brewer AssistPRO User manual

Document # 101522 0608 REV A ER 784

Installation & Operation Manual

Important Information ............................................2

Safety Information .................................................3

Component Identication ......................................3

Specications ........................................................4

Electrical Requirements ........................................4

Installation .............................................................5

Operation ..............................................................8

Table Adjustments............................................... 11

Maintenance........................................................19

Limited Warranty .................................................19

Document # 101522 0608 REV A ER 784 2

Service

If you require assistance with the installation or operation of your

AssistPRO,

call the Brewer Customer Service Department at

1-800-558-8777. Our trained staff will assist you in attempting to

correct the problem directly over the phone. If service is required,

a factory authorized technician will be sent to your location.

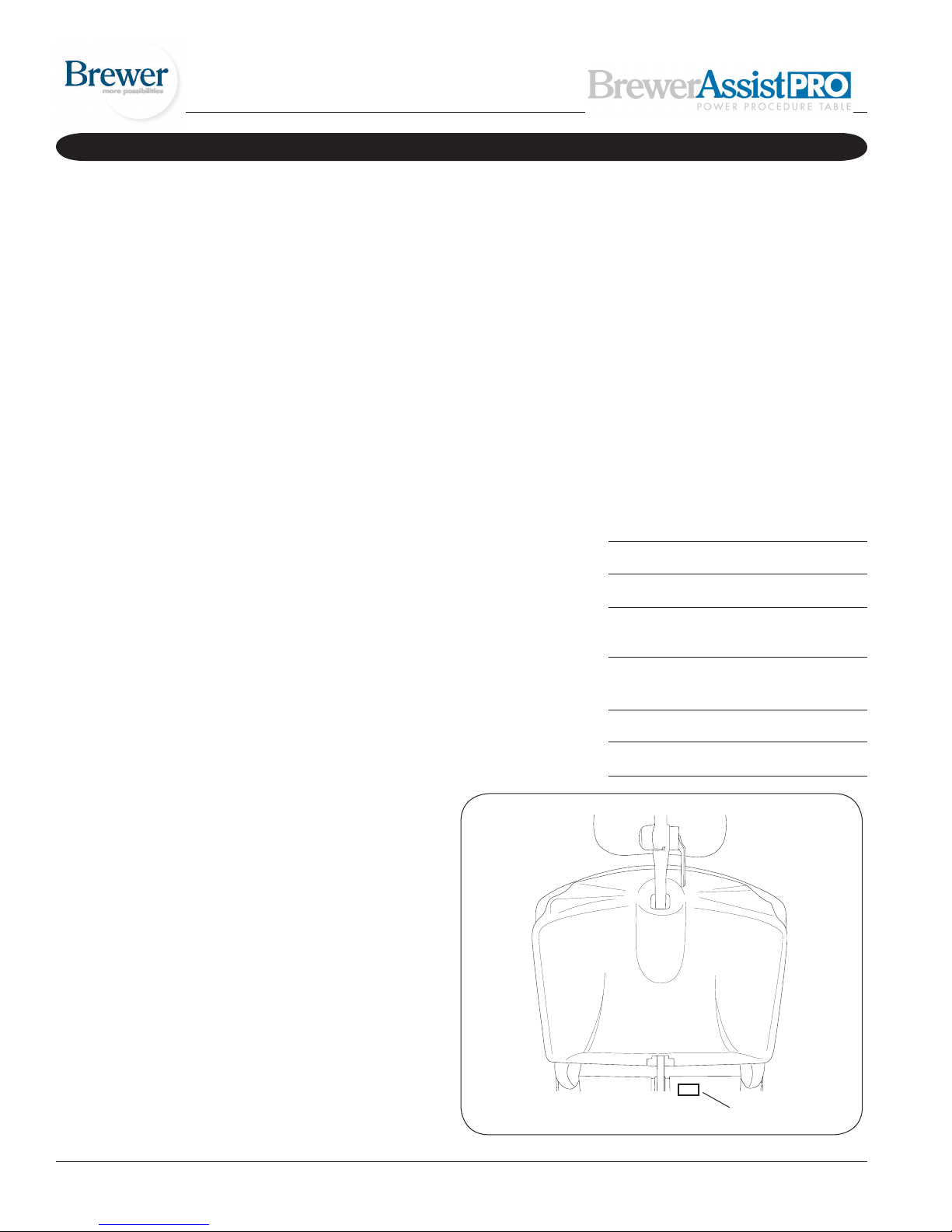

Please ll in the following information for use when calling the

Brewer Company or your distributor with questions regarding

your unit. See Figure 1 for model and serial number location.

Date of Purchase

Serial Number

Model Number

Authorized

Dealer Name

Dealer

Phone Number

Dealer Address

IMPORTANT INFORMATION

General

The AssistPRO is designed to provide positioning and

support of patients during general examinations con-

ducted by qualied medical professionals. Read and

understand all operating instructions, safety information,

and maintenance requirements contained in this manual

prior to operating the table. Become familiar with all of

the table functions before using it with a patient.

The AssistPRO is primarily used in examination rooms

for general examinations and minor procedures. The

wide variety of positions, adjustable legrest, adjustable

headrest, stirrups, and treatment pan, create a safe and

convenient patient positioning table.

Controlled via the hand pendant or foot control, four pow-

ered motions easily adjust the table into a wide variety

of positions. The table ascends to 40” high, and can be

lowered to 19” (thereby providing easier wheelchair trans-

fer). The seating surface can be tilted from a horizontal

position to an angled position of up to 30º. The backrest

can be adjusted from a at position to an 85º angle for

seating. Finally, the legrest can be adjusted from a verti-

cal position for seating, to a horizontal position for laying.

The AssistPRO is also capable of storing four preferred

positions ino the tables memory. Utilizing an intuitive two

step programming method, the user can recall any pro-

grammed position with the touch of a button. See page 14

for complete programming instructions.

In addition to the electronically controlled positions noted

above, several manual adjustments are available:

1. The legrest can be manually adjusted from a sitting to

a kneeling position.

2. With the table in the horizontal position, the legrest

can be extended an additional 5” for tall patients.

3. Stirrups may be manually extended and positioned

anywhere within the lateral range of travel.

4. A removable treatment pan is housed underneath the

front of the seat for easy access. Simply pull the tray

out for use during examinations.

5. A three point pivot system allows the user to adjust

the angle and position of the headrest.

6. The backrest incorporates a self-storing paper roll.

The table is designed to accommodate a maximum

patient weight of 450 lbs.

