Sterling Pro SP0315BC Operating instructions

EN

1

INSTALLATION, USER AND MAINTENANCE INSTRUCTIONS: BLAST CHILLERS

WARNING

HAZARDOUS

VOLTAGE

PLEASE READ

INSTRUCTIONS

PROTECTIVE

GROUNDING

EQUIPOTENTIAL

BONDING

2

CARACTERISTICAS GENERALES

ALLGEMEINE EIGENSCHAFTEN

CARACTÉRISTIQUES GÉNÉRALES

CARATTERISTICHE GENERALI

GENERAL CHARACTERISTICS

CHARAKTERYSTYKA OGÓLNA

EN

3

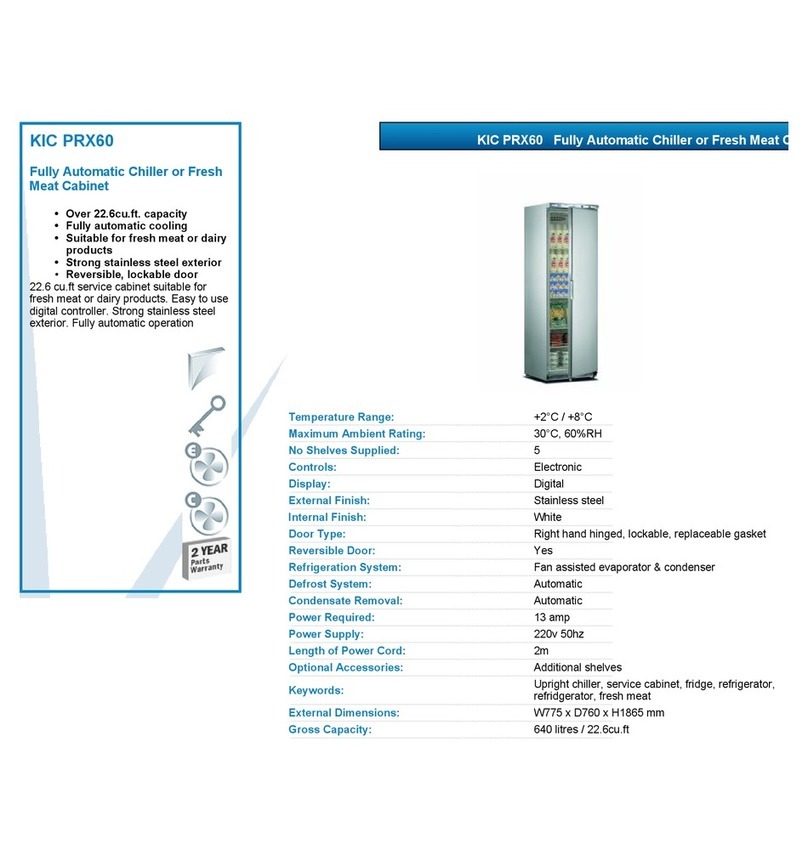

Tabla 1 / Table 1 / Tableau 1 / Table 1 / Tabelle 1 / Tabella 1 / Tabela 1/ Tabel 1 / Taulukko 1 /Tabell 1

Modelo Modèle

Model

Modell

Modello Model

Gas

Gaz

Gas

Gas

Gas Gaz

Tensión

Voltage

Tension

Tensione

Spannung

Voltage

Potencia frigorífica (W)

Puissance frigorifique

(W) Refrigerated power

(W)

Kühlleistung (W)

Potenza frigorifera (W) Moc

chłodzenia (W)

W x D x H exterior (mm)

L x P x H extérieur (mm)

W x D x H external (mm) B x

H x T außen (mm)

W x D x H exterior (mm)

W x D x H zewnętrzne (mm)

Peso neto (kg)

Poids net (kg)

Weight (kg)

Nettogewicht (kg)

Peso netto (kg)

Masa netto (kg)

SP0315BC

R452a

230V 1+N

490

570 x 700 x 514

62

SP0523BC

R452a

230V 1+N

690

790 x 700 x 850

98

SP0840BC

R452a

230V 1+N

1300

790 x 800 x 1290

145

SP1050BC

R452a

230V 1+N

1300

790 x 800 x 1420

160

PANEL DE CONTROL

BEDIENFELD

PANNEAU DE COMMANDE

PANNELLO DI CONTROLLO

CONTROL PANEL

PANEL STEROWANIA

4

1. INDEX

1. INDEX ......................................................................................................................................................

2. GENERAL INFORMATION AND WARNINGS ........................................................................................

3. PRODUCT DETAILS ...............................................................................................................................

General characteristics ....................................................................................................................

4. INSTALLATION INSTRUCTIONS ...........................................................................................................

Removal of packaging .....................................................................................................................

Positioning and levelling ..................................................................................................................

Electrical connection ........................................................................................................................

Drainage connection ........................................................................................................................

Recycling .........................................................................................................................................

5. USE AND MAINTENANCE INSTRUCTIONS .........................................................................................

Operation .........................................................................................................................................

Switching on the machine ........................................................................................................

Operational cycles ...................................................................................................................

Temperature probe insertion verification test ..........................................................................

Operational state .....................................................................................................................

Defrosting .................................................................................................................................

Compresor and evaporator fan status checking ......................................................................

Useful tips ........................................................................................................................................

Maintenance ............................................................................................................................

Prolonged non use ...................................................................................................................

6. FAULTS, ALARMS AND BREAKDOWNS ..............................................................................................

Alarms and errors ............................................................................................................................

7. RECYCLING THE PRODUCT .................................................................................................................

2. GENERAL INFORMATION AND WARNINGS

This manual has been created to help you understand the operation, installation and maintenance of the machine. It

contains all the necessary information and warnings to ensure that the appliance is installed and used correctly, together

with information about the characteristics and possibilities offered, so that you may enjoy your machine to the full.

BEFORE STARTING THE APPLIANCE, PLEASE READ THE INSTRUCTIONS

CONTAINED IN THIS MANUAL CAREFULLY.

The manual should be kept safely to hand for future reference.

If the machine is sold or transferred, please pass the manual to the new user.

THIS APPLIANCE IS EXCLUSIVELY FOR PROFESSIONAL USE, AND SHOULD ONLY BE USED

BY QUALIFIED PERSONNEL.

•The positioning and installation, and all repairs or modifications, should always be carried out by an

AUTHORIZED TECHNICIAN, in accordance with the applicable legislation of the country. The

manufacturer does not accept liability if the machine is incorrectly installed.

•The installation, incorrect adjustment, inappropriate maintenance or use of the appliance may cause

material damages and injuries.

•If your machine breaks down, please call the Technical Service Centre. Unqualified or

Use of spare parts other than original

parts will cancel the guarantee.

•During all maintenance operations, the refrigerator must be disconnected from the main power supply at

the mains power switch.

•Abrasive or corrosive products, acids, solvents and chlorine-based detergents must NOT be used to clean

the appliance, as this may damage the components.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS OR THE INCORRECT USE OF

THE APPLIANCE SHALL RELIEVE THE MANUFACTURER OF ANY OBLIGATIONS

REGARDING THE GUARANTEE OR POSSIBLE CLAIMS.

3. PRODUCT DETAILS

All the appliances have a specification plate which identifies it and indicates its technical characteristics; it is located on

one side of the machine. Don`t remove the specifications plate from the unit.

Brief introduction to the plate sticked to the machine:

NÚMERO

DESCRIPCIÓN

1

MANUFACTURER

2

MODEL

3

SERIAL NUMBER

4

VOLTAGE

5

FREQUENCY

6

CURRENT

7

REFRIGERATION POWER (W)

8

CLIMATIC CLASS (N=4)

9

WORKING TEMPERATURE

10

GAS TYPE

11

GAS (gr)

12

NORMATIVE

Note: This plate is an example; reality might differ slightly from it.

These details should be given when the technical service is called.

General characteristics

These machines have been built according to the EC directives regarding food treatment and preservation.

The use of the cooler consists of lowering the temperature suddenly from a level (cooked or fresh products) to another

level that guarantees the maintenance of the ideal nutritional, physical and chemical properties of the food.

It should be pointed out that the critical temperature range between 10 ºC and 85 ºC in the product should be passed

through as fast as possible.

It has an electronic timer and chamber temperature probe. Cycle control by time or with probe in the heart of the

food. When the cooling cycle finishes, it can be used as a refrigeration chamber: + 2, + 4 ºC; or as a frozen food

maintenance chamber: -18 ºC, for a short period of time.

Depending on several factors and according to the prepared data, it is about advising the user about a very

homogeneous and standard product in international cuisine.

MODEL

PRODUCTIONS (kg) (*)

REFRIGERATION

FREEZING

3GN 1/1

15

6

5GN 1/1

18

10

8GN 1/1

40

24

10GN 1/1

50

30

-18 ºC in 270’)

The quantity of product can vary if the test conditions change, such as temperature.

4. INSTALLATION INSTRUCTIONS

The location and installation, as well as all kind of repairs and transformation, always must be

carried out by an AUTHORIZED TECHNICIAN, according to the regulation in force in each

country

Installation, incorrect adjustment, service or unappropriated maintenance of the device, as well

as a wrong handling of it, may cause both material damages and injuries.

Removal of packaging

Remove packaging from the machine and check if any damage during transportation. If any damage is observed,

immediately notify the supplier and the transport company. In the event of doubt, do not use the machine until

the problem has been assessed.

Packaging (plastic, expanded polyurethane, staples, etc…) must not be left in the reach of children,

they are a potential hazard.

The cabinet should not be overturned. If necessary, some cabinets can be overturned by the side that is indicated

on the packaging. If not indicated, it cannot be overturned. Wait at least 2 hours to turn the machine on since the

machine is placed in the right location.

The machine should be moved using a fork-lift truck or similar to avoid damage to the structure. Transport the

machine to the installation location and then remove packaging.

All the packaging can be recycled. Dispose of packaging correctly.

Make sure the place to store the machine is free and clean, avoiding the fan absorbing the dust nearby which

might block the condenser reducing the efficency of the machine.

Remove the pallet carefully, avoiding any scratch to the machine. Level the machine by using the adjustable feet.

Once the machine is levelled, pill the protective film off by using a no sharp knife to avoid scratches in the

stainless steel.

A: BODY OF THE FEET B:

THREAD:

Rotate clock wise to lower down the machine.

Rotate counter- clock wise to elevate the machine.

The device, once it is located definitively, backside must be placed 50mm from the wall, 30mm from sides lateral

and 500mm from the ceiling.

If the machine is provided with castors, make sure the floor is totally flat.

In the commissioning make sure there is no any heat source nearby.

For an optimum performance of the equipment, it is really important that all air intakes, both in the fan located

inside the chamber and in the condenser, are not clogged.

Do not install the device outdoors.

Do not introduce any element from the fan protector or in the refrigeration equipment area.

Electrical connection must be carried out by an AUTHORISED TECHNICIAN

The legal standards in force in each country regarding connection to the mains should be taken into account.

•Check that the mains voltage corresponds to that indicated on the nameplate.

•It is essential that the electrical installation where the cabinet is going to be connected

has an GROUNDING SOCKET, in addition to the appropriate magneto-thermal switch

and differential protection (we recommend 30 mA)

•The appliance must be grounded using a differential protector. The manufacturer will

not be held liable for damage originated by failure to observe this requirement.

•The cross-section of the power cable must be suitable for the rated current of the

machine.

•The plug should be Schuko type with grounding and terminals of 4.8mm (F type). It is

forbidden to enlarge the plug for your safety. As optional, the equipment can be

supplied with British type plugs (H type) or American type plugs (B type).

•If any faults are observed during the installation, the supplier should be notified

immediately.

•Do not install the Blast Chiller outdoors.

•In case of fire do not use water. Use CO2 (carbon dioxide) extinguishers and cool the

engine area as fast as possible.

The manufacturer will not be held liable for any personal or material damage to the machine resulting

from incorrect installation or failure to comply with the manufacturer’s specifications.

The electric specifications of the machine are shown in the specification plate. Section 3.

