Borg B6 User manual

This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand

the hazards involved. Children shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without supervision.

The unit should be isolated from the electricity supply before removal of any covers. Great care must be employed when

working with high pressure carbon dioxide, and in no cases should the maximum operating pressure of 0.4MPa (4 bar)

be exceeded.

The appliance is not suitable for installation in an area where a water jet could be used.

The appliance has to be placed in a horizontal position.

WARNING: Keep ventilation openings in the appliance enclosure or in the built-in structure clear of obstruction.

WARNING: When positioning the appliance, ensure the supply cord is not trapped or damaged.

WARNING: Do not locate multiple portable socket-outlets or portable power supplies at the rear of the appliance.

This appliance is intended to be used in household and similar applications such as:-

Staff kitchen areas in shops, offices and other working environments

Farm houses and by clients in hotels, motels and other residential type environments

Bed and breakfast type environments

Catering and similar non-retail applications

A-weighted emission sound pressure level is below 70 dB(A)

R290 is a refrigerant-grade propane used on a wide range of commercial refrigeration and air

conditioning units. A highly pure propane, it has a low environmental impact and nominal global

warming potential (GWP), meaning it possesses no qualities that can destroy the ozone layer. R290

also is the preferred hydrocarbon alternative of the Environmental Protection Agency (EPA),

substituting more harmful fluorocarbon refrigerants like R22, R134a, R404a and R502.

Units with R290 can only be maintained and repaired by authorized technicians who are

properly trained and certified.

