downflow installations, factory accessory floor base MUST be

used when installed on combustible materials and wood flooring.

Special base is not required when this furnace is installed on

manufacturer’s Coil Assembly Part No. CD5 or CK5, or when Coil

Box Part No. KCAKC is used. is used.

The 58MXA 040 through 120 size units are C.S.A. (A.G.A. and

C.G.A.) design-certified for use in manufactured (mobile) homes

when factory accessory conversion kit is used. The 140 size unit is

NOT design-certified for use in manufactured (mobile) homes.

These furnaces are suitable for installation in a structure built on

site or a manufactured building completed at final site. The design

of this furnace line is NOT C.S.A. design-certified for installation

in recreation vehicles or outdoors.

This furnace is designed for continuous return-air minimum

temperature of 60 °F db or intermittent operation down to 55°F db.

Return-air temperature must not exceed 85°F db. See Fig. 4.

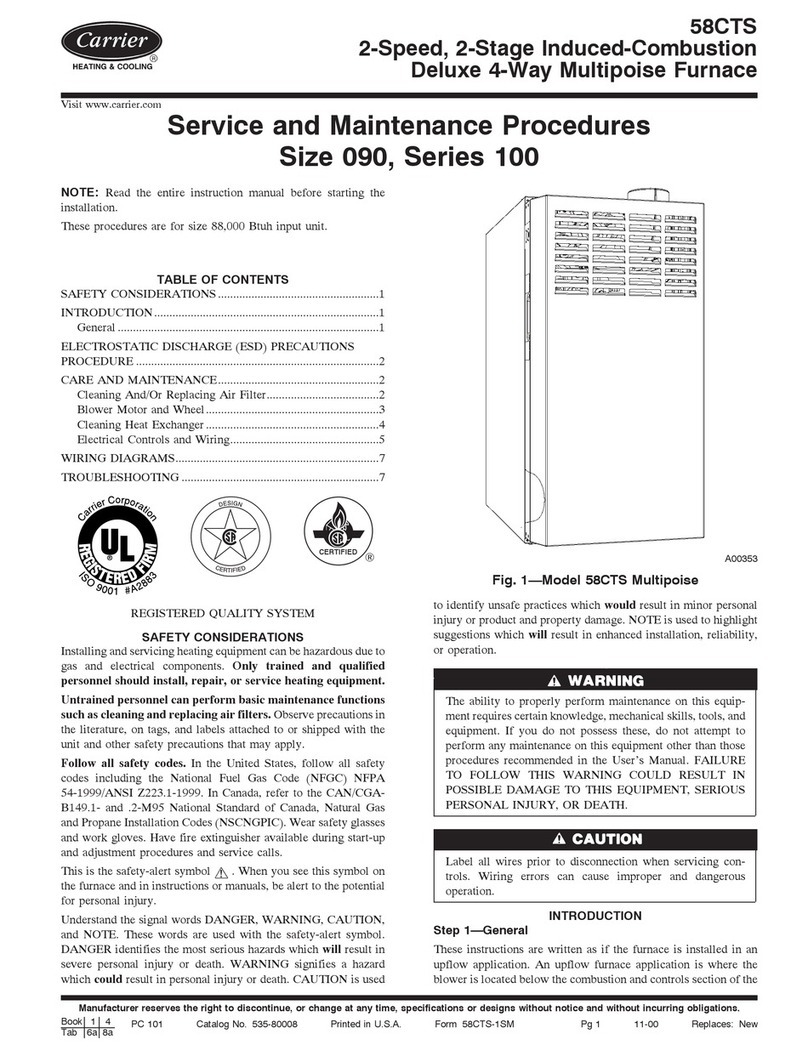

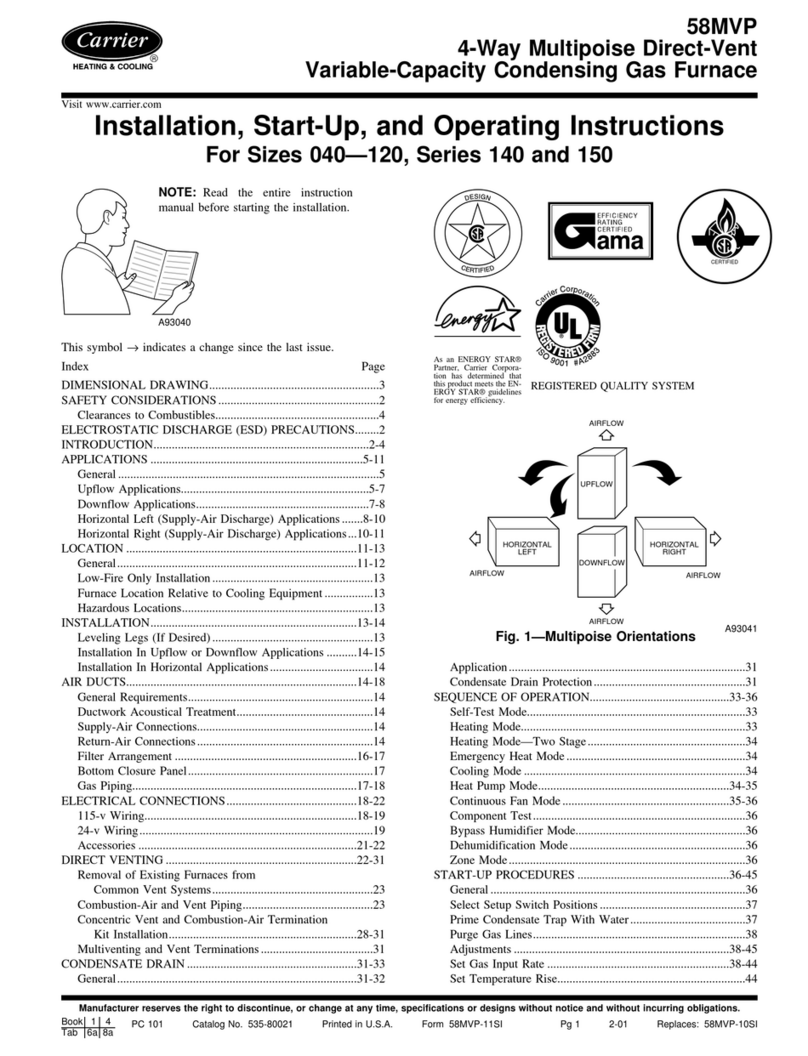

These furnaces are shipped with the drain and pressure tubes

connected for UPFLOW applications. Minor modifications are

required when used in DOWNFLOW, HORIZONTAL RIGHT, or

HORIZONTAL LEFT (supply-air discharge direction) applica-

tions as shown in Fig. 1. See details in Applications section.

This furnace must be installed with a direct-vent (combustion air

and flue) system and a factory accessory termination kit. In a

direct-vent system, all air for combustion is taken directly from the

outside atmosphere and all flue products are discharged to the

outside atmosphere. See furnace and factory accessory termination

kit instructions for proper installation.

These furnaces are shipped with the following materials to assist in

proper furnace installation. These materials are shipped in the main

blower compartment.

Installer Packet includes:

