BOSSCO RT1 User manual

BOSS RT1

GUIDE

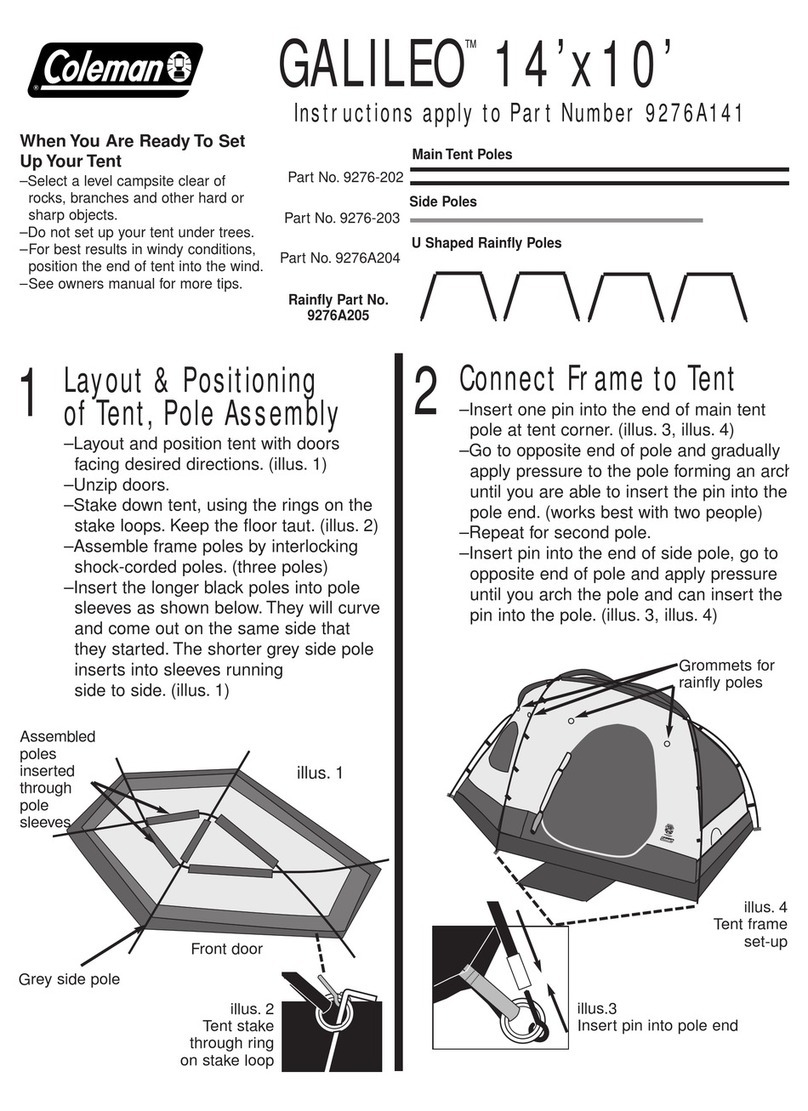

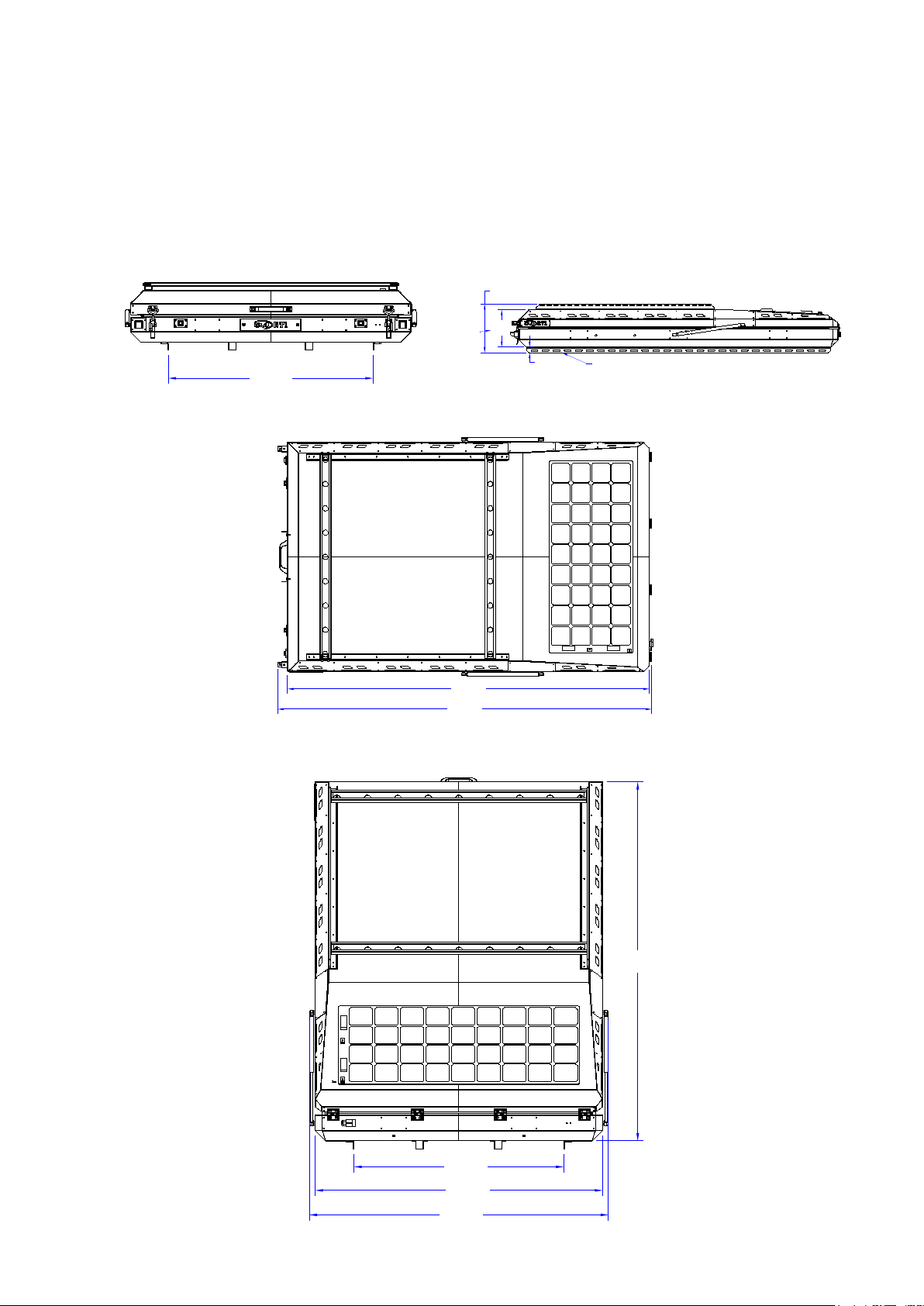

BOSS RT1 DIMENSIONS

Outside Closed:

Inside Open:

Weight:

2300L x 1450W x 260W (MM)

2165L x 1315W x 1800H

90 KG Approximately

0985-08-RTT

Title

12345678

12345678

A

B

C

D

E

F

A

B

C

D

E

F

0985-08-RTT

Size

0985-08-RTT

Project

Title

Checked

A3

Sheet 1 Rev.

Date

Dwg No.

THIRD ANGLE

PROJECTION D.W. 9/07/2020

11:05 AM

Drawn

Scale 1:10

A

D.W

BOSS ALUMINIUM

This drawing remains the property of

Boss Aluminium P/L and must not be

copied or reproduced in any way or form

without the written consent of Boss

Aluminium P/L

COPYRIGHT 2020

Factory 8/208 Canterbury road Bayswater north

Victoria3153 Ph:03-9729-3092 Fax:03-9729-3263

AD

AD

1060.0

1060.0

1453.4

1512.7

1816.3

AEAE

351.6

269.1

40

2306.4

2383.6

REAR VIEW

TOP VIEW

R/H SIDE VIEW

FRONT VIEW

INSIDE RAILS

SLOTED MOUNTING RAIL

OUTSIDE BODY

INSIDE MOUNTS

OVERALL INC GAS STRUTS

OPEN

CLOSED

0985-08-RTT

Title

12

3

4

5

6

7

8

1

23

4

5

67

8

A

B

C

D

E

F

A

B

C

D

E

F

0985-08-RTT

Size

0985-08-RTT

Project

Title

Checked

A3

Sheet 1

Rev.

Date

Dwg No.

THIRD ANGLE

PROJECTION D.W.

