Table of Contents

Section A. Before You Begin............................................................................................................................................. 4

A.1 Unit Diagram ........................................................................................................................................................... 4

A.2 System Requirements ............................................................................................................................................. 4

Section B. Unit Setup ....................................................................................................................................................... 5

B.1 Uncrating Requirements ......................................................................................................................................... 5

B.2 Uncrating Procedure ............................................................................................................................................... 5

B.3 Packing List / Loose Parts ........................................................................................................................................ 6

B.4 Initial Adjustments & Settings................................................................................................................................. 6

B.5 Unloading Cans ....................................................................................................................................................... 7

Section C. ACS Operations Overview ............................................................................................................................... 9

C.1 System Operation Walkthrough ............................................................................................................................. 9

C.2 Controllers............................................................................................................................................................... 9

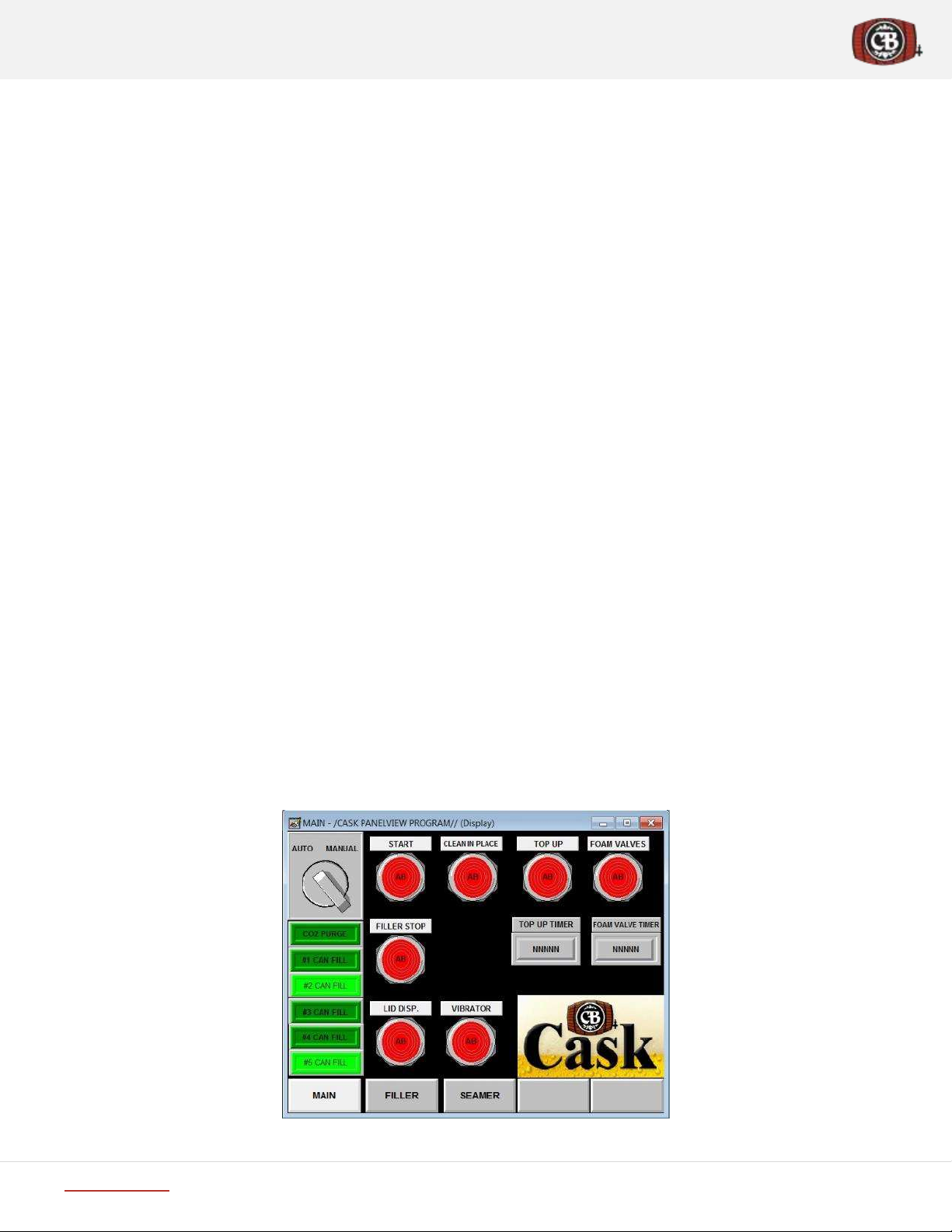

C.3 HMI Control Panel Operations .............................................................................................................................. 12

C.4 Electrical Panel Overview...................................................................................................................................... 13

C.5 Can Filling .............................................................................................................................................................. 18

C.6 Lid Dispenser ......................................................................................................................................................... 19

C.7 Parts in Motion: Pneumatics................................................................................................................................. 19

C.8 Parts in Motion: Motors........................................................................................................................................ 20

Section D. ACS System Operations................................................................................................................................. 22

D.1 Initial Start-up Adjustments & Settings ................................................................................................................ 22

D.2 Pre-Start Checklist................................................................................................................................................. 22

D.3 Startup & Operation.............................................................................................................................................. 23

D.4 Clean in Place (CIP) System ................................................................................................................................... 23

D.5 ACS Post-Operation Shutdown Checklist.............................................................................................................. 24

D.6 System Periodic Maintenance .............................................................................................................................. 25

D.7 Parts List................................................................................................................................................................ 25

D.8 Adjustment & Troubleshooting ............................................................................................................................ 27

D.9 Frequently Asked Questions ................................................................................................................................. 32

Section E. Seam Measurement.......................................................................................................................................... 37

E.1 Can Seam Evaluation Training Videos................................................................................................................... 37

E.2 Manual Seam Evaluation Process ......................................................................................................................... 38

E.3 Reading a Seam Micrometer................................................................................................................................. 38

E.4 Seam Measurement.............................................................................................................................................. 39

E.5 Seam Troubleshooting .......................................................................................................................................... 42

E.6 Seam Specifications .............................................................................................................................................. 42

Section F. Can Seamer ....................................................................................................................................................... 43

F.1 Seamer Adjustment & Troubleshooting ............................................................................................................... 43

F.2 Seamer Troubleshooting....................................................................................................................................... 47

F.3 Bearing Replacement ............................................................................................................................................ 47

Section G. Safety ............................................................................................................................................................ 49

Section H. Warranty Information ................................................................................................................................... 50

Section I. Company Information ....................................................................................................................................... 51