a safety distance of 50cm from the kiln.

• Do not store flammable li uids / gas in the same room with

the kiln.

• Place the kiln in a well ventilated area. If this is not the case a

ventilation system has to be installed.

• Place the kiln in a place that is protected from water / rain

• Place the kiln in a room

where kids and pets have no

access.

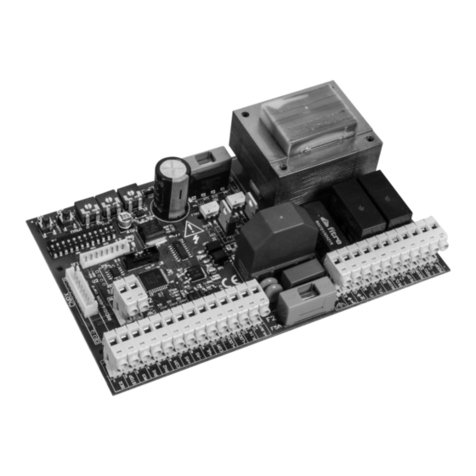

3. CONNECTION TO PO ER SUPPLY

Kiln connection to power supply must be

completed by a certified electrician.

Do not attempt to connect the kiln by your

self if you are not a certified electrician.

5

Before proceeding to connecting

the kiln please make sure that

power supply is OFF

Power supply: The phases are connected to the copper bridge of

the relays.

The copper bridges the contacts 2 / T1, 4 / T2, 6 / T3 of the relay.

Depending on the type of furnace, the two phases are connected in

red insulators, and the third phase in a copper relay truss.

Attention: The controller power cable is also connected to contact 2

/ T1.

Neutral: Attaches to the red insulator

Grounding: Attaches to the yellow screw at the base of the panel

The lower ring is electrically connected to the electrical panel

(upper ring) with an industrial type plug.

There is a terminal on the electrical panel to connect the

thermocouple. ATTENTION to the polarity of the cables

Η type kilns (1300C):

White cable connects to ( - ) contact

Red cable connects to ( + ) contact

L type kilns (1200C):

Green cable connects to ( - ) contact

Red cable connects to ( + ) contact

6

4. ABOUT THE KILN

4.1 Knowing your kiln

7

1. Exhaust air

Kiln features an exhaust air hole on the center of the lid. This hole

must be always open.

ARNING: Hot air will come through the

hole.

2. Lid safety support

Three position lid support. In the two lower positions the lid support

keeps the lid open.

The third position, is a uick cooling

position. It keeps the lid open for few

centimeters, and it helps the kiln to cool

faster.

Fast cooling can be done when the

kiln temperature is below 100C.

CAUTION:

Kiln handle may be hot

Hot air may come out from the kiln

3. Kiln stand

Kiln features a metallic stand. You must always use the kiln while it

is on the stand. DO NOT PLACE THE KILN ON FLAMMABLE FLOOR

4. Lid closure

You must always close securely the lid closure before starting a

firing. Do not use the kiln with the lid closure unsecured.

5. Bottom closures

All bottom closures must be always secured.

6. Kiln handle and bottom handles

Both kiln handles and bottom handles are to be used during

transportation of the kiln, ONLY IF the kiln is disassembled.

Do not lift the assembled kiln from kiln handles or bottom handles.

8

Please note:

In case you need to move the assembled kiln, lift it from the kiln

stand. Please ask for the kiln dis assemble manual if you need to

move the kiln.

Do not move the kiln while it is connected to

the power supply

Do not move the kiln with the lid open

7. Main Switch

Kiln power switch. When the kiln is not firing, main switch must be

to OFF position

8. Heating Element Switches

Heating element power switches. These switches must always be to

ON position

9. Heating Element Operation Lights

This indication light will light on during firing ONLY when the

heating elements are working.

During a firing this light will switch OFF and ON indicating the

heating elements operation.

