Carrier 53SSA009 1 Series User manual

Other Carrier Air Conditioner manuals

Carrier

Carrier 40MHH User manual

Carrier

Carrier SUPRA HE Series User manual

Carrier

Carrier 48TC series Guide

Carrier

Carrier 53QPCT18H-708F User manual

Carrier

Carrier 40JX Manual

Carrier

Carrier INFINITY 24ANA User manual

Carrier

Carrier 48/50PG Series User guide

Carrier

Carrier COMFORT 52C SERIES User manual

Carrier

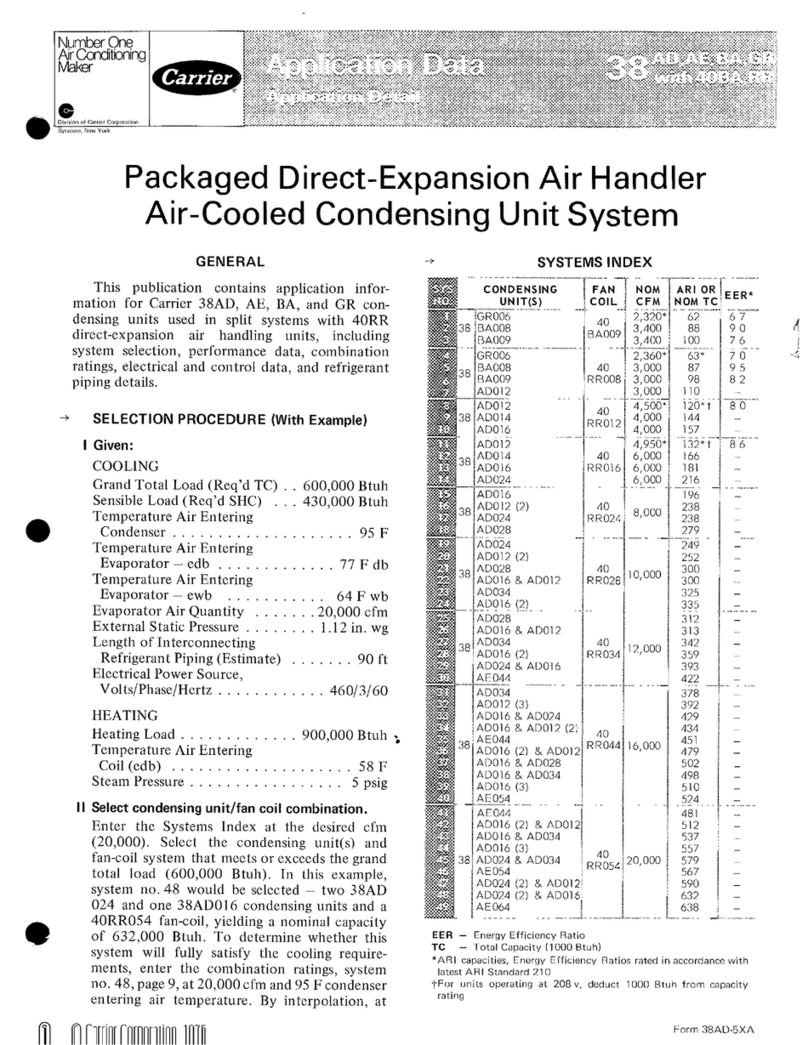

Carrier 38BA User guide

Carrier

Carrier Performance 50VG Instruction Manual

Carrier

Carrier 42NQ024 User manual

Carrier

Carrier Performance 15 48VR-A Instruction Manual

Carrier

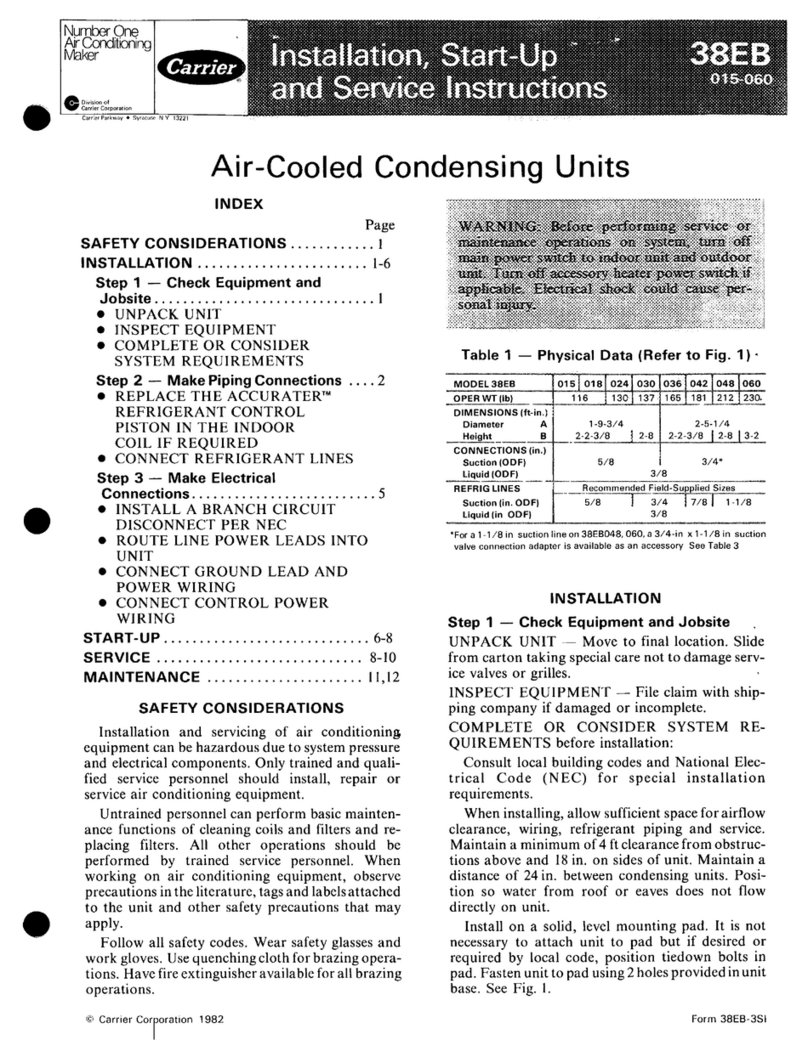

Carrier 38EB Dimensions and installation guide

Carrier

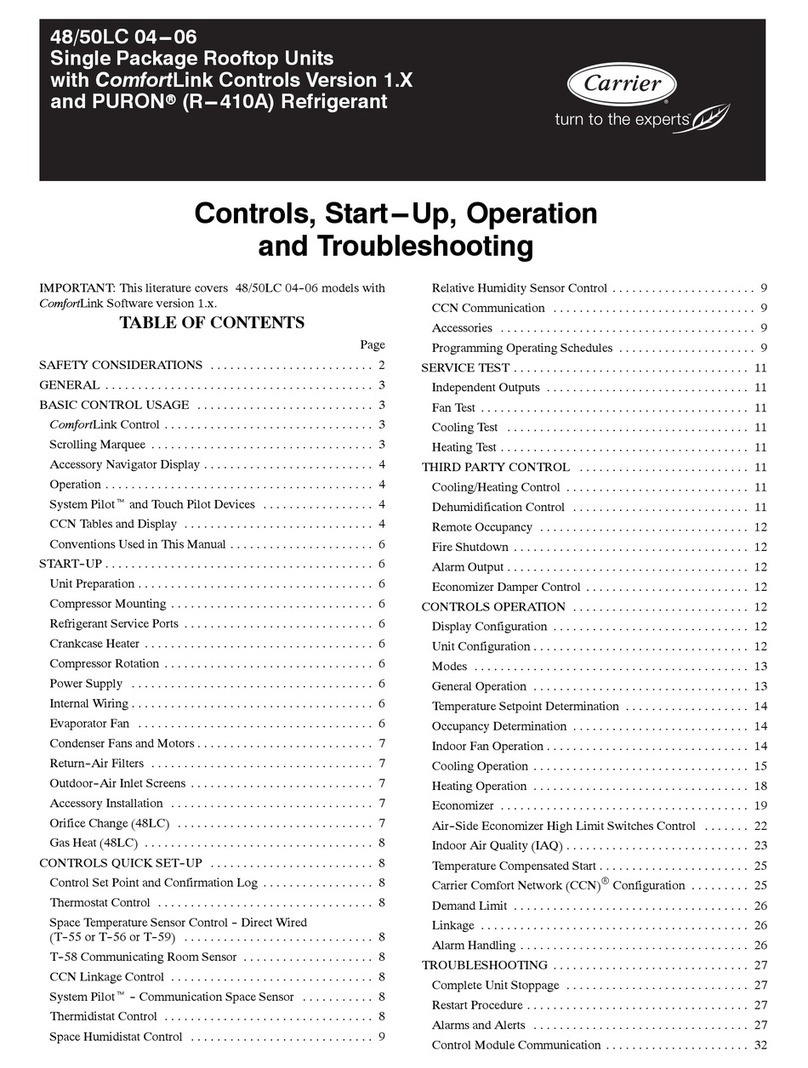

Carrier WeatherExpert 50LC User manual

