Breezair MobileMAX III User manual

INSTRUCTION

MANUAL

FOR MODELS

MobileMAX II & MobileMAX III

High Performance Mobile

Evaporative Coolers

1. Safety Instructions

2. Assembly

3. Features

4. Operation

5. Maintenance

6. Replacement Parts

7. Troubleshooting

TM

SEELEY

|NTERNATnONAL

(Am e_icas)

Read this manual before

operating the product

Section 1 - SAFETY

WARNING: The warnings and

safety instructions in this

manual MUST be followed to

reduce the risk of fire, electric

shock, or injury, and to provide

reasonable safety and efficiency

in using this cooler.

The operator is responsible for

following the warnings and

instructions in this manual and

on the cooler. Read the entire

manual before using the cooler.

Restrict the use of this cooler to

persons who read, understand,

and follow the warnings and

instructions in this manual and

on the cooler. Never allow

children to operate this cooler.

Failure to observe these

warnings and instructions will

void manufacturer's warranties

and discharge manufacturer of

all liability.

CA UTION:

Always disconnect the cooler

from the power supply before

commencing maintenance

procedures.

During maintenance procedures

: NEVER use a naked flame for

any inspection or cleaning

purposes as a fire could be

caused as a result of a flame

coming into contact with the

cooler's structure.

Avoid Dangerous Situations:

Protect the cooler from all

sources of ignitions because

polymers and filter pads will

burn.

NEVER use a water hose to

squirt the cooler's interior for

cleaning as residual water

could damage electrical

components and create the risk

of fire and/or electric shock to

the user after re-assembly

Installation, Repair and

Operation

•All installation and repair work

must conform to local electrical,

water supply, environmental

codes, rules and regulations, and

applicable national standards.

Ensure compliance with local

regulations.

•Installation and repair work must

be done by a licensed and

qualified electrician and/or a

qualified experienced heating,

ventilation, air conditioning

technician. All installation and

repairs must be made with factory

authorized parts only.

• Use only approved replacement

parts for all electrical components.

If in doubt about what replacement

parts to use, do not guess,

contact Convair Cooler

Corporation.

Use of wrong replacement parts

creates risk of severe electric

shock and fire, which may result

in serious property damage,

personal injury or death.

•Use only thermal overload

protected pumps! Water pumps

may seize up and overheat,

creating a fire risk. Pumps that

have thermal overload protection

are designed to shut off electricity

to the pump if the pump seizes and

overheats.

•Use only water pumps with

three pronged grounded plugs!

Use of ungrounded plugs creates

risk of severe electrical shock and

fire. Never use pumps with bare

ended wires.

Water pump must be replaced

with authorized pump models

(See Appendix 1).

•Use only evaporative cooler

motors with thermal overload

protection! Evaporative cooler

motors may seize up and overheat,

creating a fire risk. Motors with

thermal overload protection are

designed to shut off the motor if

motor seizes and

See Appendix 1 for authorised

replacement fan motors.

The following safety requirements

should be met to ensure safe and

reliable operation of your new

cooler:

•This cooler is not flame

retardant. Polymers will burn if

ignited, protect cooler from all

sources of ignition (flame/

electrical shorts).

•Disconnect electrical power

before servicing, cleaning or

performing maintenance on the

cooler. Turn OFF the isolating

switch inside the cooler before

installing, servicing, cleaning or

performing maintenance on the

cooler.

• Use only a voltage supply as

shown on the name plate of the

motor.

• Before servicing the equipment

make certain children, people and

animals are a minimum of 30ft.

(lOm) away from the work area.

•Dress safely !,Jewellery, loose

clothing, clothing with loosely

hanging straps, ties, tassels, etc.,

can be caught in moving parts.

•Keep loose hair, fingers and all

other parts of the body away from

openings and moving parts.

• Check the cooler before

operation. Look for worn, loose,

missing or damaged parts. Do not

use the cooler until it is in proper

working order.

Section 1 - SAFETY & Section 2 -ASSEMBLY

•Avoid dangerous situations. Do

not use in the presence of

flammable fiquids or gases to

avoid creating a fire or explosion

and/or causing damage to this

cooler.

•Avoid any body contact with any

grounded conductor, such as a

metal pipe to avoid possibility of

electric shock.

• Ground Fault Circuit Interrupter

(GFCI) protection should be

provided on the circuit used for

this cooler. Receptacles are

available having butt-in GFCI

protection and may be used for

this measure of safety.

•Never drain the air cooler onto

the floor. Connect a hose from the

drain fitting to a drain or gutter.

Water residue could stain or cause

you to slip.

•Always use the correct tools.

WARNING:

The plastic

covering this

cooler

can be a safety

hazard

Please dispose

of thoughtfully.

This column is intentionally left

blank Removal & Replacement of

Pad Frames

Each pad frame is clipped into the

cooler and is removable by use of

a medium screwdriver inserted into

slots at the base of the sides and

levered downwards (see Fig. 1

,page 4). The side will then slide

down and out of the cooler cabinet.

To replace the pad frame, ensure

that it is the right way up, i.e. with

the water channel upwards.

Then fit the side in and up at the

top and then in at the bottom. Use

the screwdriver again, and insert it

between the bottom of the side and

the pan/tank wall at the center, and

lever upwards, until the side locks

into place.

Fitting the Wheels

Two wheels and two castors (with

brakes) are supplied with each

MobileMAX. They are packed

inside the cooler.

1. Remove the rear pad frame.

2. Remove the package of

castors, wheels and fasteners from

inside the cooler.

3. Carefully roll the cooler onto

one side, onto a piece of carpet or

cardboard so as not to damage the

cooler.

Warning :

Check to be sure that the voltage

rating of the cooler components is

compatabile with your electrical

voltage system

4. Fit the two fixed wheels to the

front of the mobile tank using the

screws provided (screw type). It is

not necessary to drill holes for

these screws. DO NOT

OVERTIGHTEN.

MobileMAX

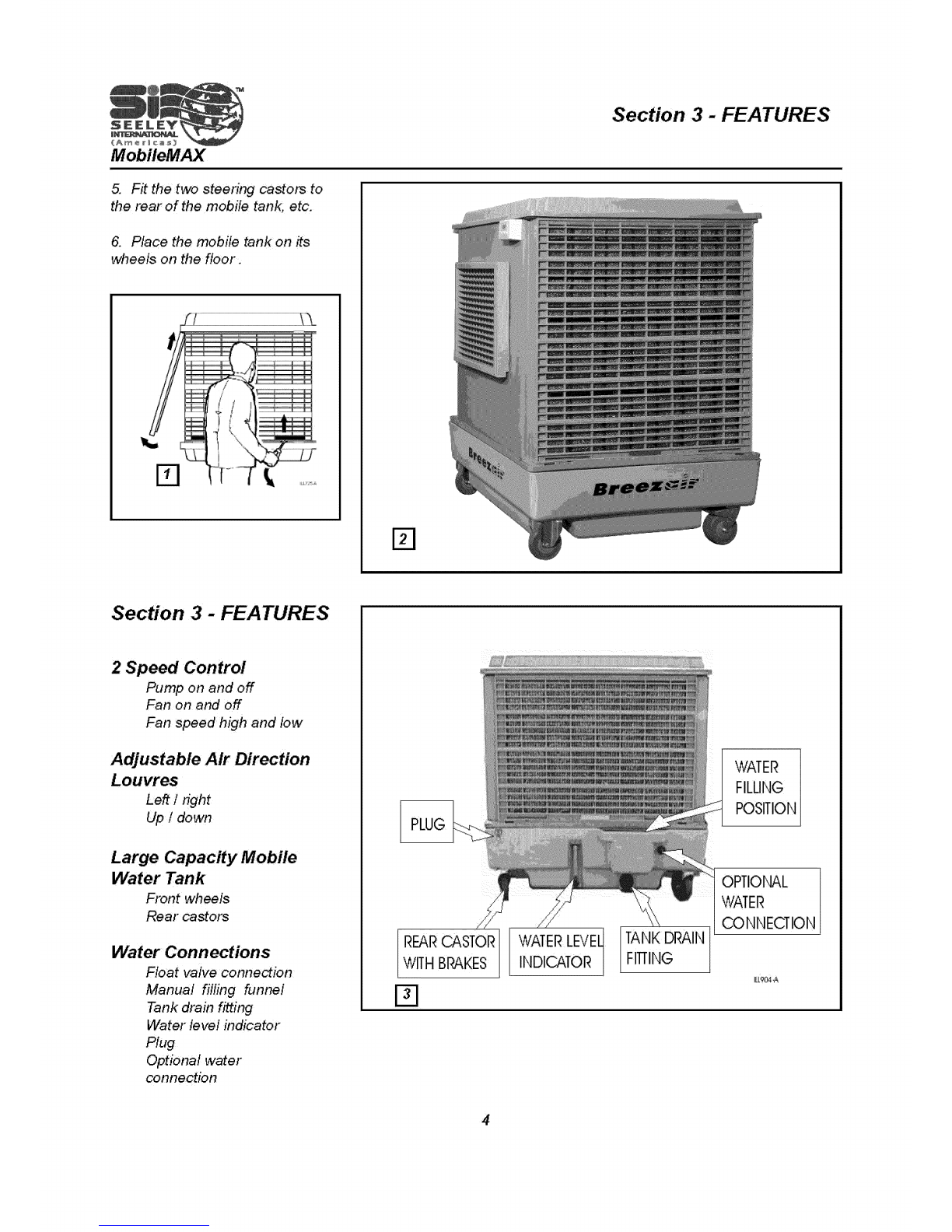

5. Fit the two steenng casto_ to

the rear of the mobile tank, etc.

6. Place the mobile tank on its

wheels on the floor.