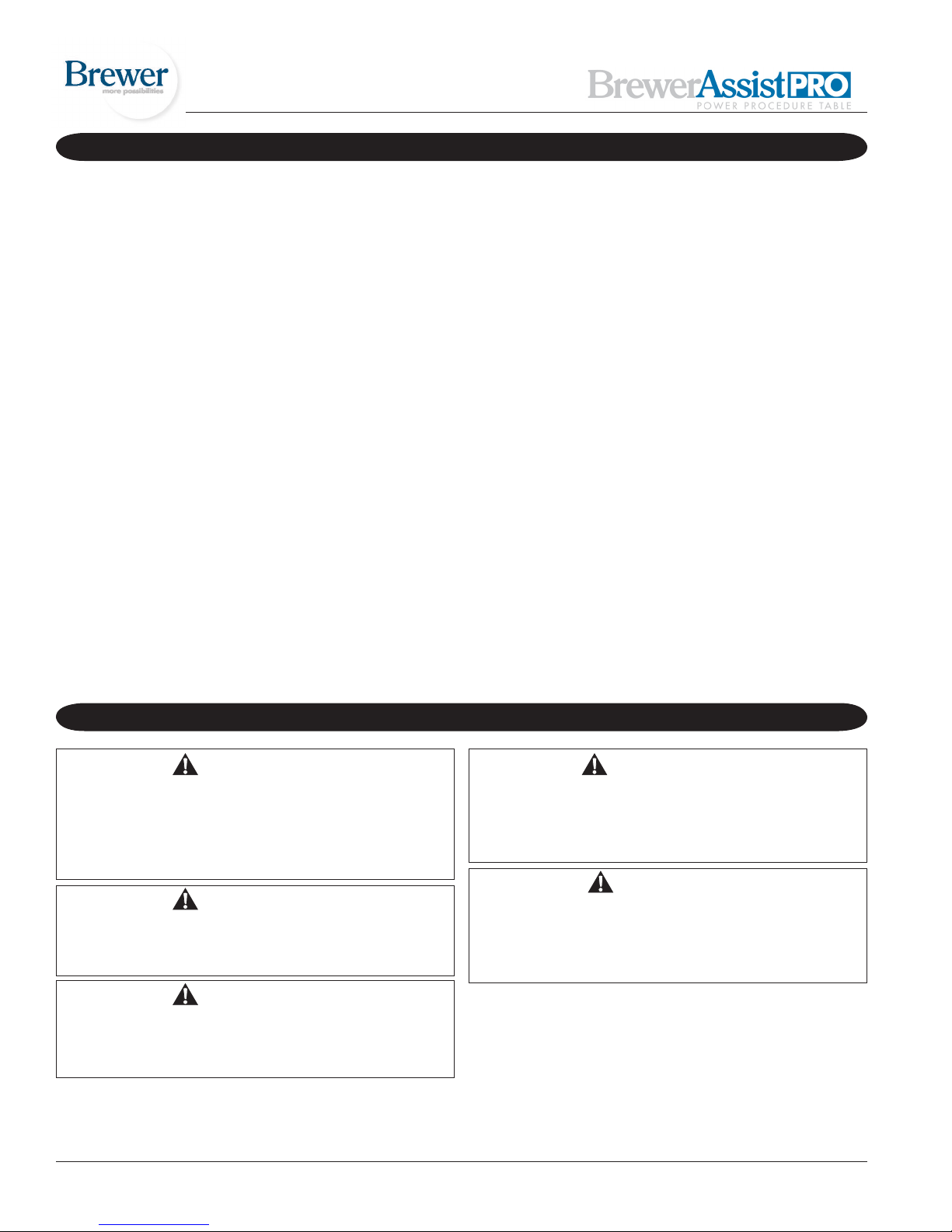

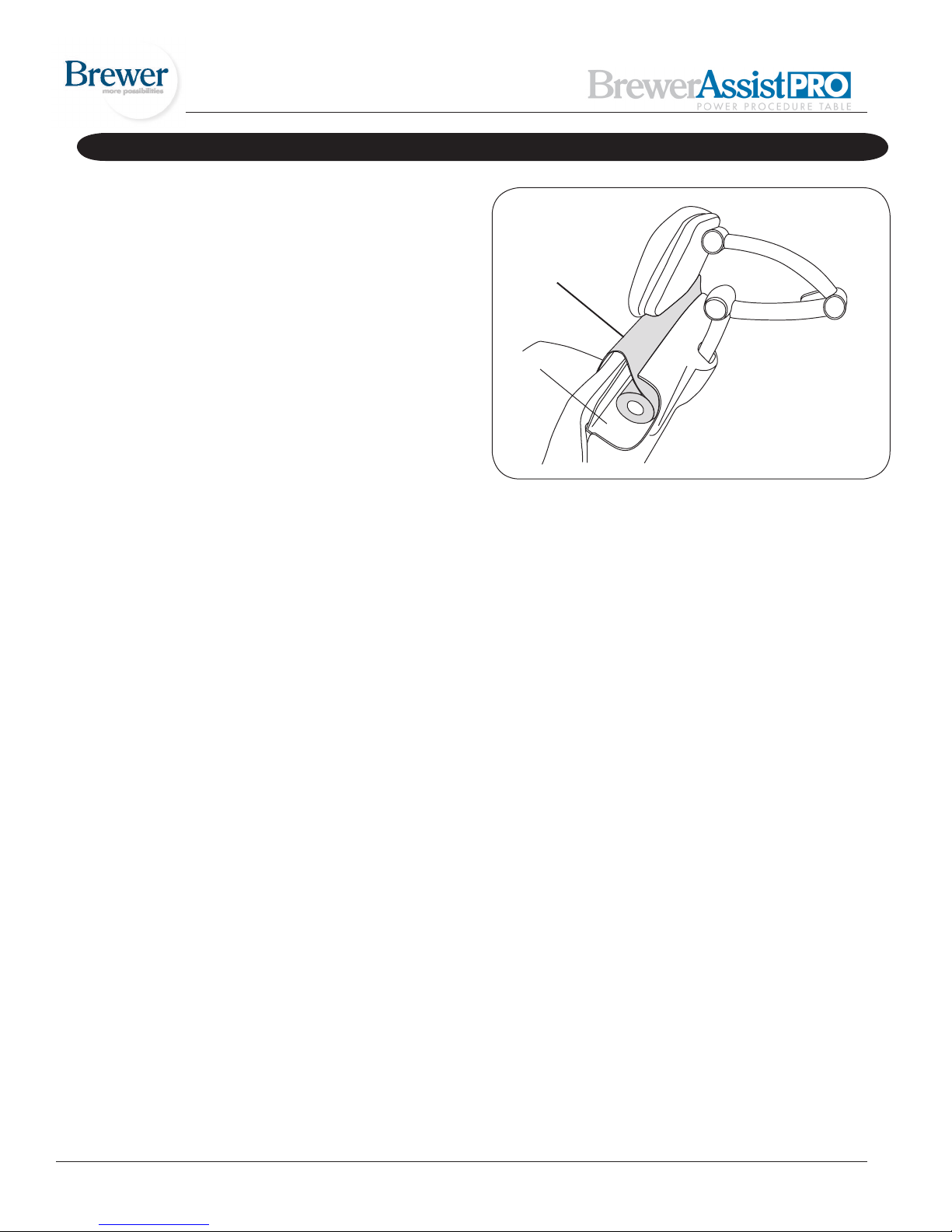

Figure 1. Model and Serial Number Location

Model &

Serial Number

Remember to read through the entire manual. The fea-

tures briey mentioned are just an introduction into the

capabilities provided by the AssistPro. This table was spe-

cically engineered to be the most accessible and safest

table on the market. Multi-density upholstery, push-only

actuators, and numerous on/off switches are just a few

of the many touches that make the AssistPRO the best

procedure table for every ofce.