Release date 01.07.2022

B6 Install & Operation

Manual

Safety

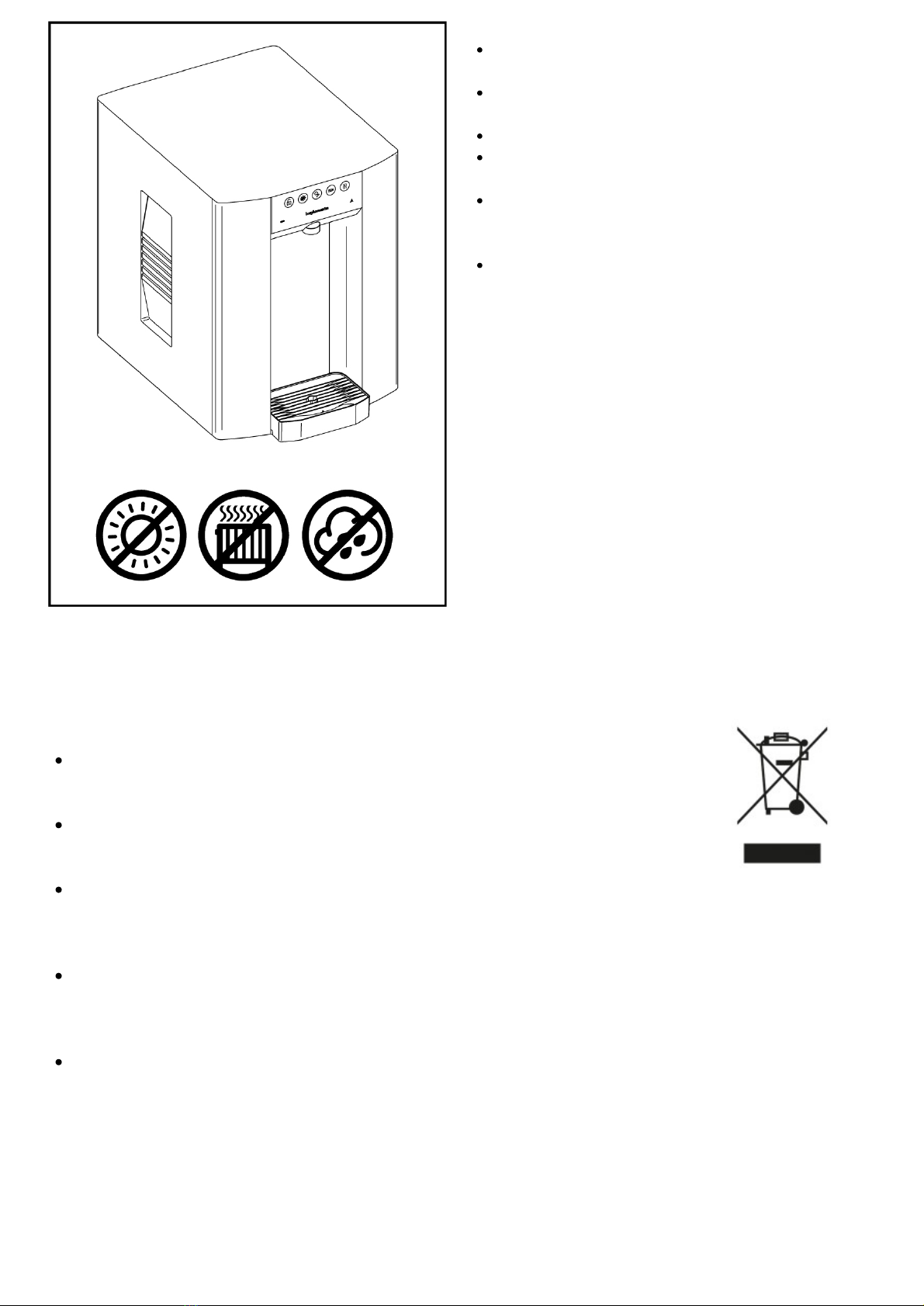

Always place the dispenser in its vertical position, on

a surface which can capably support its weight.

During use this machine must remain in its upright

position.

Adequate ventilation must be allowed for.

Keep the machine away from sunlight, heat and

moisture.

Power and water supply points must be available

near the dispenser, and must meet the criteria

specified in the ‘Specification’ section of this manual.

The environment where this machine is installed must

be free of dust and corrosive/explosive gases.

The WEEE symbol indicates that this item contains electronic components which must

be collected and disposed of separately.

Never dispose of electrical waste in general municipal waste. Collect and dispose of

such waste separately.

Make use of the return and collection systems available to you, or your local

recycling programme. Contact your local authority or place of purchase to find out

what schemes are available.

Electrical and electronic equipment contains hazardous substances which, when

disposed of incorrectly, may leak into the ground. This can contribute to soil and

water pollution which is hazardous to human health; and endangers wildlife.

It is essential that consumers look to re-use or recycle electrical or electronic waste

to avoid it going to landfill sites or incineration without treatment.

Waste Electrical Products:

COOLING SYSTEM Stainless steel direct chill coil encased in a solid-block system for instant

response cool down action. Ultra efficiency compression system with capillary

control. Environmentally friendly R290 refrigerant.

COLD TEMPERATURE 2°C - 11°C.

OUTPUT PER HOUR 50 litres Chilled 50 litres Sparkling

MAXIMUM RUNNING POWER

CONSUMPTION - CHILLED &

AMBIENT

0.14kW - 230V

MAXIMUM RUNNING POWER

CONSUMPTION - CHILLED,

SPARKLING & AMBIENT

0.22kW - 230V

MAXIMUM RUNNING POWER

CONSUMPTION - CHILLED,

AMBIENT & HOT

1.5kW - 230V

MAXIMUM RUNNING POWER

CONSUMPTION - CHILLED,

AMBIENT, SPARKLING & HOT

1.6kW - 230V

QUANTITY OF REFRIGERATION

GAS

R290a 33g

POWER SUPPLY 220V - 240V AC (50 Hz)

WATER CONNECTION Mains in - 3/4” BSP

C02 CONNECTION 1/4” Push Fit.

DIMENSIONS (w x d x h) 320 x 465 x 420mm.

WEIGHT - CHILLED & AMBIENT 18Kg

WEIGHT - CHILLED, SPARKLING &

AMBIENT

22Kg

WEIGHT - CHILLED, AMBIENT &

HOT

20Kg

WEIGHT - CHILLED, SPARKLING,

AMBIENT & HOT

23.5Kg

RATED CURRENT - CHILLED &

AMBIENT

1.1A

RATED CURRENT - CHILLED,

SPARKLING & AMBIENT

1.5A

RATED CURRENT - CHILLED,

AMBIENT & HOT

6.5A

RATED CURRENT - CHILLED,

AMBIENT, SPARKLING & HOT

7.1A

FUSE RATING 10A

MINIMUM TO MAXIMUM INLET

WATER PRESSURE

0.05MPa (0.5 bar) - 1.0 MPa (10 bar) Internally regulated to 0.3 MPa (3 bar)

CO2 PRESSURE 0.4MPa (4 Bar) Maximum

MINIMUM TO MAXIMUM

AMBIENT ROOM OPERATING

TEMPERATURE

5°C - 35°C

CLIMATIC CLASS N

Introduction

Hygienic and ergonomic, B6 flourishes in all environments – from boardroom to sports hall. Its compact size, large

dispense area for bottles, multiple water options and flexible configuration.