Section 3-

2 Speed Control

Pump on and off

Fan on and off

Fan speed high and low

Adjustable Air Direction

Louvres

Left / fight

Up/ down

Large Capacity Mobile

Water Tank

Front wheels

Water Connections

Float valve connection

Manual filling funnel

Tank drain fitting

Water level indicator

Plug

Optional water

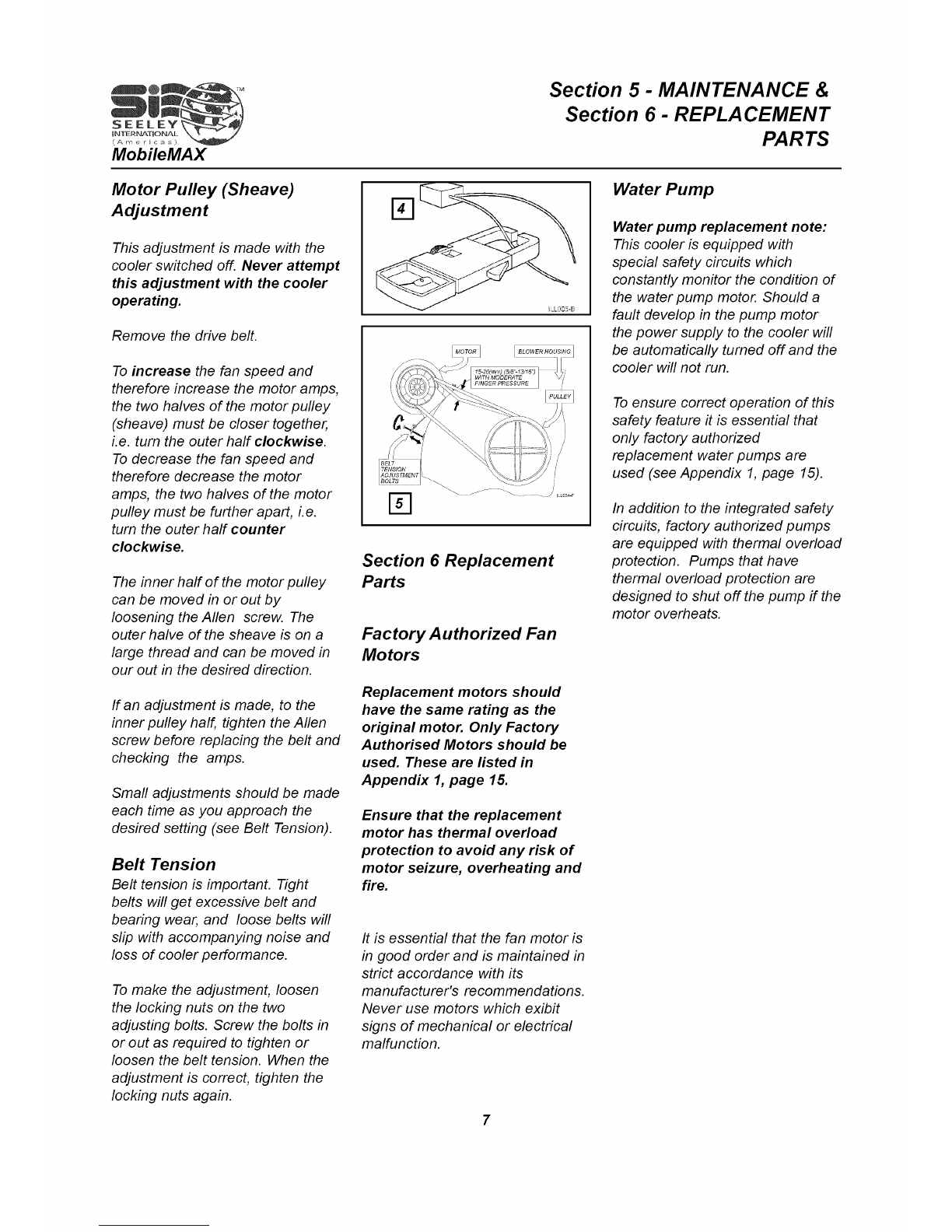

PLUG

REARCASTOR

WITHBRAKES WATERLEVEq

INDICATOR|

TANKDRAIN

FITTING

WATER

FILLI[IG

POSITION

OPTI©NAL

WATER

CO Nr,,IECTIOI',,I

I[L'?04-A

4

Section 4 - OPERATION & Section 5 - MAINTENANCE

Location & Orientation

When choosing a location for

the cooler, maintain asafe

distance from flame or other

possible sources of ignition and

ensure compliance with local

regulations.

Using your Cooler

To operate effectively, evaporative

air coolers always need to function

on 100% fresh outside air. Always

locate the cooler where it will

receive a plentiful supply of fresh

air and not in an area where it

may be starved for air or where the

air is polluted.

Open or provide exhaust outlets in

the building you are cooling. Such

outlets may be provided by the

opening of doors and/or windows.

Locate the cooler close to an

opening but blowing into an area to

be cooled.

If the design of your building does

not allow such easy exhaust

provisions, then you must install

mechanical ventilation, such as an

exhaust fan which can extract

approximately 80% of the air that

the cooler is discharging.

Generally, the higher the ambient

relative humidity, the higher the air

quantity required from the cooler.

You should therefore control the

speed of your cooler accordingly,

On very dry days the cooler will

give maximum cooling and this will

decrease as the humidity

increases.

Never allow cooler air to be

discharged into a closed space,

# must always be allowed to

exhaust out.

You can keep your building cool for

about 1/4 of the cost of refrigerated

air conditioning.

The outlet grille for your Convair

MobileMax has four way adjustable

direction Iouvres.

Keep Iouvres as wide open as

possible for maxiumum effect.

Cooler Operating

Instructions

•Fill the tank, or if connected via a

hose, turn on the water supply at

the source.

•The Cooler's tank may be filled

by bucket, hand-held hose or

automatically via the float valve by

connecting a high pressure hose.

• For extended pad life and

effective cooling your Convair

MobileMax needs a continuous

supply of good quality water.

• Turn on the electrical power at

the source.

• Wait ten (10) minutes for the

water to fill the cooler pan/tank.

• Watch the water level indicator,

do not overfill the tank at any time.

• Using the switch on the front of

the cooler, turn on the pump only

to properly wet the pads. Run for

five (5) minutes.

• Select LOWfan speed at the fan

switch.

• At times when the outside

humidity is high, you may feel

more comfortable by turning off the

pump and running the fan only,

This will not cause any damage

to the pump. High speed - no

pump for high humidity, low

speed - pump on low humidity.

• Ensure there are exhaust

openings in the building.

Section 5 Maintenance

Allow for adequate access around

the cooler when performing

maintenance.

Provision must be made for

access to electricity and water

supplies.

Never force parts together, all

parts are designed to fit together

easily without undue force.

Pre-Season Maintenance

• Turn off the electric power

supply.

• Tum off the water supply.

• Remove the pad frames.

• Fit new pads if necessary. The

frequency of replacement depends

on the condition of the

environment and the water.