Document # 101522 0608 REV A ER 784 3

Failure to follow instructions with this symbol

could result in serious personal injury and/or damage

to the unit.

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death

or serous injury.

CAUTION indicates an imminently or poten-

tial hazardous situation which, if not avoided, may

result in serious injury and/or equipment damage.

Safety Information

The primary concern of The Brewer Company is that the

equipment is operated and maintained with the safety of

the patient and healthcare staff in mind. To ensure safe

and reliable operation:

•Read and understand all instructions in this manual

before attempting to install or operate the unit.

•Ensure that appropriate personnel are informed on

the manual contents. This is the responsibility of the

purchaser.

•Ensure that this manual is located near the table, or if

possible permanently afxed to the table.

SAFETY INFORMATION

COMPONENT IDENTIFICATION

Leg Section

(adjustable angle)

Headrest (ad-

justable)

Backrest

(adjustable angle)

Stirrups

Seat

(adjustable angle)

Treatment

Pan

Headrest Linkage

Assembly

Programmable

Foot Control

Programmable

Hand Pendant

Figure 2. Component Overview

Document # 101522 0608 REV A ER 784 4

WARNING

When performing a cauterization or similar treat-

ment, the patient must be insulated from the metal

portions of the table by nonconductive material.

Failure to do so may result in electrical shock or

burns to the patient.

WARNING

Use 115 VAC, 60 Hz alternating current only. Failure

to do so may result in electrical shock to personnel

and will result in damage to the table.

WARNING

Do not use this table in an explosive or oxygen-

enriched atmosphere. Failure to do so may result

in serious personnel injury or death.

CAUTION

Do not use any power supply other than that

listed on the rating label (Figure 1). Failure to do

so may result in serious injury and/or equipment

damage.

SPECIFICATIONS

Power Cord.......................................................................

............ Extends 70 in. (Minimum) from table. 18 AWG / 3

............. conductor, SJT grey jacketed junior hard service

............with hospital plug

Type of protection against electrical shock …….. Class 1

.......................................................................... Grounded

Type of protection

against electrical shock …….. .................. B applied parts

Type of protection against ingress of water……. Ordinary

Type of protection against ingress of water for foot control..IPX1

Can accept paper rolls of

....................................................................18 in. x 3.0 in.

....................................................................21 in. x 3.0 in.

Certications*.................................UL6060-1; UL2601-1;

..........................IEC60601-1; CAN-CSA C22.2 No. 601.1

Transport and Storage Conditions:

Temperature Range......................................-20º to 150º F

Relative Humidity...........................................10% to 90%

Operating Conditions:

Temperature Range........................................ 65° to 85°F

Relative Humidity...........................................10% to 90%

* ETL classied in the United States and Canada

per the following standards.

Weight of Table.....................................................550 lbs.

Load Rating (maximum):

Seat/Back .............................................................450 lbs.

Legrest (Flat & Kneeling)......................................450 lbs.

Headrest...............................................................100 lbs.

Back Section Range...............0° (horizontal) to +85° ± 5°

Table Top Height Range ...........19 ± 0.5 in. to 40 ± 1.0 in.

Leg Section Range............0° (horizontal) to 90° (vertical)

Table Top

Tilt Range ................ 0° (horizontal) to +30° ± 5° (foot up)

Dimensions:

Upholstered Headrest..................13 in. wide x 11 in. high

Upholstered Top ....................28.0 in. wide x 44.5 in. long

Upholstered

Leg Rest ....…………………16.5 in. wide x 11.25 in. high

Overall Length ..................................................69 in. long

With Headrest/

Footrest Extended ............................................90 in. long

Electrical Requirements

..................115 VAC nominal, 60 HZ, 5.8 amps maximum

Duty Cycle (10%)

................. 2 minutes on / 18 minutes off (motor run time)

ELECTRICAL REQUIREMENTS

CAUTION

This product has been evaluated with respect to

electrical shock, re, and mechanical hazards only

in accordance with UL60601-1; IEC60601-1;

UL2601-1; CAN/CSA C22.2 No. 601.1

Document # 101522 0608 REV A ER 784 5

Overview

Perform the following sequence in order when setting up

the table:

- Uncrating

- Leveling the Base

- Installing the Foot Control & Hand Pendant

Uncrating

NOTE: Inspect all boxes and contents for damage. Re-

port any damage to the carrier immediately.

CAUTION

To avoid damaging the table’s upholstery or paint-

ed surfaces, DO NOT use a knife or other sharp

object to open the packaging. Also, to avoid dam-

aging the table lift only at points indicated in Figure

3. Do not lift at other points as indicated in Figures

3 and 4.

1. Using a 1/2” open-end wrench, or socket, unbolt the

table from the wooden shipping skid by removing the

four bolts located underneath the table’s base; two on

each side.

2. Remove the table from the shipping skid by sliding it

off the front of the skid. Be sure to lift at the correct

points as indicated in Figure 3. Position the table in

the desired room location.

WARNING

The table weighs approximately 550 lbs. Two or

more people should assist in removing the table

from the shipping skid. Also, use proper lifting

techniques when lifting. Failure to do so could

result in serious injury.

3. Remove packing tape from stirrups (Figure 4). Pull

out treatment pan slide and remove packing tape

from the treatment pan assembly components. Re-

turn treatment pan slide to its stowed position.

4. The electrical rating for this unit is 115 VAC, 60 Hz,

5.8 amps. The three-pronged grounding plug on the

table power cord must be plugged into a matching

three-pronged, grounded, non-isolated, correctly

polarized 115 VAC receptacle.

INSTALLATION

Figure 3. Table Lift Points

Figure 4. Stirrups and Treatment Pan

DO NOT lift at these points!

Lift table at these points

Do Not Lift

Document # 101522 0608 REV A ER 784 6

Leveling the Table

A leveling screw pad (Figure 5) is located in six places

under the table’s base. Adjust the six leveling pads to

achieve a solid, level installation.

