16

The sound made by a reversing valve as it begins or ends defrost is

a “whooshing” sound, as the valve reverses and pressures in system

equalize. An experienced service technician detects this sound and

uses it as a valuable troubleshooting tool.

Using a remote measuring device, check inlet and outlet line

temperatures. DO NOT touch lines. If reversing valve is operating

normally, inlet and outlet temperatures on appropriate lines should

be close to each other. Any difference would be due to heat loss or

gain across valve body. Temperatures are best checked with a

remote reading electronic--type thermometer with multiple probes.

Route thermocouple leads to inside of coil area through service

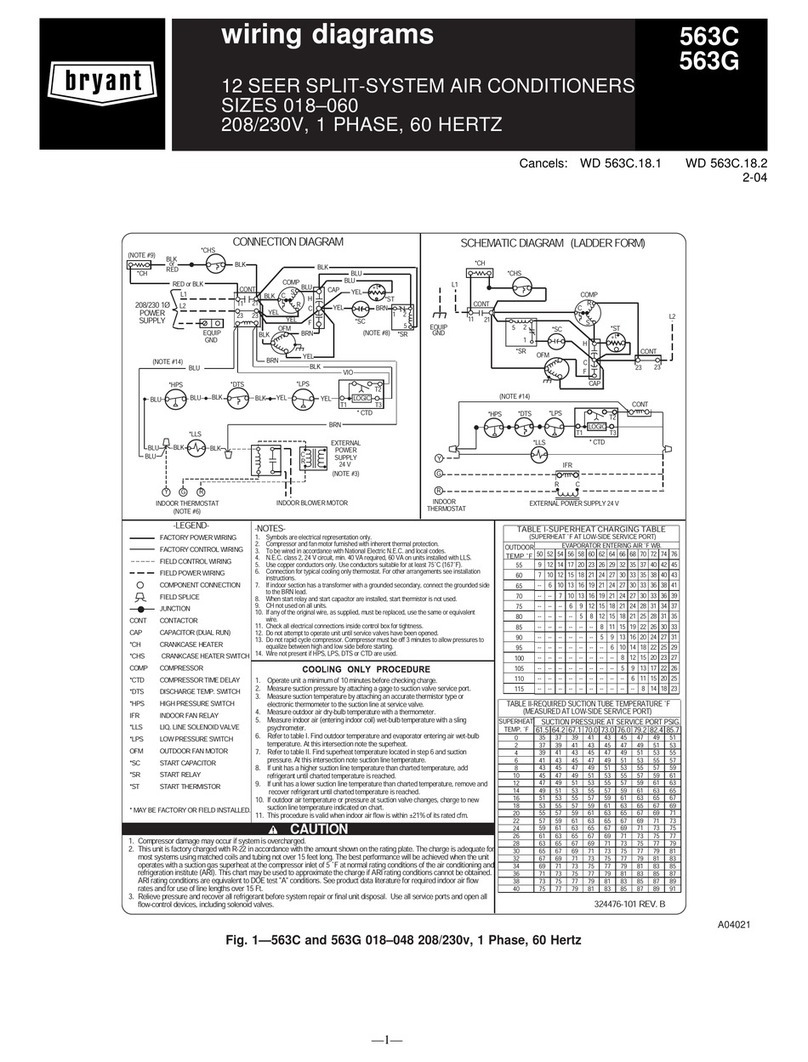

valve mounting plate area underneath coil. Fig. 12 and Fig. 13

show test points (TP) on reversing valve for recording

temperatures. Insulate points for more accurate reading.

If valve is defective:

1. Shut off all power to unit and remove charge from system.

2. Remove solenoid coil from valve body. Remove valve by

cutting it from system with tubing cutter. Repair person

should cut in such a way that stubs can be easily re--brazed

back into system. Do not use hacksaw. This introduces

chips into system that cause failure. After defective valve is

removed, wrap it in wet rag and carefully unbraze stubs.

Save stubs for future use. Because defective valve is not

overheated, it can be analyzed for cause of failure when it is

returned.

3. Braze new valve onto used stubs. Keep stubs oriented

correctly. Scratch corresponding matching marks on old

valve and stubs and on new valve body to aid in lining up

new valve properly. When brazing stubs into valve, protect

valve body with wet rag to prevent overheating.

4. Use slip couplings to install new valve with stubs back into

system. Even if stubs are long, wrap valve with a wet rag to

prevent overheating.

5. After valve is brazed in, check for leaks. Evacuate and

charge system. Operate system in both modes several times

to be sure valve functions properly.

