2

CONTENTS

1 - Application - Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 - Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 - Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 - Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 - Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 - Cooling performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

7 - Corrections to be made when using anti-freeze . . . . . . . . . . . . . .8

8 - Curves of available pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

9 - Sound levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

10 - Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

11 - "ECH" electronic control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

12 - Installation information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

MARKING

This product marked conforms to the essential requirements of the Directives:

- Low voltage no 2006/95/EC.

- Electromagnetic Compatibility no. 89/336 EEC, modified 92/31 EEC and 93/68 EEC.

- Pressure Equipment Directive No. 97/23/EC.

1 - APPLICATION - USE

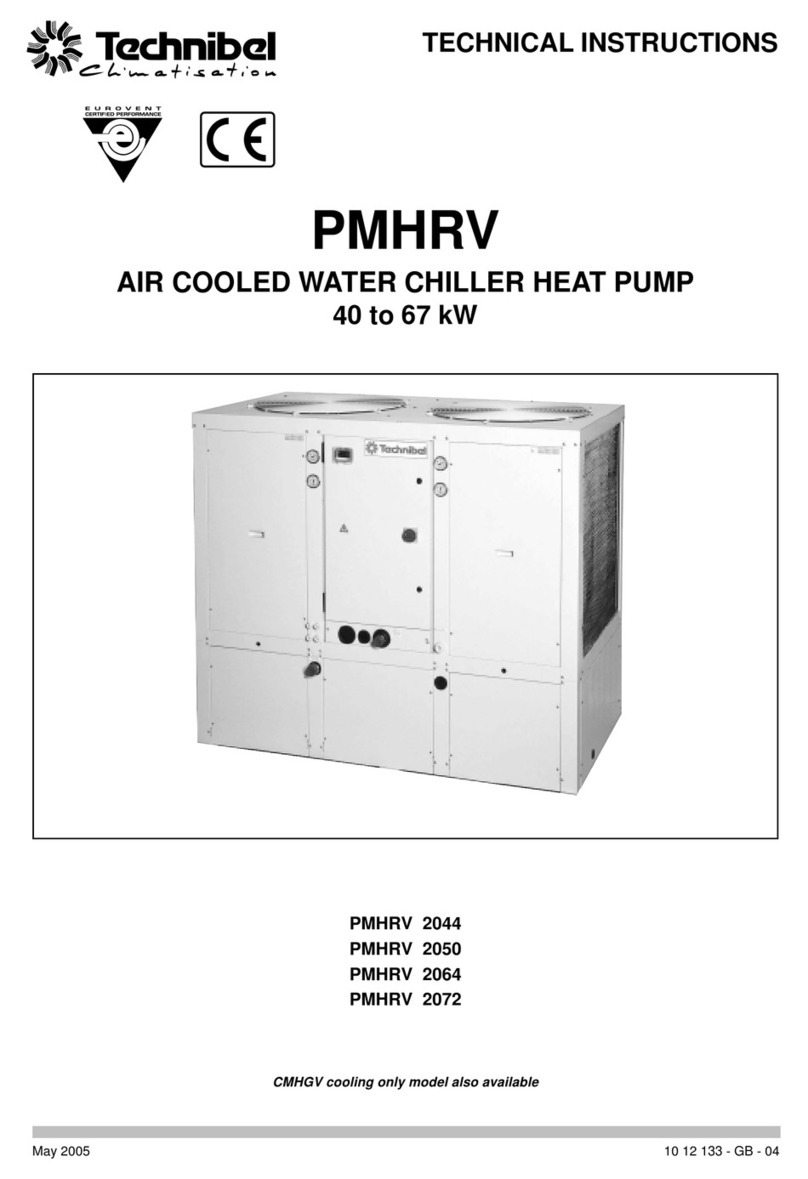

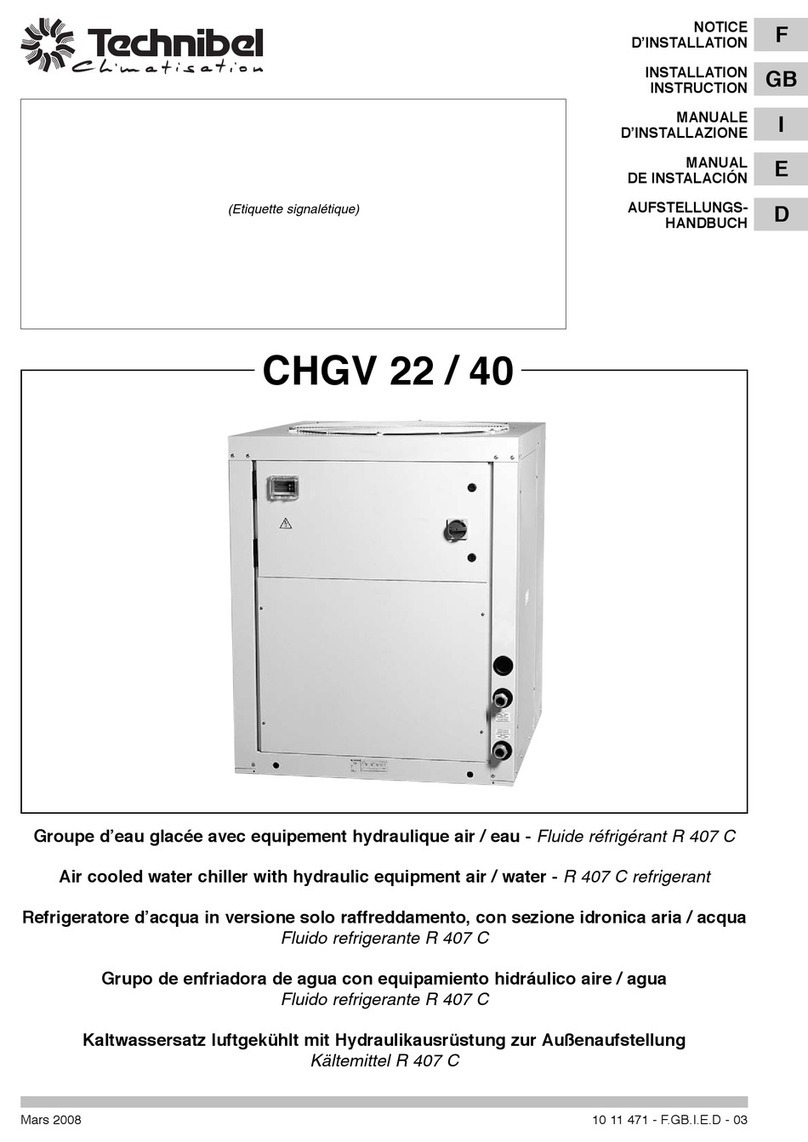

• Air cooled type chilled water generator intended for climate control in buildings.

• Single package unit, factory assembled and tested.

•Designed for outdoor installation.

• Supplied fully charged with R 407 C refrigerant.

• Convenient hydraulic and electrical connections.

• Practical service access via removable panels.

R 407 C

•Fluid R 407 C, as opposed to R22, is not a pure fluid but a

blend composed of:

- 23% R 32 + 25% R 125 + 52% R 134 A.

•The compressors approved for operation with this fluid are

filled beforehand with polyalcohol oil.

