4

2. Safety Instruction

Before assembly and putting the machine into operation, please read

carefully the operating instructions:

1. Be thoroughly familiar with the controls and the proper use of the equipment.

Know how to stop the unit and disengage the control quickly.

2. Never allow children or people unfamiliar with these instructions to operate the

machine. Incorrect operation may result in bodily injury and damage to machine.

3. Never operate if people, especially children or pets are nearby

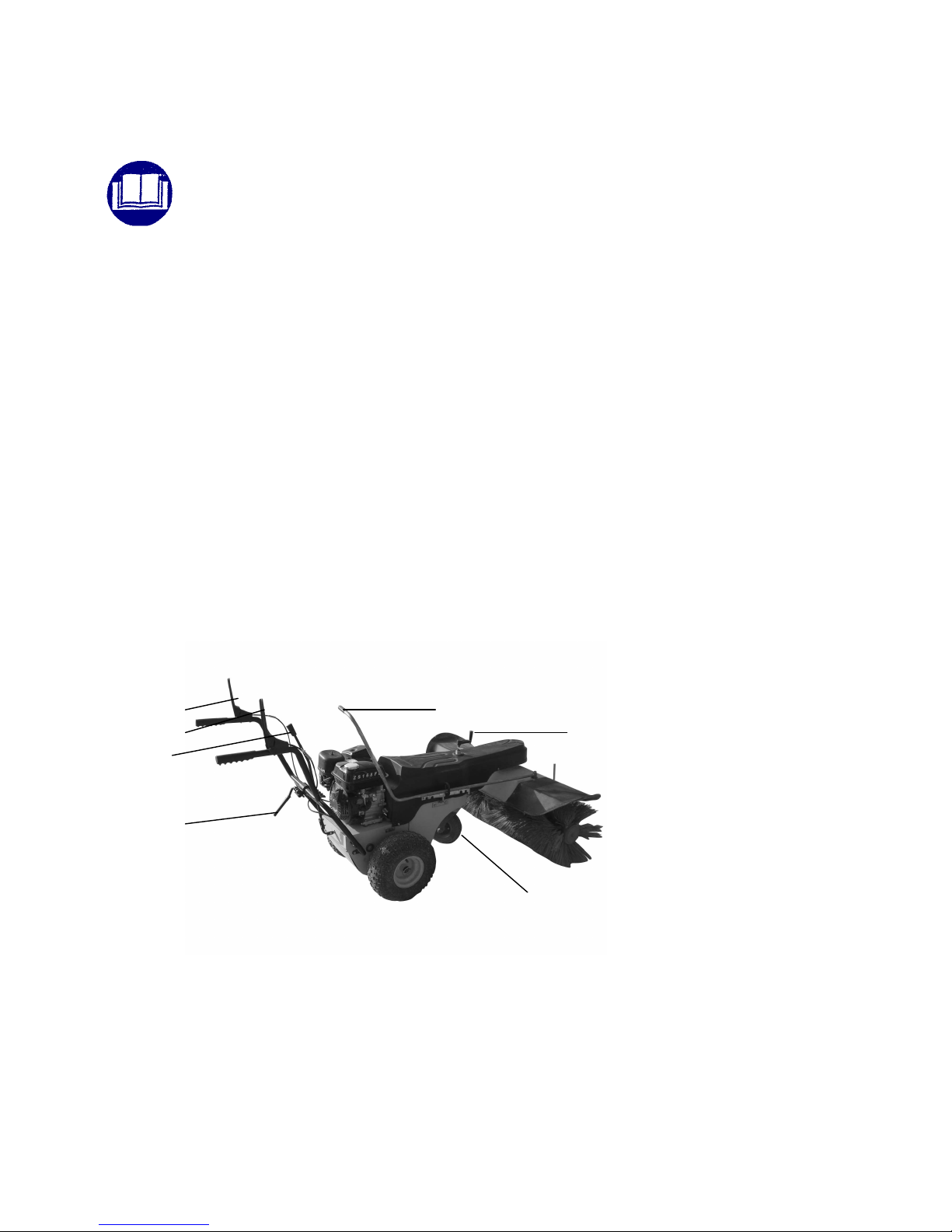

4. Do not run when pushing this unit, but walk at a normal speed while operating this

machine.

5. Keep your body and clothes away from the heating or rotating parts of this unit. No

loose clothes, neckties and necklaces are allowed when you operate this unit.

6. Inspect the working area of this unit completely and remove all obstacles.

7. Do not use this unit on a bumpy or steep road. Exercise caution to avoid slipping or

falling, especially when operating in reverse.