The pads supplied have been

selected to give the highest

possible cooling performance. Do

not use alternatives. The

manufacturer is not responsible

for the performance of the cooler

when alternative pads are used.

When replacing the pads, ensure

the material is evenly distributed

across the entire frame to a

thickness of about 2". Regular

"thin" pads will reduce the cooling

efficiency of the cooler. Particular

attention must be given to the

comers of the pad frames. Avoid

gaps and holes in the pad.

Daily Maintenance

• Drain the water from the tank

and refill with fresh water

Section 5 - MAINTENANCE

•If the pads are reused they can

be easily cleaned by squirting them

with a hose. Do not use excess

pressure. This may create holes in

the pad.

• Remove the pad from the pad

frame, clean, and evenly

redistribute the wood wool over the

pad. Re-assemble the pad frame

• Inspect the pump and check that

it will freely rotate by hand. If it is

jammed with salt build-up, then

remove it and clean it thoroughly.

After cleaning the pump replace it

into the cooler, making sure that it

is securely in place.

• Check belt tension and adjust if

necessary.

• Lubricate motor bearings (if oiler

fitted) -only lightly.

• Replace the pad frames.

• Refill the tank.

• Restore electrical power supply

and follow Operating Instructions.

In-Season Maintenance

DAILY"

• Drain the water from the tank and

refill with fresh water,

MONTHLY

• Tum off the electrical power

supply.

• Remove the pad frames.

• Inspect the pads and clean or

replace the material as required

(see Pre-Season Maintenance).

•Check the water level and adjust

the float if necessary.

•Check the pump operation.

• Clean the tank.

• Replace the pad frames.

• Restore electrical power supply

and follow Operating Instructions.

• Check that the wood-wool is

evenly distributed, and that there is

no gaps.

End Season Maintenance

• Tum off electrical power supply.

• Tum off water supply if

connected.

• Remove the pad frames. Hose

them down carefully, do not use

excess pressure as this may

create holes in the pad material

(see Pre-Season Maintenance).

• Remove and clean the special

patented water "spreader plates"

located under the top panel of the

cooler, above each pad frame (see

Fig. 12, page 10, item 43). When

replacing them, ensure the

spreader is correctly locating in the

notches under the top panel,

halfway along the side.

It should not be necessary to

remove the spreader from the

hoses, simply clean them at the

cooler.

• Drain all the water from the

cooler.

• Clean the bottom pan/tank

thoroughly.

• Disconnect the water supply line.

Leave disconnected until next

season to prevent freezing and

splitting.

• Replace the pad frames.

• Cover the cooler for the winter or

store indoors.

Motor Power (Amps)

Your cooler is fitted with an

adjustable motor pulley (sheave) to

enable the cooler to provide

maximum cooling. The adjustment

of the pulley must be done by a

trained, licensed technician using a

clip on ammeter Maximum amps

should not exceed the motor

nameplate amps.

Install all pad frames, except the

one on the motor side.

Set the cooler running at highest

speed for approximately ten (10)

minutes or until the motor has

reached its normal operating

temperature. Motor load must be

checked without the water pump

running.

Locate the motor current test wire

in the terminal box. Measure the

motor current using a clip-on

ammeter (see Fig. 4, page 7). This

should be done by a trained,

licensed technician. Check the

measured amps against the

motor's nameplate rating.

If the measured amps are less

than the nameplate amps the

adjustable pulley may be altered to

increase the fan speed, thereby

delivering the full cooler capability

to your installation. The measured

amps should be equal or very

close to the motor's nameplate

amps (see heading Pulley

[Sheave] Adjustment below).

If the measured amps are

greater than the nameplate

amps the fan must be slowed by

adjusting the same pulley in the

opposite direction. Failure to do

this will overheat the motor

which may result in a fire.

Replace all covers when

adjustments are complete.