The B6 features a control panel designed for immaculate hygiene. Completely flush with no intricate buttons to harbour

germs and contaminants, the touch sensitive console delivers instant high-quality chilled, ambient, hot and sparkling water.

Model Overview

1. Unit Lid, 2. Side Panel, 3. Carry Handle, 4. Control Panel, 5. Dispense Outlet, 6. Drip Tray, 7. Power Connection, 8.

On/Off Switch, 9. CO2 Inlet*, 10. Water Inlet

Please Note:

Mains Installation Kit & Filters are supplied as extra items

according to individual ordering requirement.

*Sparkling versions only

Dimensions

Installation Requirements

Identify a suitable location for the B6 unit. It should be positioned within 2.0m of suitable services connections. Allow 15cm

of free space at the rear for ventilation.

The ProCore unit must be installed in accordance with the relevant requirements of:

The appropriate building regulations by application of either The Building Regulations (England and Wales), The Building

Regulations (Scotland) or The Building Regulations (Northern Ireland). In territories other than those listed the local

regulations in force must be complied with.

The Water Supply (Water Fittings) Regulations (England, Wales and Northern Ireland) or The Water Byelaws in Scotland.

The unit must not be installed where it is liable to freeze. If the unit is thought to be frozen it must not be switched on. It

should be allowed to thaw and must then be thoroughly inspected to ensure it is undamaged.

Service Requirements

Water: Mains potable water – internally regulated to 0.2MPa (2 bar)

CO2: Food Grade CO2 to be supplied

Min mains pressure 0.05MPa (0.5 bar)

Electricity: 10A supply – Earth Leakage Protected

Installation

Dispensing cold water from unit:

Press and hold dispense icon and release to finish dispense

• Chilled icon flashing – Unit is chilling down

• Sparkling icon flashing – Tank is refilling

Dispensing hot water from unit:

Press the unlock icon and then press and hold the hot button to dispense.

‘eco’ Mode:

‘eco’ mode symbol illuminates when unit is in ‘eco’ mode, to awaken unit press and hold any dispense icon. The

ProCore will activate ‘eco’ mode in the below instances:

Dispense inactivity

Low room light level

Warning Symbol

‘Warning triangle’ symbol will illuminate and flash upon a fault. The number of flashes relates to a particular fault. Click

to view fault codes

Advanced functions

Hold ‘Hot Unlock Icon’ for 10 seconds for decommissioning and commissioning.

