User Manual n°648261 – Page 4

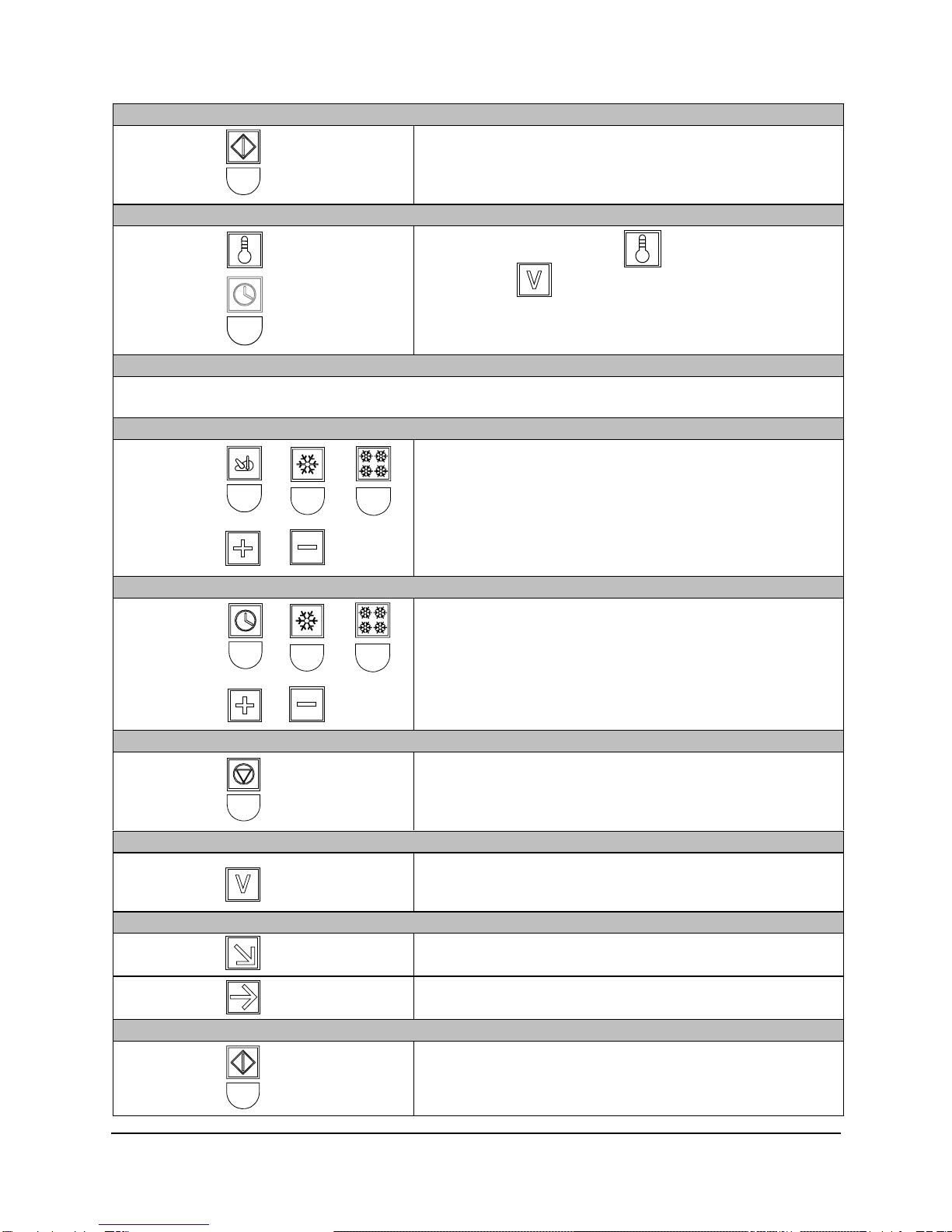

1.3 GENERAL RECOMMENDATIONS

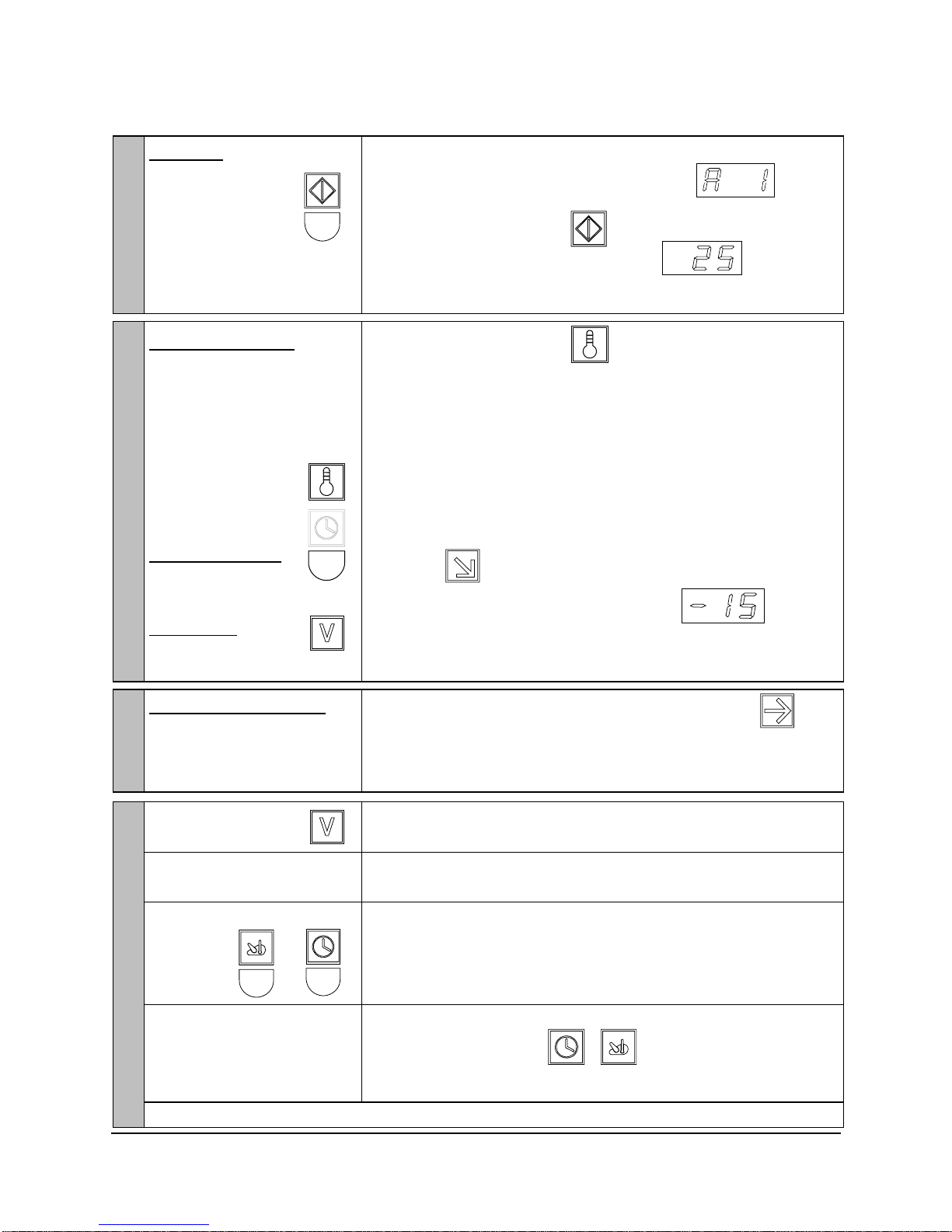

1.3.1 DEFROST, PREFUNCTION CYCLE

Before loading products, a prefunction cycle should be launched in order to cool the

interior of the appliance. It can be launched automatically when the appliance is powered up,

by modifying the factory settings (see ‘instructions’).

Each prefunction cycle is automatically preceded by a defrost cycle. If needed, this

function can be stopped (see paragraph 1.6 ‘special settings’)

During the defrost and/or the prefunction cycle, the display indicates the ambient

temperature of the appliance. Defrost is made with a weak ventilation (except for MI3). It can

be made with a strong ventilation by modifying the factory settings (see ‘instructions’).

After loading products into the appliance, choosing the chilling cycle at the closing of the

door can be made compulsory by modifying the factory parameters (see ‘instructions’)

1.3.2 CYCLE WITH CORE PROBE

It is recommended to use the core probe whenever it is possible because it

automatically controls the cycle. The 5 points core probe allows to read the hotest point at the

heart of the product. The cycle ends when the hotest sensor reaches the required

temperature (factory settings : +10°C in chilling mode and –18°C in freezing mode, which can

be modified case by case). The display alternately indicates the temperature at the heart of

the product and the remaining duration of the cycle.