8. Take care in operation, especially when crossing a road, to prevent accidents.

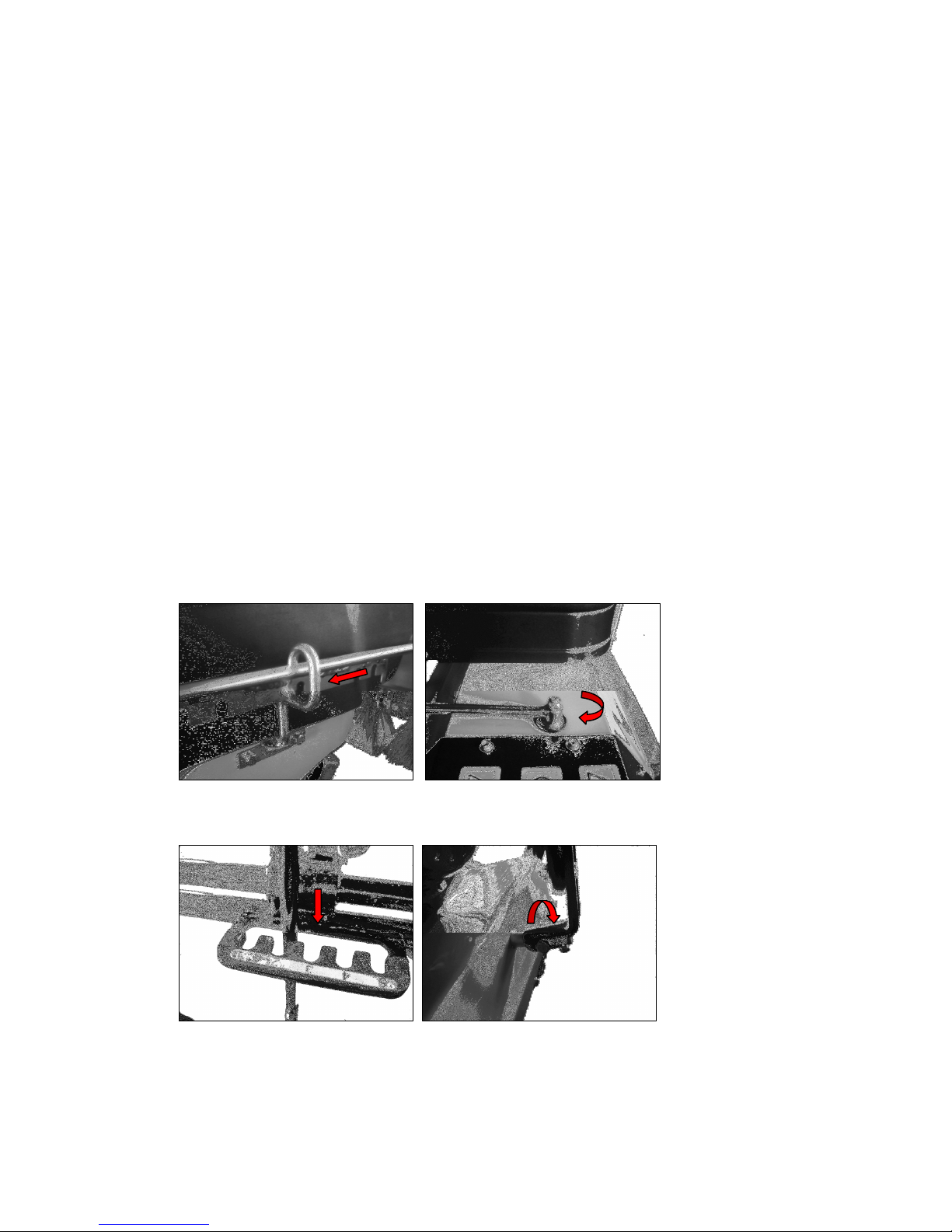

9. Inspect that all nuts, bolts and brush rollers are tight and well connected to ensure

the safety and reliability of this unit prior to any operation.

10. Adjust the clutch pull cable to ensure it is flexible and reliable.

11. Adjust the brush to proper height prior to any operation.

12. If the unit strikes a foreign object or starts to vibrate abnormally, stop the engine

and check immediately for the cause (this is very important!)

13. Stop the engine and pull out the spark plug whenever you leave the operating

position, before making any repairs, adjustments, inspections or approaching

running parts.

14. Inspect the air pressure in the tires prior to use and pay attention to sharp objects

when using this unit to prevent the tire from being pierced.

15. Replace worn components for safety reasons prior to use.

16. Take care during the adjustment or maintenance of this unit to prevent any injury to

your fingers.

17. Don’t operate this machine without essential safety equipment (goggles, earplug

and dust proof mask, etc.).

18. Inspect the fuel container before operating the machine; the fuel container must be

full.

Warning: Gasoline is highly flammable.

* Use the approved fuel.

* Add fuel before starting engine. Never remove the cap of the fuel tank or add fuel to

a running or hot engine.

* Refuel outdoors only and don’t smoke while refueling.

* Screw the filler cap on securely and wipe up spilt petrol.

* Move machine at least 3m away from the refueling point before starting engine.

* Always store gasoline in a container approved for containing flammable liquids.