Brobo Group

brobo.com.au

CHAPTER 2 - Safety & Accident Prevention

The Brobo Group 3M Drill has been designed & manufactured in accordance with Australian Standards. It is

HIGHLY RECOMMENDED that the instructions & warnings contained in this chapter be carefully followed for correct

usage of the machine.

2.1. Operation of the Machine

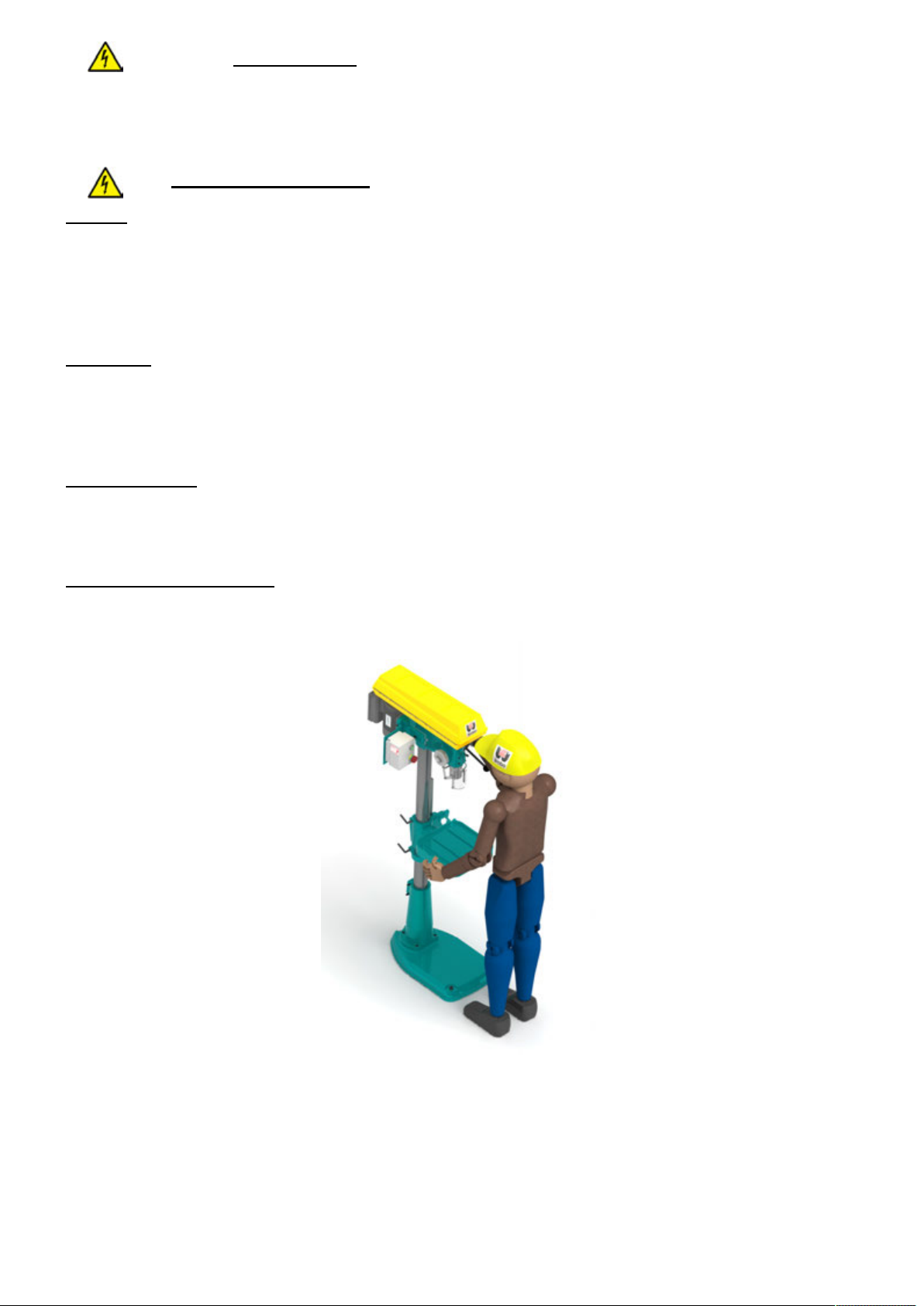

The Brobo Group 3M Drill is specifically designed to drill through ferrous & metal cross sections with thin-walled

or “plate” profiles. Other types of material & machining are not compatible for use with the specifications of the drill.

This machine involves a high-speed revolution; therefore extreme caution is required when operating the

device.

The employer is responsible for instructing the personnel who, in turn, are obliged to inform the operator of any

accident risks, safety devices, noise emission & accident prevention regulations provided for by national &

international laws governing the use of the machine. The operator must be fully aware of the position &

functions of all the machine’s controls.

All those concerned must strictly adhere to ALL instructions, warnings, & accident prevention standards in

this manual.

The following definitions are those provided for by the EEC DIRECTIVE ON MACHINERY No. 98/37/CE:

Danger Zone - any zone in and/or around a machine in which the presence of a person constitutes a

risk to the safety & health of that person.

Person Exposed - any person finding him or herself, either completely or partly in a danger zone.

Operator - the person or persons are given the responsibility of installing, operating, adjusting,

maintaining, cleaning, repairing, & transporting the machine.

2.1.1. Noise Level

The noise level of an idling drill has been measured to be below 85 dBA. This complies with the Australian

Occupational Health & Safety (Noise) Regulations 1992.

Please note that peak impulse noise levels will be experienced due to variables including drill characteristics, type,

& condition. This will also vary accordingly depending on the size & type of sample being drilled. Under these

circumstances, management should make available to the operator(s) the appropriate hearing protection equipment

as prescribed under the above-stated act.

WARNING – UNAUTHORISED MODIFICATIONS/REPLACEMENTS/USE

The manufacturer declines any responsibility whatsoever, either civil of criminal, in the case of

unauthorised interference or replacement of one or more parts or assemblies on the machine,

or if accessories, tools & consumable materials used are different from those recommended by

the manufacturer, or if the machine is inserted in a plant system & its proper function is altered.