10. Main Fuse 6Α

11. Controller plug

Controller is connected

to the kiln by a simple

plug and play plug.

Controller connection

can be done by the kiln

user with no danger.

Before connecting the

controller please

make sure that the

kilns main switch is

OFF

9

4.2 Transport of kiln

In case you need to move the assembled kiln, lift it from the kiln

stand.

Do not lift the assembled kiln from kiln handles or bottom handles.

Do not move the kiln while it is connected to the power supply

Do not move the kiln with the lid open

Kiln handles and bottom handles are to be used during

transportation of the kiln, ONLY IF the kiln is disassembled.

Please ask for the kiln dis assemble manual if you need to

move the kiln.

4.3 Kiln Operation

Before operating the kiln please make sure that there is nothing

flammable inside the kiln.

Please make sure there are not any cables or other flammable

materials close or in contact with the kiln.

When loading unloading the kiln the main switch must be OFF.

Do not place in the kiln any material with unknown reaction to

firing.

Do not move the kiln while in operation

Do not open the kilns while in operation

Always open the kiln after cooling down to 50C

Do not place flammable objects in the kiln.

Note At high firing temperatures a slit may become visible

along the edge of the lid. This is normal and does not

compromise the kiln's function or safety.

This kiln is EXCLUSIVELY for firing ceramics ONLY.

Any other use is prohibited.

In case of malfunction please switch OFF the main switch,

and cut off the power to the kiln

DO NOT ATTEMPT TO FIX ANY PROBLEM BY YOURSELF.

PLEASE CONTACT OUR TECHNICIANS, OR A LOCAL CERTIFIED

ELECTRICIAN.

10

4.4 Maintenance

Before proceeding to any maintenance or

service operation Kiln main switch must be

OFF, kiln must be unplugged or safety switch

must be OFF

1. Kiln chamber must be kept clean, and any broken ceramic pieces

must be taken out carefully. You can use a vacuum cleaner to clean

the chamber.

2. Use a vacuum to clean kilns lid (inside) from time to time.

3. Before starting a firing inspect all cables for any kind of damage.

In case of damage, do not use the kiln before replacing the

damaged cables.

4. Inspect thermocouple connections and cables that are properly

placed and free from any kind of lesions.

5. Heating elements must be kept clean, and any piece from

broken ceramic, glaze etc, must be taken out before using the kiln.

You can use a vacuum cleaner to remove particles from the heating

elements. Please not that when cold, heating elements are

extremely brittle

4.5 Insulation

The kiln insulation is made from high-grade fireproof material. Due

to thermal expansion, cracks in the insulation will occur after a few

heating cycles. These have no influence on the function, safety or

uality of the kiln.

The refractory bricks (insulation) are of a particularly high uality.

Due to the manufacturing process small holes or cavities may

occur. These are uite normal and underline the uality features of

the bricks.

5. USING YOUR KILN

Before using your new kiln please make sure you fully read

and understand the complete kiln operation manual

5.1 Kiln shelves

Kiln shelves are available as whole, or half (depending on your kiln

size whole shelves may not be available)

Placing two half plates will make one whole shelf, or you can load

half of the kiln with plates as shown in the below image

11

Kiln shelves must be smaller from the kiln interior diameter, as you

need a gap between the shelf and kiln wall, for your hand to fit in,

and for the hot air to circulate evenly.

Supporting kiln shelves

We advise you to support whole kiln shelves in 3 points.

Always position the stilts one above the other for each layer, to

avoid kiln shelf deformation or cracking.

Please Note:

You must always leave a gap

between kiln floor and the first kiln

shelf.

You must place small stilts, or

pieces of broken kiln shelves on

the bottom of the kiln, and you

first kiln shelf will be placed on top

of these stilts.

12

5.2 Kiln loading

During loading / unloading of the

kiln, the main switch must be OFF,

the kiln must be unplugged from

power, or the power switch must be

also to OFF position

Make sure the lid is well supported

before loading / unloading the kiln.