Carrier

Carrier MODU-PAC 50DF Operation manual

Carrier

Carrier Expressions 38CS030 User manual

Carrier

Carrier Viento 200 Installation and operating instructions

Carrier

Carrier CDII-184R1-0CTR4 User manual

Carrier

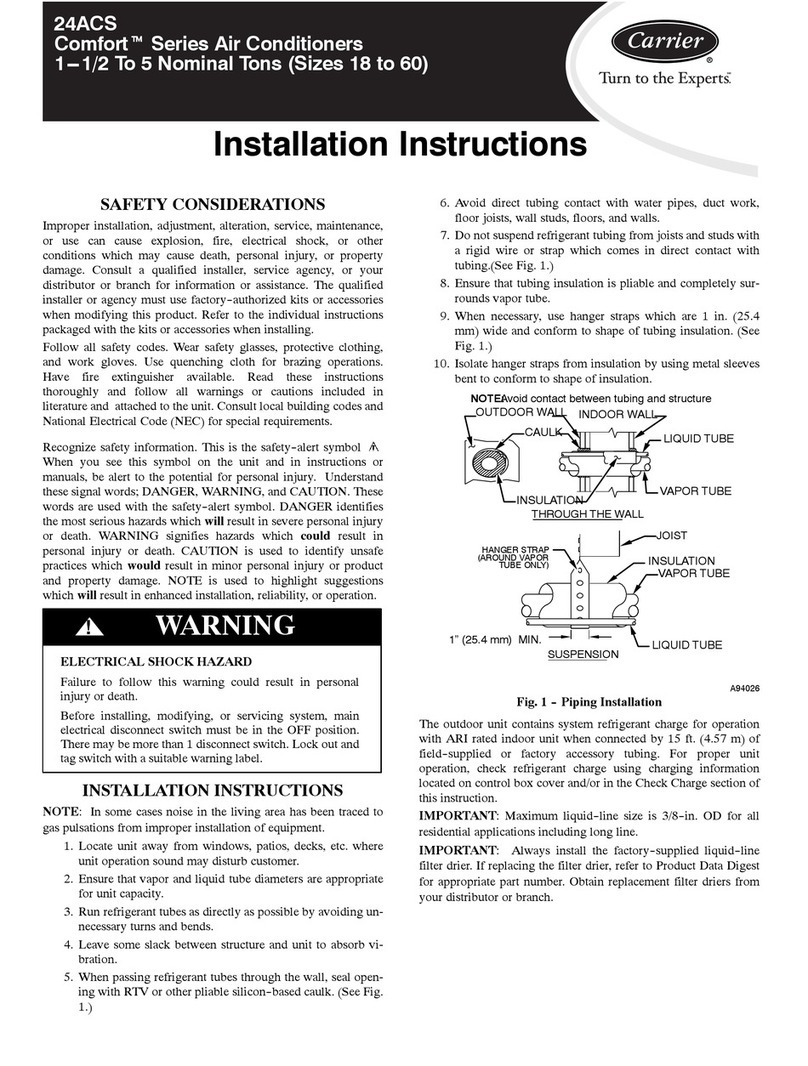

Carrier Comfort 24ACS User manual

Carrier

Carrier 38CKC User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions