Index

1

Brave 30 ES - Brave 60 ES- Brave 90 ES

Index

1 - Safety .....................................................................................................................3

1.1 Intended use ..................................................................................................................... 3

1.2 Improper use .................................................................................................................... 3

1.3 List of hazards ................................................................................................................... 4

1.4 Residual risks .................................................................................................................... 6

2 - General information ............................................................................................... 7

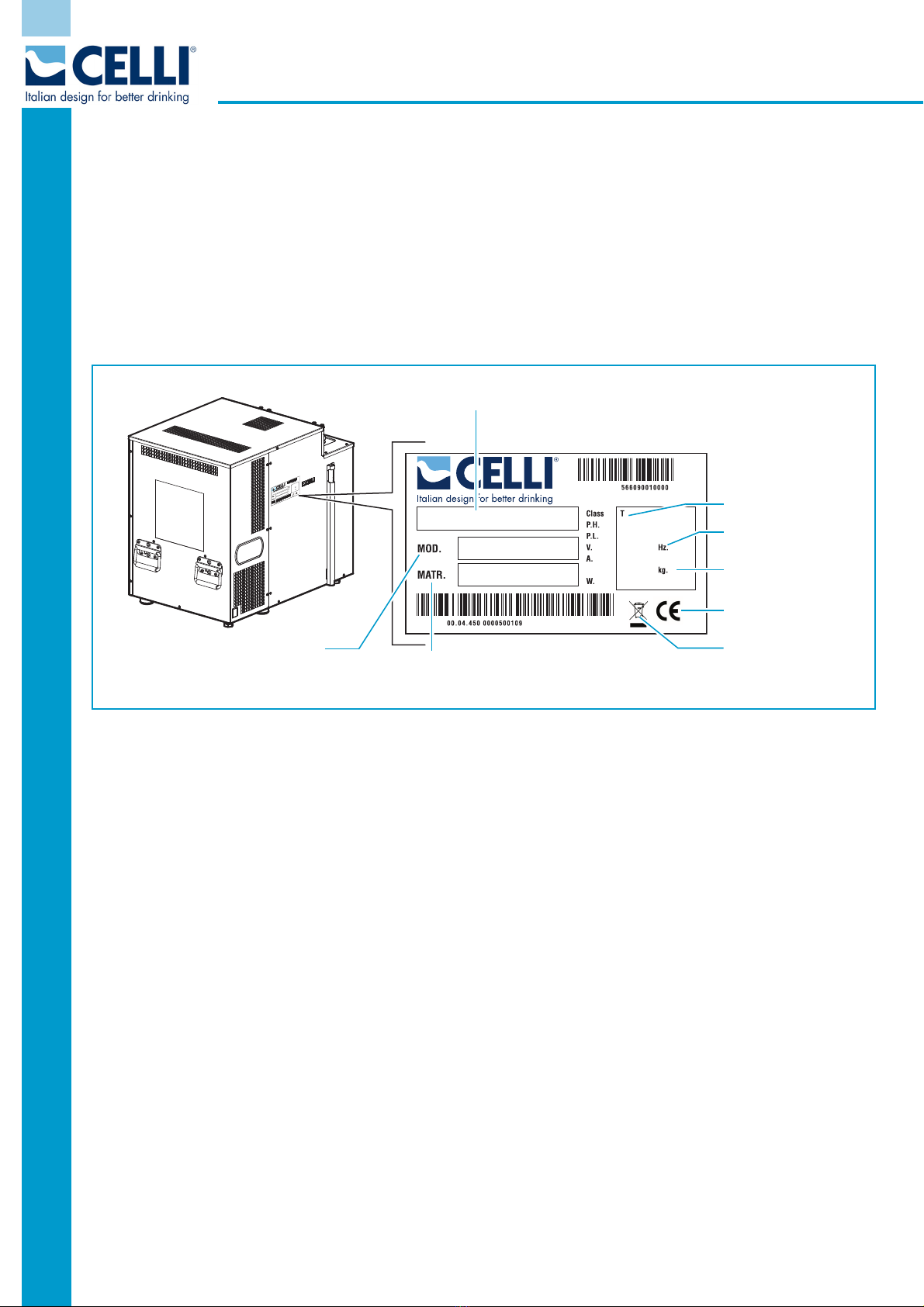

2.1 Manufacturer’s details ........................................................................................................ 7

2.2 Machinery identification...................................................................................................... 8

2.3 Warranty........................................................................................................................... 8

2.4 Symbols used in the manual ............................................................................................... 9

2.5 Staff qualification............................................................................................................... 9

3 - Description of the machine ..................................................................................10

3.1 Main components of the BRAVE 30 ES................................................................................11

3.2 Main components of the BRAVE 60 ES................................................................................13

3.3 Main components of the BRAVE 90 ES................................................................................15

3.4 Operating principle............................................................................................................17

3.5 Energy Saving control unit, and button pad with display ......................................................20

3.5.1 Standard functions ...................................................................................................21

3.5.2 Optional functions ....................................................................................................22

3.6 Technical data ..................................................................................................................25

3.6.1 Sound emissions ......................................................................................................25

3.7 Dimensions in mm ............................................................................................................26

3.7.1 BRAVE 30 ES............................................................................................................26

3.7.2 BRAVE 60 ES............................................................................................................26

3.7.3 BRAVE 90 ES............................................................................................................26

3.8 Differential-switch power cord (optional) ............................................................................27

4 - Installation ........................................................................................................... 28

4.1 Checks and Unpacking ......................................................................................................28

4.2 Positioning .......................................................................................................................28

4.3 Environmental conditions...................................................................................................29

4.4 Electrical requisites ...........................................................................................................29

4.5 Connections .....................................................................................................................30

4.5.1 Preparing the machine..............................................................................................30

4.5.2 Water intake connection ...........................................................................................31

4.5.3 Connecting the syrup lines ........................................................................................33

4.5.4 Connecting the soda recirculation line ........................................................................33

4.5.5 Connecting the python..............................................................................................34

4.5.6 Carbon dioxide (CO2) connection ...............................................................................35

4.5.7 Electrical connection .................................................................................................37

4.6 Adjusting the carbon dioxide (CO2) supply..........................................................................38

4.7 Checking for leaks.............................................................................................................39

4.8 Adjusting the dispensing valves .........................................................................................39

4.9 First start-up ....................................................................................................................41