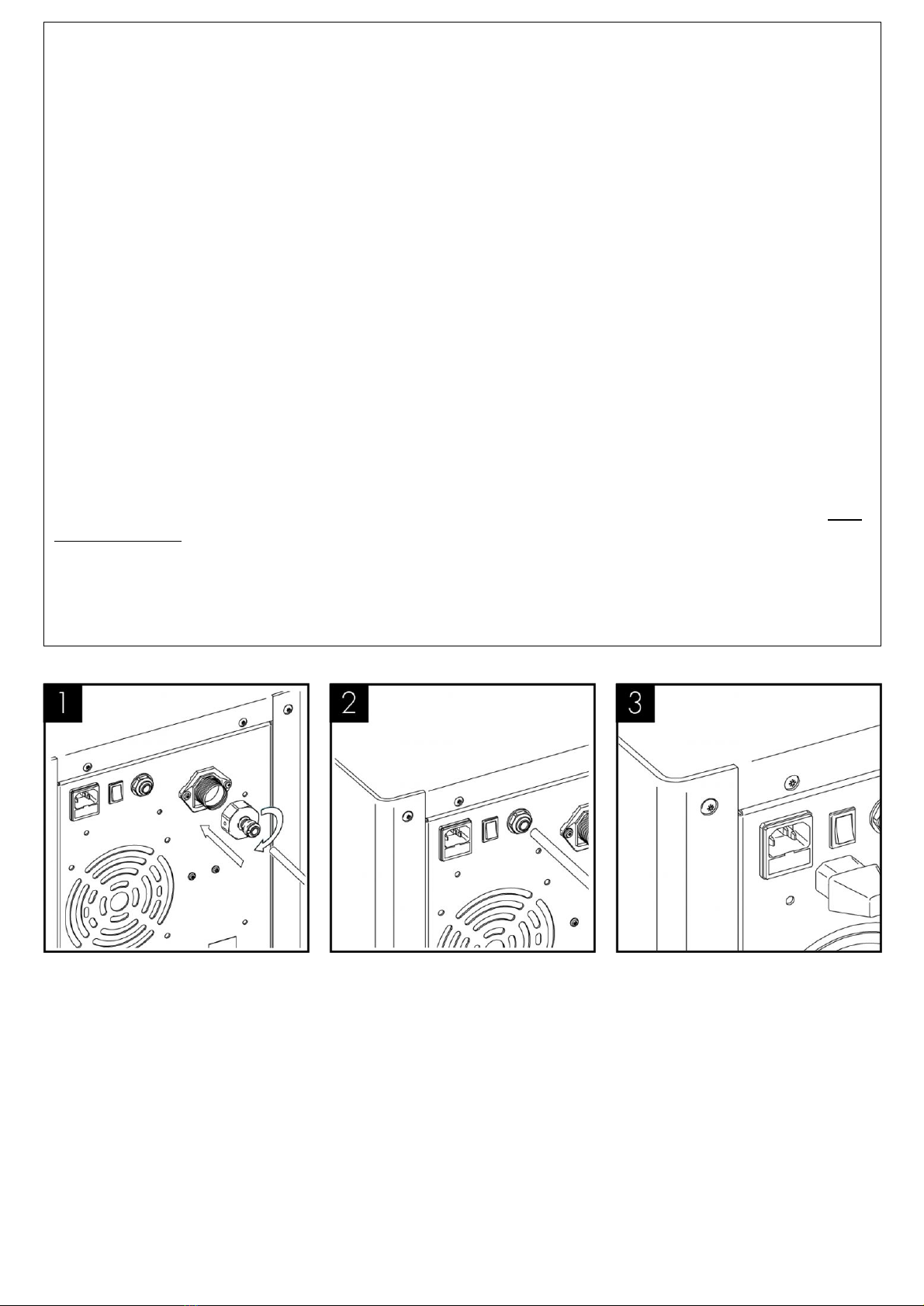

B6 Installation & Water Connection

Connect the water inlet adapter as

supplied and connect to the water

supply.

Connect the CO2 supply from gas

regulator, ensuring the pressure is set to

max 58 PSI (4 bar), and turn on the

supply (See CO2 Installation section).

Connect the chiller to the electricity

supply and ensure unit is switched on.