Installation, Startup, and Operating Instructions

Service and Maintenance Instructions

User’s Information Manual

Warranty Certificate

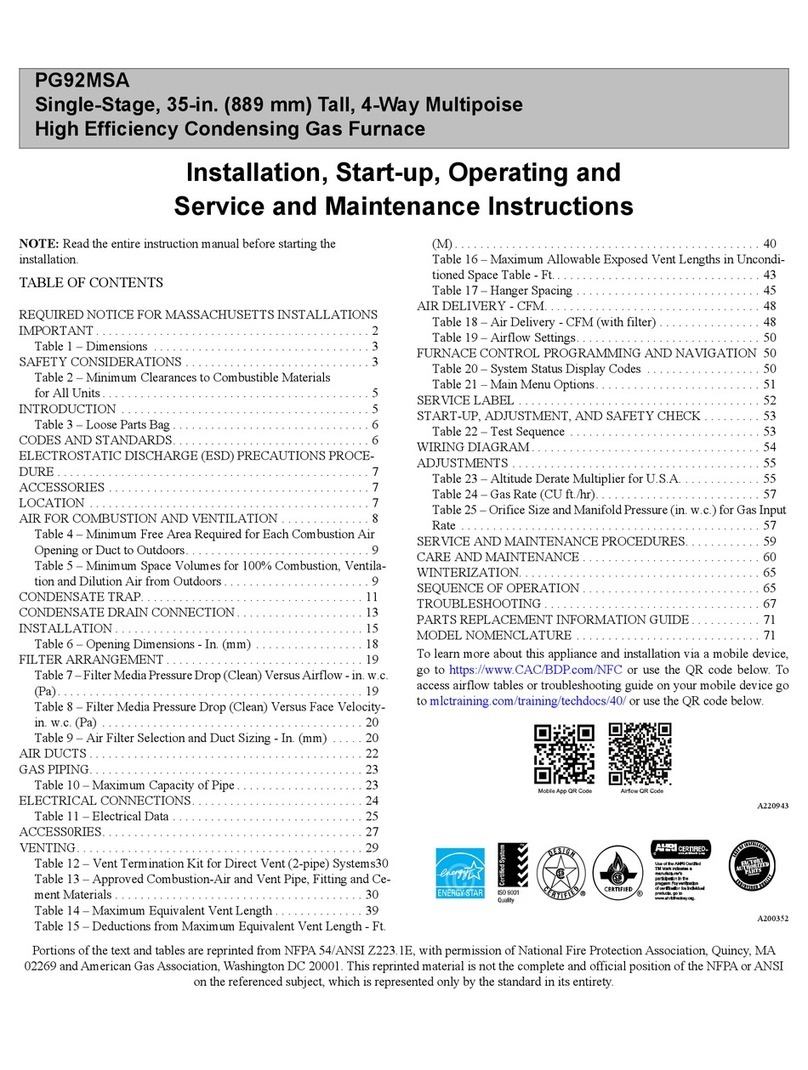

Loose Parts Bag includes: Quantity

Pressure tube extension 1

Collector Box or condensate trap extension tube 1

Inducer housing drain tube 1

1/2-in CPVC street elbow 2

Drain tube coupling 1

Drain tube coupling grommet 1

Vent and combustion-air pipe support 2

Condensate trap hole filler plug 3

Vent and combustion-air intake hole filler plug 2

Combustion-air pipe perforated disk assembly 1

Vent Pipe Extension 1*

* ONLY supplied with some furnaces.

INTRODUCTION

The model 58MXA 4-way multipoise, Gas-Fired, Category IV,

direct-vent condensing furnace is available in model sizes ranging

in input capacities of 40,000 to 138,000 Btuh.

CODES AND STANDARDS

Follow all national and local codes and standards in addition to

these instructions. The installation must comply with regulations

of the serving gas supplier, local building, heating, plumbing, and

other codes. In absence of local codes, the installation must

comply with the national codes listed below and all authorities

having jurisdiction.

In the United States and Canada, follow all codes and standards for

the following:

Step 1—Safety

•US: National Fuel Gas Code (NFGC) NFPA 54-1999/ANSI

Z223.1-1999 and the Installation Standards, Warm Air Heating

and Air Conditioning Systems ANSI/NFPA 90B

•CANADA: National Standard of Canada, Natural Gas and

Propane Installation Code (NSCNGPIC) CSA B149.1-00

Step 2—General Installation

•US: NFGC and the NFPA 90B. For copies, contact the National

Fire Protection Association Inc., Batterymarch Park, Quincy,

MA 02269; or for only the NFGC contact the American Gas

Association, 400 N. Capitol, N.W., Washington DC 20001

•CANADA: NSCNGPIC. For a copy, contact Standard Sales,

CSA International, 178 Rexdale Boulevard, Etobicoke (Tor-

onto), Ontario, M9W 1R3, Canada.

Step 3—Combustion and Ventilation Air

•US: Section 5.3 of the NFGC, Air for Combustion and

Ventilation

•CANADA: Part 7 of the NSCNGPIC, Venting Systems and Air

