English - 2

■Never touch the rotating tool insert. Danger

of injury.

■Use appropriate detectors to determine if

utility lines are hidden in the work area or

call the local utility company for assis-

tance.

Contact with electric lines can lead to fire and

electric shock. Damaging a gas line can lead

to explosion. Penetrating a water line causes

property damage or may cause an electric

shock.

■Hold the power tool only by the insulated

handles, when performing an operation

where the tool insert can run into hidden

wiring or its own mains cable. Contact with

a “live” wire can make metal parts of the power

tool “live” and lead to an electric shock.

The machine is intended for trimming edges in

wood, plastic and light building materials. It is

also suitable for routing of grooves, profiles and

slots as well as for contour routing.

■Before any work on the machine itself, pull the

power plug.

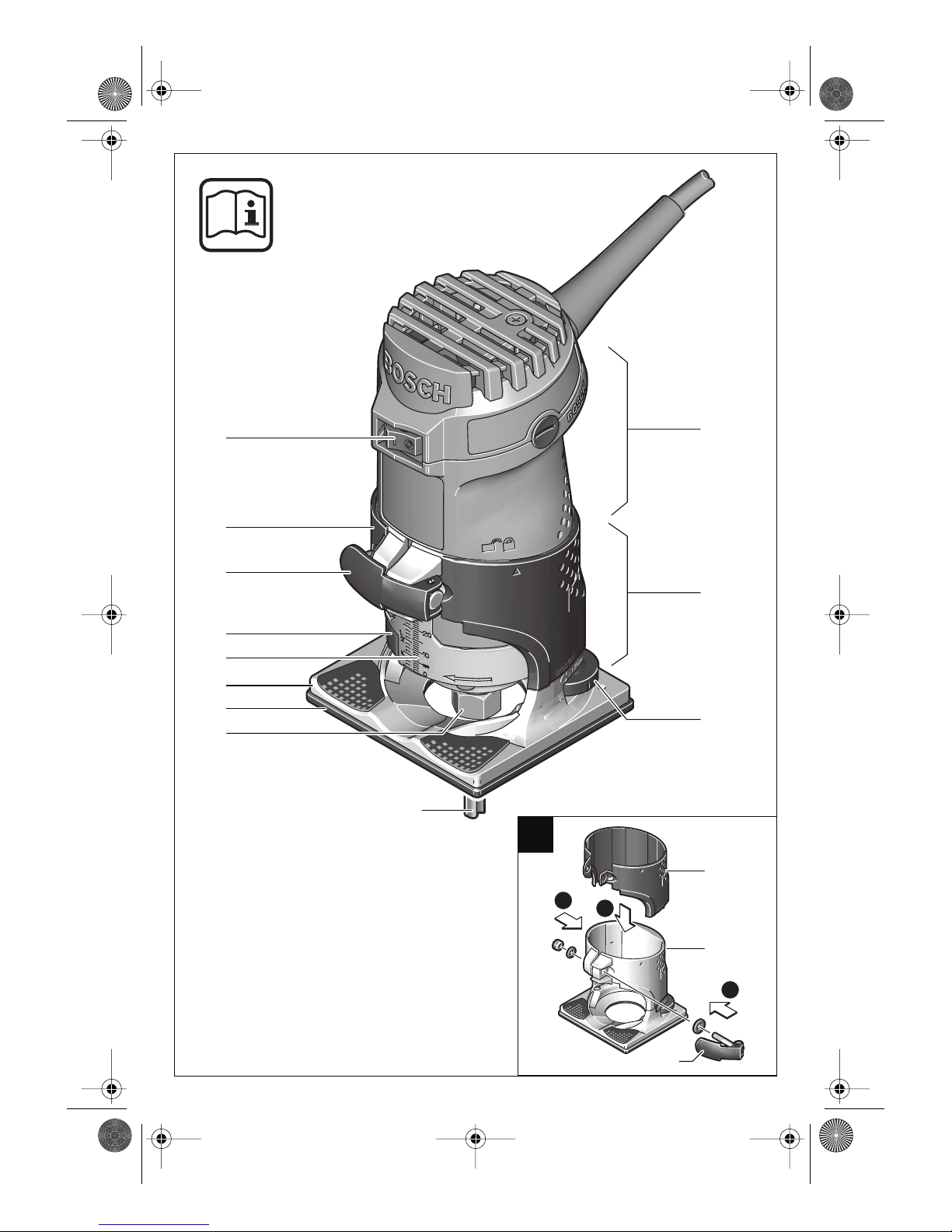

Assembling the Base Cover Sleeve

(see figure )

For assembly of the base cover sleeve 11, re-

move the clamping lever 10. Place the base

cover sleeve 11 onto the routing base 2 from

above and reassemble the clamping lever 10

again in such a manner that the motor unit 1 is

held securely in the routing base 2 when the

clamping lever is locked.

