Copyright 2015 © C. B. GiƩy CraŌer Supply 6

board extend out over the box (which makes the instru-

ment more versatile when being played), or you can cut

off the bottom part off the fretboard so that it ends at the

box edge.

One benefit of the latter is that it lets you gain access to

the box interior after the ukulele has been built - this can

be handy if you want to install a pickup, or at least want

to leave yourself the option of doing so later.

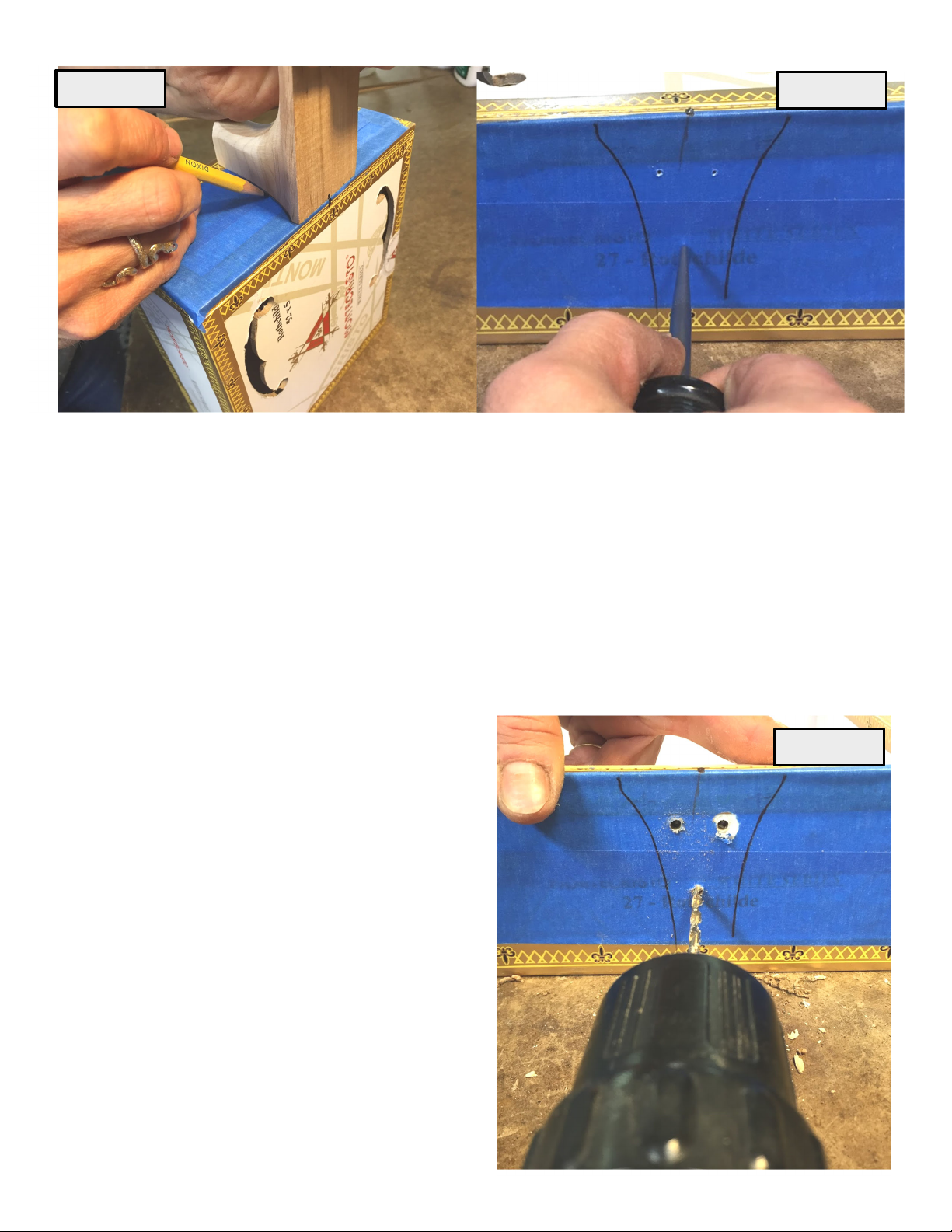

For the purposes of this guide, we’re going to cut off the

“excess” fretboard, so it’s time to mark the fretboard to

be cut.