Section 5 - MAINTENANCE &

Section 6 - REPLA CEMENT

PARTS

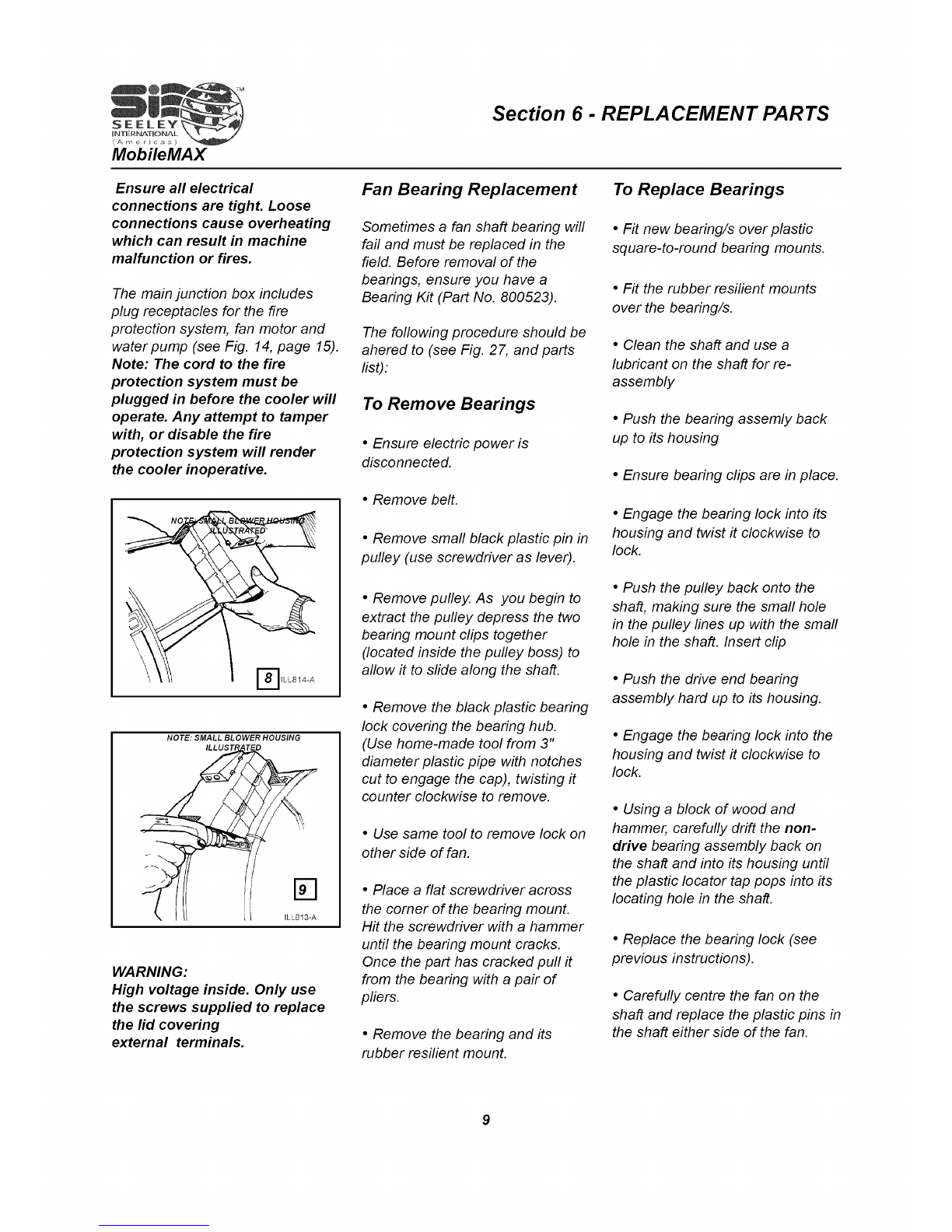

Motor Pulley (Sheave)

Adjustment

This adjustment is made with the

cooler switched off. Never attempt

this adjustment with the cooler

operating.

Remove the drive belt.

To increase the fan speed and

therefore increase the motor amps,

the two halves of the motor pulley

(sheave) must be closer together,

i.e. turn the outer half clockwise.

To decrease the fan speed and

therefore decrease the motor

amp& the two halves of the motor

pulley must be further apart, i.e.

turn the outer half counter

clockwise.

The inner half of the motor pulley

can be moved in or out by

loosening the Allen screw. The

outer halve of the sheave is on a

large thread and can be moved in

our out in the desired direction.

If an adjustment is made, to the

inner pulley half, tighten the Allen

screw before replacing the belt and

checking the amps.

Small adjustments should be made

each time as you approach the

desired setting (see Belt Tension).

Belt Tension

Belt tension is important. Tight

belts will get excessive belt and

bearing wear, and loose belts will

slip with accompanying noise and

loss of cooler performance.

To make the adjustment, loosen

the locking nuts on the two

adjusting bolts. Screw the bolts in

or out as required to tighten or

loosen the belt tension. When the

adjustment is correct, tighten the

locking nuts again.

Section 6 Replacement

Parts

Factory Authorized Fan

Motors

Replacement motors should

have the same rating as the

original motor. Only Factory

Authorised Motors should be

used. These are listed in

Appendix 1, page 15.

Ensure that the replacement

motor has thermal overload

protection to avoid any risk of

motor seizure, overheating and

fire.

It is essential that the fan motor is

in good order and is maintained in

strict accordance with its

manufacturer's recommendations.

Never use motors which exibit

signs of mechanical or electrical

malfunction.

Water Pump

Water pump replacement note:

This cooler is equipped with

special safety circuits which

constantly monitor the condition of

the water pump motor. Should a

fault develop in the pump motor

the power supply to the cooler will

be automatically turned off and the

cooler will not run.

To ensure correct operation of this

safety feature it is essential that

only factory authorized

replacement water pumps are

used (see Appendix 1,page 15).

In addition to the integrated safety

circuits, factory authorized pumps

are equipped with thermal overload

protection. Pumps that have

thermal overload protection are

designed to shut off the pump if the

motor overheats.

Section 6 - REPLACEMENT PARTS

Motor Connection (non

Seeley motors)

The new cooler is supplied with a

special motor cord. If replacing

motor, remove cord from old motor

and connect to new motor as

follows:

green/green-yellow- to motor

grounding screw

black -high speed

red / brown -low speed

white / blue -common / neutral.

WARNING:

Take care to ensure correct

connection of fan motor.

Incorrect connection can create

a risk of electric shock or fire.

Replace the electrical connection

coven Place the motor into the

cradle so that the motor shaft

protrudes at the same side as the

fan pulley; fit the clamps (with the

heads of the screws facing you)

and tighten securely.

When placing the motor in the

cradle, rotate it so that the vent

holes are positioned in accordance

with the motor manufacturer's

recommendations. Ensure the cord

is not stressed in any way.

Take the adjustable aluminium

motor pulley and slide it onto the

motor shaft with the adjustable side

of the pulley towards the end of the

shaft, making sure that the Allen

screw will tighten down onto the

"flat" on the motor shaft.

Now align the motor and fan

pulleys. It is essential that the

pulleys are correctly aligned. Poor

alignment will cause excessive

belt, pulley and bearing wear.

The correct alignment of the

pulleys and the tightening of the

motor pulley (sheave) onto the

"flat" of the shaft is most important

to ensure successful transmission

of the motor power (torque) to the

fan and prevent slipping.