To enhance even temperature distribution we strongly suggest to

load your kiln evenly.

Please Note:

In top load kilns it is recommended

not to place low height ceramics on

the bottom shelf.

We strongly recommend to place

medium height ceramics on the

bottom shelf (approximately 5cm or

more)

If you place low height ceramics on

the bottom shelf you must use stilts

of bigger height to have the re uired

gap for firing properly your ceramics.

13

5.3 Kiln Cooling

Your new kiln features a multilayer insulation, which ensures

minimum heating loss, and very slow cooling.

To cool the kiln faster you can use the

uick cooling position of the kilns lid

support.

This position keeps the lid open for few

centimeters, and it helps the kiln to cool

faster.

Fast cooling can be done when the

kiln temperature is below 100C.

CAUTION:

Kiln handle may be hot

Hot air may come out from the kiln

5.4 Kiln unloading

During loading / unloading of the

kiln, the main switch must be OFF,

the kiln must be unplugged from

power, or the power switch must be

also to OFF position

Make sure the lid is well supported

before loading / unloading the kiln.

CAUTION: Ceramics may still be hot during unloading

14

6. Controller ST 535

6.1 Controller ST215 Features

· Multiple zone control (2 or 3)

· 32 programs each with 32 segments

· 1 controlled heating / cooling ramp + soak per segment

· Soak times up to 99 hours 59 mins

· Ramp rates from 1 to 999°/hour + FULL

· Ideal for glass or ceramics use

· Programs can be altered while firing

· Program pause and advance facilities

· Keyboard lockable

· Delayed start facility - up to 99 hours 59 mins

· Power failure recovery

· Energy used display

· Setpoint display

· Alarm buzzer & alarm output

· °C/°F operation

15

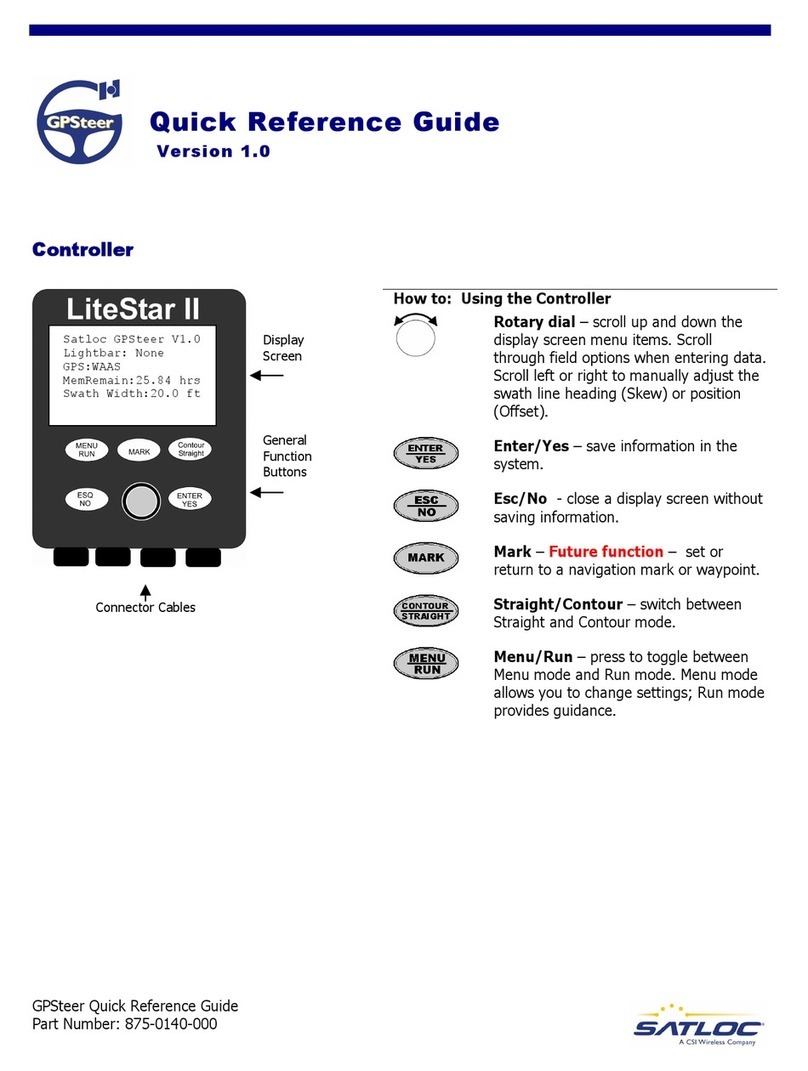

6.2 Controller overview

6.3 Turning On

When turned on the ST535 performs a

display test by lighting all of the display

segments and illuminating all of the front

panel indicator lamps.

16

The version number of the software

embedded within the ST535 is now

displayed. If you need technical support

you might be asked for this code together

with the serial number.

Next displayed is the thermocouple type

setting.This should match the type of

thermocouple fitted to the kiln and can be S

for 1300C, or K for 1200C

The final display will show the kiln

temperature.

All other lamps should be off.

Next to the main display, zone indication will light (1, indicates the

temperature of the lower zone, 2 of the middle zone and 3 of the