9/07/2020

11:05 AM

Drawn

Scale

1:10

A

D.W

BOSS

ALUMINIUM

This drawing remains the property of

Boss Aluminium P/L and must not be

copied or reproduced in any way or form

without the written consent of Boss

Aluminium P/L

COPYRIGHT 2020

Factory 8/208 Canterbury road Bayswater north

Victoria3153 Ph:03-9729-3092 Fax:03-9729-3263

AD

AD

1060.0

1060.0

1453.4

1512.7

1816.3

AEAE

351.6

269.1

40

2306.4

2383.6

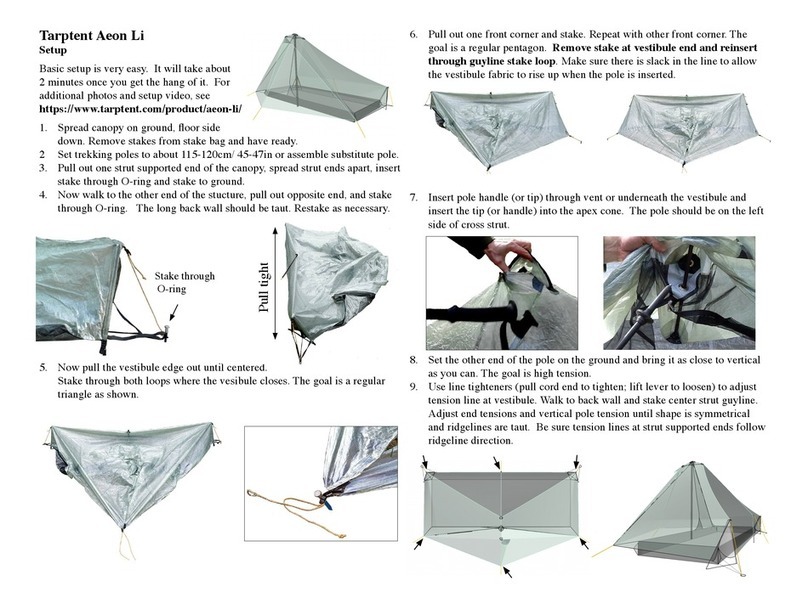

REAR VIEW

TOP VIEW

R/H SIDE VIEW

FRONT VIEW

INSIDE RAILS

SLOTED MOUNTING RAIL

OUTSIDE BODY

INSIDE MOUNTS

OVERALL INC GAS STRUTS

OPEN

CLOSED

0985-08-RTT

Title

1

23

4

5

6

7

8

1

2

3

4

567

8

A

B

C

D

E

F

A

B

C

D

E

F

0985-08-RTT

Size

0985-08-RTT

Project

Title

Checked

A3

Sheet 1

Rev.

Date

Dwg No.

THIRD ANGLE

PROJECTION

D.W. 9/07/2020

11:05 AM

Drawn

Scale

1:10

A

D.W

BOSS

ALUMINIUM

This drawing remains the property of

Boss Aluminium P/L and must not be

copied or reproduced in any way or form

without the written consent of Boss

Aluminium P/L

COPYRIGHT 2020

Factory 8/208 Canterbury road Bayswater north

Victoria3153 Ph:03-9729-3092 Fax:03-9729-3263

AD

AD

1060.0

1060.0

1453.4

1512.7

1816.3

AEAE

351.6

269.1

40

2306.4

2383.6

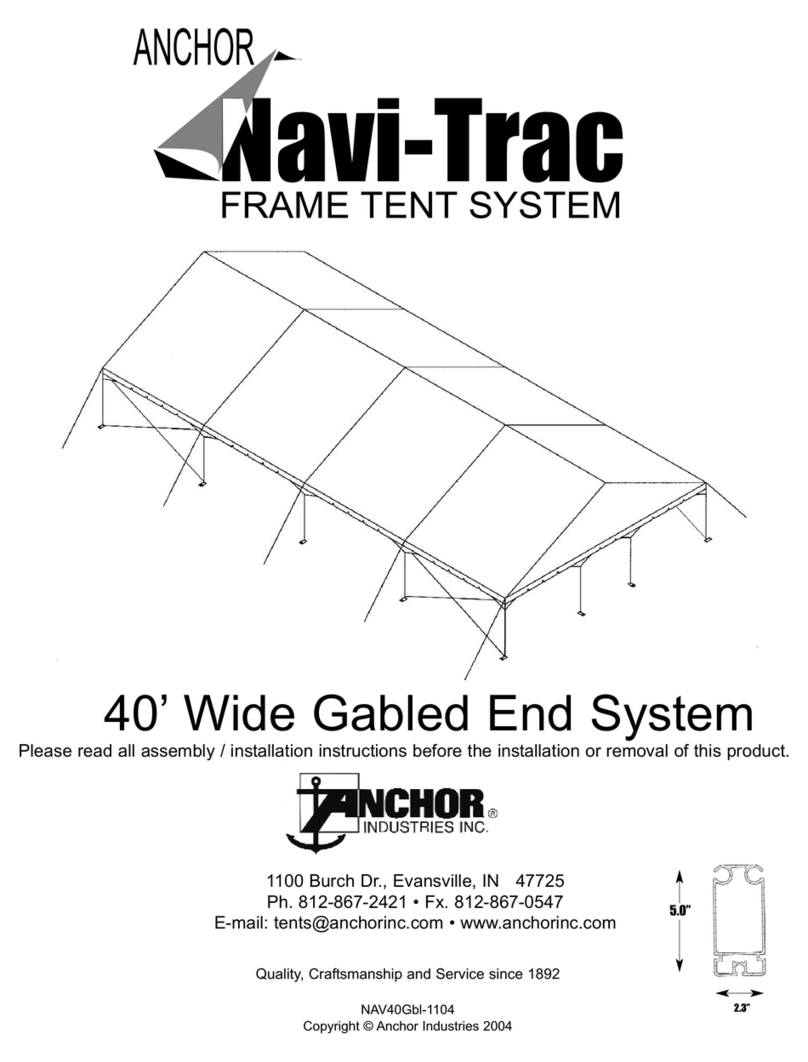

REAR VIEW

TOP VIEW

R/H SIDE VIEW

FRONT VIEW

INSIDE RAILS

SLOTED MOUNTING RAIL

OUTSIDE BODY

INSIDE MOUNTS

OVERALL INC GAS STRUTS

OPEN

CLOSED

REAR VIEW

TOP VIEW

FRONT VIEW

R/H SIDE VIEW

0985-08-RTT

Title

12345678

12345678

A

B

C

D

E

F

A

B

C

D

E

F

0985-08-RTT

Size

0985-08-RTT

Project

Title

Checked

A3

Sheet 1 Rev.

Date

Dwg No.

