Borg & Overstrom f4 Instruction sheet

Install & Operation Guide

Page No

2

3

3

4

5

5

6

6

7

8

Contents

Description

Major Components

Parts to Assemble

Installation

Water Connection

Operation & Maintenance

Performance Data

Fault Diagnosis Guide

Electrical Diagram

General Safety Advice

Maintenance & Removal

chilled

GB

GB

Major Components

Before using this machine, we advise you to

read this manual thoroughly. Please follow the

instructions for proper operation to prevent risk

or damage.

26 25 24 23 22

21

20

19

18

17

16

15

14

13

12

1110987654321

1. Main Shell

2. Dust Cap

3. Power Cable Terminal

4. Lower Back Panel

5. G¾ BSP - Male Water

Connection

6. G½-¼ Connection

7. Fan

8. Condenser

9. Compressor

10. Adjustable Feet

19. Top Panel

20. Bubbler Faucet

21. Swan-neck Faucet*

22. Push--fit Connector of the

Swan neck Faucet

23. Cold Tank Fix Brackets

24. Waste Tray

25. Flexible Waste pipe*

26. Terminal Box

27. Power Cord Set*

11. Tank Insulation

12. Front Panel

13. Drain Plug

14. Cold Water Tank

15. Connector of Cold Tank

Outlet Water

16. Connector of Cold Tank

Inlet Water

17. Cold Thermostat

18. Push-fit Connector of the

Bubbler Faucet

* Supplied loose packed for fitting at point of installation.

GB

Parts to Assemble

The swan-neck installation instruction is as

following:

Tap

Sink Top

Rubber

Washer and

Spacer

Washer

Nut

Pipe

Connection

Water Pipe

Installation

The following is a guide but the installer is responsible to comply with any local

regulations that may be applicable to this type of installation.

1. Install near to a convenient place to connect

to a mains pressure water supply of drinking

water quality and 220-240V/50Hz electrical

supply.

2. Avoid areas exposed to excessive heat,

humidity, rain or snow or direct contact with

water spray or splashing.

3. Avoid positions of direct sunlight or solar

heat.

4. Install only on flat, level and well supported

surfaces.

GB

Installation continued

5. Avoid tilting the machine during installation.

If the machine has been tilted excessively for

more than a few minutes during or before

installation, leave to stand for approximately

one hour before switching on.

6. Allow an air gap of at 100mm each side

and at the front of the machine.

7. Once positioned and levelled remove the

Front panel.

8. Unpack the swan-neck tap, fasten to the sink

top and connect to the water pipework. If

necessary remove the sink top to carry this out.

(See page 3)

9. Install/connect the waste water system as

selected. Do not use the fountain without any

waste system being fitted to the open end of

the waste fitting.

10. An access port hole for services is

provided on the rear of the cabinet and there is

a closed rubber grommet pre-fitted which can

be opened to protect the cabinet and pipe

where it passes through the access port hole.

IMPORTANT!

ALWAYS ENSURE SECURITY CLIPS

ARE USED ON ALL WATER AND

CO2 CONNECTIONS.

Water Connection

1. Connect the inlet water supply to the 3/4”

threaded connection at the rear. (Fit a Pressure

Reducing Valve to regulate the water pressure

as required. Max 3.5 bar) Ensure a stop tap

valve for the water is easily accessible. We

also recommend the use of a water-block and

non-return valve to be fitted.

2. We recommend that a filter is also fitted to

ensure water of the highest quality. A mounting

bracket is provided inside the cabinet. Always

pre-flush any filter before fitting.

3. Switch on the water and check the water

tightness of all connections and fittings.

to vent the system until the water dispenses.

This may take time while the system fills. Flush

through at least 5 ltrs of clean water. The

fountain is supplied in clean condition but it is

the responsibility of the installer to ensure an

acceptable standard of hygiene. If necessary

carry out a sanitization procedure upon initial

installation at this point taking care to avoid

contaminating any filters as fitted. Continue to

ensure water tightness of all connections and

fittings.

5. Connect the power cord set provided into

the connection point inside the cabinet and

securely fasten the cable in the 2 cable clamps

also provided. Switch on the electrical supply.

4. Open both the swan-neck and bubbler tap

GB

6. The thermostat is factory preset and should

not need further adjustment.

7. Refit the Front panel.

8. Allow 1hr for the water to cool before

the dispense water reaches its

operational temperature.

10c

4c

Operation & Maintenance

1. Frequently clean the fountain using warm

soapy water. Avoid all abrasive and corrosive

cleaning materials.

2. Do not pour any dregs or other waste into

the waste water fitting to avoid blocking the

waste system.

3. If required, the power can be switched off

when not using the fountain for an extended

period of time (e.g. more than 3 days) to

conserve energy. However we recommend

that the fountain is cleaned and at least 10

litres of water is flushed through upon switching

on again for re-use. It may also be necessary

to change the filter after an extended period of

dis-use.