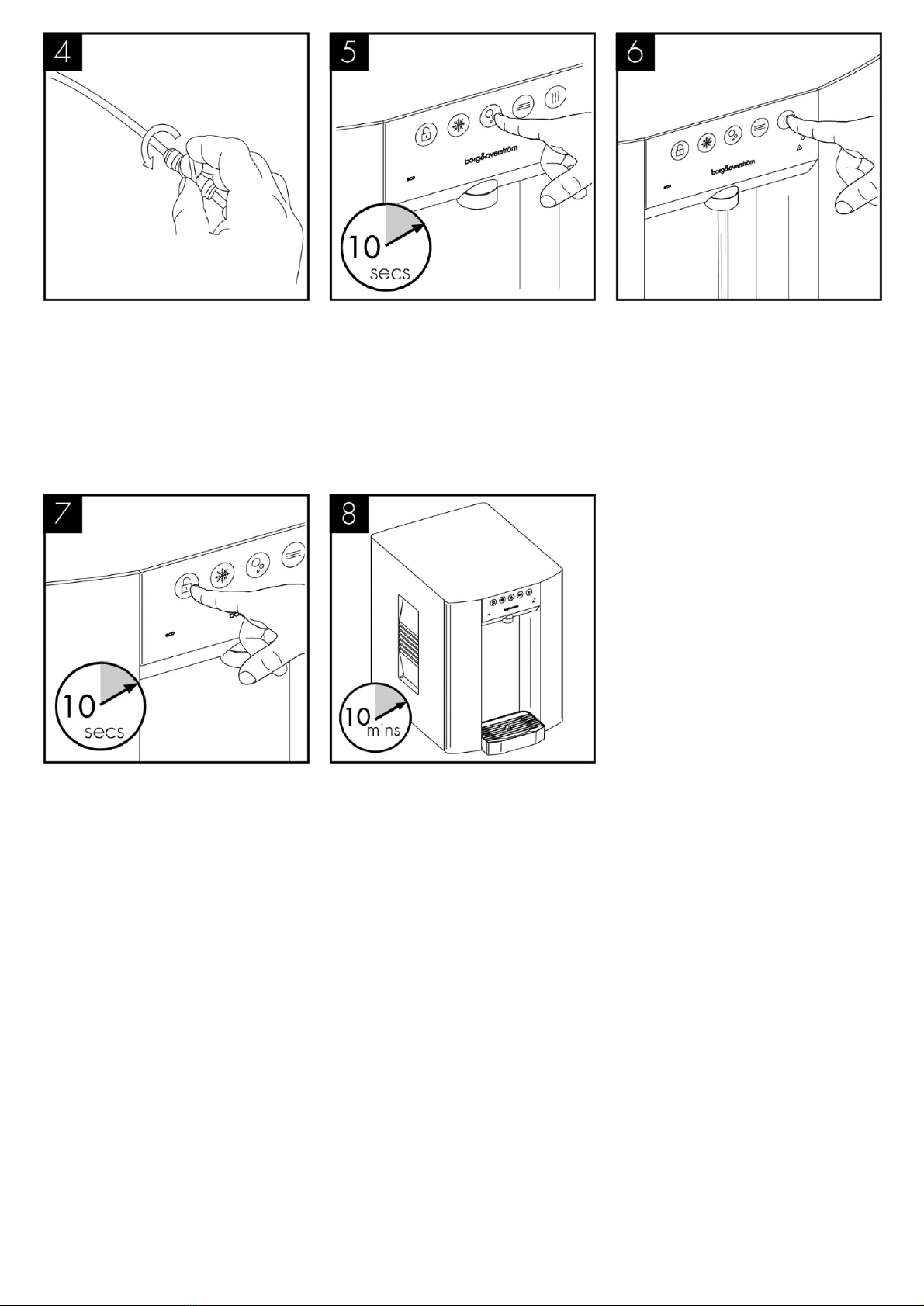

Turn on the water supply. The carbonator should be purged of

air by activating the sparkling water

dispense for approximately 10

seconds.

The hot versions will be in

commissioning mode which stops the

unit from running only allowing

dispensing.

With hot water versions fill the hot tank

until you see water dispense.

Press the lock symbol for 10 seconds

to take the unit out of commissioning

mode and the LED’s and display will

change.

Allow the machine to stand for 8 - 12

minutes for the initial chilling process to

complete.