Electrical Installation

Wiring must comply with local

codes and regulations and should

only be carried out by a trained,

licensed technician.

Wiring must be rated to carry at

least the nameplate current

(amperes) of the fan motor and

must be protected by a suitable

fuse or circuit breaker.

The main junction box is factory

sealed, do not attempt to open

this junction box, there are no

field terminations or serviceable

parts within.

O

WASHERS

UNDERNEATH

BOLTHEAD

BELT

TENSION

ADJUSTING

NUTS

BRACKET

MOTOR

HOUSING

BOOT

MOTOR

MOUNTING

PLATE

SCROLL NO WASHERS ILL016

Ensure all electrical

connections are tight. Loose

connections cause overheating

which can result in machine

malfunction or fires.

The main junction box includes

plug receptacles for the fire

protection system, fan motor and

water pump (see Fig. 14, page 15).

Note: The cord to the fire

protection system must be

plugged in before the cooler will

operate. Any attempt to tamper

with, or disable the fire

protection system will render

the cooler inoperative.

NOTE: SMALL BLOWER HOUSING

TED

WARNING:

High voltage inside. Only use

the screws supplied to replace

the rid covering

external terminals.

Section 6 - REPLACEMENT PARTS

Fan Bearing Replacement

Sometimes a fan shaft bearing will

fail and must be replaced in the

field. Before removal of the

bearings, ensure you have a

Bearing Kit (Part No. 800523).

The following procedure should be

ahered to (see Fig. 27, and parts

list):

To Remove Bearings

•Ensure electric power is

disconnected.

• Remove belt.

• Remove small black plastic pin in

pulley (use screwdriver as lever).

•Remove pulley. As you begin to

extract the pulley depress the two

bearing mount clips together

(located inside the pulley boss) to

allow it to slide along the shaft.

•Remove the black plastic bearing

lock covering the bearing hub.

(Use home-made tool from 3"

diameter plastic pipe with notches

cut to engage the cap), twisting it

counter clockwise to remove.

•Use same tool to remove lock on

other side of fan.

• Place a flat screwdriver across

the comer of the bearing mount.

Hit the screwdriver with a hammer

until the bearing mount cracks.

Once the part has cracked pull it

from the bearing with a pair of

pliers.

•Remove the bearing and its

rubber resilient mount.

To Replace Bearings

•Fit new bearing/s over plastic

square-to-round bearing mounts.

•Fit the rubber resilient mounts

over the bearing/s.

•Clean the shaft and use a

lubricant on the shaft for re-

assembly

•Push the bearing assemly back

up to its housing

•Ensure bearing clips are in place.

•Engage the bearing lock into its

housing and twist it clockwise to

lock.

•Push the pulley back onto the

shaft, making sure the small hole

in the pulley lines up with the small

hole in the shaft. Insert clip

•Push the drive end bearing

assembly hard up to its housing.

•Engage the bearing lock into the

housing and twist it clockwise to

lock.

•Using a block of wood and

hammer, carefully drift the non-

drive bearing assembly back on

the shaft and into its housing until

the plastic Iocator tap pops into its

locating hole in the shaft.

•Replace the bearing lock (see

previous instructions).

• Carefully centre the fan on the

shaft and replace the plastic pins in

the shaft either side of the fan.

Exploded Diagrams

Bearing

LOOI¢ _t01JNT

vS

INgO PtSLLtTY

Section 6- REPLACEMENT PARTS

Drive S

@

Unit

14

ILL835-B

/

/

,/

i

@10

MobileMAX

ITEM

1

2

3

4

5

6

7

8

9

10

13

15

17

18

19

20

21

22

23

24

25

27

28

29

DESCRIPTION

PAN/TANK

LID

PANEL FRONT

PAD FRAME

PAD ASSEMBLY

WIRE ASSEMBLY

POST CORNER

SCROLL L/H (MOTOR)

SCROLL R/H

PLATE CUTOFF

BAFFLE

SEALING TAPE

PLATE MOTOR MOUNT

BOLT CUP HEAD

WASHER MIO x 21 x 1.6ZP

NUT WHIZ M8ZN

BRA CKE T MOTOR MOUNT

ADJUSTING

BOLT

BOOT

RIVETS & WASHERS (FOR PLATE

MOTOR MOUNT NOT ILLUSTRATED

PLUG HOLE TRANSITION

PUMP MOTOR

MOTOR

JUNC TION/TERMINAL BOX

QTY

1

1

1

3

3

3

4

1

1

1

2

1

4

2

8

2

2

2

1

1

1

Section 6-REPLACEMENT PARTS

ITEM

3O

31

32

33

34

35

36

37

38

39

4O

42

43

44

45

46

47

48

49

5O

51

52

53

54

55

56

DESCRIPTION

FAN CENTRIFUGAL

SHAFT (FAN)

BEARING

MOUNT RESILIENT BEARING

MOUNT BEARING (NON DRIVE END

MOUNT BEARING (DRIVE END)

LOCK BEARING (NON DRIVE END)

LOCK BEARING (DRIVE END)

PULLEY FAN (205 or 225)

PULLEY MO TOR ADJUS TABLE

PIN BLACK PLASTIC

V-BELT

SPREADER

4 WAY DISTRIBUTOR

PVC TUBE 3/4" (ID)

PVC TUBE 1/2" (ID)

FIRE DETECTOR (If used)

BOTTLE (RESERVOIR)

SPRINKLER AND TEE-PIECE ASSY

FLOAT VALVE ASSEMBLY

NUT

GRILLE

GRILLE MOUNT

CASTOR (LOCKING)

SCREW M8 x 75 (NOT ILLUSTRATEE

CASTOR WHEELS

QTY

1

1

2

2

1

1

1

1

1

1

3

1

3

1

1

1

1

1

1

1

1

2

11

Section 7- TROUBLESHOOTING

This is a list of some common service problems, with probable causes and suggested remedies.