If you have decided to not cut the fretboard shorter, skip

this next step. With the fretboard held in position on the

neck, turn the neck over and make a pencil mark on the

back of the fretboard (Figure 12). Make sure you have

allowed the 1/8” for the nut up at the top!

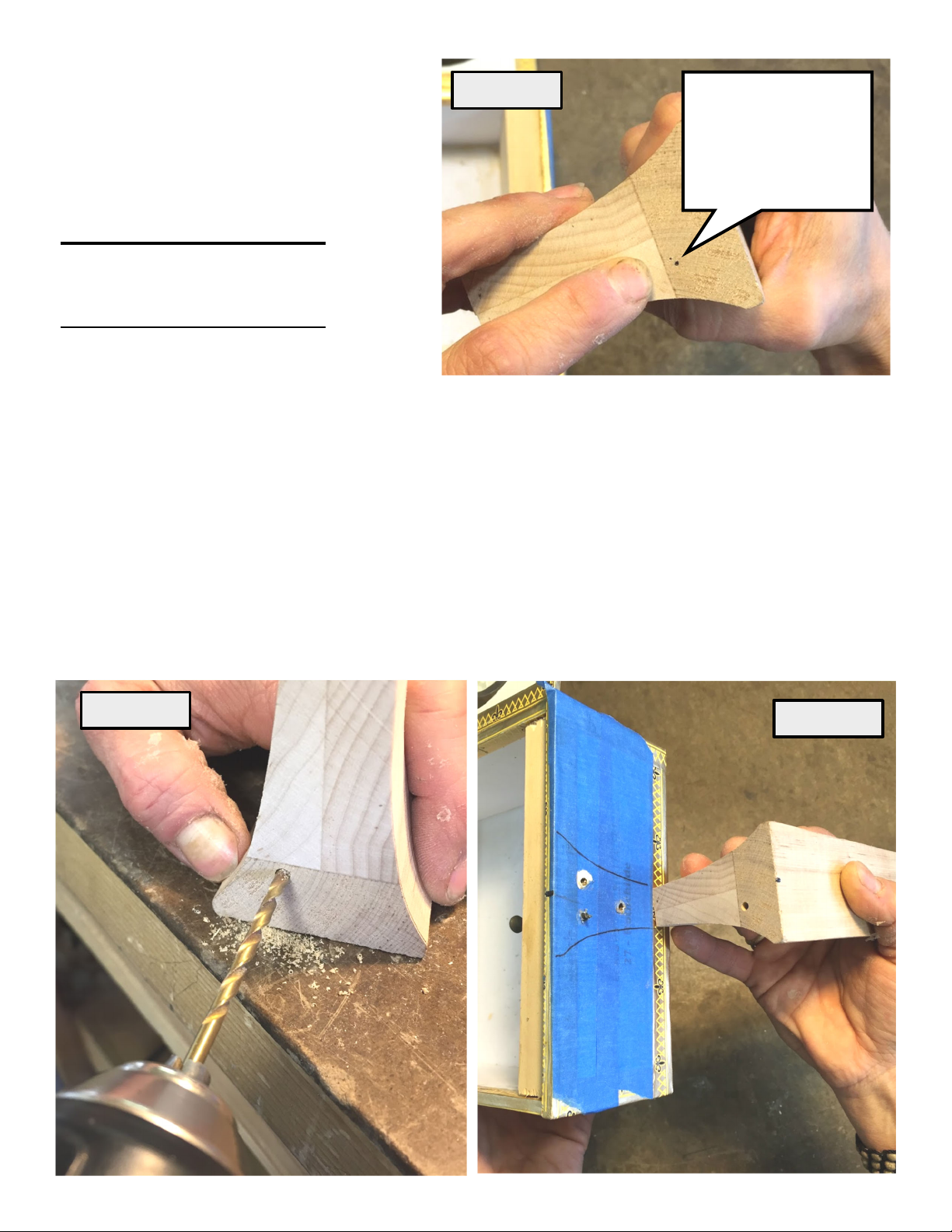

Once cut, your fretboard should line up evenly with the

end of the neck, as shown in Figure 13. Sand and

smooth the cut edge to remove any sharp points.