upper zone)

All other indications must be OFF

If any other indications are ON, press START/STOP ▶

6.4 Quick Start Guide

Press button ▶(arrow to the right)

Main display will show a program

number

Use buttons ▲ or ▼ until display shows the desired program

number

Press START/STOP ▶

Main display will show the program

start delay time (00.00) After 10

seconds program will start

automatically

17

6.5 Firing Program

Controller ST535 can store up to 32 programs.

Each program can have up to 32 segments.

A firing segment comprises of a ramp rate (degrees per hour), the

final segment temperature, and a soak period.

Two segments can be used for simple firing (biscuit firing for

example) or several segments can be used per program for

complex firing (crystal glazing or glass-making for example).

The ST535 ramps the kiln temperature at the re uired ramp rate

until the kiln reaches the soak / target temperature It then soaks

(dwells) at the soak temperature for the soak time. It then runs the

next segment until the end of the program is reached.

The ST535 is capable of both positive (heating) ramps and negative

(cooling) ramps - as used in glassmaking for annealing. The type of

ramp is clearly shown on the mimic display during firing.

The ramp rate is settable in the range 1°C/hour to 999°C/hour or

FULL (full power is for uncontrolled, fast heating. To enter full

power you must increase heat rate to 1000°C/hour. Display will

then show FULL).

Entering “0” as ramp rate will show “End” (end of program).

The soak / target temperature is settable over the range 0 to 1200

or 1300°C (depends on kiln model).

The soak time is settable over the range 00.00 (no soak) to 99

hours 59 mins.

Note: during soaking the ST535 display alternates every 5

seconds between kiln temperature and soak time remaining.

18

6.6 Program Samples

The below table shows three different programs:

NORMAL rate– The basic program, suitable for most ceramics

SLO rate – Suitable for thick and large ceramics

FAST / GLAZE – Suitable for small thin ceramics, as well as for

Glaze firings

<

HEATING RATE C/h SEGMENT

FINAL

TEMPERATURE

SOAK

SEG NORMAL SLO FAST

GLAZE hh.mm

1 60 40 80 250 00.00

2 100 80 120 540 00.00

3 80 60 100 600 00.00

4 150 120 150 *MAXIMUM

TEMPERATURE 00.00**

5 END

*Set the desired maximum temperature, according to your clay

needs

** Usual soak time:

- Bis ue 10 minutes (00.10)

- Glaze 20 to 30 minutes (00.20 – 00.30)

You can use this program template, and only change the

maximum temperature and soak time at segment 4.