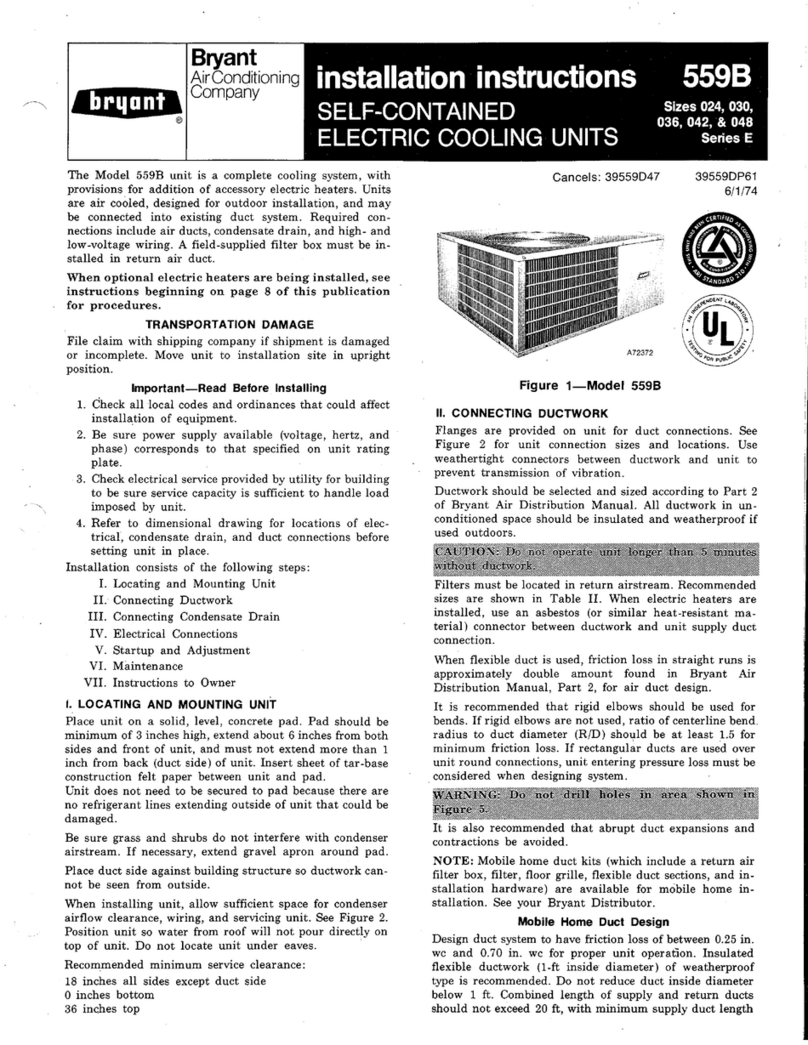

A10189

Fig. 12 – Reversing Valve

(Cooling Mode or Defrost Mode, Solenoid Energized)

Liquid Line Filter Drier

Filter driers are specifically designed for R--410A refrigerant. Only

operate with the appropriate drier using factory authorized

components.

There is a liquid line drier located inside the unit in the compressor

section. The liquid line drier also acts as a strainer.

Suction Line Filter Drier

The suction line drier is specifically designed to operate with

R--410A, use only factory authorized components. Suction line

filter drier is used in cases where acid might occur, such as burnout.

Heat pump units must have the drier installed between the

compressor and accumulator only. Remove after 10 hours of

operation. Never leave suction line filter drier in a system longer

than 72 hours (actual time).

Accumulator

The accumulator is specifically designed to operate with R--410A

pressures; use only factory--authorized components. Under some

light load conditions on indoor coils, liquid refrigerant is present in

suction gas returning to compressor. The accumulator stores liquid

and allows it to boil off into a vapor so it can be safely returned to

compressor. Since a compressor is designed to pump refrigerant in

its gaseous state, introduction of liquid into it could cause severe

damage or total failure of compressor.

The accumulator is a passive device which seldom needs replacing.

Occasionally its internal oil return orifice or bleed hole may

become plugged. Some oil is contained in refrigerant returning to

compressor. It cannot boil off in accumulator with liquid

refrigerant. The bleed hole allows a small amount of oil and

refrigerant to enter the return line where velocity of refrigerant

returns it to compressor. If bleed hole plugs, oil is trapped in

accumulator, and compressor will eventually fail from lack of

lubrication. If bleed hole is plugged, accumulator must be changed.