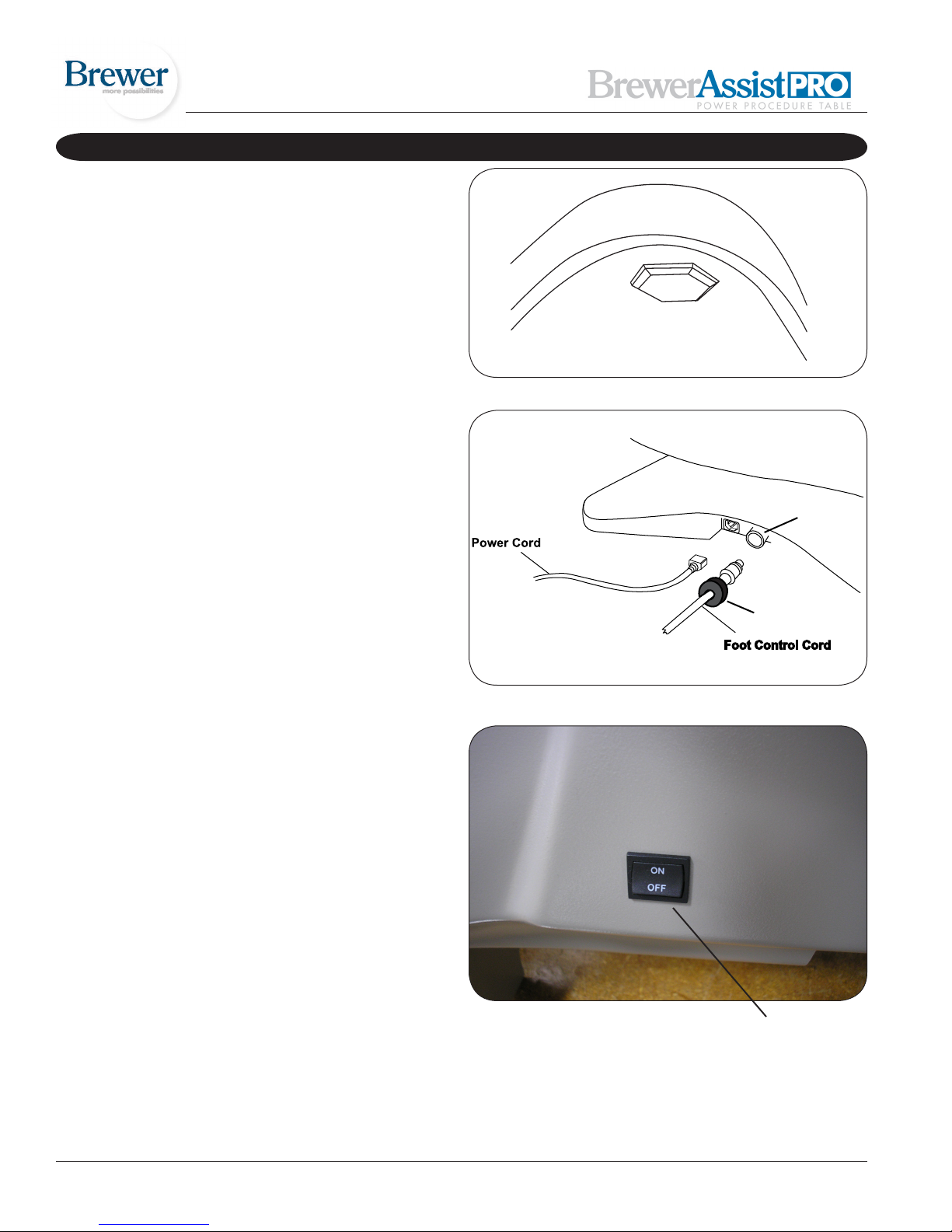

Installing the Power Cord

1. Remove the power cord from the shipping box.

2. Insert the plug end of the power cord into the recep-

tacle on the table (Figure 6). Make sure the plug end

shape is correctly oriented to the receptacle shape.

Installing the Foot Control

1. Remove the foot control from the shipping box.

2. Insert the end of the cord into the foot control recep-

tacle on the table (Figure 6). Make sure the tab on the

cord plug is aligned with the groove in the receptacle,

and the plug is fully seated.

3. Thread the locking collar onto the receptacle

4. Make sure the on/off switch located on the backrest

shroud is turned to the “on” position. See gure 7.

5. Make sure both Safety On/Off Switches are on (lighted).

See gure 9.

6. Test the foot control for operation.

Figure 5. Leveling Screw Pad (located under table)

Figure 6. Power Cord & Foot Control Cord Receptacles

Figure 7

INSTALLATION (CONTINUED)

Locking Collar

Receptacle

Foot Control/Hand

Pendant On/Off

switch

Document # 101522 0608 REV A ER 784 7

Installing the Hand Pendant

1.Remove the hand pendant from the shipping bag

2.Insert the plug end of the cord into the hand pendant

receptacle on the backrest shroud. See gure 8.

3.Make sure the tab on the cord plug is aligned with the

groove in the receptacle and plug is fully seated

4.Thread the locking collar onto the receptacle

5.Test the hand pendant for operation

Figure 8

INSTALLATION (CONTINUED)

Receptacle

Hand

Pendant

Cord

Locking

Collar

Document # 101522 0608 REV A ER 784 8

General

WARNING

If the table malfunctions, immediately remove your

hand or foot from the controls, unplug the power

cord from the electrical receptacle, and assist the

patient from the table. If table continues to mal-

function, call for service. Do not attempt to repair

table yourself.

WARNING

Before initiating power, keep personnel and equip-

ment clear of the table movement to avoid personal

injury or equipment damage.

OPERATION

NOTE: For optimum table performance, allow the table to

reach room temperature before operating.

NOTE: The table is not designed for continuous opera-

tion. If the table is operated continuously causing the

control to exceed its allowable operating temperature, the

table will go into a reduced speed mode. If normal opera-

tion ceases, do not attempt to operate the table. Allow the

table to cool for 10-15 minutes before attempting to use

again.

NOTE: If operation does not resume after a cooling

period of one hour, contact your dealer or an authorized

service center for repair.

Figure 9

Safety On/Off switches

1.The table is equipped with two On/Off switches that dis-

rupt the main power to the table.

2.The switches are located on the upper left and right hand

sides of the backrest shroud. See gure 9.

3.In the “On” position the switch is lighted green.

Both switches must be in the On, lighted position for the

table to operate.

Document # 101522 0608 REV A ER 784 9

WARNING

Keep personnel and equipment clear of table be-

fore initiating movement to avoid personal injury

or damage to the equipment.

CAUTION

The foot control and hand pendant are moisture

resistant and run on low voltage. To avoid tempo-

rary or permanent damage to the controls, do not

immerse in water or liquids.

CAUTION

Keep foreign objects away from controls. To avoid

accidental operation, be sure the controls are NOT

positioned below the legrest or headrest linkage.

Failure to do so could result in unwanted motion

and possible damage to the table.

NOTE: Each control function will automatically stop mov-

ing when either the UP or DOWN travel limit is reached.

If the button is pressed with travel at its limit, the actua-

tor will not run. Sensors prevent the actuator motor from

operating when travel limit has been reached, preventing

wear of the actuator.