THIRD ANGLE

PROJECTION D.W. 9/07/2020

11:05 AM

Drawn

Scale 1:10

A

D.W

BOSS ALUMINIUM

This drawing remains the property of

Boss Aluminium P/L and must not be

copied or reproduced in any way or form

without the written consent of Boss

Aluminium P/L

COPYRIGHT 2020

Factory 8/208 Canterbury road Bayswater north

Victoria3153 Ph:03-9729-3092 Fax:03-9729-3263

AD

AD

1060.0

1060.0

1453.4

1512.7

1816.3

AEAE

351.6

269.1

40

2306.4

2383.6

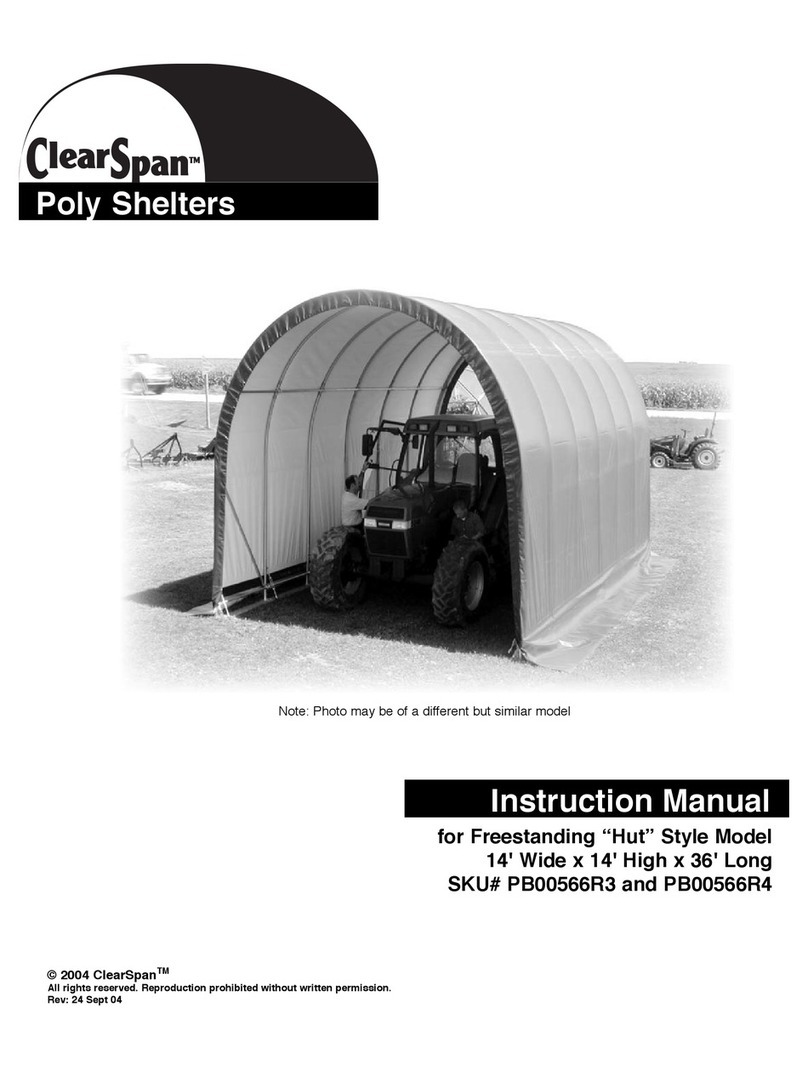

REAR VIEW

TOP VIEW

R/H SIDE VIEW

FRONT VIEW

INSIDE RAILS SLOTED MOUNTING RAIL

OUTSIDE BODY

INSIDE MOUNTS

OVERALL INC GAS STRUTS

OPEN

CLOSED

BOSS RT1 MOUNTING

• There are 2 slotted mounting rails that must be used to

mount the tent.

• Use 8 M8 bolts (4 on each side) to secure the tent to

your mounts.

• Ensure your mounts are adequite and hardware is tight.

0985-08-RTT

Title

12345678

12345678

A

B

C

D

E

F

A

B

C

D

E

F

0985-08-RTT

Size

0985-08-RTT

Project

Title

Checked

A3

Sheet 1 Rev.

Date

Dwg No.

THIRD ANGLE

PROJECTION D.W. 9/07/2020

11:05 AM

Drawn

Scale 1:10

A

D.W

BOSS ALUMINIUM

This drawing remains the property of

Boss Aluminium P/L and must not be

copied or reproduced in any way or form

without the written consent of Boss

Aluminium P/L

COPYRIGHT 2020

Factory 8/208 Canterbury road Bayswater north

Victoria3153 Ph:03-9729-3092 Fax:03-9729-3263

AD

AD

1060.0

1060.0

1453.4

1512.7

1816.3

AEAE

351.6

269.1

40

2306.4

2383.6

REAR VIEW

TOP VIEW

R/H SIDE VIEW

FRONT VIEW

INSIDE RAILS

SLOTED MOUNTING RAIL

OUTSIDE BODY

INSIDE MOUNTS

OVERALL INC GAS STRUTS

OPEN

CLOSED

CANVAS CARE

Before Use:

New canvas should be thoroughly wet before use and

allowed to dry.

• Boss Aluminium has wet the canvas once

• Repeat an additional 2-3 times to ensure sealing up of

the seams.

Maintaining Canvas Quality:

Clean only with cold water and brush - do not use soap

or detergent.

• Ensure product is completely dry prior to storage.

• Do not expose to petrol, oil or solvents.

• Restore well worn products with DYNAPROOF

CANVAS SPECIFICATIONS

WEIGHT:

• Dynaproofed: 275g/sq.m (8 oz) +/- 30gsm

CONSTRUCTION:

• Woven 65/35 Poly/Cotton Pla in Weave Japara

• 39.4 ends per cm. 26.8 picks per cm.

