10

2005 Boreal Geothermal Inc. www.boreal-geothermal.com

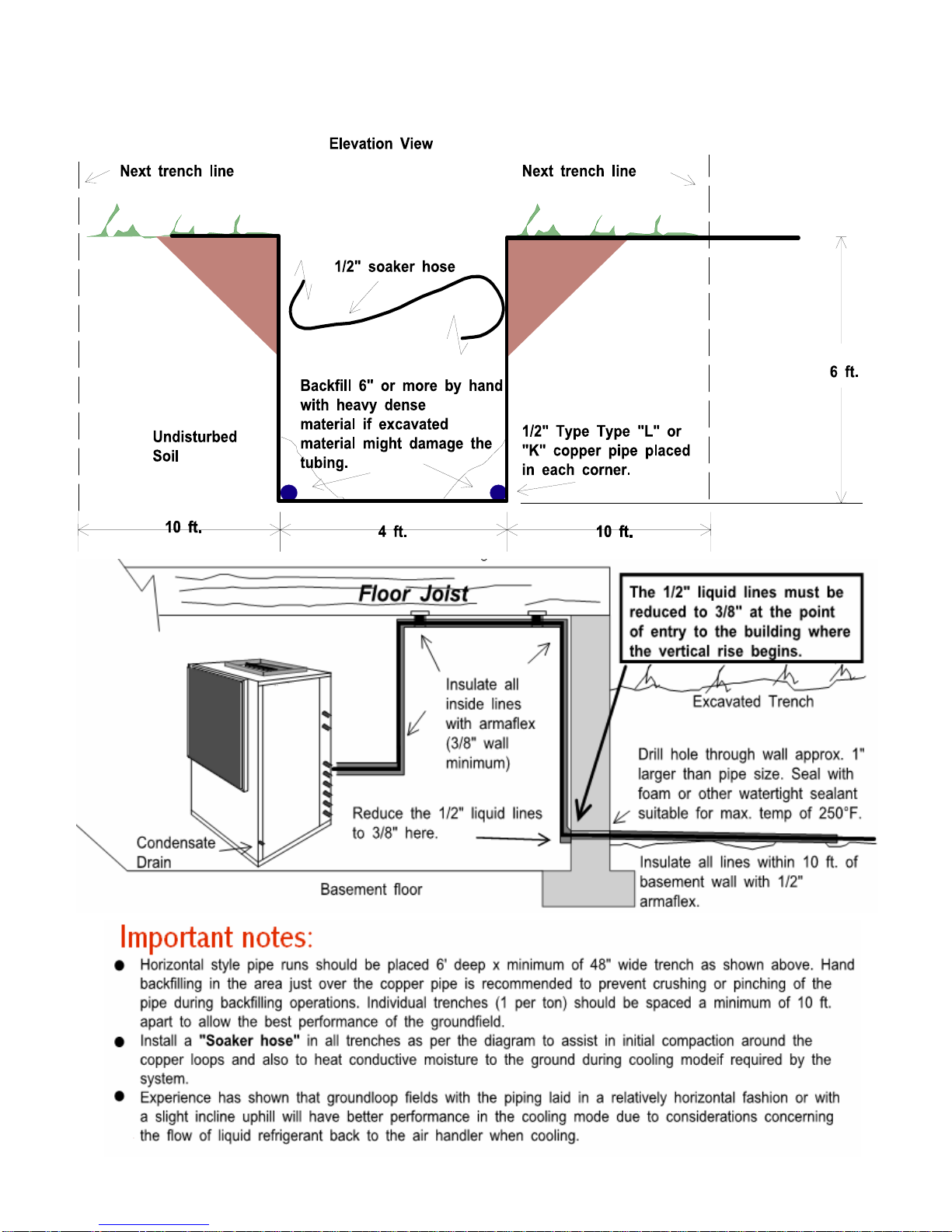