6.6 Entering a program

When not firing there are no indicators

lit on the mimic panel, the run indicator

is off and the display shows the current

kiln temperature.

The controller settings can be reviewed by pressing the ► key.

19

The first push of the ► key flashes the

program number display.

The re uired firing program can now be selected with the ▲ & ▼

keys.

Note: holding down the ▲ or ▼ keys causes rapid change

of the displayed value

When the desired program number is displayed push ► to enter

program values.

Small, segment display will show

number “1” which indicates the first

segment of the selected program.

Main display shows the ramp rate in the

range End , 1-999°C/HR or FULL.

This can be altered with the ▲ & ▼

keys.

The heating ramp ( ◥ ) or the cooling

ramp (◢ ) indicator on the mimic panel

will flash.

If End is shown but another segment is re uired then push the ▲

key to obtain the re uired ramp rate (in the range 1°C/hr to

999°C/hr).

If FULL is shown but another segment is re uired then push the ▼

key to obtain the re uired ramp rate (in the range 1°C/hr to

999°C/hr).

When the desired rate is set press button ►

20

Other manuals for ST535

1

Table of contents

Popular Controllers manuals by other brands

Toshiba

Toshiba BMS-IFBN1281U-UL instruction manual

National Instruments

National Instruments PXI-8109 installation guide

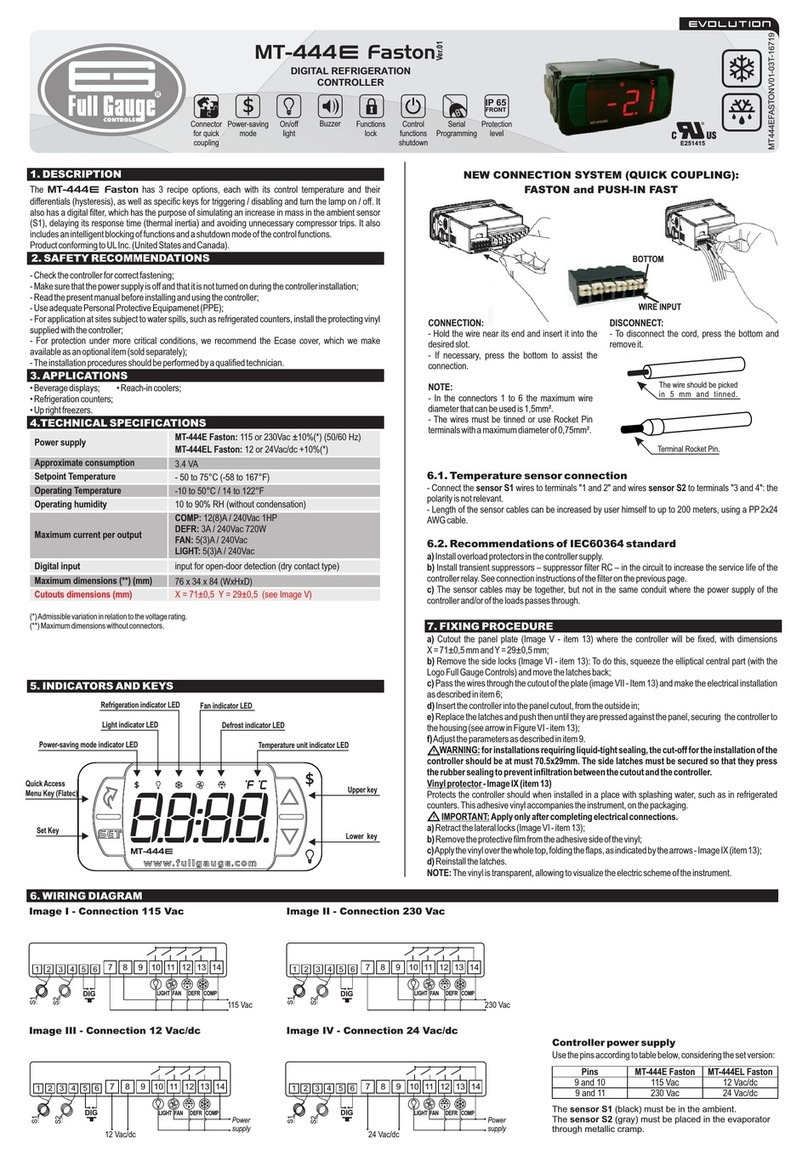

Full Gauge

Full Gauge Faston MT-444e instructions

Delta Controls

Delta Controls DLC-G1212 Installation & Application Guide

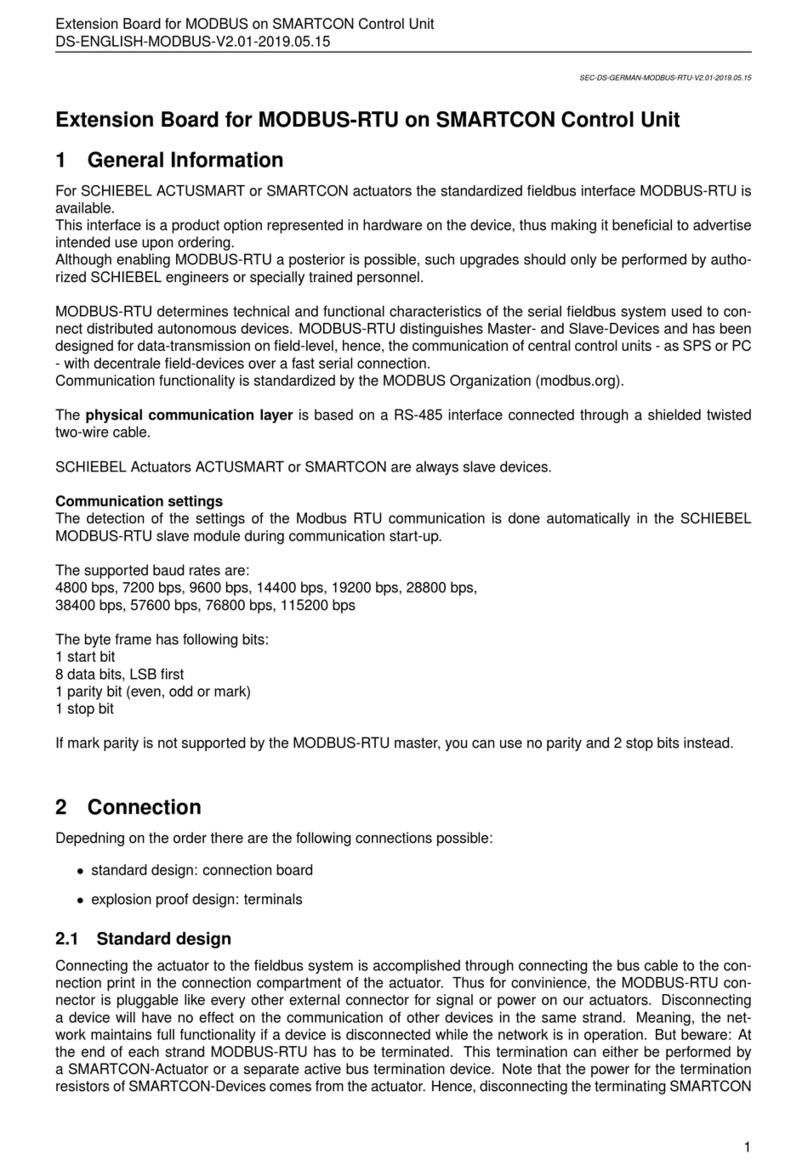

SCHIEBEL

SCHIEBEL ACTUSMART manual

UNI Geräte

UNI Geräte EVF Series manual