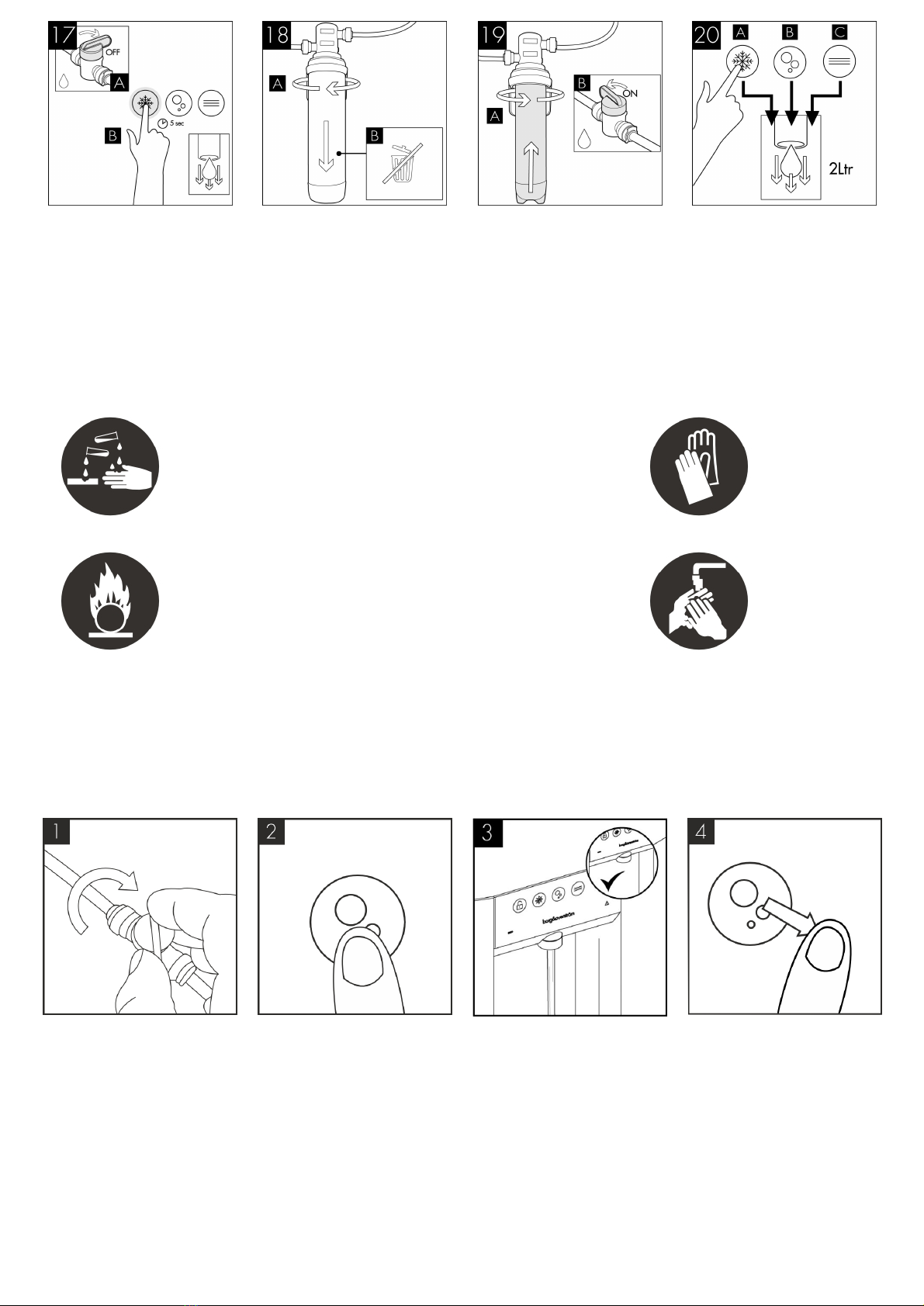

CO2 Bottle Installation - Sparkling Versions Only

Unpack CO2 Regulator and fit elbow

fitting to spigot outlet.

Attach the regulator to the disposable

CO2 bottle, ensuring the small

pressure relief vent in the stem is facing

away from you or anyone else. Ensure

the regulator is closed. Hand tighten

securely.

Connect the assembled CO2 bottle

and regulator to the CO2 inlet using a

¼” pipe.

Stand the cylinder in a suitable place. We recommend between 3.5 - 4 bar

(58 PSI) (max). Do not exceed 4 bar

pressure.

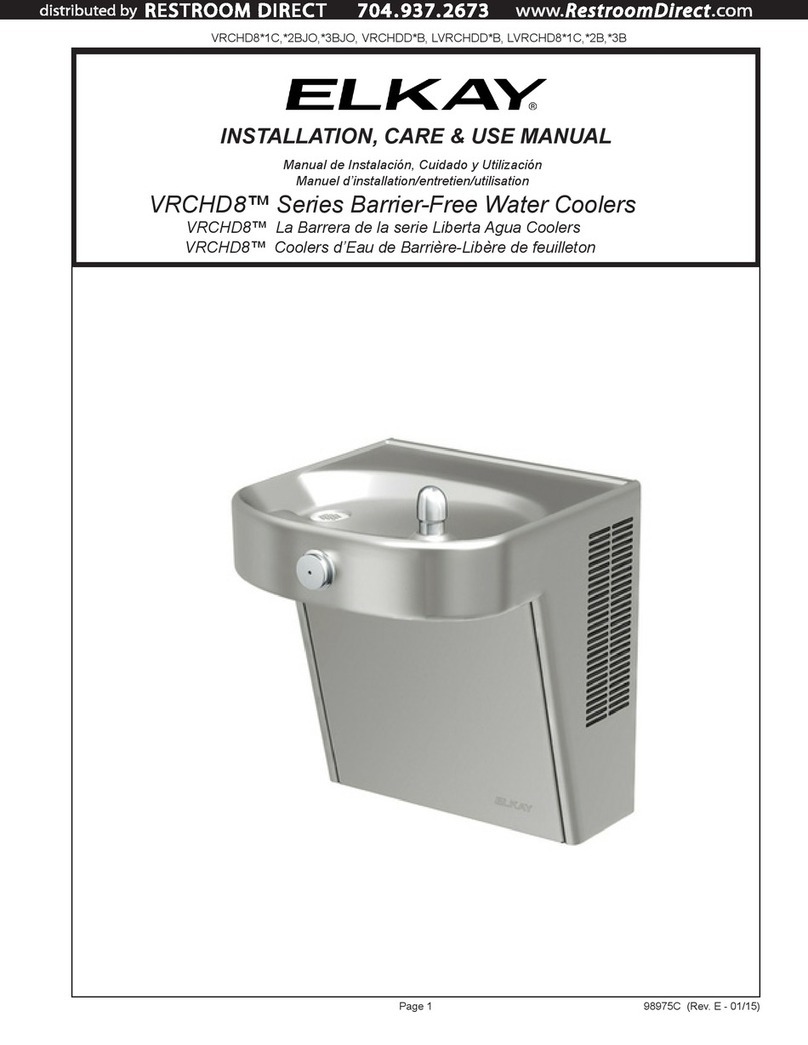

Sparkling Water Flow Rate - Sparkling Versions Only

NOTE: Sparkling water flow rate factory setting = 2.4L per minute MAX. This may need adjusting

depending on inlet pressure. To do so follow below steps:

Remove the 2 screws

holding the unit lid down

and slide the lid off.