4. Keep the area surrounding the fountain

clean and dry.

In the event of any leakages, switch off the

water and power and call your service

engineer.

Performance Data

Function

Cooling

Voltage Frequency Max Cooling Power

Cooling

Capacity

Refrigerant

Type

Refrigerant

Charge

220 - 240V 50Hz 120W

40 Ltrs/Hour R134a 110g

GB

Fault Diagnosis Guide

Fault Possible Cause Suggested Action

Not Cooling The compressor is not running Check the power is switched

on

The power is on but not

cooling

The thermostat is set too high Reduce the thermostat

temperature setting

Water leakage The pipes or connections are

leaking

Switch off power turn off water

and call your service engineer

Slow water flow The filter is blocked Change the filter

No water dispenses from the

taps

Water inlet valve(s) closed

or other blockage

Open and/or reset the water

inlet valve(s) and/or check

water supply pipe

Drainage waste blocked Debris has blocked up the

waste system

Clear the obstruction

In the event of any other breakdown, please call your service engineer.

Electrical Diagram

Cold Thermostat

Fuse

Compressor

GB

General Safety Advice

2

Avoid areas exposed to excessive heat,

humidity, rain or snow or direct contact

with water spray or splashing.

Avoid positions of direct sunlight or

solar heat.

Be sure to use single outlet socket with correct

power voltage. Plug the power cord directly

into the electrical socket.

3

Allow an air gap of at least 100mm on each

side and at the front of the machine.

100mm

1

GB

Maintenance & Removal

Please make sure the machine is completely

disconnected from electricity before carrying

out any maintenance work.

Turn off the water supply.

12

3

To drain the Direct Chill tank, remove the cap

at the bottom of the tank. This is located

behind the front panel. We recommend it is

refitted immediately upon draining being

completed.