Step 2—Gluing on the Fretboard

Please note: if you have decided to leave your

fretboard at full length, you should not glue it

onto the neck until the neck has been mount-

ed onto the box.

Once the fretboard is glued on, you won’t be

able to open the box any more, so it is best to

wait to do this until towards the end of the as-

sembly process. The rest of these instructions

assume that the fretboard has been cut short-

er.

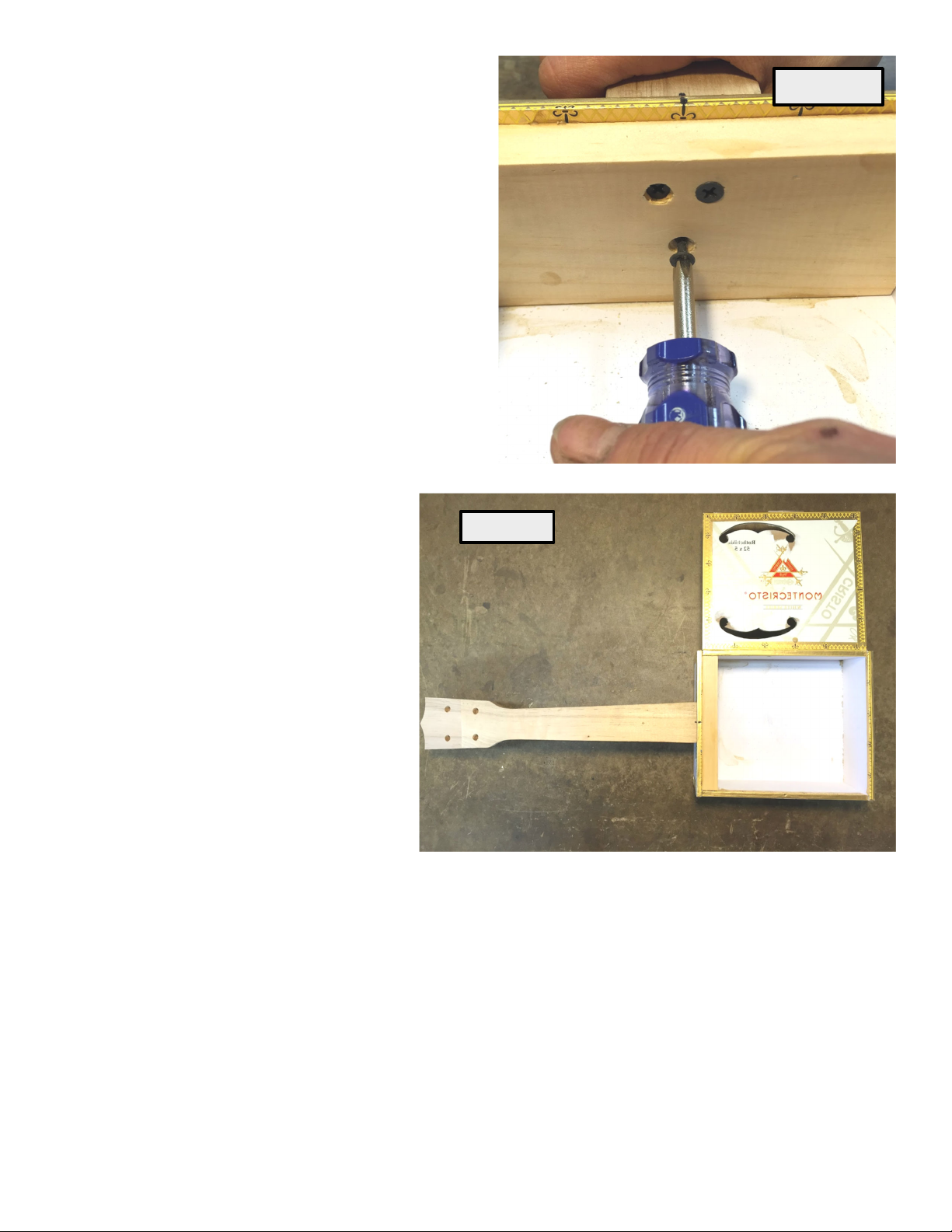

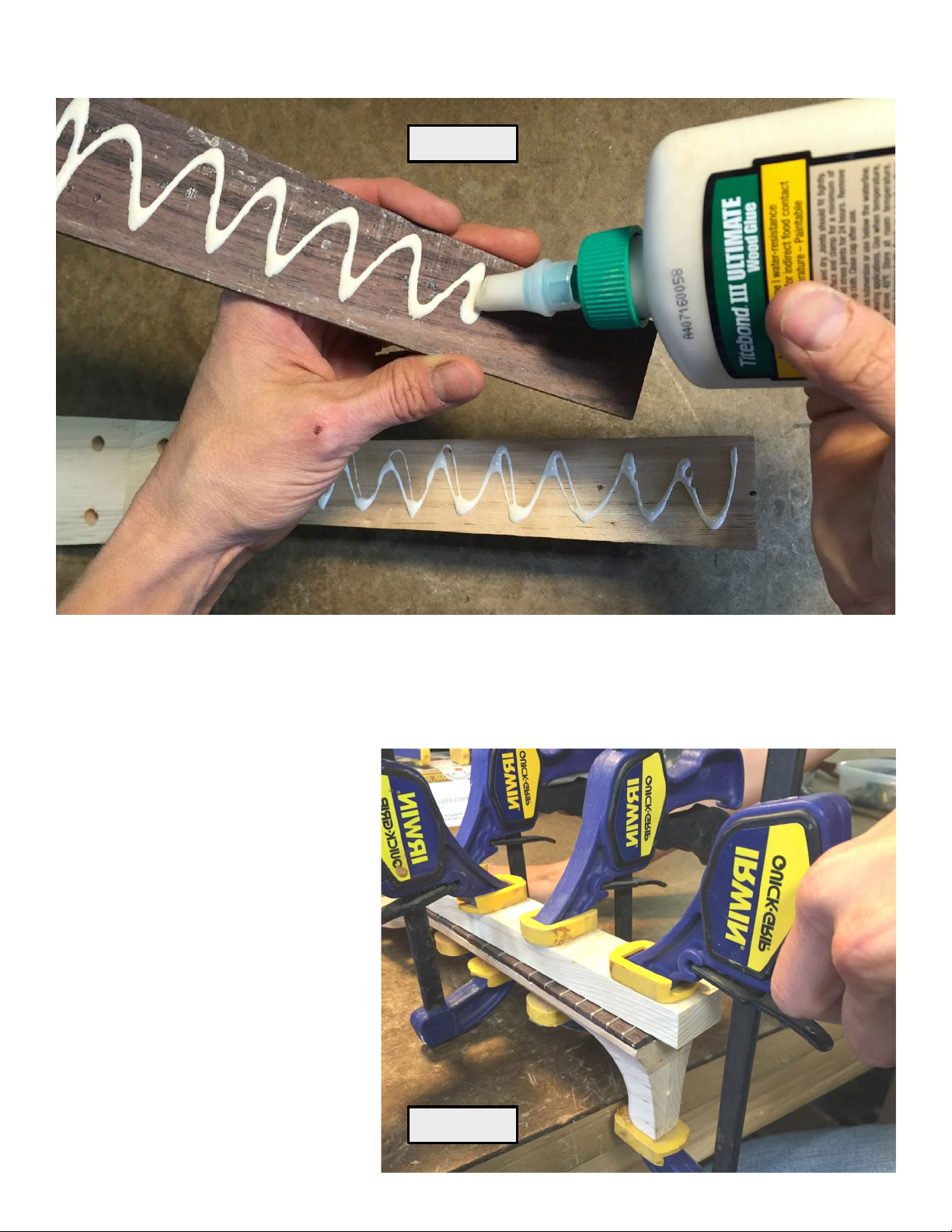

Once you have your fretboard cut to length, it

is time to get it glued onto the neck. Apply

wood glue to both the back of the fret board

and the top of the neck, as shown in Figure

14. Make sure to spread the glue around over

the entire surface—you want to make sure this

is a good, strong joint.