If you want to place the drain in a fixed and definitive location, it must be connected to a general drain, creating

a siphon with said drain to avoid cold losses. This operation must be carried out by qualified personnel. See

Figures 1 - 4 for the location of the drain.

The product packaging consists of:

•A wooden pallet.

•Cardboard.

•A polypropylene band.

•Expanded polystyrene.

All the packaging used around the machine can be recycled; The correct disposal of these products will help to

protect the environment. For further information regarding the recycling of these products, please refer to the

relevant office of the local body. Dispose of these materials in accordance with current legislation.

5. USE AND MAINTENANCE INSTRUCTIONS

The steps required to optimize the operation of your machine are shown below, with all the available options.

The control panel has an On/ Off switch and one thermostat. In the Figure 5 you can see them in detail.

•Once the interior of the cabinet has been cleaned, connect it to the electrical network and turn the switch

(1, Fig.5) to ON. The switch must be illuminated.

•If the appliance is on and no cycle is running, the DISPLAY (Fig.5) shows the temperature of the chamber.

•If there is no active cycle, after 10 seconds without any icon being pressed, DISPLAY (Fig.5) will

automatically turn off, except for the low consumption LED. To turn the display on again, press any icon.

•If there is 60s elapse time without any icon being pressed, the display will show “Loc” and the keyboard

will automatically lock. To unlock the keyboard, press any icon for 1 second. The display will show “UnL”.

Operational cycles

The blast chiller you have adquired is controlled by an electronic timer with a chamber temperature probe, which

allows 2 blast chilling methods. First one, time controlled cycle, in which the blast chilling cycle ends once the time

CONTAINED IN THIS MANUAL CAREFULLY.

defined for the process has elapsed and second one, temperature controlled cycle, whose process ends, once the

temperature sensor inserted in the food reaches the defined temperature.

In turn, there are 2 blast chilling processes, depending on the final temperature to be reached, refrigeration and

freezing, which can be accessed by pressing the SET button (14, Fig.5).

Press SET button to select a cycle

PoS

Refrigeration, time controlled cycle

nEG

Freezing, time controlled cycle

PoS

Refrigeration, temperature controlled cycle.

nEG

Freezing, temperatura controlled cycle

Press START/STOP button in the following 15 seconds.

5.1.2.1 Time controlled chilling cycle

To run a time controlled blast chilling cycle follow these steps:

1. Make sure that the keyboard is not locked and that no chill or defrost cycle is active.

2. Press SET button (14, Fig.5) to choose between a refrigeration chilling process “PoS” or freezing chilling

process”nEG” and ensure that the TIME CONTROLLED CYCLE icon (10, Fig.5) blinks. By default, refrigeration

cycle lasts 90 minutes, while freezing cycles lasts 240 minutes.

3. OPTIONAL: Parameters related with cycle duration, setpoint of the chilling cycle and conservation cycle setpoint

can be adjutasted.

oPress button DOWN (12, Fig.5), before 15 seconds and press button SET (14, Fig.5) to see

default cycle duration and modify it. In order to change the value press UP (11, Fig.5) or

DOWN (12, Fig.5). Press again SET button (14, Fig.5) to exit and continue to the next step.

oTo check and modify the set point of the chilling process, press DOWN button (12, Fig.5), before

15 seconds and press SET (14, Fig.5). In order to change the value press UP (11, Fig.5) or

DOWN (12, Fig.5). Press again SET button (14, Fig.5) to exit and continue to the next step.

oTo check and modify the set point of the conservation cycle, press DOWN button (12, Fig.5), before 15

seconds and press SET (14, Fig.5). In order to change the value press UP (11, Fig.5) or DOWN

(12, Fig.5). Press again SET button (14, Fig.5) to exit and continue to the next step.

oThis is a temporary adjustment. When activating a new cycle or when a power failure occurs, these values

are reset to those defined by the manufacturer.

4. Press START/STOP (13, Fig. 5), the cycle will run and TIME CONTROLLED CYCLE icon (10,

Fig.5) will light up.

During the chilling process, the DISPLAY will show remaning cycle time. When the cycle time is over, the

DISPLAY will show the word “END” and the buzzer will be activated during the time specified on “AA”

parameter. To mute the buzzer press any icon.