Leg

Down Table

Down

Figure 10

Controls

1. See gure 10 for the pedal and button identications on

the foot control

2. See gure 11 for the button identications on the hand

pendant

OPERATION (CONTINUED)

Program Recall

Mode

Stop

Program

Recall #3

Program

Recall #4

Tilt

Down

Back

Down

Program

Recall #2

Program

Recall #1

Program

Set

Leg

Up Table

Up

Tilt

Up

Back

Up

Document # 101522 0608 REV A ER 784 10

Leg Up

Leg Down

Tilt Down

TiltUp

Program Recall #2

Program Recall #4

Back Up

Back Down

Table Down

Table Up

Program Recall #1

Program Recall #3

Figure 11

OPERATION (CONTINUED)

Document # 101522 0608 REV A ER 784 11

TABLE ADJUSTMENTS

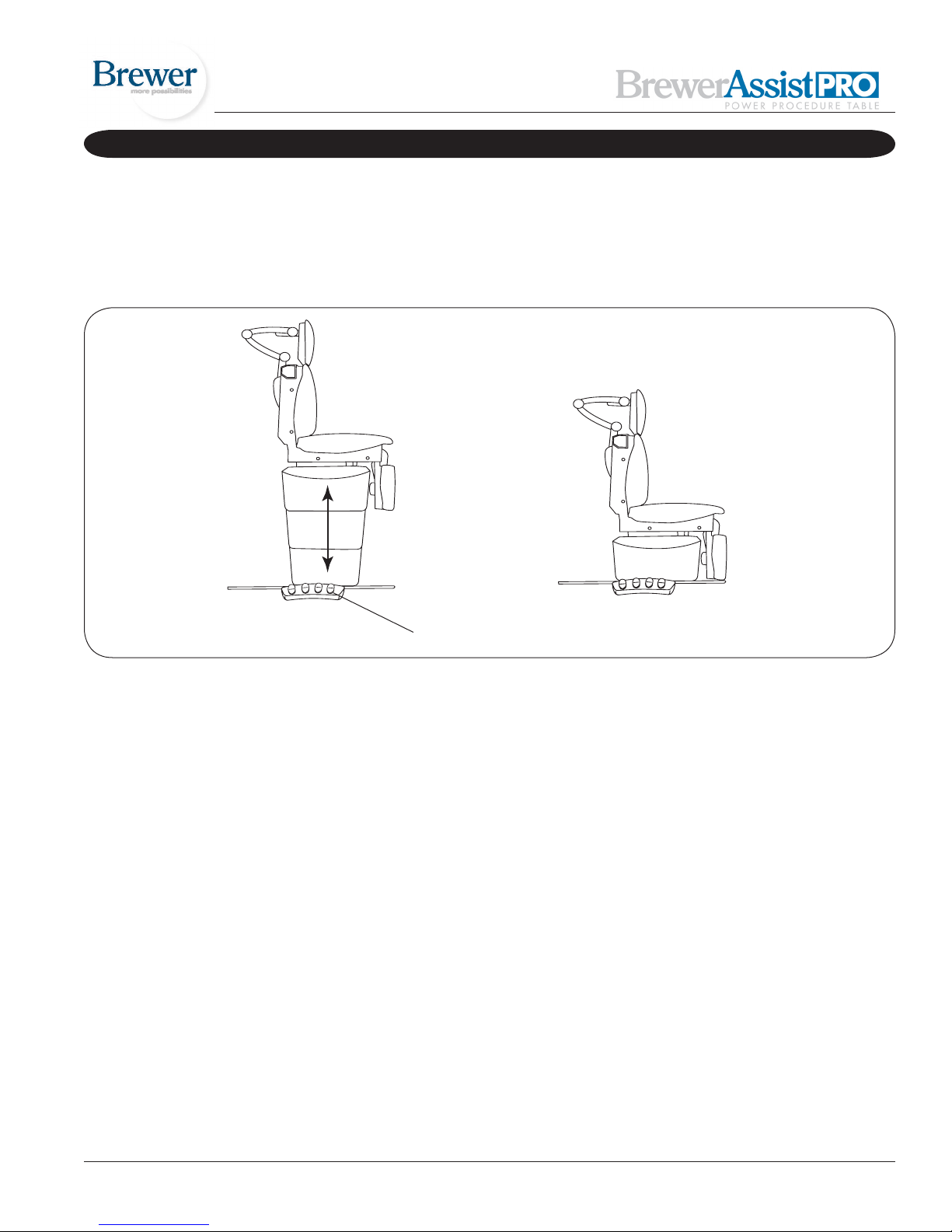

Figure 12. Table Height Positioning

Table Height Control

Table Height (Figure 12)

The table top can be adjusted to any height between 19”

to 40”.

1. To raise the table, depress and hold the Table/Up

function until the desired height is achieved.

2. To lower the table, depress and hold the Table/Down

function until the desired height is achieved.

Document # 101522 0608 REV A ER 784 12

TABLE ADJUSTMENTS (CONTINUED)

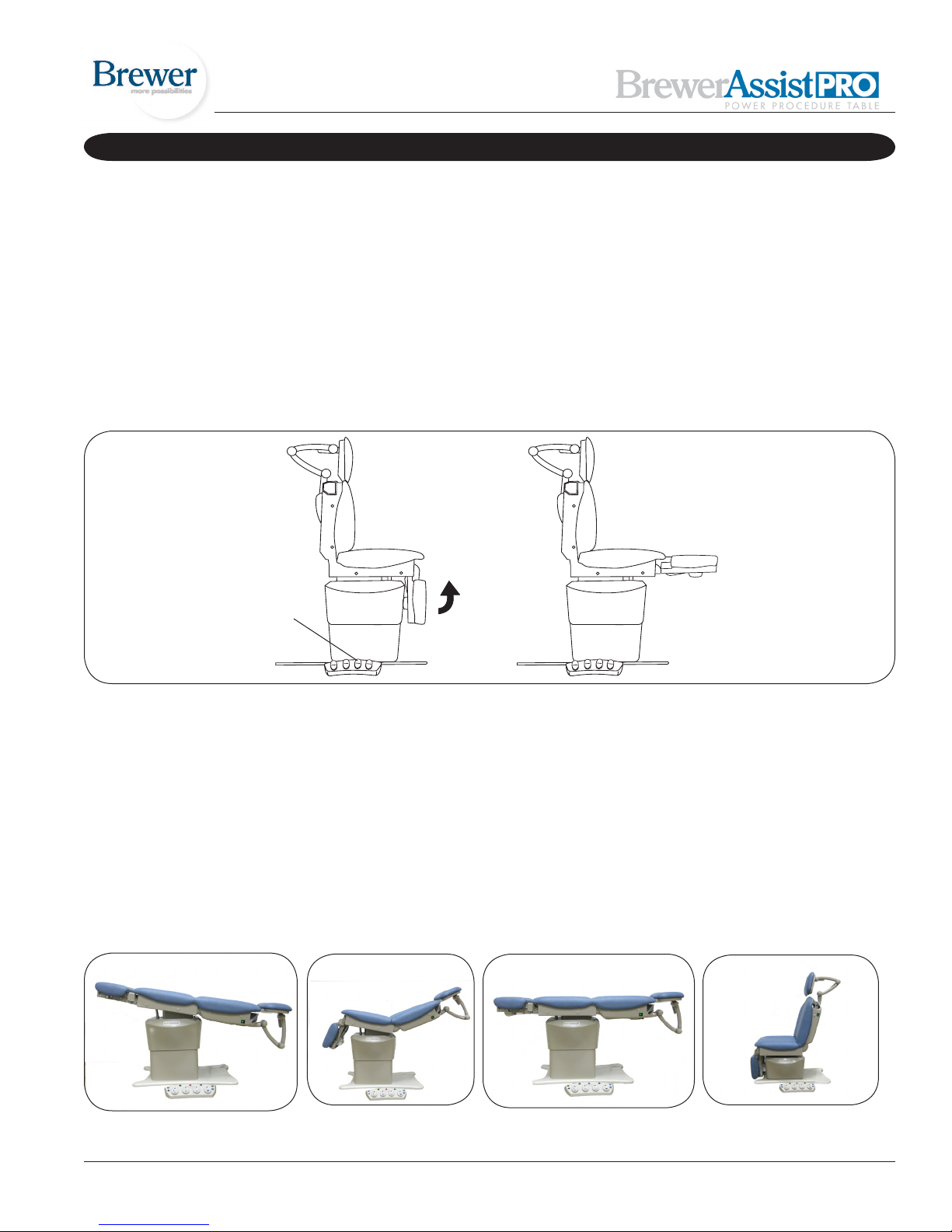

Tilt Function (Figure 14)

The table top can be tilted to any angle between

horizontal and +30° (foot end of table raised).