PROBLEM PROBABLE CAUSE SUGGESTED REMEDY

Inadequate cooling Insufficient fresh air. Ensure cooler is located adjacent

to a door or adequate fresh air

supply.

Insufficient air discharge openings

or inadequate exhaust from area

being cooled, causing high

humidity and discomfort.

Undersized cooler.

Clogged or dirty filter pads.

Dry pads or lack of water while

cooler is in operation.

Excessive Ambient Humidity (see

also item above re: inadequate

exhaust).

Fan turning backwards.

Fan running too slow.

Belt slipping.

Faulty water pump.

NOTE: This cooler is equipped

with an electronic safety system

which continuously monitors the

condition of the water pump. This

safety system will automatically

turn the isolating switch to OFF

position when a water pump defect

is detected.

Make sure there is adequate

provision for exhausting air from

area being cooled (open windows

and/or doors).

Replace with larger cooler or

additional coolers.

Clean or replace pads.

Check water distribution system for

possible obstruction in tubing.

Check Pump.

On days during the summer when

the ambient humidity is high, the

cooler will not reduce temperature

as much as on drier days. There is

no remedy except to shut off the

pump.

Reconnect motor for correct

rotation.

Check motor amps. If below name

plate amperage, re-adjust motor

(sheave) pulley to increase fan

speed.

Tighten belt by re-adjusting

position of motor. Replace belt if

worn.

Replace the water pump and reset

the isolating switch to ON position.

12

Section 7- TROUBLESHOOTING

This is a list of some common service problems, with probable causes and suggested remedies.

PROBLEM

Fan fails to start (cont.)

Belt Slipping or wearing

excessively

PROBABLE CAUSE

Circuit breaker tripped or fuse

blown.

Loose electrical connections.

Defective control switch.

Motor bumed out.

Belt or pulley loose.

Belt broken or missing.

Belts too tight.

Wrong setting of adjustable motor

pulley (sheave) causing motor

overload.

Low system voltage.

Incorrect motor, motor has been

changed and wrong size fitted.

Belt loose.

Pulleys out of fine.

Moisture getting on belt.

Worn belts.

Worn or imperfect pulleys.

SUGGESTED REMEDY

Reset circuit breaker or replace

fuse. See procedure Section 1 -

Safety.

Check all electrical connections.

Replace.

Replace.

Tighten belt and pulleys.

Install new belt.

Adjust belt tension.

Adjust pulley (sheave) so motor

amperes do not exceed full load

amperes shown on motor

nameplate (see earlier instruction

in this manual).

Consult with Electrical Authority if

voltage is low.

Fit correct size motor.

Tighten belt.

Align pulleys.

Stop any water leaks.

Replace belts.

Replace pulleys.

Pump fails to operate Pump motor failure.

Incorrect wiring of pump motor and

control switch.

Loose electrical connections.

Pump control switch faulty.

13

Replace complete pump.

Correct wrong electrical

connection.

Tighten electrical connections.

Replace pump control switch.

Section 7- TROUBLE SHOOTING

This is a list of some common service problems, with probable causes and suggested remedies.

PROBLEM PROBABLE CAUSE SUGGESTED REMEDY

Pump fails to operate (cont.) Insufficient water in pan/tank. Refill water tank.

Pump strainer blocked. Clean strainer.

Blocked water tubing. Clean the tubing.

Foreign material lodged in the

"water spreader/s" Remove spreader/s and clean out

foreign material.

Noisy Air Cooler Fan out of balance due to dirt, etc. Clean fan.

Cooler delivering more air than

needed. Adjust motor pulley (sheave) to

slow down fan.

Belt "squealing',. Tighten belt by adjusting motor.

Apply belt dressing to belt. In some

cases it may be necessary to

replace belt or pulley.

Water being thrown into room Loose water tubing connections. Tighten all connections.

Break in water tubing. Replace any cracked or broken

tubing.

Pads not properly installed in pad

frames. Make sure pads are properly

installed.

Incorrect or damaged pads fitted. Replace with the manufacturer's

recommended pads.

Overflow of water Float valve not sealing properly. Clean or replace valve washer.

Unpleasant Odour New cooler pads. Run pump continuously for a while

to flush the pads.

Cooler located near source of

unpleasant odor. Remove source of odor or place a

barrier between cooler and source

of odor.

Algae in pan/tank water. Drain pan/tank and clean

thoroughly. Fill with fresh water.

Install new pads.

Pads remain wet after shut down. Allow fan to run for about ten (10)

minutes after pump is shut off to

dry out pads.

Rapid formation of white

deposits on Pads and Louvres High mineral content of supply

water. Drain water from tank more

regularly and refill with fresh water.