Supply for Appliances

Step 4—Duct Systems

•US and CANADA: Air Conditioning Contractors Association

(ACCA) Manual D, Sheet Metal and Air Conditioning Con-

tractors National Association (SMACNA), or American Soci-

ety of Heating, Refrigeration, and Air Conditioning Engineers

(ASHRAE) 2001 Fundamentals Handbook Chapter 34.

Step 5—Acoustical Lining and Fibrous Glass Duct

•US and CANADA: current edition of SMACNA, NFPA 90B as

tested by UL Standard 181 for Class I Rigid Air Ducts

Step 6—Gas Piping and Gas Pipe Pressure Testing

•US: NFGC; chapters 2,3,4, and 9 and national plumbing codes

•CANADA: NSCNGPIC Parts 3, 4, 5, A, B, E, and H.

Step 7—Electrical Connections

•US: National Electrical Code (NEC) ANSI/NFPA 70-2002

•CANADA: Canadian Electrical Code CSA C22.1

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

Electrostatic discharge can affect electronic components.

Take precautions during furnace installation and servicing to

protect the furnace electronic control. Precautions will pre-

vent electrostatic discharges from personnel and hand tools

which are held during the procedure. These precautions will

help to avoid exposing the control to electrostatic discharge

by putting the furnace, the control, and the person at the same

electrostatic potential.

1. Disconnect all power to the furnace. Multiple disconnects may

be required. DO NOT TOUCH THE CONTROL OR ANY

WIRE CONNECTED TO THE CONTROL PRIOR TO DIS-

CHARGING YOUR BODY’S ELECTROSTATIC CHARGE

TO GROUND.

2. Firmly touch the clean, unpainted, metal surface of the furnace

chassis which is close to the control. Tools held in hand during

grounding will be discharged.

3. You may proceed to service the control or connecting wires as

long as you do nothing to recharge your body (moving or

shuffling feet, touching ungrounded objects, etc.).

4. If you touch ungrounded objects, firmly touch a clean,

unpainted metal surface again before touching control or

wires.

5. Before removing a new control from its container, discharge

your body’s charge to ground. If the control is to be installed

in a furnace, follow items 1 through 4 before bringing the

3

→

→