1. To tilt the foot end of the table upward, depress and

hold the Tilt/Up function until the desired angle is

achieved.

2. To tilt the foot end of the table downward, depress

and hold the Tilt/Down function until the desired angle

is achieved.

NOTE: The headrest linkage may contact the oor or other

object when the table is tilted (Figure 15). If this occurs,

raise the table, reduce the amount of tilt, or raise the back.

Figure 14. Tilt Function

Figure 13. Adjusting Backrest

Backrest Position Control

Figure 15. Do Not Allow Headrest to Contact Objects

Back Positions (Figure 13)

The back can be adjusted to any angle between horizon-

tal and 85°.

1. To adjust the back from a chair (upright) position to a

horizontal position, depress and hold the Back/Down

function until the desired angle is achieved.

2. To adjust the backrest from a horizontal position to a

chair (upright) position, depress and hold the Back/Up

function until the desired angle is achieved.

NOTE: The back is controlled by an actuator that raises

the back when activated. When lowered, the actuator

retracts and gravity causes the back to lower.

Tilt Function Control

Document # 101522 0608 REV A ER 784 13

Figure 16. Legrest Positions

Legrest Positions (Figure 16)

The legrest can be adjusted from a horizontal position to

a vertical position.

1. To adjust the legrest from a vertical position to a

horizontal position, depress and hold the Legrest/Up

function until the desired angle is achieved.

2. To adjust the legrest from a horizontal position to a

vertical position, depress and hold the Legrest/Down

function until the desired angle is achieved.

NOTE: A safety switch inhibits upward movement of the

legrest when the treatment pan tray is extend-

Legrest Position Control

ed preventing the legrest from contacting the treatment

pan tray. If the legrest is inoperable, check to ensure

that the treatment pan tray is in its fully stowed position

(inward). *When the treatment pan tray is extended, a

light on the foot control labeled “Pan Out” is illuminated.

The legrest will not rise. Depressing the legrest up func-

tion will cause the light to blink and a double beep alarm

to sound.

NOTE: The legrest mechanism is controlled by an

actuator that raises the legrest when activated. When

lowered, the actuator retracts and gravity causes the

legrest to lower.

TABLE ADJUSTMENTS (CONTINUED)

Using the Program Feature

1. The table can be programmed using the hand pen-

dant or the foot control. Up to four different positions

can be programmed.

2. The table is already programmed from the factory with

four preset positions. See gure 17 below.

3. Refer to gure 10. The mode in which the pre-pro-

grammed positions are recalled can be set by the

end user. The black “Program Recall Mode” button is

used to set the recall motion to “Auto Run” or “Con-

Position 1 Position 2 Position 3 Position 4

tinuous Touch”. In the “Auto Run” mode, a single

instantaneous touch of a blue Program Recall

button will recall that position. In the “Continuous

Touch” mode, the blue Program Recall button must

be held down continuously until the table reaches

the programmed position.

4. To set the program mode, depress the black “Pro-

gram Recall Mode” button on the foot control for (5)

ve seconds, until (2) beeps are heard. A light

Figure 17

(Continued...)

Document # 101522 0608 REV A ER 784 14

TABLE ADJUSTMENTS (CONTINUED)

on the foot control will indicate if the “Auto-Run” mode

is on or off. To set the program mode using the hand

pendant, simultaneously depress the program recall

number “3” and number “4” buttons for ve seconds

until two beeps are heard.

5. When the table is moving in the auto run mode, motion

of the table can be stopped by:

a. Tapping the “Stop” button on the foot control.

b. Tapping any pedal or button on the foot control.

c. Depressing any button on the hand pendant

Note: For emergency situations, the table can be turned

off using either of the two lighted switches located

at the top of the backrest. See gure 9.

Programming the Table with the

Foot Control

1. Using the foot control pedals, move the table to the

desired position. (see gure 10) Tap the black “Pro-

gram Set” button. The four blue “Program Recall”

buttons will ash. Tap one of the blue buttons to store

the position. The blue light will stay lit for that position

and two beeps will sound.

Note: The blue lights will ash for three seconds, after

which the program set mode is discontinued.

2. Move the table to a new position and repeat step 1 to

store up to three additional positions.

3. Any of the four stored positions can be re-pro

grammed by following the steps above.

Note: if the treatment pan tray is out, the position

recall will not work if the pre-set position requires the

legrest to move upward.

Safety

The table has a built in safety feature which helps avoid injury to the patient or physician when recalling a pro-

grammed position in the “Auto-Run” mode:

The table will stop moving downward once the legrest (in the stowed position) reaches a height of four inches1.

off the ground

The legrest will stop one inch from the lift column shrouding.2.

The pelvic tilt will stop after moving to 10 degrees3.

Programming the Table with the

Hand Pendant

1. Move the table to the desired position. Simultaneous-

ly depress the number “1” and the number “2” “Pro-

gram Recall” buttons. (see gure 11) Release the two

buttons. Depress one of the four “Program Recall”

buttons to store the position. Two beeps will sound.

Note: The Program Set Mode will remain active for

three seconds after simultaneously depressing the

number “1” and the number “2” “Program Recall” but-

tons.

2. Move the table to a new position and repeat step 1 to

store up to three additional positions.

3. Any of the four stored positions can be re-pro

grammed by following the steps above.

Note: if the treatment pan tray is out, the position

recall will not work if the pre-set position requires the

legrest to move upward.

Document # 101522 0608 REV A ER 784 15

CAUTION

To prevent damage to the unit, the legrest must be

returned to the shortest position prior to lowering

the legrest to the vertical position.

