n° 6BE648285NI-0606 – Page 4

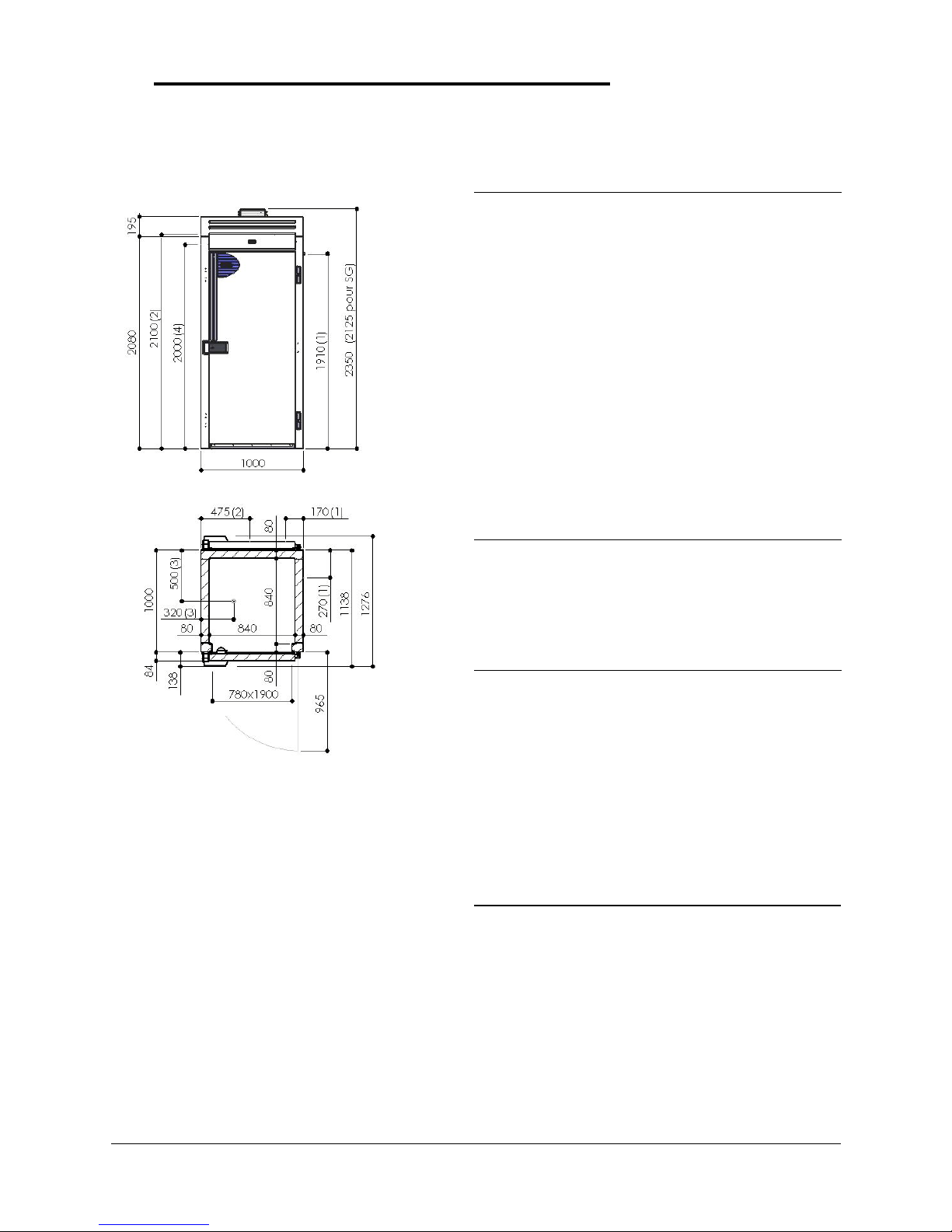

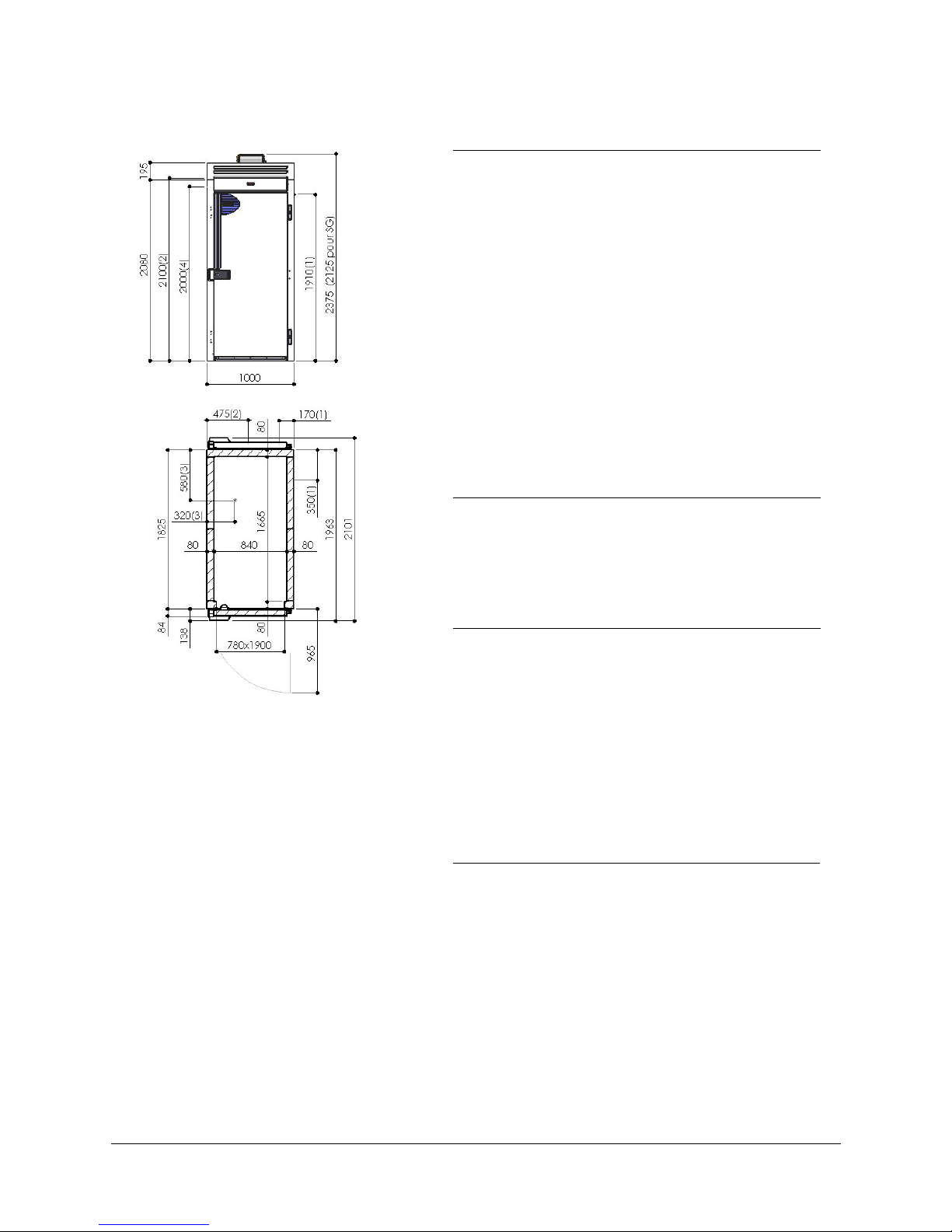

1.3 Model 3x1C

S200B31 : Model 3x1C Stainless 1D to RHS

S201B31 : Model 3x1C Stainless 1D to LHS

S202B31 : Model 3x1C Stainless 1D central

S210B31 : Model 3x1C White 1D to RHS

S211B31 : Model 3x1C White 1D to LHS

S212B31 : Model 3x1C White 1D central

Roll in model shown with 1 door to the right and clearance

for a rear door (roll through).

(1) Defrost water drain (PVC pipe ∅20)

(2) Electrical connection (supply cable 3m long)

(3) Refrigeration connection (SG version)

(4) Height under evaporator housing 1900mm

Note :

- With a glass door operating at +3°C, the temperature

and humidity conditions required for operation without

condensation are +25°C and 65% RH or equivalent

LOCATION

The cabinet must be installed on a flat, smooth and

perfectly horizontal surface. A bead of silicone mastic is

required around the perimeter.

CONSTRUCTION

- Internal and external panels in austenitic stainless or

white plastic coated steel (except the external roof in

corrosion proof galvanised sheet).

- Slatted louvered compressor cover (not supplied with

models without compressor).

Insulated body

- Demountable panels assembled by a system of hooks.

- Expanded polyurethane foam insulation. 80mm thick

- Thermal break between cavity and outer structure.

- Floor fixing strips in austenitic stainless steel.

- Radiused stainless base (optional).

Door

- Removable magnetic door seal with base blade

- 2 rising hinges with stay open position and self closure,

avoids wear on the door base seal.

- Closure by central lockable handle and catch with

internal push button safety release.

- Door opening can be handed (if undertaken on site

new lexan signage will be required)

ELECTRICAL CHARACTERISTICS

Voltage : 1~230V 50Hz+E

Max power : 1250W

Protection : aM 6

Unit supplied with a cable and plug

The installer is responsible for electrical protection of the

supply circuit

REFRIGERATION CHARACTERISTICS

Refrig power : 1200 W at -15/+55°C

Refrigerant : R404A

Charge : See units data plate

Compressor : Hermetic

Condenser : air cooled

Evaporator : Double flux ventilation, anti-corrosion

treated

Expansion : Capillary (model without compressor

supplied with T.E.V.)

Defrost water : Two drain points (1) are provided at the

rear or the right hand side (connection

and traps to be provided by the installer).

Conforms to norms :

Electrical safety : EN 60 335-1

Food hygiene : XP U 60 010

Conforms to European directives for : CE