Disassembling the Motor Unit

(see figure )

For disassembly of the motor unit 1, open the

clamping lever 10 and turn the routing base 2 to

the symbol “ ” on the motor unit. Then pull the

motor unit 1 upwards out of the routing base 2.

Router Bit Selection

Depending on the processing and application,

router bits are available in the most different de-

signs and qualities:

Router bits made of high speed steel (HSS)

are suitable for the machining of soft materials,

e. g., soft wood and plastics.

Carbide tipped router bits (HM) are especially

suitable for hard and abrasive materials, e. g.,

hard wood.

Original router bits from the extensive Bosch ac-

cessories program are available at your special-

ized hardware store.

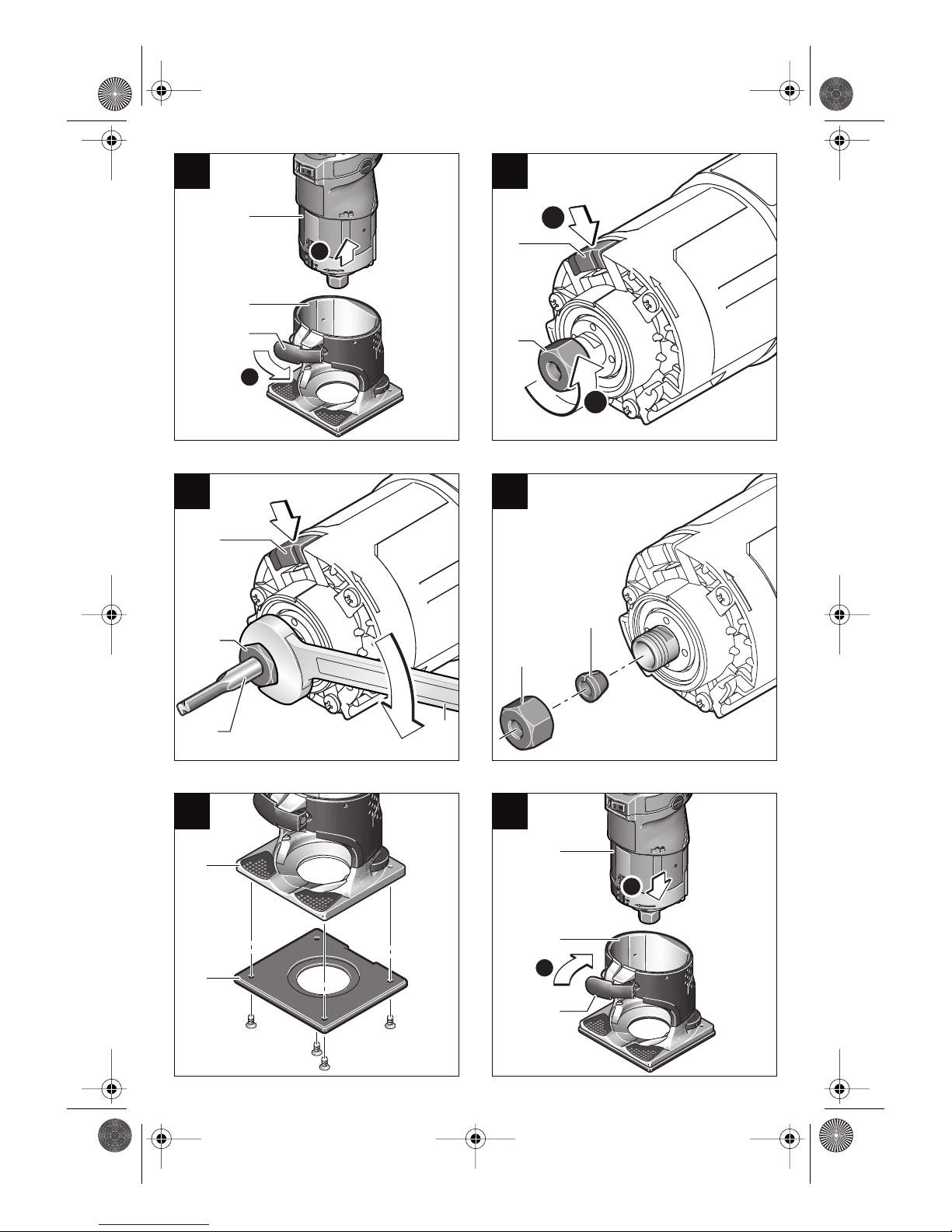

Inserting Router Bits

(see figures + )

■Before any work on the machine itself, pull the

power plug.

■It is recommended to wear protective gloves

when inserting or replacing router bits.

Disassemble the motor unit as described in the

respective section.

Press the spindle locking button 9 and keep it de-

pressed. If need be, turn the spindle by hand until

the lock engages.

■Press the spindle lock button only when at a

standstill.