Finally, once process finishing is indicated, conservation process is activated lightning up

CONSERVATION (7, Fig.5) icon and chamber temperature is shown in the DISPLAY.

Additionally, during chilling cycle, it is possible to show the chamber temperature in the display. Press DOWN

button (12, Fig.5), choose the chilling option which is in force “PoS” for refrigeration or “nEG” for frezzer. Once

the cycle is choosen, press again DOWN button (12, Fig.5) to show this value. To exit the process, press SET

button (14, Fig.5) or do not take any further action for the following 15 seconds.

In order to interrupt a chilling process, press START/STOP (13, Fig. 5), for 2 seconds.

5.1.2.2 Temperature controlled chilling cycle

To run a time controlled blast chilling cycle follow these steps:

1. Make sure that the keyboard is not locked and that no chill or defrost cycle is active.

2. Press SET button (14, Fig.5) to choose between a refrigeration chilling process “PoS” or

freezing chilling process”nEG” and ensure that the TEMPERATURE CONTROLLED CYCLE icon (2, Fig.5)

blinks. By default, food temperature probe set point for refrigeration cycle is set in 3°C, while for freezing cycle is

defined in -18°C.

3. Before a temperature controlled cycle starts, an automatic test is carried out, in order to check that the temperature

sensor is correctly inserted into the food to be chilled. If test fails, corresponding time controlled cycle starts.

4. OPTIONAL: Parameters related with the temperature probe value at the end of chilling cycle, maximum cycle

duration time, chamber setpoint during chilling cycle and chamber setpoint on conservation cycle can be adjutasted.

oPress button DOWN (12, Fig.5), before 15 seconds and press button SET (14, Fig.5) to check

the product final temperature value and modify it. The value can be changed by pressing UP

(11, Fig.5) or DOWN (12, Fig.5) buttons. Press SET to come back to previous level.

oIn order to watch and modify chilling cycle maximum duration press DOWN (12, Fig.5), button again

in a period not exceeding 15 seconds and press SET (14, Fig.5) button again. Press UP (11, Fig.5) or

DOWN (12, Fig.5) buttons to change the value. Press SET (14, Fig.5) to come back to previous level.

oIn order to watch and modify chamber temperature set point during chilling process press DOWN (12,

Fig.5), button again in a period not exceeding 15 seconds and press SET button again. Press UP (11,

Fig.5) or DOWN (12, Fig.5) buttons to change the value. Press SET (14, Fig.5 to come back to previous

level.

oIn order to watch and modify the set point during conservation process press DOWN (12, Fig.5), button

again in a period not exceeding 15 seconds and press SET (14, Fig.5) button again. Press UP (11, Fig.5)

or DOWN (12, Fig.5) buttons to change the value. Press SET (14, Fig.5 to come back to previous level.

oThis is a temporary adjustment. When activating a new cycle or when a power failure occurs, these values

are reset to those defined by the manufacturer.

5. Press START/STOP (13, Fig. 5), the cycle will run and TIME CONTROLLED CYCLE icon (10,

Fig.5) will light up.

If the temperature detected by food temperature probe reaches cycle set point, before maximum duration time

has been reached, “EnD” word will be displayed on the screed, buzzer will be activated during the period

established on “AA” parameter and the devices will go on conservation mode. Press any button to mute the

buzzer and press again another button to remove “EnD” indicator.

If the temperature detected by food temperature prove does not reach cycle set point, when maximum cycle

duration time has been reached, the cycle will continue till the set temperature is reached. Then,

TEMPERATURE CONTROLLED CYCLE (2, Fig.5). icon will blink and ALARM (6, Fig.5) will

light up and buzzer will be active. Press any button to mute the buzzer.

Finally, once the cycle process ending is indicated, if the chilling has bee successful, the device goes on

conservation mode lightning up CONSERVATION (7, Fig.5) icon together with

TEMPERATURE CONTROLLED CYCLE (2, Fig.5). On the oppsite, if the cycle has failed, ALARM (6,

Fig.5) icon will lifht up. While this status last, compartment temperature will be displayed on the screen.