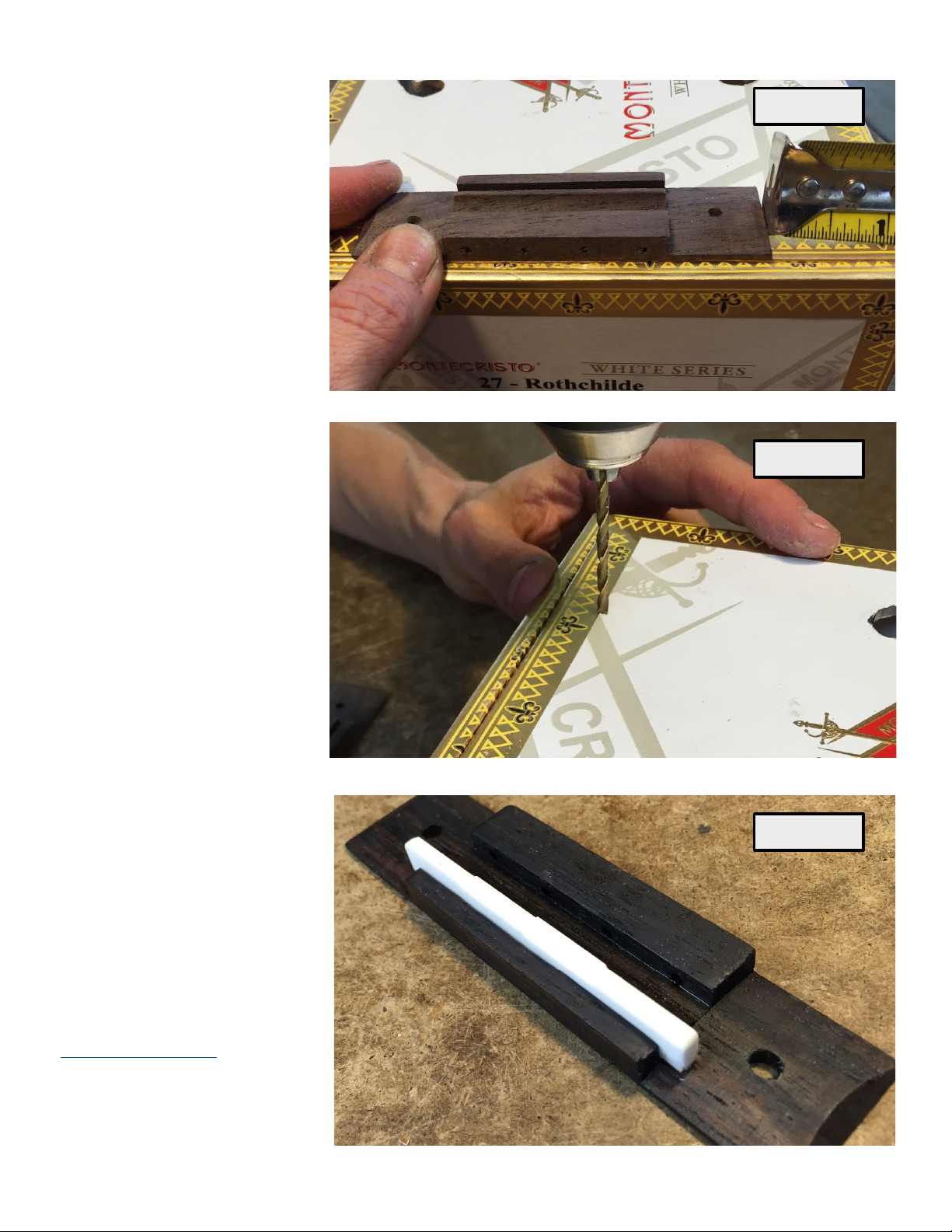

Line the top edge of the fretboard up with the mark you’ve made at the top of the neck. Firmly clamp the fret-

board to the neck, wiping off any excess glue that may squeeze out from between the two surfaces. Use as

many clamps as necessary to get a nice tight glue joint.