Horizontal Trench Requirements

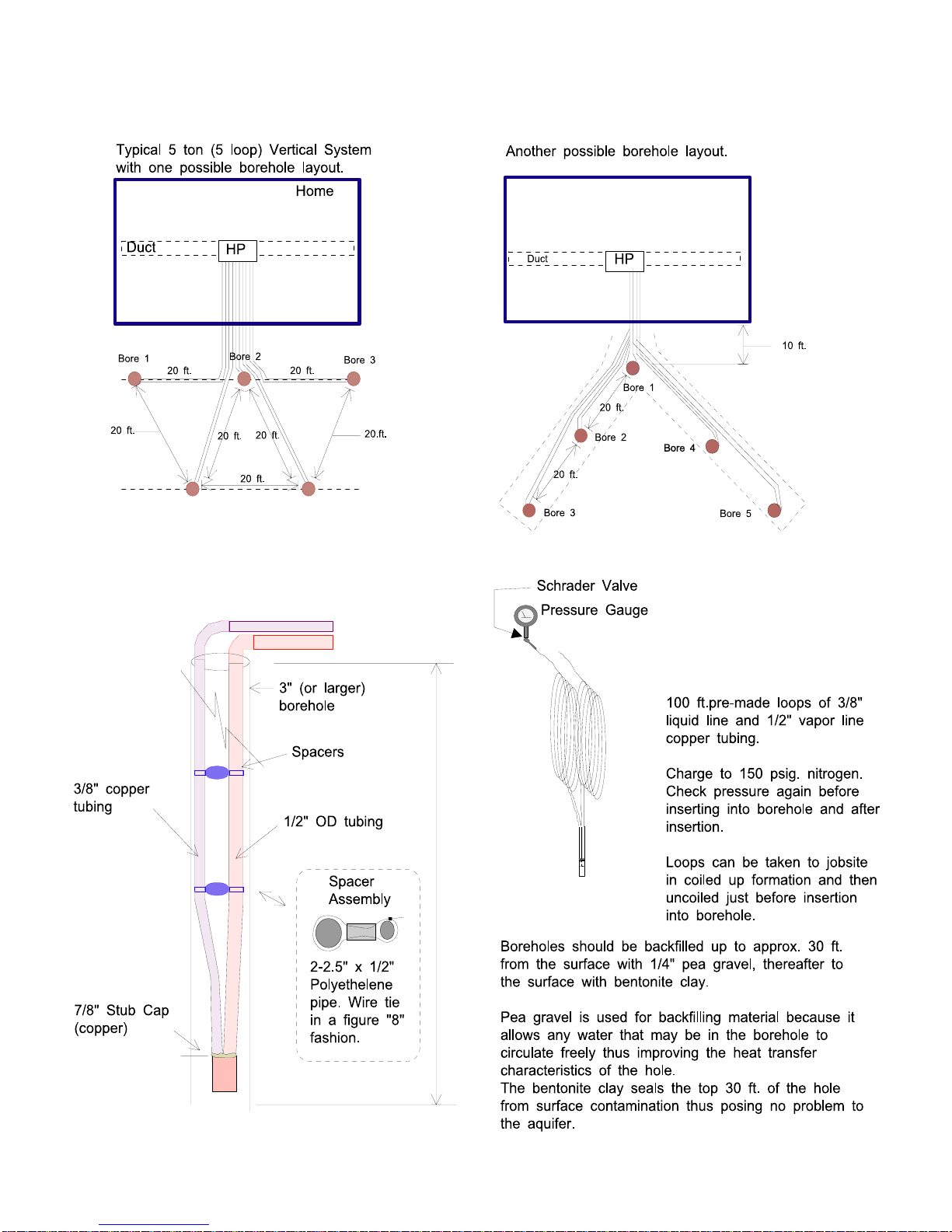

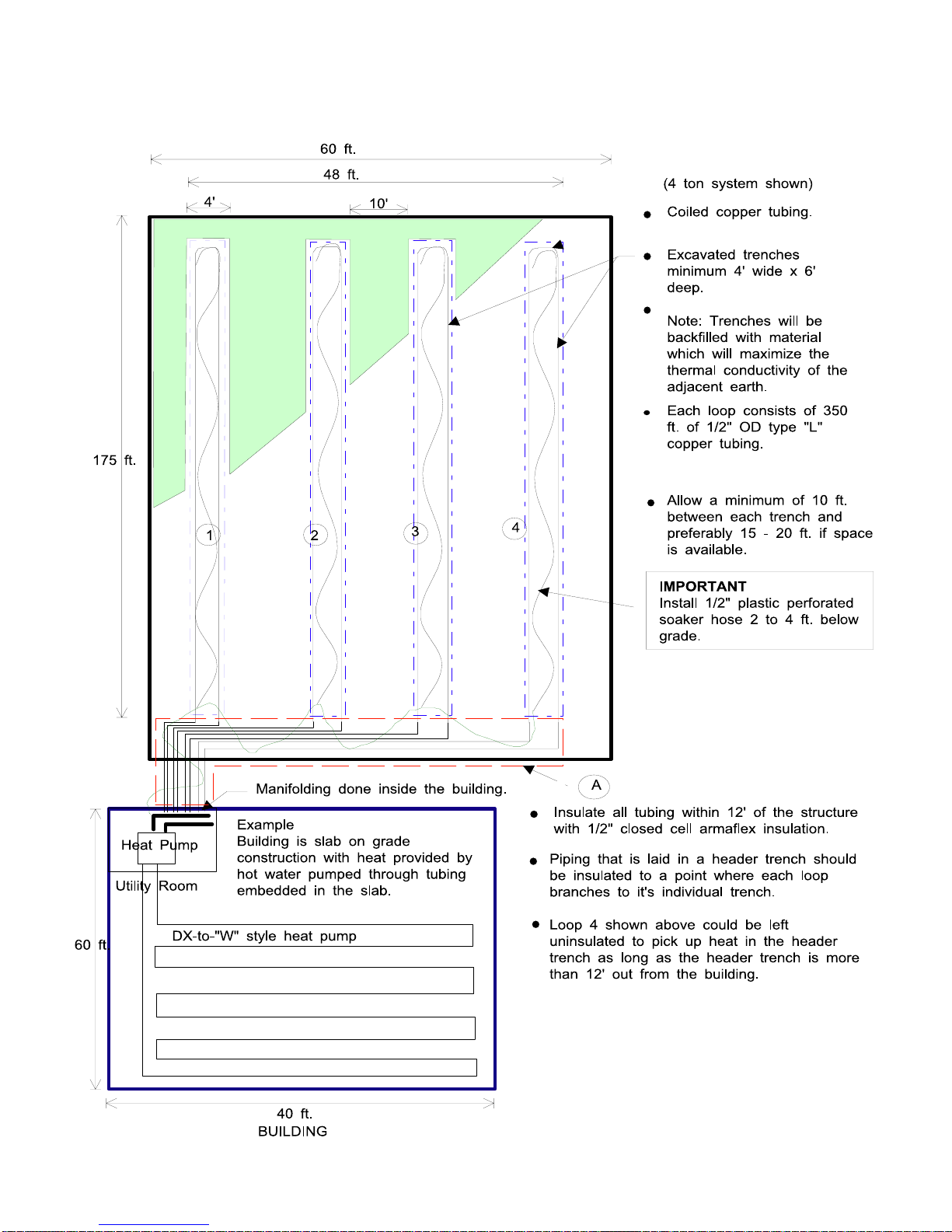

The ACDX heat pump requires one groundcoil or "loop"

per nominal ton of capacity.