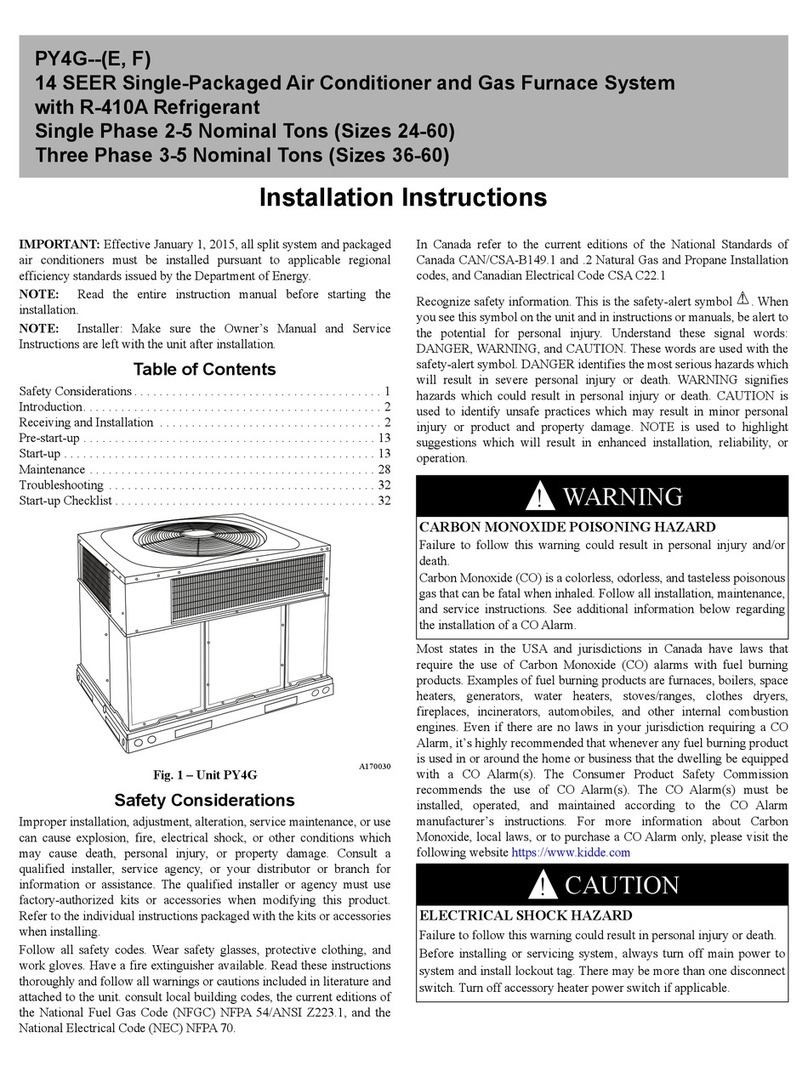

The accumulator has a fusible element located in the bottom end

bell. (See Fig. 14.) This fusible element will melt at 430_F/221_C

and vent the refrigerant if this temperature is reached either internal

or external to the system. If fuse melts, the accumulator must be

replaced.

To change accumulator:

1. Shut off all power to unit.

2. Recover all refrigerant from system.

3. Break vacuum with dry nitrogen. Do not exceed 5 psig.

NOTE: Refer to appropriate sections of Service Manual for

instructions.