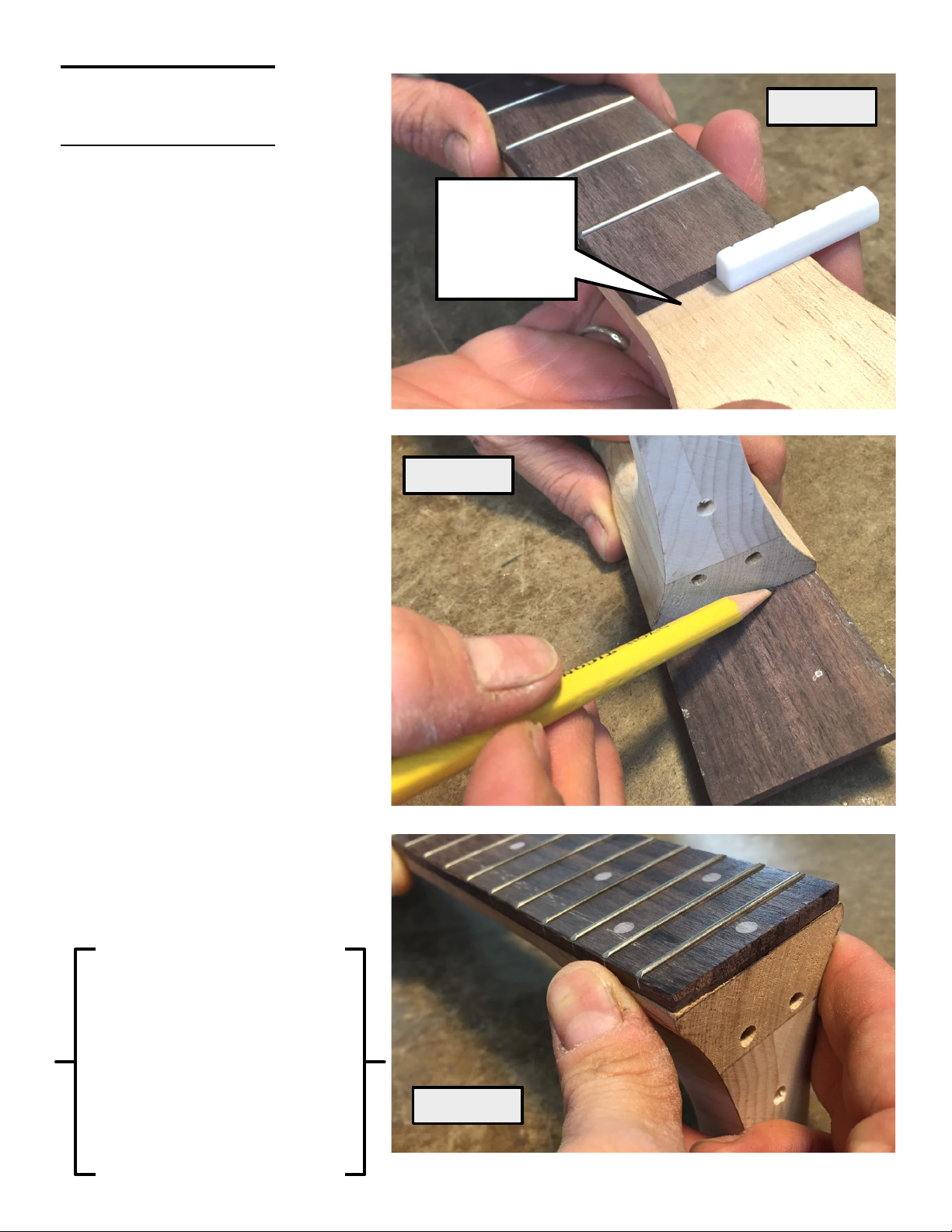

You may find it beneficial to use a scrap block of wood between the clamps and the fret board, as shown in

Figure 15. The wood block will help to protect the fret board and will evenly apply pressure across the entire

surface while the glue dries.

Be sure to let the glue set up for as long as is recommended on the glue bottle. In the C. B. Gitty shop we use

Titebond II or III wood glue, which creates a very strong glue bond (often stronger than the wood itself), but

you can use any standard-purpose wood or carpenter’s glue with good results.

Once the glue has dried, remove the clamps and examine your handiwork. This is a good time to do any final

sanding of the neck and fretboard, smoothing of fret ends and other finishing work on the neck.

Figure 9

Figure 10