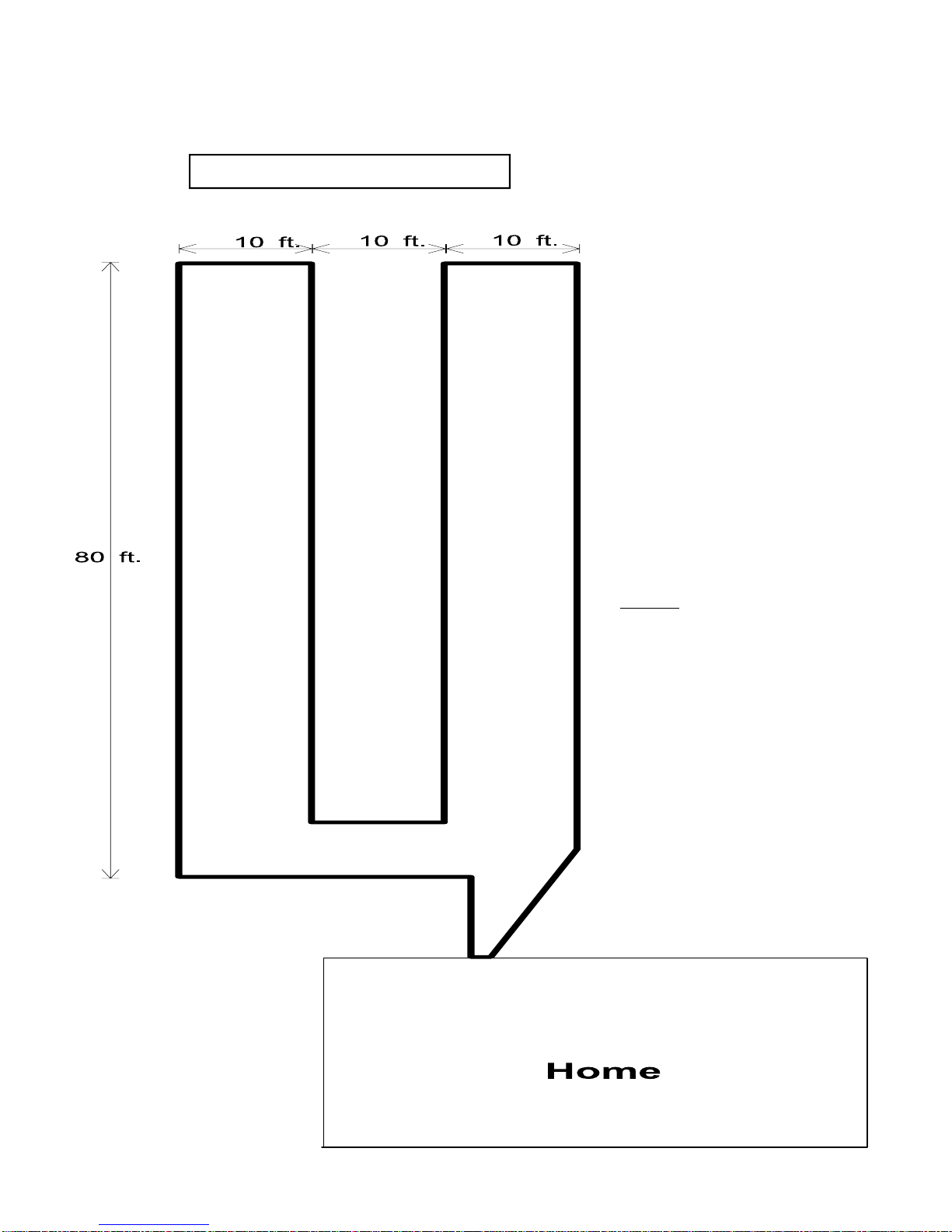

Trenching for the ACDX heat pump can be best accom-

plished with a tracked excavator equipped with a 44” to 48”

bucket. If a wider bucket is available and you can afford the

extra cost, the trenches could be wider for improved perform-

ance. The object, of course, is to allow the copper loops to

contact earth which has not been influenced by the prox-

imity of another loop. The trenches are dug from 5 to 6 ft.

deep to a total length of 180'. Each of the ACDX loops is

350' long and when laid in the form of a U down each side of

the trench the turn at the end will occur at 175' allowing for a

small degree of error by the excavator operator. Take special

care that the bottom of the trench is kept as smooth as possi-

ble to reduce the chance of pinching or crushing the copper

tubing when backfilling the trench. If rocky conditions are

encountered it is recommended that the bottom of the trench,

especially the corners where the pipe will lay, be covered by

hand with limestone tailings, or some other heavy dense ma-

terial t provide a relatively smooth resting place for the cop-

per pipe. Unlike plastic pipe, the copper tubing will stay

where you put it when unrolled rather than arguing with you,

as plastic does, on a cool day. Once the pipe has been un-

rolled and placed, backfilling by hand to a depth of 4-6" with

fill as described above will ensure that the pipe is protected

from falling rock etc. during the machine backfilling proce-

dure.

Other excavating devices such as a ditch-witch (chain

digger) or a regular back-hoe can be used if ground conditions

permit however you will have to dig a U shaped trench with

spacing 5 ft. to 10 ft.. We have found that the greater speed

of the tracked excavator in most soil conditions and the fact

that you only have to dig one trench (which is excellent width

for a man to work in) more than compensates for it's extra

rental or operational costs.

An alternative technique for burying the underground cop-

per tubing would be to dig a large shallow pit with a bull-

dozer. This pit would have to be large enough to accommo-

date all the loops required in the system. The copper tubes

should have a spacing of at least 6 ft. minimum. A wider

spacing would lead to slightly greater efficiency.

