KE-434C,435C

CONTENTS

1. NAME OF EACH PART .............................. 1

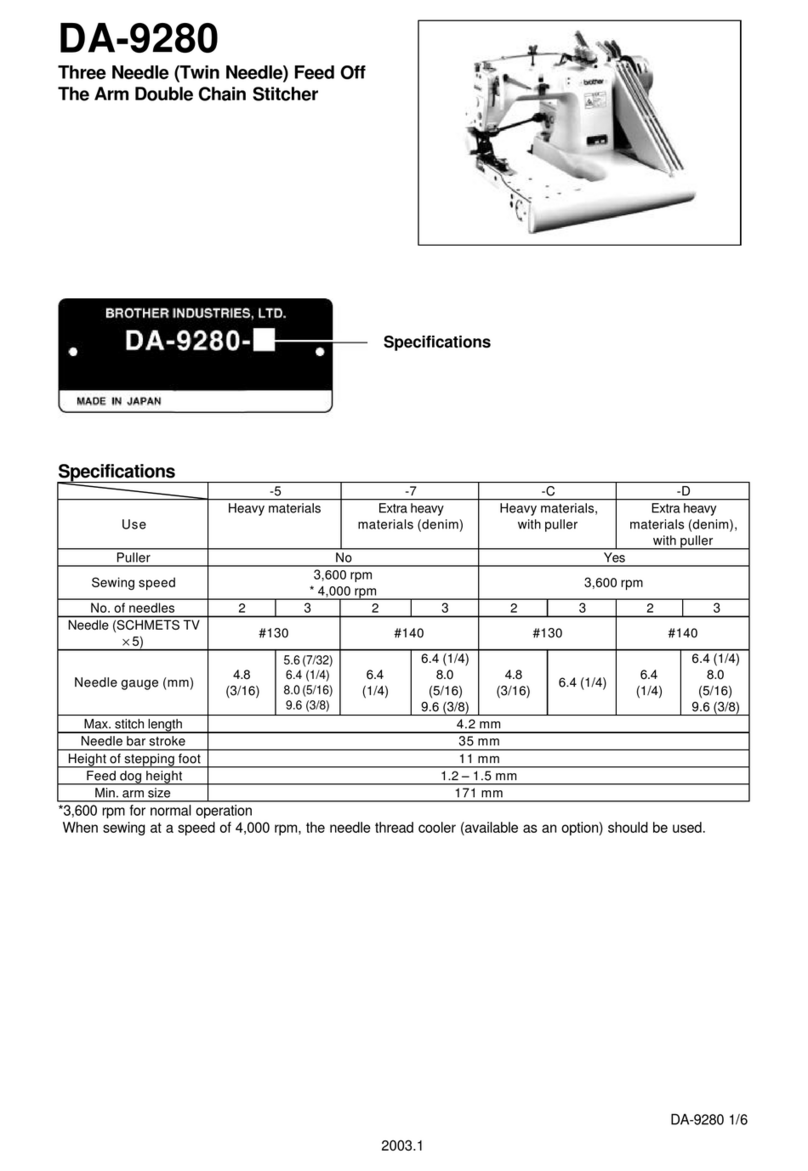

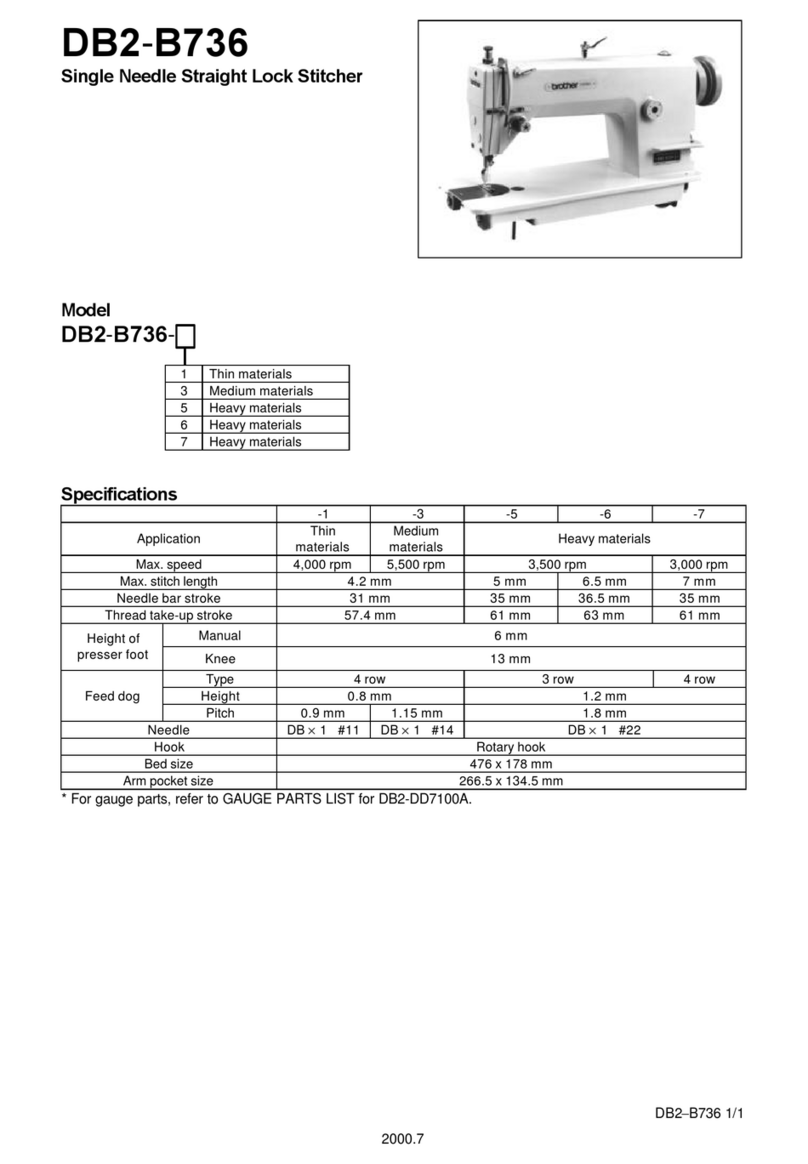

2. SPECIFICATIONS ...................................... 2

2-1. Specifications......................................................... 2

2-2. Examples of sewing patterns ................................. 3

3. INSTALLATION .......................................... 4

3-1. Power table............................................................ 4

3-2. Installing the control box ........................................ 5

3-3. Installing the rubber cushions ................................ 6

3-4. Installing the oil pan ............................................... 6

3-5. Installing the cushions............................................ 6

3-6. Installing the switching plate .................................. 7

3-7. Installing the machine head ................................... 7

3-8. Installing the head rest........................................... 8

3-9. Installing the liquid cooling tank, optional............... 8

3-10. Installing the operation panel............................... 9

3-11. Connecting the ground wire................................. 9

3-12. Connecting the cords.......................................... 10

3-13. Piping (for pneumatic)......................................... 13

3-14. Installing the belt cover ....................................... 16

3-15. Installing the foot switch...................................... 16

3-16. Installing the needle sub plate ............................ 17

3-17. Installing the spool stand .................................... 18

3-18. Installing the eye guard....................................... 18

4. LUBRICATION........................................... 19

4-1. Lubrication points.................................................. 19

5. OPERATION .............................................. 20

5-1. Name and function of each operation panel item ..... 20

5-2. Operating procedure............................................. 22

5-3. Operating the foot switch ...................................... 24

5-4. Operating the emergency stop switch................... 25

5-5. Operating the thread wiper switch (KE-435C)....... 25

6. CHECKING THE SEWING PATTERN........ 26

7. CORRECT USE ......................................... 27

7-1. Selecting the needle and thread ........................... 27

7-2. Installing the needle.............................................. 27

7-3. Threading the upper thread .................................. 27

7-4. Winding the lower thread ...................................... 28

7-5. Replacing the bobbin case and

threading the thread.............................................. 29

7-6. Thread tension...................................................... 29

8. SEWING .................................................... 32

9. MAINTENANCE AND INSPECTION.......... 33

9-1. Checking the needle ............................................. 33

9-2. Cleaning the rotary hook....................................... 33

9-3. Lubrication ............................................................ 34

9-4. Draining the oil...................................................... 35