Loosen the tightening nut 5 with an open-end

spanner 13 (size 17 mm) by turning it several

times, but do not unscrew the tightening nut.

Insert the shank of the router bit 4 as far as it will

go into the collet.

Tighten the tightening nut 5 with the open-end

spanner 13 (size 17 mm) and release the spindle

locking button 9.

Do not tighten the tightening nut of the

collet without a router bit inserted.

Replacing the Collet (see figure )

Depending on the routing tool to be used, differ-

ent collets can be inserted, see “Tool Specifica-

tions”.

Press the spindle locking button 9 and keep it de-

pressed. If need be, turn the spindle by hand until

the lock engages.

Completely unscrew the tightening nut 5.

Release the spindle locking button 9.

Insert the collet 14 and tighten the tightening

nut 5 again.

Do not tighten the tightening nut of the

collet without a router bit inserted.

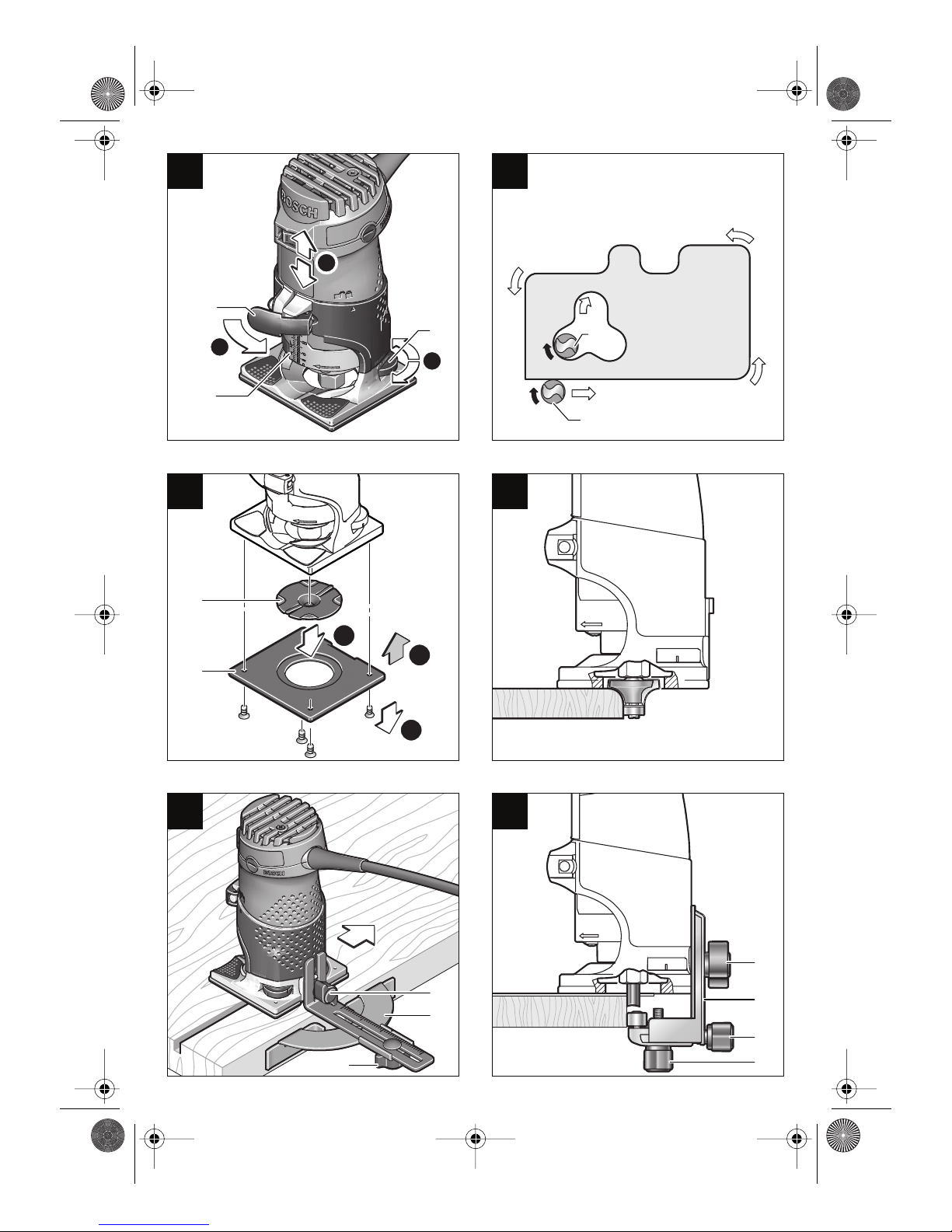

Mounting the Guide Plate

(see figure )

The guide plate 6 prevents the surface of delicate

materials from being scratched up.

Mount the guide plate 6 to the bottom side of the

base plate 7 with the 4 pan head screws.

Intended Use

Mounting