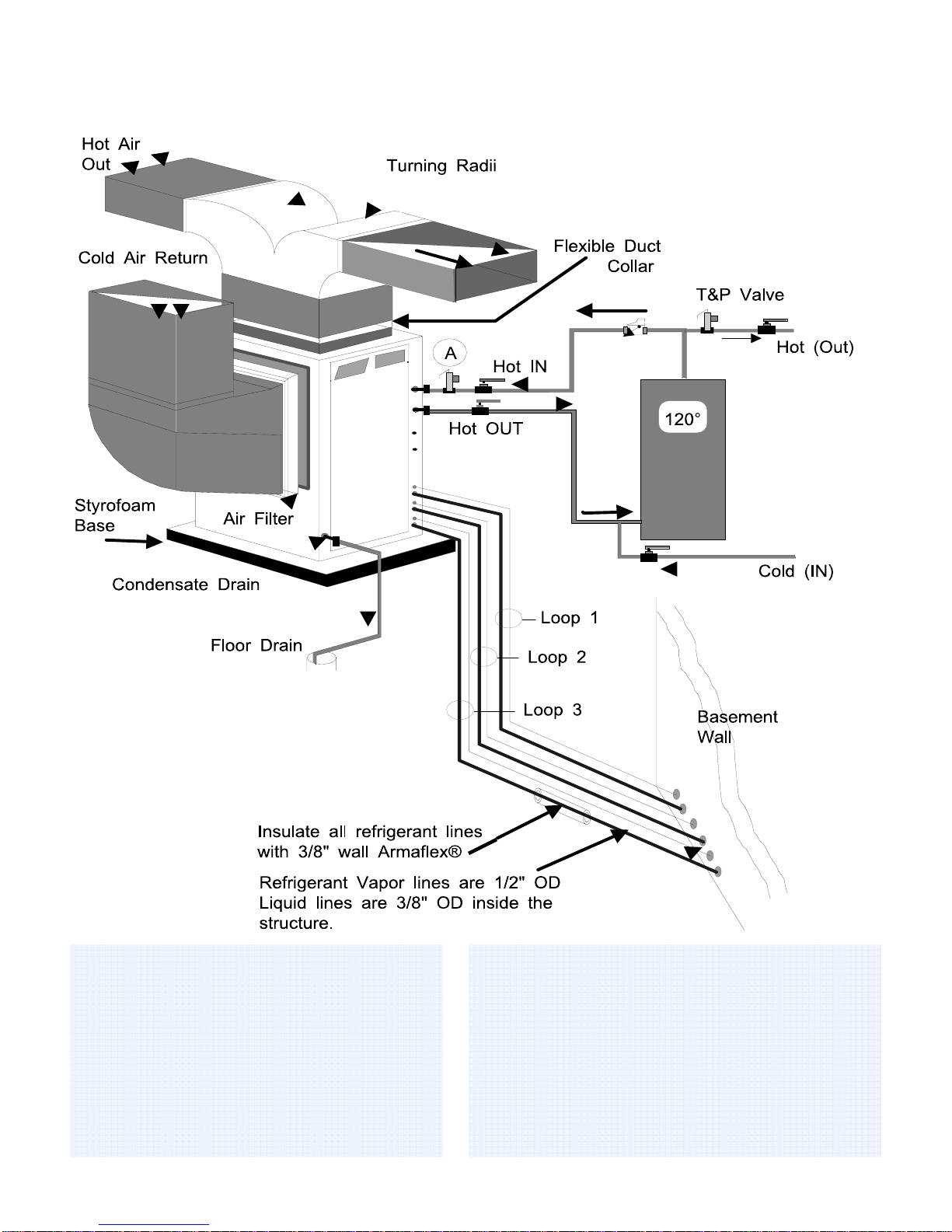

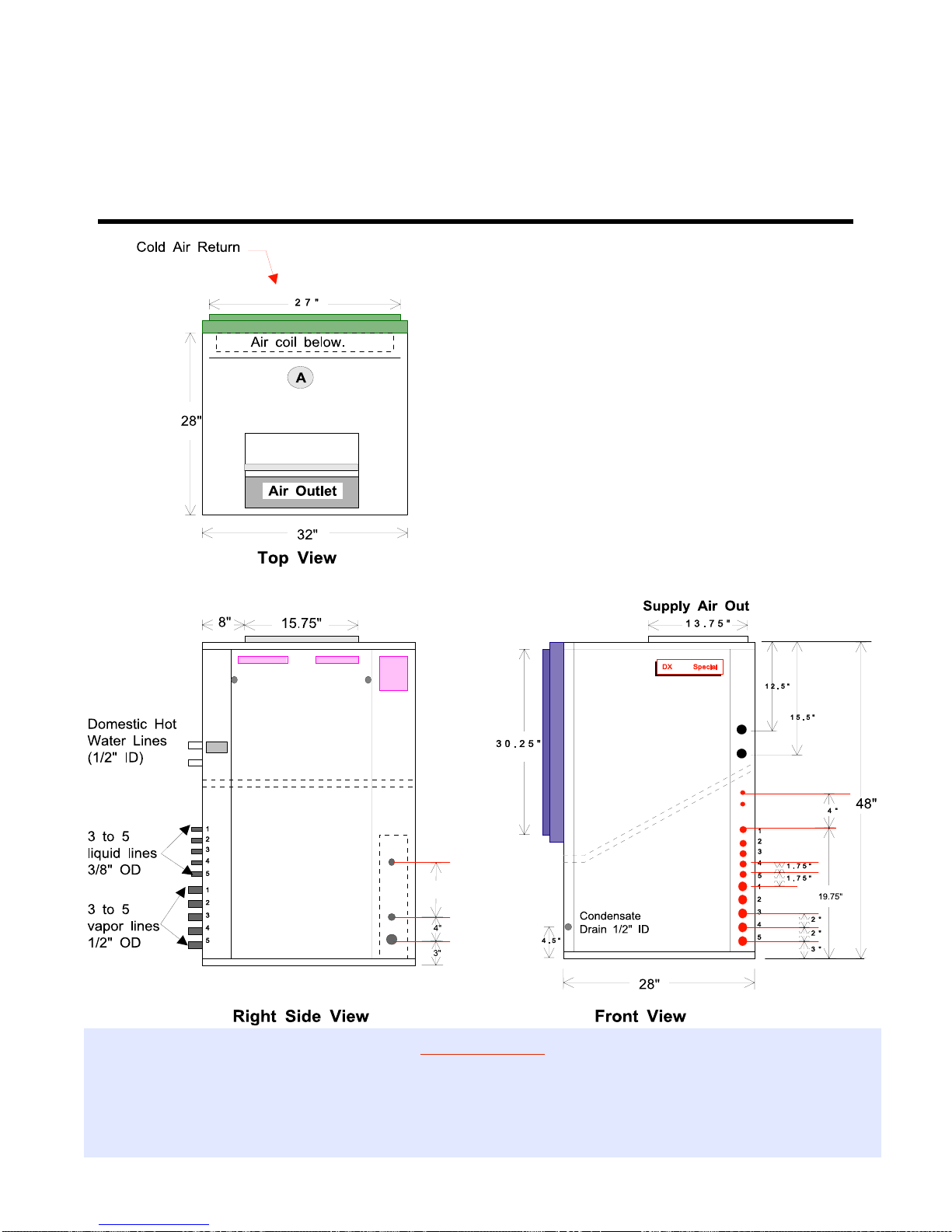

Entering dwelling

The copper ground loops must enter the dwelling at some

location typically through the concrete foundation just above

the poured floor. An alternate method would be to run the

pipe (insulated) up the outside wall making a 90 degree turn

above ground and entering the dwelling between the floor

joists just below the first floor. These pipes should be insu-

lated with a minimum of 3/4" of closed cell weatherproof

insulation. There will be two 1/2" OD copper tubes for each

nominal ton of capacity of the heat pump being installed. For

example a 3-ton unit would have 3 groundloops and thus 6

ends to go through the concrete wall. We recommend that you

drill these holes to a diameter large enough to allow for the

insertion of a plastic sleeve, (see drawing ) and the tubing

with it's insulation jacket. Suitable measures must be taken to

seal the installation from water penetration before the trench

is backfilled.

Unrolling & placing the Tubing

Each 50' roll of tubing is taped both individually and to

the next roll in the group so that at any one time only 50' of

the 350' is free to unroll. This allows for easier unrolling and

prevents kinking the pipe. Observe how the taping is done so

that you know which side of the loop to start unrolling first.

To begin, unroll approximately 12' of copper tubing. Slide

two 6' lengths of armaflex closed cell insulation with wall

thickness of at least 1/2”over the end of the tubing and insert

it through the plastic sleeve of hole # 1 approximately 8" into