Remove the right hand side

panel screws. 2 screws are

located at the back and

one on top. Then slide the

panel back to gain access

to the flow controller.

Locate the flow control

adjuster, this is towards the

front of the unit.

Flow can then be adjusted

as follows: turning the cap

anti-clockwise to increase

flow and clockwise to

restrict flow. After each

adjustment the flow rate

should be timed to an

acceptable flow rate

and/or uninterrupted

sparkling dispense.

Once the correct flow rate is achieved place the cover back on to the unit by sliding it in place and replacing the

screws.

NOTE: Failure to use sanitising products and processes approved by Borg & Overström will invalidate your warranty.

This operation must only

be carried out by trained

staff.

A sanitisation procedure is

recommended every 6

months.

Turn off incoming mains

water

Briefly press chilled

dispense button to release

internal water pressure

from the machine.

Remove the existing filter Use hand gel and put on

protective gloves.

Add 25 ml of Bioguard

Internal Sanitising Solution

to a clean and empty

service filter cartridge.

Connect to filter head.

Sanitisation Guide

Maintenance & Cleaning

Turn on incoming water,

allow the service filter

cartridge to fill

Dispense water using the

chilled button until the

water appears pink.

Repeat with sparkling &

ambient water buttons.

Leave the solution inside

machine for sanitisation to

take effect (minimum 5

minutes) while thoroughly

cleaning the dispenser

externally. (All

maintenance operations

must be carried out with

the dispenser switched

off.)

Pay particular attention to

the dispense faucet and

the push button controls.

For this use Sterizen

External Sanitiser and

Sanitising Wipes.

Remember to include the

drip tray. If a Waste

Overflow System is fitted,

empty this and flush

through with a small

amount of sanitisation fluid

if needed.

Attend to any cosmetic

marks as needed. For this

we recommend the use of

Bioguard External

Sanitiser.

Reconnect the power and

switch on the dispenser.

When the external

cleaning (minimum 5

minutes) is completed, flush

the machine using the

chilled button with clean

water until the dispense

water runs clear.Repeat

briefly with the ambient

and sparkling buttons if

present.

Turn off water and briefly

press chilled dispense

button to release internal

water pressure from the

machine.

Remove the service filter.

Retain service filter for

reuse.

Fit new filter and turn on

incoming water supply.

Pre-flush the new filter to

waste using the chilled

button until the water

appears clear and is free

of air. Flush through a

small amount of water to

check all functions.

Please note that this sanitisation fluid contains an active

caustic/alkaline agent.

Always use responsibly and with care remembering that due to

its alkaline nature unnecessary concentrated/prolonged contact

with any materials, including metals, can cause damage.

Always rinse all contact surfaces after use with clean water.

Avoid skin

contact and

wear

protective

gloves when

handling

sanitisation

fluids.

In the event of

any skin

contact, flush

immediately

with clean,

cold water.

Emptying the CO2 Tank

Turn off the water supply. Press and hold the Sparkling

water dispense button until

all the water is expelled and

only CO2 gas is being

released.

The tank is empty of

sparkling water when only

CO2 is being released.

Ensure to release the

Sparkling water button and

take care to avoid releasing

excess amounts of CO2 gas

as this may damage the

tank.

Problem/Report Possible Cause Suggested Action

No Water Dispensing Power supply

turned off

Check the power supply has been fitted properly and turned on.

Water Pressure

Regulator

Check water flow through the regulator.

Replace if necessary.

Check Tap HMI

Control

Check fault codes.

Water isolated

from machine

Check water inlet supply.

Leak detection in

unit triggered

Disconnect the power and water supply, check for leaks.

Commissioning

mode

Ensure hot tank is full by dispensing hot option and then take unit out

of commissioning mode.

Lock icon not

pressed

To dispense from hot, press the lock symbol first then hot shortly after.

No Sparkling Water No CO2 pressure Check CO2 bottle, regulator and non-return valve. Supply pressure

should be 58 psi (4bar), replace as necessary.

Carbonator Tank

Not Filling

Check carbonator probe for possible short circuit to ground.

Check for pump timeout, cycle power off & on then purge

carbonator.

Poor Quality

Carbonation

Incorrect CO2

Pressure

Check CO2 bottle, regulator and non-return valve. Supply pressure

should be 58 psi (4bar), replace as necessary.