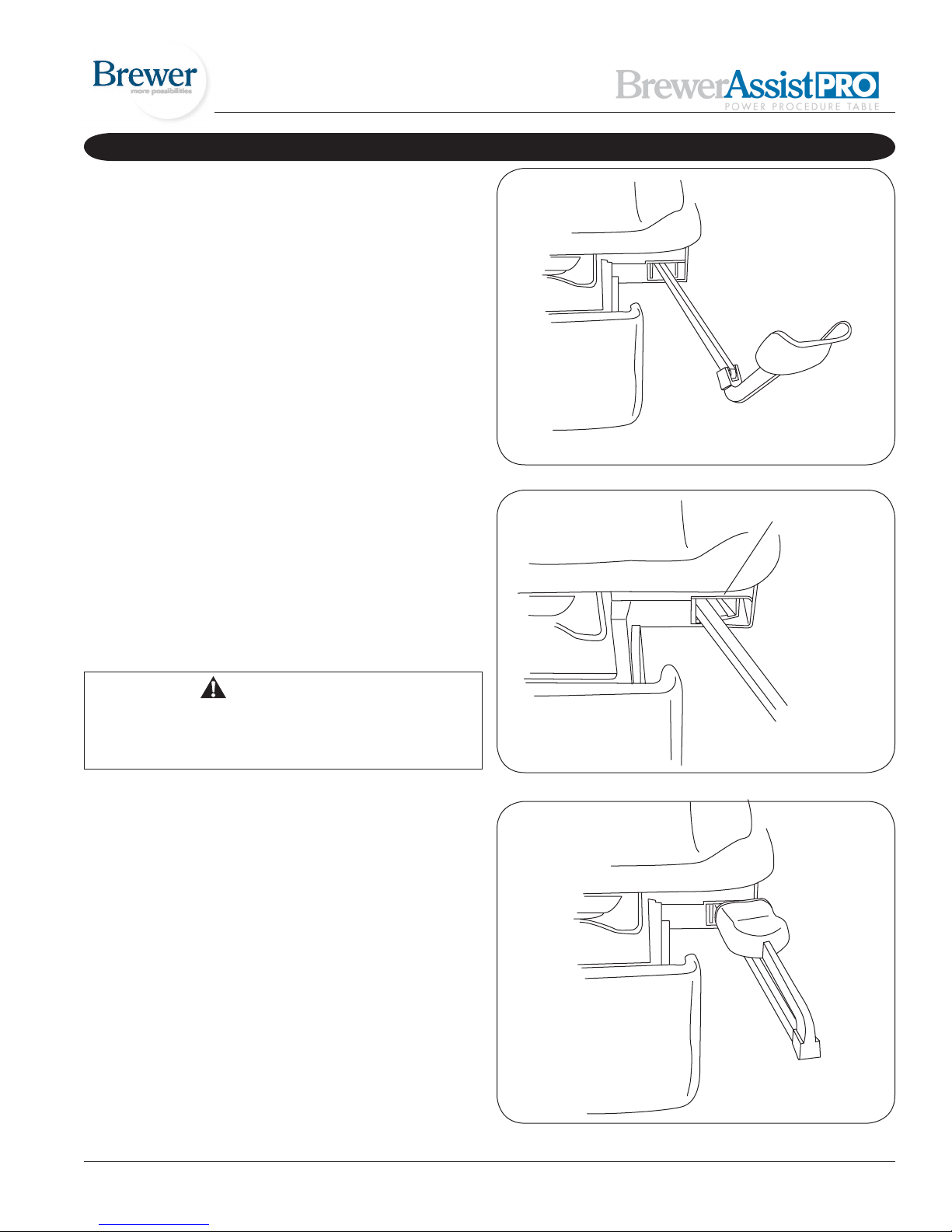

Figure 19. Legrest Kneeling Position

Legrest Kneeling Position (Figure 19)

The legrest can be rotated to a kneeling position.

1. Grasp the legrest cushion on both sides.

2. Rotate the cushion upward until rotation stops.

3. Slide the legrest downward and rotate the cushion

downward to engage the stop. Two height positions

are provided.

TABLE ADJUSTMENTS (CONTINUED)

Cam positioned in slot

Lift up over-center

NOTE: Make sure the legrest cushion is full engaged with

the stops on both sides. When properly engaged, the

legrest cushion is parallel to the ground.

1 2 3

Legrest Extension (Figure 18)

In the horizontal position, the legrest can be extended 5”

to increase the overall length of the table.

Lift up on the legrest and pull outward to extend the

legrest. To return the legrest to the shortest position, lift

up on the legrest and push fully inward.

Figure 18. Legrest Extension

Document # 101522 0608 REV A ER 784 16

Figure 20. Paper Roll

Slot

Paper

TABLE ADJUSTMENTS (CONTINUED)

Paper Roll (Figure 20)

To change a paper roll, insert the paper through the slot

in the backrest shrouding and set the paper roll in the

holder.

Document # 101522 0608 REV A ER 784 17

Stirrups

Figure 21. Operating the Stirrups

Op e r a t i n g t h e St i r r u p S (Fi g u r e 21)

1. To operate the stirrups, grasp end of stirrup and pull

straight out of the table. Lift up slightly while sliding

the stirrup out.

NOTE: Do not apply any downward pressure when pull-

ing stirrup from table or it may be difcult to move. This

is normal and is part of the stirrup friction locking mecha-

nism

2. Unfold stirrup upward to the fully open position.

3. Adjust the stirrup to the desired length by sliding it in

or out.

St i r r u p La t e r a L ad j u S t m e n t (Fi g u r e 22)

1. Lift end of stirrup and then rotate outward to

desired position.

2. When the desired position is achieved, lower the stir-

rup to engage the lateral locking mechanism.

3. Check that lateral locking mechanism is engaged by

attempting to rotate stirrup assembly without lifting on

the stirrup end.

WARNING

Failure to engage the lateral locking mechanism

could allow patient to lose balance resulting in

personal injury to patient.

St O r i n g t h e St i r r u p S (Fi g u r e 23)

1. To store the stirrups in the table, grasp end of stirrup

and pull straight out to its full extension.

2. Fold stirrup down against bar, then rotate it to the

inner most lateral position and slide it back into the

stowed position.

Figure 22. Stirrup Lateral Adjustment

Pull Stirrup out, then unfold

Lateral Locking Mechanism

Figure 23. Storing the Stirrups

TABLE ADJUSTMENTS (CONTINUED)