In addition, during conservation, if the process has been succesfull, the elapse between real cycle time and default

maxium cycle duration time can be checked. Whereas, if the process failed, the elapse of time between the

maxium cycle duration and the instant when the food temperature probe detects the set point can be displayed.

For both cases, press DOWN (12, Fig.5) button. Press DOWN DOWN

(12, Fig.5) button, once again so as to display chamber temperature and press SET (14,

Fig.5), button to exit the application.

To interrupt chilling process in any of its state, press START/STOP (13, Fig. 5), button for 2 seconds.

5.1.2.3 Start a cycle with the same program as the last cycle started

Make sure that the keyboard is not locked. Press SET type of cycle will be displayed. Press SET

(14, Fig.5) button in the following 15 seconds.

Temperature probe insertion verification test

Set-temperature cycles are preceded by a test step in order to check correct pin probe insertion.

The test has two stages:

•The outcome of the first stage is positive if “the temperature measured by the pin probe - the temperature of the

cabinet” is greater than the value set by parameter rc at least 3 times out of 5 (the comparison is made every 10 s),

if parameter rc is set to 0, neither the first nor second stages will be run.

If the outcome of the first stage is positive, the second will not be run

•If the outcome of the first stage is negative, the second will be run. The outcome of the second stage is positive if

the difference “temperature measured by the pin probe - temperature of the cabinet” is greater by at least 1ºC/1ºF

(with respect to the previous comparison) at least 6 times out of 8 (the comparison is made every “rd/8 s”).

If the outcome of the test is positive, the cycle will be activated.

If the outcome of the test isn’t positive, the cycle will be started in timed mode and icon (2, Fig.5)

If power is interrupted during the test, when power is restored, the test will start again from the beginning.

“ON” STATUS

The device is switched on but operating cycle is running, If power is interrupted:

•During a timed blast chilling operation, when power is restored, chilling will continue from the time point at which

the interruption occurred (with a maximum error of 10 minutes);

•During a set-temperature blast chilling operation, when power is restored, chilling will start again from the

beginning;

•During a storage operation, when power is restored the storage operation will be reset.

“STAND-BY” STATUS

•The device is switched on but no operating cycle is running. If power is interrupted while in “stand-by” mode,

when power is restored the device will be in the same state.

The blast chiller you have adquired only has a manual defrost process. The food that is introduced into the appliance,

as well as the opening of doors, generate humidity inside the machine. When performing a blast chilling cycle, this

moisture condenses and freezes at the coldest point of the blast chiller, which is the evaporator, accumulating ice.

In some cases, this accumulation might cause evaporator blocking and subsequently chilling cycles are not carried

out correctly. For this reason, it is advisable to carry out a defrost process from time to time, especially if several

chilling cycles are performed consecutively.

In order to start a defrosting cycle, make sure that no other procedure is in use and press UP/DEFROST

(11, Fig.5) button for 4 seconds.

The duration of the defrost can be configured with parameters d3 and d7. Contact your technical service

for modification.

In order to check the statur of the compressor, ensure ther eis no other cycle active. Press DOWN Fig.5) button once

and the status of the compressor will be displayed as follows:

•“C-1”, the compressor is switched-on

•“C-0”, the compressor is switched off

•“C-P”, compressor protection active (parameters C0, C1, C2 and i7).

To check the statur of evaporator fan, press (12, Fig.5) button once again and the status of the fan will be displayed as

follows:

•“F- “F-0”, the evaporator fan will be switched off

•“F-P”, then evaporator fan deferred activation will be ongoing (parameter F8).

To exit the procedure, Press SET (14, Fig.5) button or do not take any further action for the following 15 seconds.

Read carefully the below advices so as to reach the full potential of the refrigeration cabinet.

Carry out necessary cleaning operation in order to enlarge the service life of the machine.

•Remove any waste from the machine at the end of each day. Before cleaning the machine, unplug the

machine from the electricity supply and put the switch in OFF or O position. The appliances include a

drainage in the bottom of refrigerated chamber (Except 3 trays models), to help the cleaning operation,

as well as the eventual output of liquids from food. During the cleaning operation it is essential to

remove the drain plug and clean it, to prevent clogging by solid elements. It prevents accumulated

liquids from stagnating.