Contrary to mineral oil, it is very hygroscopic: it absorbs the

humidity of the ambient air very quickly. This can modify its

lubricant properties and lead in time to the destruction of the

compressor.

MAINTENANCE INSTRUCTIONS

1- Never add oil to the appliance; the compressor is filled

with polyalcohol oil, a special oil which cannot tolerate the

presence of other oils.

2- The instruments used for:

- filling,

-pressure measurements,

- emptying under vacuum,

- recovering the fluid,

must be compatible and only used for the R 407 C fluid.

3- The weight of the refrigerant contained in the storage

bottle must be checked constantly. Do not use it from the

moment the remaining weight is less than 10% of the total

weight.

4-In the case of a new charge:

- do not use the charging cylinder,

-use a balance and a dip pipe type R 407 C cylinder,

-charge the weight of R 407 C as per the value indicated

on the unit’s identification plate,

- IMPORTANT: see instruction 3 above.

5-The charge must be undertaken in liquid phase.

6- In case of leakage, do not complete the charge: recover

the remaining refrigerant for recycling and perform a total

charge.

Recovery, recycling or the destruction of the fluid must be

done in compliance with the laws in force in the country

concerned.

7- If the refrigerant circuit is opened, you must:

- avoid the entry of air into the circuit as much as

possible,

- replace the filter drier,

- perform the "vacuum operation" at a minimum level of

0.3 mbar (static).

8- Do not release R 407 C fluid into the atmosphere. This

fluid is a fluorinated greenhouse gases, covered by the

Kyoto Protocol with a Global Warming Potential

(GWP) = 1653 - (CE Directive 842 / 2006).

APPLIANCES FILLED WITH R 407 C