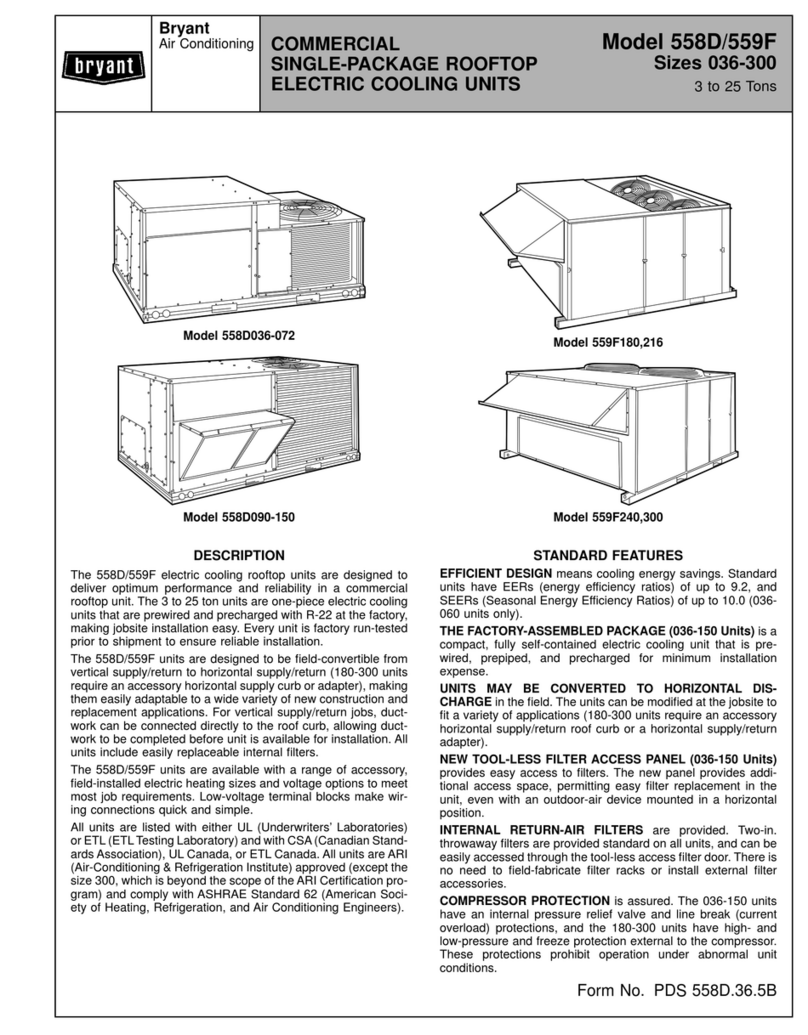

A10188

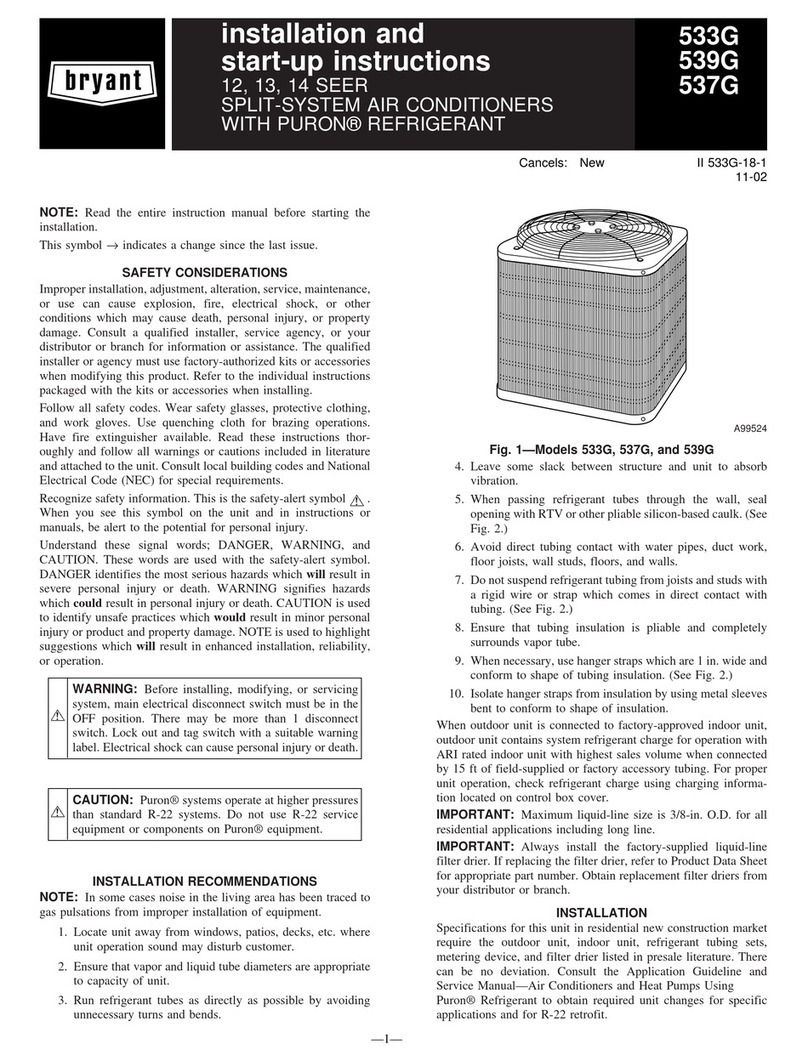

Fig. 13 – Reversing Valve

(Heating Mode, Solenoid De--Energized)

PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal injury.

Wear safety glasses, protective clothing, and gloves when

handling refrigerant.

CAUTION

!

4. Remove accumulator from system with tubing cutter.

5. Tape ends of open tubing.

6. Scratch matching marks on tubing studs and old

accumulator. Scratch matching marks on new accumulator.

Unbraze stubs from old accumulator and braze into new

accumulator.