Document # 101522 0608 REV A ER 784 18

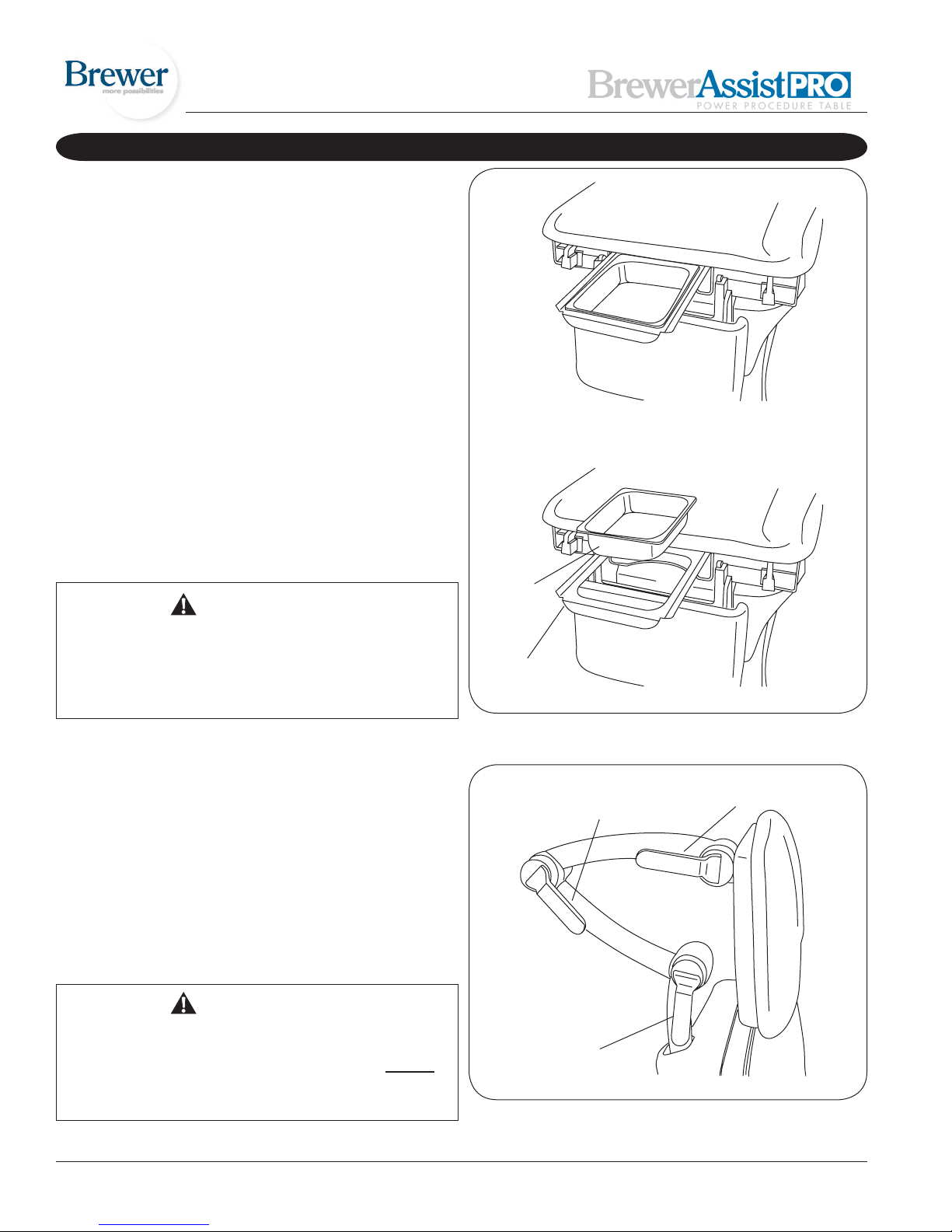

Figure 24. Treatment Pan

Figure 25. Headrest Handles

Treatment Pan (Figure 24)

NOTE: A safety switch prevents upward motion of the

legrest when the treatment pan tray is extended. This pre-

vents the legrest from contacting the treatment pan tray. If

the legrest upward motion is inoperable, check to ensure

that the treatment pan tray is in its fully stowed position

(inward). A light clicking sound will be heard just before

the treatment pan reaches its fully stowed position.

1. To expose the treatment pan for use, grasp the tray

handle and pull until tray is fully extended (Figure 24).

2. The pan can be easily removed for cleaning with

the tray fully extended. Fully seat pan into tray when

clean.

3. Push the tray handle as far in as it will go to fully stow

the treatment pan after use. A light clicking sound will

be heard just before the pan reaches its fully stowed

position.

Headrest Positions (Figure 25)

WARNING

Make sure headrest is securely locked into position

before use. Failure to have the three handles cor-

rectly locked could result in headrest falling during

a procedure which could result in serious personal

injury.

1. To move the headrest, rotate the three handles to

their open position. Move the headrest to its desired

location. Rotate the 3 handles to their locked position

as shown in Figure 25.

2. Each section of the headrest can be adjusted inde-

pendently by rotating the handle to the open position,

moving the desired section, and then rotating the

handle to the closed position.

NOTE: Make sure all three handles are locked. A handle

is locked correctly when it is pushed past center and

the force of the clamping action pulls the handle into the

locked position and holds it there.

WARNING

If any of the handles fails to lock properly, the

headrest assembly could fall during a procedure.

This could cause severe injury to a patient. Do not

attempt to repair the headrest assembly yourself;

call for service.

TABLE ADJUSTMENTS (CONTINUED)

Headrest Handle

(Locked)

Upper Handle

(Locked)

Lower Handle

(Locked)

Tray

Treatment

Pan

Document # 101522 0608 REV A ER 784 19

MAINTENANCE

Preventative Maintenance

CAUTION

Failure to perform periodic inspections of the

table could result in personal injury or equipment

damage.

• Periodically inspect the electrical cord to ensure it is

free of cuts or damage.

• Inspect the mechanical functions to ensure satisfac-

tory operation.

• Check fasteners to make sure they are present and

tightened securely.

• Lubricate moving parts (such as back, tilt, and legrest

hinges) with a light machine oil.

• Have your authorized dealer inspect your table every

6 months.

CAUTION

The upholstery material is resistant to most medici-

nal type stains, but may be damaged by solvents

and dyes. Remove any spilled uids from the up-

holstery immediately.

Clean the table weekly, wiping the painted metal and

plastic surfaces with a clean, soft cloth. If desired, mild

cleaners may be used.

Table Care

LIMITED WARRANTY

The Brewer Company

GENERAL TERMS AND CONDITIONS

Warranty: The Brewer Company warrants its AssistPRO programmable power table to be free from defects in parts and work-

manship under normal use and service for a period of three (3) years from date of shipment. The Brewer Company will not be

responsible for any Product failure due to abuse, misuse, modication or improper use or for any use which exceeds the published

capacity of the Product. Products returned by prepaid freight for inspection and found defective will, at the option of The Brewer

Company, be repaired or replaced at no charge, but no claim for outside labor or other charges will be allowed. Products must

not be returned without proper written authorization from The Brewer Company. Requests for authorization must be in writing and

accompanied by the original purchase order, The Brewer Company invoice number and a copy of the invoice for the Product. THIS

WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES AND REMEDIES WHATSOEVER, INCLUDING BUT

NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE. NO

AGENT, EMPLOYEE, OR REPRESENTATIVE OF THE BREWER COMPANY HAS ANY AUTHORITY TO MAKE ANY AFFER-

MATION, REPRESENTATION, OR WARRANTY NOT SET FORTH IN THESE TERMS AND CONDITIONS CONCERNING ANY

PRODUCTS OF THE BREWER COMPANY. THE BREWER COMPANY SHALL HAVE NO LIABILITY WHATSOEVER FOR DAM-

AGES CAUSED BY TRANSPORTATION, ACCIDENTS, FIRE, UNAUTHORIZED ALTERATION, OR NORMAL WEAR OR ABUSE,

NOR SHALL THE BREWER COMPANY HAVE ANY LIABILITY WHATSOEVER FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES, including without limitation, lost prots or any such damages arising from (a) the design, manufacture, sale, delivery,

installation, repair, operation or use of products of The Brewer Company or any part thereof, (b) any actual or alleged failure or de-

fect in products of The Brewer company or any part thereof, or (c ) any actual or alleged breach or non-performance by The Brewer

Company of this limited warranty.

Freight Claims: Upon receipt, merchandise should be carefully examined to ascertain that proper amount has been received in

good condition. Any claim for shortage or damage must be made with delivering carrier within ve (5) days from receipt of goods.

We do not assume any responsibility for loss or damage in transit, and compensation for such loss must be obtained from the car-

rier

Table of contents