•Do not use abrasive, corrosive or acid products, chlorine-based detergents, solvents or petrol derivatives

to clean the machine.

•Do not use pressurized water to clean the machine.

•Take precautions before accessing to the unit condenser zone, due to the high temperatures there might

be risk of burns

•Cleaning the condenser: During cleaning, avoid any bending of the condenser aluminum fins. It could

affect on the condenser air circulation, causing serious damage to the equipment, being the repair out

of warranty in that case.

•Check that the doors close perfectly.

•If any change of wires is needed, do not change for a lower section one

•The assembly of the electrical installation cover in the control panel is important. If disassembling is

needed, it must be tightened back as it was.

•Twice a year call the technical service to carry out the relevant revisions:

oReview of the status of the joints.

oReview of the state of the components.

•If the wire is damaged, it should be replaced by the manufacturer, its after sales service department or

by an autorized technicial to avoid any personal or equipment damage.

If the machine is kept out of service for a long period of time (holidays, temporary closure…), please observe

the following:

•Clean the equipment carefully.

•Switch off the mains power supply.

6. FAULTS, ALARMS AND BREAKDOWNS

The steps to be followed in the event of a fault or operating error are described below. The possible causes and possible

solutions are listed in the following table. In the event of doubt, or if you are unable to resolve the problem, please contact

the technical service.

Do not handle electrical components, as there is a risk of death as the components are under network

voltage

FAULT

POSSIBLE CAUSE

SOLUTIÓN

Blast chiller does

not work

There is no power supply.

Check whether the circuit breaker has been triggered. If there is light

in the switch the machine is powered.

Insufficient

temperature

Location of the equipment

Check there is not a heat source nearby

Ambient temperature

Check that ambient temperatura is below +32ºC in freezer cabinets

and +38 ºC in refrigeratios and fish storage cabinets.

These are devices guaranteed maximum working temperature

Door closing

Check that the doors close correctly

Food distribution inside the machine

Check that food does not block the air ventilation and the time

elapsed from the time the food is stored inside the cabinet is enough

for cooling the products.

Cleaning of the condenser

Check that the condenser is clean. Consider that the cleaner the

refrigerator is the more energy will be saved. The cleaning frequency

will depend on the conditions of the location. In case the condenser

is dirty call after sales service.

Strange or loud noise

Incorrect levelling and bad closing of the

doors.

Check the levelling and good closing of the doors.

Friction in the movable zones

Check there is nothing in touch with the movable elements of the

refrigerator.

NOTE: If a fault occurs and is not listed in the above table, please call the technical service. The manufacturer reserves the

right to modify the technical characteristics with prior warning.

Together with this manual, it is supplied the instructions of the thermostat.

COD.

MEANING

SOLUTIONS

CONSEQUENCES

AL

Minimum temperature alarm

Check the cabinet temperature Check

Parameters A1 and A2

The device will continue to function normally

AH

Maximum temperature alarm

Check the cabinet temperature Check

Parameters A3 and A4

The device will continue to function normally

id

Door switch alarm input alarm (Only in

“stand-by” mode and if parameter

i0 is set to 0 or 1)

Close the door

Check the causes which activated the input.

Check parameters i0 and i1

The evaporator fan will stay hold until alarm ends

iA

Compressor protection input alarm (Orly

if parameter i0 is set to 2)

Check the causes which activated the input.

Check parameters i0 and i1

Compressor + evaporator fan stop working

Pr1

Cabinet probe error

See PO parameter

Check probe integrity

Check probe-device connection

Check the cabinet temperature

If the error occurs while in "Stand by" mode:

If parameter C11 = 0 no cycle will be allowed to start If

parameter C11 = 1. Pin probe will work as cabinet probe and

only time cycle will be allowed.

If the error occurs during time controlled cycle:

-If parameter C11 = 0, cycle will be interrupted

-If parameter C11 = 1, pin probe will workd as cabinet

probe and the chilling operation will continue.