With the factory settings, a core probe insertion test indicates that the probe is not used

for a hot product (sound alarm and the indication ‘SP’ is displayed)

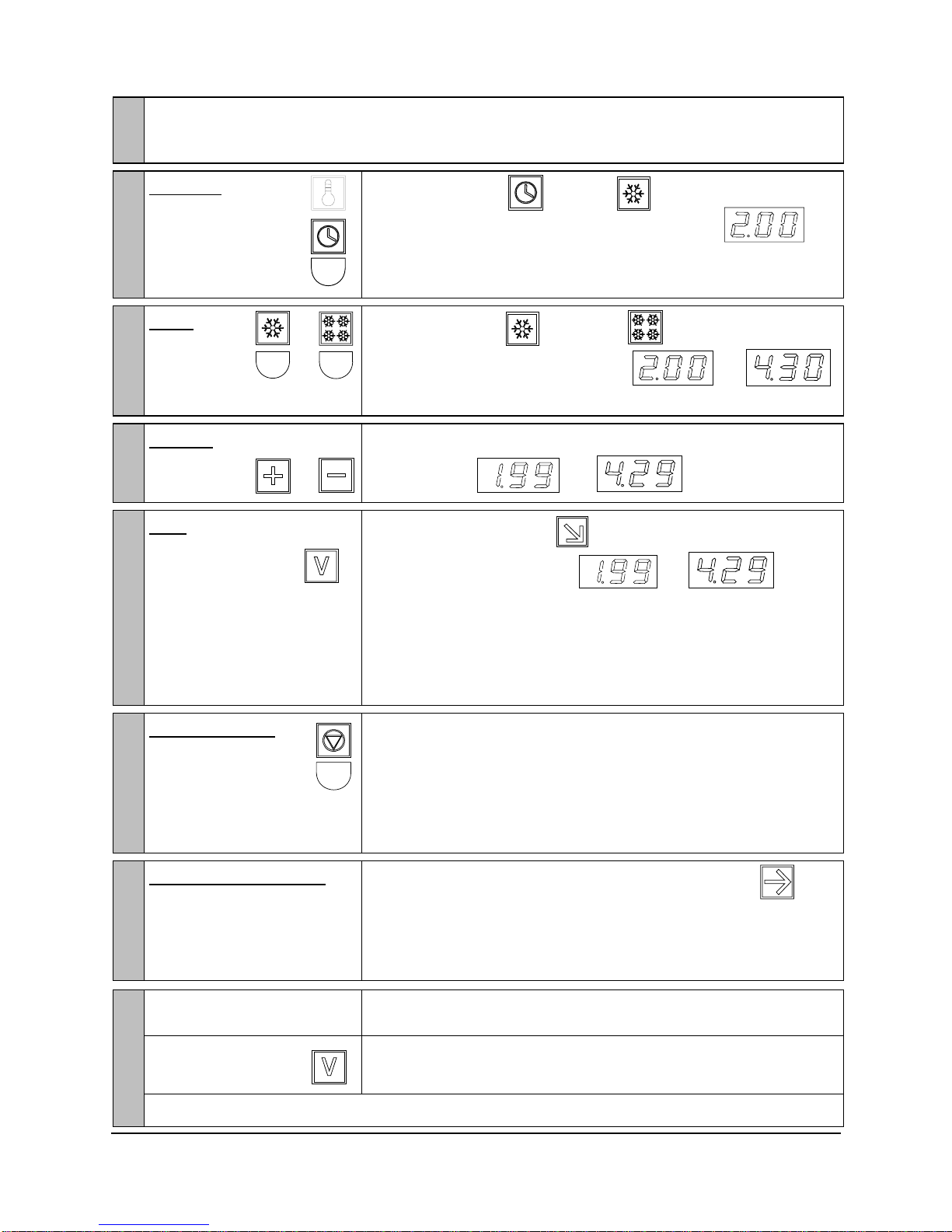

1.3.3 CYCLE WITH TIMER

When the use of the core probe is impossible, a cycle with timer is possible (factory

settings : 2 hours in chilling mode and 4h30 in freezing mode. This can be modified case by

case). The cycle programming time depends on the type and the quantity of food to be

cooled. During the cycle the display indicates the remaining duration.

1.3.4 VENTILATION (except for MI3)

To avoid water spattering on the products, the ventilation power is automatically

controlled by the temperature of the appliance, with a factory level pre set at 12°C.

1.3.5 "FRAGILE PRODUCTS" FUNCTION

In some cases, in blast chilling cycle, it is possible to refrigerate the products avoiding

frost deposit (anti-freezing function). This function should only be used for reduced quantities

of products. After selecting the chilling cycle with core probe or with timer, press "Fragile

Products" key. In this case, the cycle will operate following the factory settings, with an air

temperature superior to -15°C with a strong ventilation. This can be modified case by case

whenever it is needed, for example, a weak ventilation can be applied for light products

(except for MI3) (see paragraph 1.6 ‘Special settings’)

1.3.6 PRESERVATION AFTER THE CYCLE

At the end of each cycle, the appliance programs automatically the preservation to a

temperature of +3°C for a chilling cycle with a weak ventilation (except for MI3), or to a

temperature of –18°C for a freezing cycle. The display indicates the ambient temperature.

The storage duration inside the appliance can be unlimited thanks to an automatic control of

the defrost during the preservation cycle.