n

be alert to the potential for personal injury. Understand these signal

words: DANGER. WARNING. and CAUTION. These words are

used with the safety-alert symbol. DANGER identifies the most se-

rious hazards which will result in severe personal injury or death.

WARNING signifies hazards which could result in personal injury

or death. CAUTION is used to identify unsafe practices which may

result in minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in en-

hanced installation, reliability, or operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing or servicing system, always turn off main

power to system. There may be more than one disconnect

switch. Turn off accessory heater power switch if applicable.

FIRE, EXPLOSION, ELECTRICAL SHOCK AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury

or unit damage.

A qualified installer or agency must use only

factory-authorized kits or accessories when modifying this

product.

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to relieve system pressure could result in personal

injury and/or death.

1. Relieve pressure and recover all refrigerant before servicing

existing equipment, and before final unit disposal. Use all

service ports and open all flow-control devices, including

solenoid valves.

2. Federal regulations require that you do not vent refrigerant

into the atmosphere. Recover during system repair or final unit

disposal.

INTRODUCTION

The 48SD unit (see Fig. 1) is a fully self-contained, combination

Category I gas heating/electric cooling unit designed for outdoor

installation (See Fig. 3 and 4 for unit dimensions). All unit sizes

have return and discharge openings for both horizontal and

downflow configurations, and are factory shipped with all

downflow duct openings covered. Units may be installed either on

a rooftop, a cement slab, or directly on the ground if local codes

permit (See Fig. 5 for roof curb dimensions).

Models with an N in the fifth position of the model number are

dedicated Low NOx units designed for California installations.

These models meet the California maximum oxides of nitrogen

(NOx) emissions requirements of 40 nanograms/joule or less as

shipped from the factory and must be installed in California Air

Quality Management Districts or any other regions in North

America where a Low NOx rule exists.

NOTE: Low NOx requirements apply only to natural gas

installations.

RECEIVING AND INSTALLATION

Step 1--Check Equipment

IDENTIFY UNIT

The unit model number and serial number are stamped on the unit

information plate. Check this information against shipping papers.

INSPECT SHIPMENT

Inspect for shipping damage while unit is still on shipping pallet. If

unit appears to be damaged or is torn loose from its anchorage, have

it examined by transportation inspectors before removal. Forward

claim papers directly to transportation company. Manufacturer is

not responsible for any damage incurred in transit. Check all items

against shipping list. Immediately notify the nearest equipment

distribution office if any item is missing. To prevent loss or damage,

leave all parts in original packages until installation.

Step 2_Provide Unit Support

For hurricane tie downs, contact distributor for details and PE

(Professional Engineering) Certificate if required.

ROOF CURB

Install accessory roof curb in accordance with instructions shipped

with curb (See Fig. 5). Install insulation, cant strips, roofing, and

flashing. Ductwork must be attached to curb.

IMPORTANT: The gasketing of the unit to the roof curb is critical

for a water tight seal. Install gasketing material supplied with the

roof curb. Improperly applied gasketing also can result in air leaks

and poor unit performance.

Curb should be level to within 1/4 in. (6.4 mm). This is necessary

for unit drain to function properly. Refer to accessory roof curb

installation instructions for additional information as required.