9-5. Cleaning the control box air inlet port.................... 35

9-6. Cleaning the air holes of belt cover

and frame side cover ............................................ 35

9-7. Cleaning the eye guard......................................... 35

10. STANDARD ADJUSTMENTS...................36

10-1. Adjusting the needle bar height...........................36

10-2. Adjusting the needle bar lift amount ....................36

10-3. Adjusting the driver needle guard........................37

10-4. Adjusting the needle clearance ...........................37

10-5. Adjusting the shuttle race thread guide ...............37

10-6. Adjusting the thread take-up amount...................38

10-7. Adjusting the movable knife.................................39

10-8. Adjusting the work clamp lift amount ...................42

10-9. Work clamp interchangeability.............................43

10-10. Adjusting the needle up stop position................43

10-11. Adjusting the thread wiper.................................44

10-12. Checking the input sensor and DIP switch input .....45

10-13. Checking the input voltage ................................46

10-14. Clearing all memory settings .............................46

10-15. Moving stitch patterns .......................................47

10-16. Adjustment of air pressure (for pneumatic)........48

10-17. Adjustment of inner clamping device .................48

10-18. Work clamp adjustment (KE-435C) ...................49

10-19. Changing the work clamp lift (KE-435C)............49

11. USING THE COUNTERS .........................50

11-1. Using the bobbin thread counter .........................50

11-2. Using the production counter...............................50

12. CHANGING FUNCTIONS USING

THE DIP SWITCHES................................51

12-1. Operation panel DIP switches .............................51

12-2. DIP switches inside the control box.....................52

12-3. Using user programs ...........................................53

13. CHANGING SPECIAL FUNCTIONS

USING THE MEMORY SWITCHES .........55

13-1. Using the cycle sewing function ..........................58

14. SETTING THE WORK CLAMP MODE..... 60

14-1. Setting solenoid work clamp mode......................60

14-2. Setting pneumatic work clamp mode...................60

14-3. Light work clamp .................................................62

14-4. Setting reverse work clamp mode .......................63

15. TABLE OF ERROR CODES ....................64

16. GAUGE PARTS LIST ACCORDING TO

SUBCLASSES.........................................66

17. MAKING THE FEED PLATE AND WORK CLAMP

PLATE FOR INNER CLAMPING DEVICE ......... 69

17-1. Sewing area ........................................................69

17-2. How to make a sewing pattern ............................69

17-3. How to make the feed plate.................................70

17-4. How to make the work clamp plate......................71

17-5. Replacing the work clamp crank and work clamp

plate holder..........................................................72

18. TROUBLESHOOTING .............................73

19. OPTIONAL PARTS .................................. 76