Table of contents

Popular Outdoor Fountain manuals by other brands

Frontgate

Frontgate 154855 Assembly instructions

Campania International

Campania International Small Del Rey FT-317 Series quick start guide

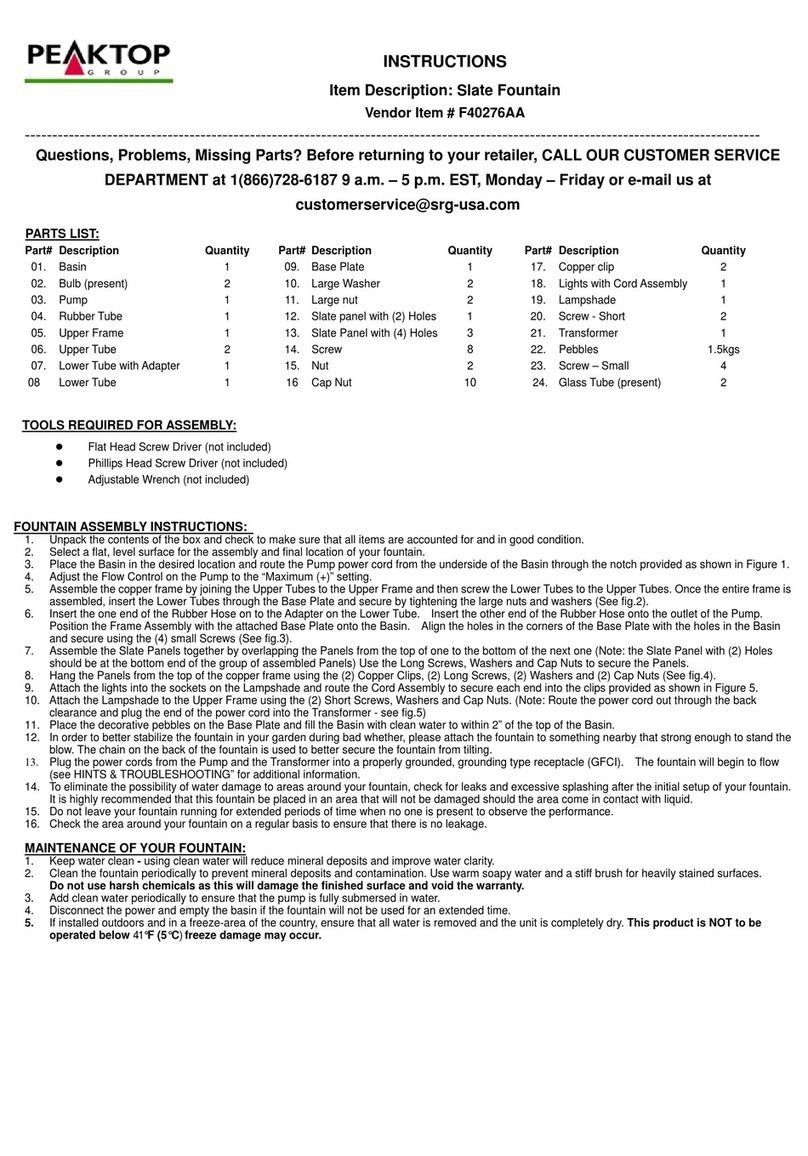

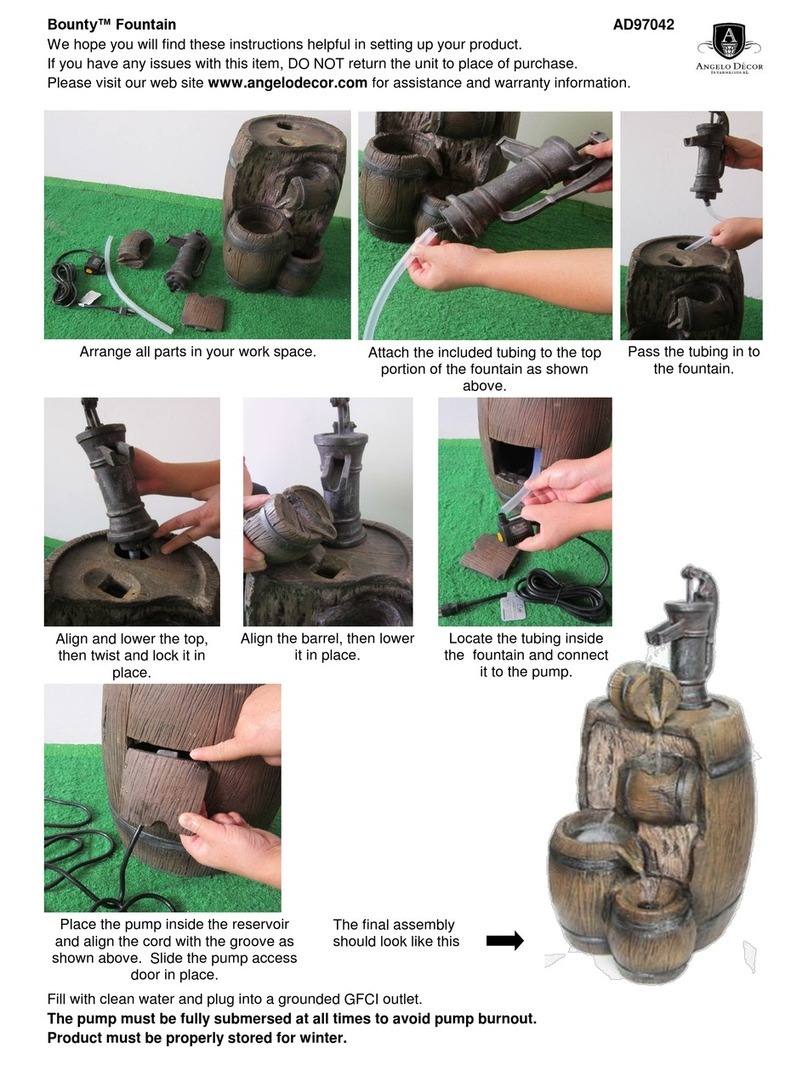

Angelo Decor

Angelo Decor Bounty quick start guide

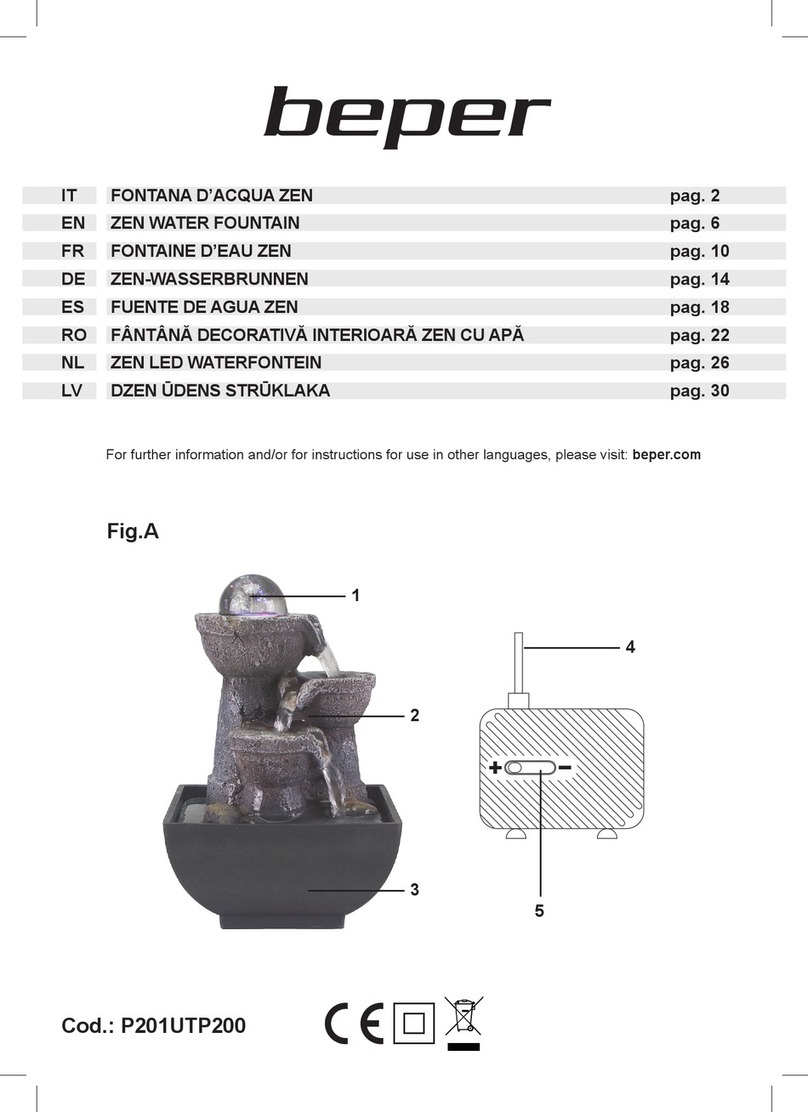

Beper

Beper P201UTP200 Use instruction

Campania International

Campania International Mari FT-405 Assembly instructions