Yarn Count:

• 1/20 ECC x 1/20 ECC

Maximum Shrinkage

• 2% in Warp

Tear Resistance:

• WARP – 39N

• (AS 2001.2.10) WEFT – 28N

Breaking Force

• WARP – 1221N

• (AS 2001.2.3) WEFT – 1087N

Hydrostatic Head:

• 750mm min

• (AS 2001.2.17)

Cone Test:

• Pass

TELESCOPIC LADDER

Precautions

Safety Instructions

• Top of ladder and roof top tent locating pins are non-load bearing

• Do not stand on the top 3 steps/rungs

• Do not exceed 75°

• Ensure ladder is on an even, level and unmovable base

• Do not exceed maximum total load

• Always check that all buttons are on the “locked” position before you climb the ladder

• Always extend from the bottom rung

Before use:

• Ensure you are fit to use the ladder. Certain medical conditions, medications, alcohol or drug

use could make ladder use unsafe.

• When transporting ladders on roof racks or in trucks, ensure they are suitably placed and

secured to prevent damage.

• Inspect the ladder after delivery and before each use to confirm the condition and operation

of all parts.

• Visually check that the ladder is not damaged and is safe to use at the start of each working

day when the ladder is to be used.

• Ensure the ladder is suitable for the task at hand.

• Do not ever use a damaged ladder.

• Remove any contamination from the ladder, such as wet paint, mud, oil, ice or snow.

• Before use of the ladder in any work environment, a full risk assessment should be carried

out.

Positioning and erecting ladder

• Inclination angle should not exceed 75 degrees.

• Ladder should be on an even, level and unmovable base.

• The leaning ladder should be placed against a flat, non-fragile surface and should be

• secured before use, e.g. tied down or with an assistant standing on the bottom rung to secure

it.

• When positioning the ladder, take into account any risk of collision with the ladder from pe-

destrians, vehicles, doors or windows in the work area. Never set the ladder up in the

• vicinity of a closed fire exit as it may be opened urgently.

• Identify any electrical risks in the work area, such as overhead lines or other exposed electri-

cal equipment.

• The ladder should never be positioned on a slippery surface (such as ice, polished surfaces

or significantly contaminated solid surfaces) unless additional effective measures are

taken to prevent the ladder slipping.

Use of the ladder

• Do not exceed the maximum total load.

• Do not overreach. Users should keep the trunk of their body inside the stiles, with both feet on

the same step/rung throughout the task.

• Do not step off a leaning ladder at a higher level without additional security, such as tying off, or

the use of a suitable stability device.

• Do not use standing ladders to access another level.

• Do not stand on the top three steps/rungs of a leaning ladder.

• Ladders should only be used for light work of short durations.

• Do not use the ladder outside in adverse weather conditions, such as in a strong wind.

• Take precautions against children playing on the ladder.

• Face the ladder when ascending or descending.

• Keep a secure grip on the ladder when ascending or descending.

• Do not use the ladder as a bridge.

• Wear suitable footwear when climbing a ladder.

• Avoid excessive side loadings (e.g drilling brick or concrete)

• Do not spend long periods on a ladder without regular breaks.

• If you must use a ladder to gain access to a higher level, the top of the ladder should extend to

at least 1m above the landing point.

• Equipment to be carried while using a ladder should be light and easy to handle. If you are

lifting/lowering heavy or bulky equipment, the use of stairs, an elevator or a hauling bag with a

pulley system should be used.

Opening the Ladder

With automatic locking, each rung of the ladder has 2 locking pins that are blocked, which

are automatically inserted into the slots of the uprights when the ladder is extended.

The condition of the lock is indicated by the two black buttons on the side of each rung, as

shown below:

Complete Extension of the Ladder

1. Place the ladder onto firm and level ground, then place one foot on the lowest rung.

2. Lift the top rung up and ensure that the buttons are locked (as shown above) Repeat

this process with each of the lower rungs in turn, until the arms are completely extended.

Partial extension of the ladder

1. Place the ladder onto firm and level ground, then place one foot on the lowest rung.

2. Lift the top rung up and ensure that the buttons are locked (as shown above). Repeat

this process with each of the lower rungs until the desired ladder and rung height has

been achieved.

Shortening the Ladder

• Place the ladder on firm and level ground.

• Unlock the two buttons on the highest rung you can safely reach to lower the rung

down to the closed position. Continue doing this until the top rungs are all closed.

• Work your way down via each lower level, unlocking the buttons and then lowering

therungs until the ladder is all packed away.

Table of contents