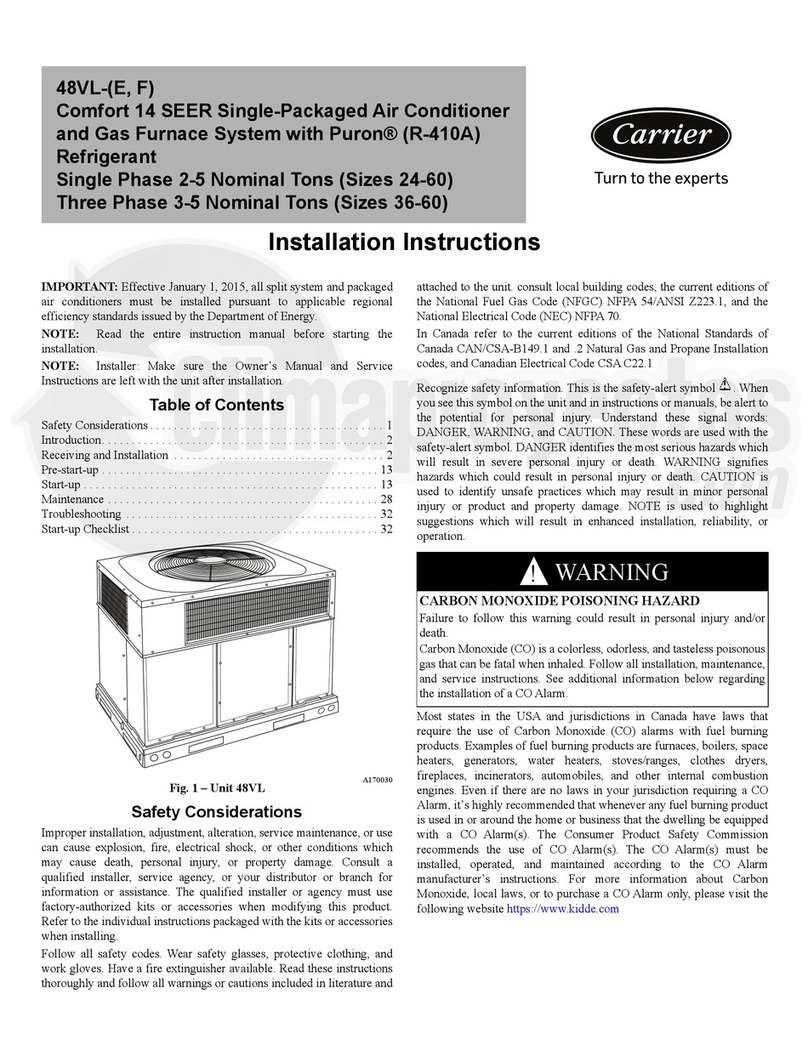

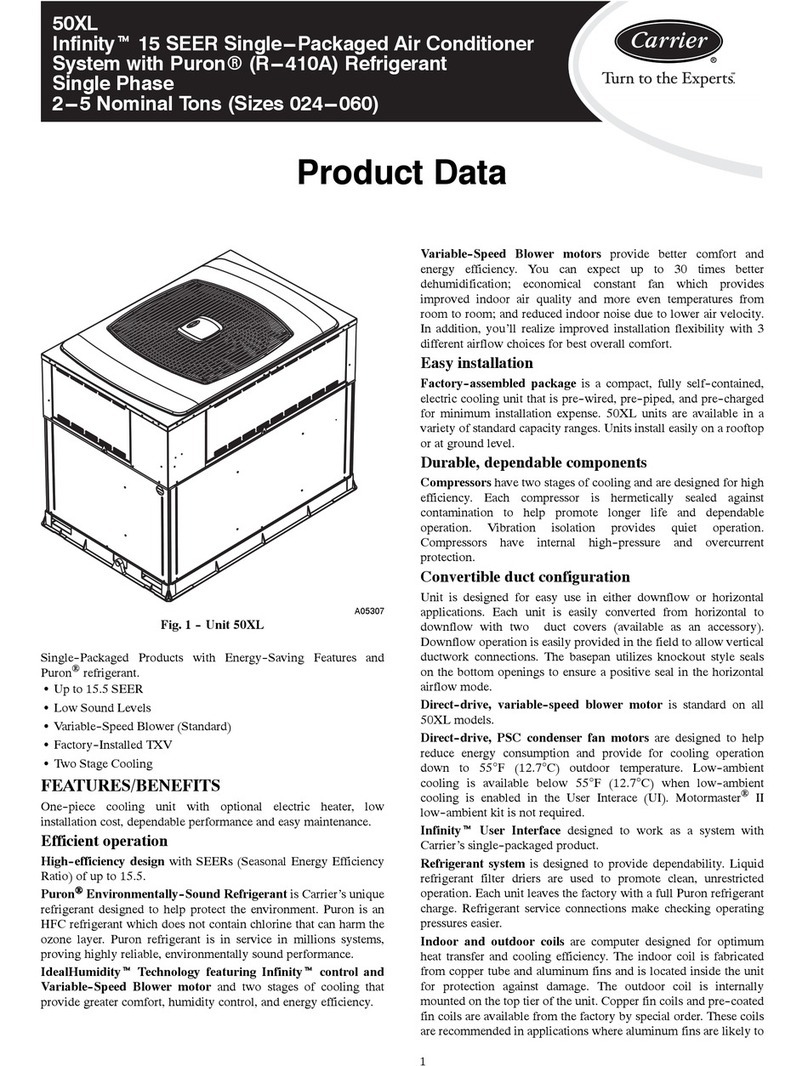

SLAB MOUNT

Place the unit on a solid, level concrete pad that is a minimum of 4

in. (102 mm) thick with 2 in. (51 mm) above grade (See Fig. 2). The

slab should extend approximately 2 in. (51 mm) beyond the casing

on all 4 sides of the unit. Do not secure the unit to the slab except

when rec uired by local codes.

EVAR COIL COND. COIL

c9g096

Fig. 2 - Slab Mounting Details

GROUND MOUNT

The unit may be installed either on a slab or placed directly on the

ground, if local codes permit. Place the unit on level ground

prepared with gravel for condensate discharge.

Step 3--Field Fabricate Ductwork

Secure all ducts to roof curb and building structure on vertical

discharge units. Do not connect ductwork to unit. For horizontal

applications, unit is provided with flanges on the horizontal

openings. All ductwork should be secured to the flanges. Insulate

and weatherproof all external ductwork, joints, and roof openings

with counter flashing and mastic in accordance with applicable

codes.

Ducts passing through an unconditioned space must be insulated

and covered with a vapor barrier.

If a plenum return is used on a vertical unit. the return should be

ducted through the roof deck to comply with applicable fire codes.

A minimum clearance is not required around ductwork. Cabinet

return-air static shall not exceed -.25 in. wc.