Sunnydaze Decor

Sunnydaze Decor WNC-375 manual

for Living

for Living 19391 Assembly instructions

Murdock

Murdock A131-VR-BF4 Series Installation & maintenance instructions

Murdock

Murdock A132-BF4 Series Installation & maintenance instructions

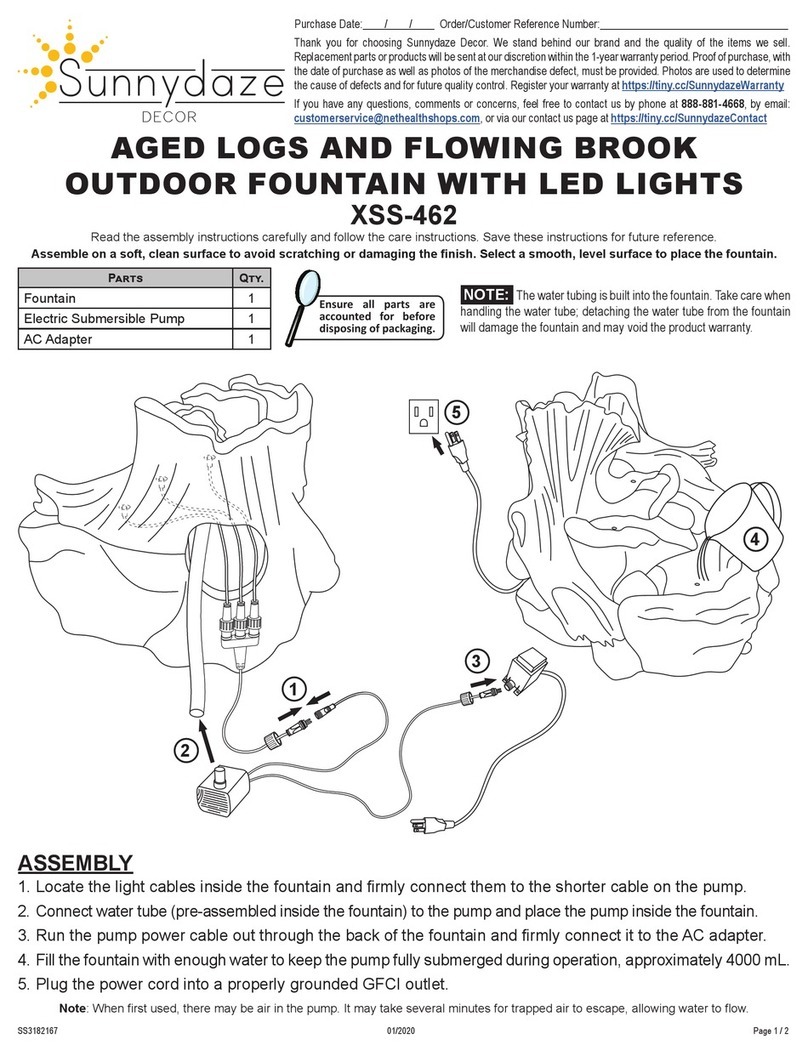

Sunnydaze Decor

Sunnydaze Decor XSS-462 manual

Garden Oasis

Garden Oasis LIGHTHOUSE FOUNTAIN owner's manual

Travis Industries

Travis Industries Ring of Fire owner's manual