If the error occurs during a temperature controlled cycle:

-If parameter C11 = 0, cycle will be interrupted

-If parameter C11 = 1, the pin probe will work as cabinet probe

and the chilling operation will continue

If the error occurs during conservation mode:

-If parameter C11 = 0, compressor activity will depend on C4, C5

y C6 parameters.

-If parameter C11 = 1, the pin probe will work as cabinet probe

and the storage operation will continue.

Pr2

Pin probe error

See PO paramet

Check probe integrity

Check probe-device connection

Check the cabinet temperature

If the error occurs during “Stand by" mode:

- Only tied operation cycles will be allowed to start.

If the error occurs during a time controlled cyle:

- Chilling will continue

If the error occurs during temperature controlled cycle:

- Chilling will continue in time mode

If the error occurs during conservation mode:

- Conservation mode will continue.

7. RECYCLING THE PRODUCT

The European Directive 2012/19/EU relating to Waste Electrical and Electronic Equipment (WEEE)

states that household appliances should not be disposed of using the normal solid urban waste cycle.

Exhausted appliances should be collected separately in order to optimise the cost of re-using and recycling

the materials inside the machine, while preventing potential damage to the atmosphere and to public health.

The crossed-out dustbin is marked on all products to remind the owner of their obligations regarding

separated waste collection. For more information, relating to the correct disposal of household appliances,

owners should contact their local authorities or appliance dealer.

This manual suits for next models

3

Table of contents

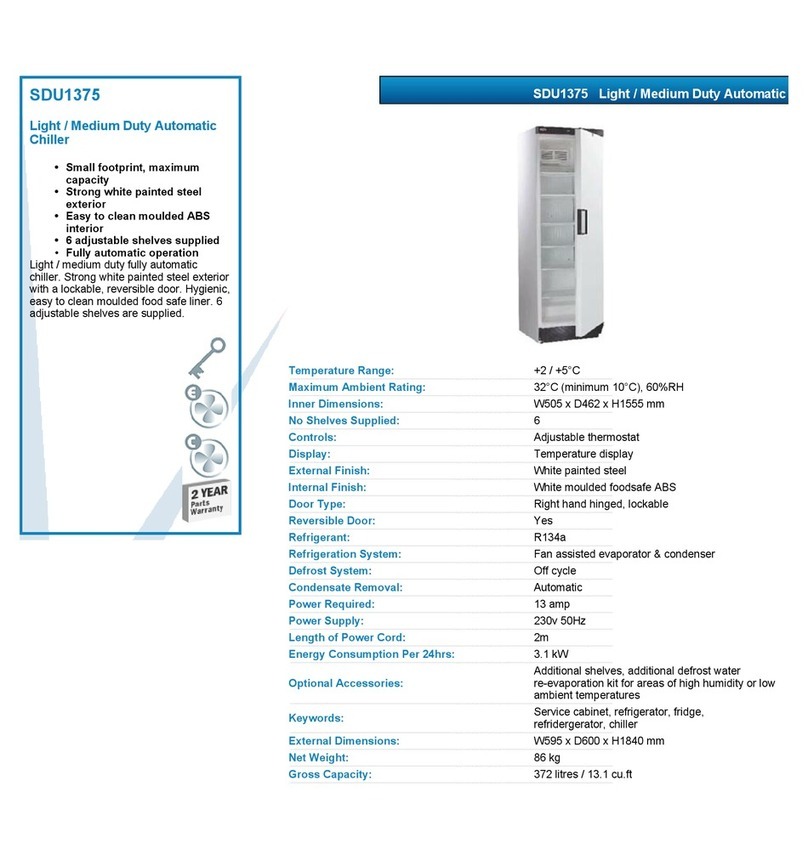

Popular Chiller manuals by other brands

Parker Hiross

Parker Hiross Hyperchill-Plus ICEP002 user manual

S&A

S&A CW-5000 Series Service and repair handbook

Skope

Skope SK700 Operating and service manual

Everpure

Everpure Commercial Grade Water Chiller CGCL1 Installation and operating guide

Riedel

Riedel P030 operating manual

RCS

RCS Cooper Cooler HC01 Instruction booklet