14

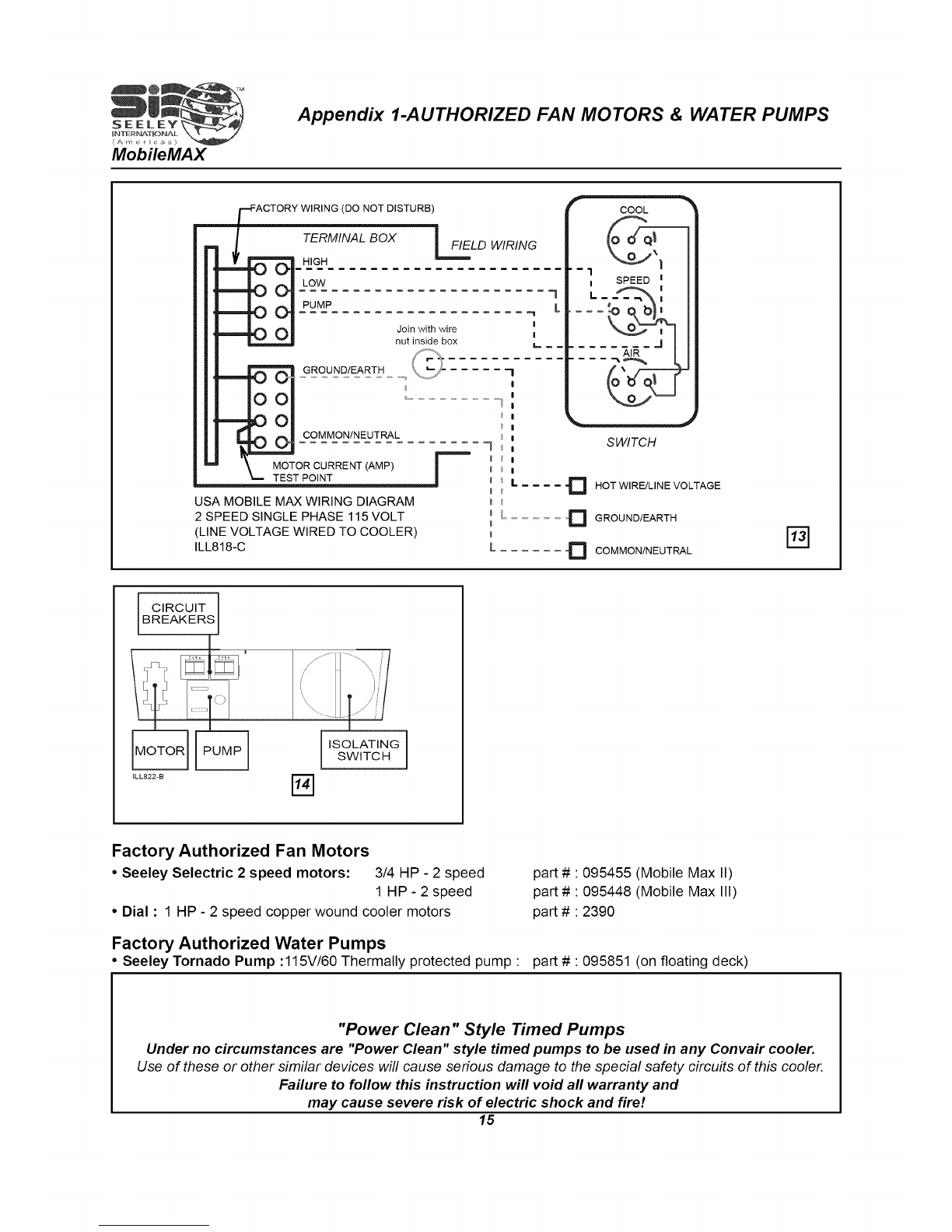

Appendix 1-AUTHORIZED FAN MOTORS & WATER PUMPS

(DO NOT DISTURB)

m

TERMINAL BOX IFIELD WIRING

HIGH

PUMP

GROUND/EARTH

COMMON/NEUTRAL

MOTOR CURRENT (AMP)

TEST POINT

USA MOBILE MAX WIRING DIAGRAM

2 SPEED SINGLE PHASE 115 VOLT

(LINE VOLTAGE WIRED TO COOLER)

ILL818-C

SWITCH

D HOTWIRE/LINE VOLTAGE

_'D GROUND/EARTH

D COMMON/NEUTRAL

CIRCUIT

BREAKERSJ

tLL822-B %ISOLATING

SWITCH

Factory Authorized Fan Motors

•Seeley Selectric 2 speed motors: 3/4 HP - 2 speed

1 HP- 2 speed

• Dial : 1 HP - 2 speed copper wound cooler motors

Factory Authorized Water Pumps

•Seeley Tornado Pump :115V/60 Thermally protected pump •

part # 095455 (Mobile Max II)

part # 095448 (Mobile Max III)

part # •2390

part # •095851 (on floating deck)

"Power Clean" Style Timed Pumps

Under no circumstances are "Power Clean" style timed pumps to be used in any Convair cooler.

Use of these or other similar devices will cause serious damage to the special safety circuits of this cooler.

Failure to follow this instruction will void all warranty and

may cause severe risk of electric shock and fire!

15

Owners Name:

Appendix 2 - CHECK LIST

Telephone:

Address:.

Dealer:

Installer:

Date Installed:

Model No.:

Serial No.:

Motor Type:

Motor H.R:

1202 N 54th Ave

Building 2 Suite 117

PHOENIX AZ 85043

Phone:l-602-353 8066

Fax:l-602-353 8070

SERVICE ENQUIRIES:

Contact your local Retailer.

As the policy of the Company is one

of continuous product improvement,

D

Belt tension and alignment correctly adjusted.

Fan runs in correct direction at all speeds (clockwise when

viewed from pulley side).

Motor amps tested at high speed with vents and windows

open.

Amps input to motor recorded High amps

Low amps

Motor and pump are properly plugged into sockets.

Fire protection system plugged in.

Motor pulley adjusted and tight on shaft.

Drain fitting correctly installed.

Water level and float adjustment checked.

Pump runs and water evenly distributed to all filter pads.

All control functions checked.

Owner instructed in correct operating proceedure and

supplied with operating instructions.

16 609324-B 0607

DO NOT OPERATE COOLER UNTIL THE CHECKLIST

BEL OW HAS BEEN SATISFACTORILY COMPLETED

This manual suits for next models

1

Table of contents