Air in Carbonator

Tank

Visit to view steps for purging tank.

Residue in

Carbonator Tank

After prolonged use, a surface film can develop within the

carbonator tank. Refer to cleaning and sanitising instructions.

Warm Drinks Insufficient cooling

air flow through

the

fridge.

Check that the condenser is not blocked.

Check supply to cooling fans (230V AC).

If supply present replace fans.

If supply not present move on to the compressor. The supply to the

fans and the compressor are linked.

Compressor not

running

Check supply to compressor (230V AC).

Check NTC probe is not faulty

Check for system over heat. Allow the unit to cool and check for

airflow obstructions. Once the unit has cooled the fridge system will

restart. If the problem persists contact technical support.

Fridge failure (See

fault codes)

If compressor & fan are running and there is no cooling contact

technical support.

Table of contents

Popular Water Dispenser manuals by other brands

US Water Systems

US Water Systems Fusion owner's manual

Elkay

Elkay VRCHD8 Series Installation, care & use manual

Greenway Home Products

Greenway Home Products GWD5440W Use & care guide

Crysalli

Crysalli CR-UCM1 Quick installation guide

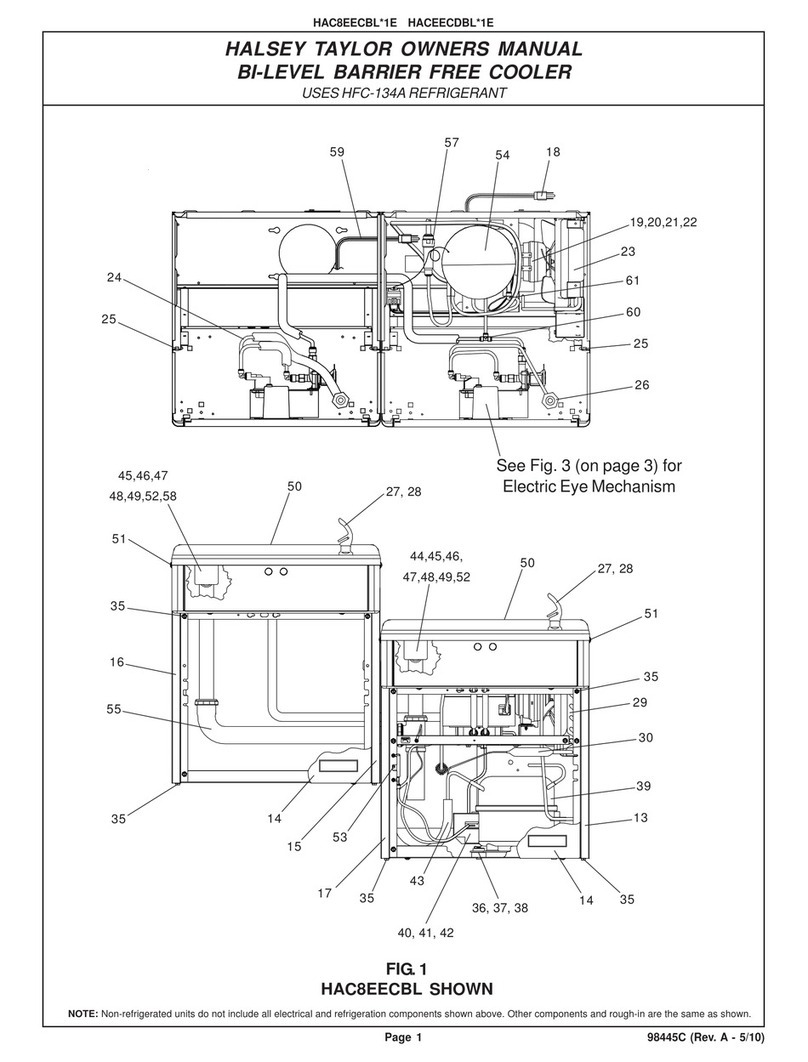

Halsey Taylor

Halsey Taylor WM14WQ 1L Series owner's manual

Halsey Taylor

Halsey Taylor HAC8EECBL 1E Series owner's manual

Pentair

Pentair Fleck 2910 NXT2 user guide

Premium

Premium PWC205T Use & care manual

Omnifilter

Omnifilter R12 installation instructions

Greenway Home Products

Greenway Home Products GWD5400W Use & care guide

Aqua Cooler

Aqua Cooler OASIS Series Usage and Care Manual

Honeywell

Honeywell HWB1052 Series owner's manual