the basement. It is good practice to label this line "loop 1 -

gas" to identify it when interconnecting linesets inside the

building. Unroll the copper tubing down one corner of the

trench. When 175 ft of tubing has been laid out make your

turn and proceed back the other side of the trench to the foun-

dation of the building. Slide two 6' lengths of armaflex insula-

tion onto the tubing and insert the stub end through hole # 2 in

the wall to match the other end of the loop. Label this end of

the line "loop 1 - liquid" so that the complete loop can be

identified later. Manually backfill the loop with fill to a depth

of 4 to 6" for protection during the machine backfill process.

Duplicate the process described above applying labels to

identify the two ends of successive loops (loop 2,3,4 etc.)

until all required loops are in place.

Insulation placement near foundation

It is important to apply closed cell insulation to the copper

ground loops as they come within 12' of the building to pre-

vent the possible build up of ice near the foundation of the

home. Applying 1/2” wall closed cell waterproof insulation to

the tubing as described above will insure that very little heat

is absorbed from the ground near the basement wall thus

avoiding possible frost damage to the structure.

Pressure testing linesets

Using the 1/4" schrader valve supplied on each loop the

installer can again check the pressure on each lineset with his

refrigeration gauge set before releasing the pressure and cut-

ting the loop stubs coming into the basement to the proper

lengths.