23

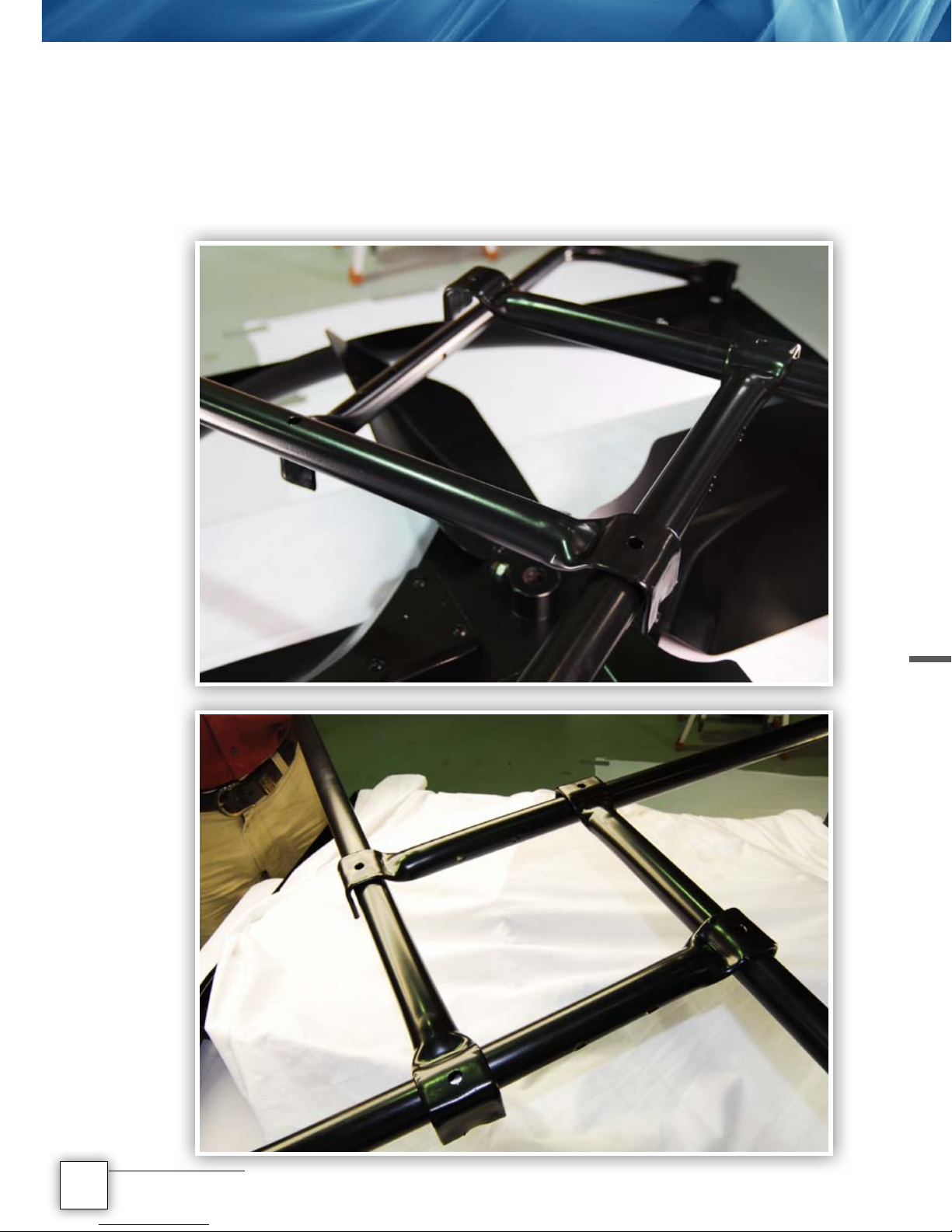

This picture shows the bend bars and fan in position around the fan shroud.

There is no particular start point to lay the bend bars out but what you have

to take care in, is that the bars have a running sequence. Start with the motor

mounting plate bend bar and place it at one of the 4 smaller holes punched

around the fan shroud and lay it over the fan in the middle. Then collect a

bearing housing bend bar (1 of 2 supplied) and lay it underneath the hand of

the motor mounting plate bend bar. What you effectively have, is left and over

right. Then take the bend bar with no additional holes along the shaft and lay

it underneath the 2nd bend bar (left hand over right). The last remaining bend

bar (should have 2 holes along the shaft for the bearing housing) is placed

underneath the 3rd bend bar and over the 1st. Again left hand over right.

Place the square piece of nylon (spacer) over the hole on the fan shroud

and underneath the foot of the bend bar.

Push the bolt from the underside of the fan shroud, up through the hole, the

nylon spacer and up through the foot of the bend bar. Place the washer over

the bolt and do the nylock nut up nger tight. Let go of the bend bar.

The smallest bolt, a washer and a nylock nut are used to locate the bend

bars into place. A 13mm spanner on both the nut and washer is generally all

that is needed.

6Fan Assembly 7

Fan Assembly

9

11

10