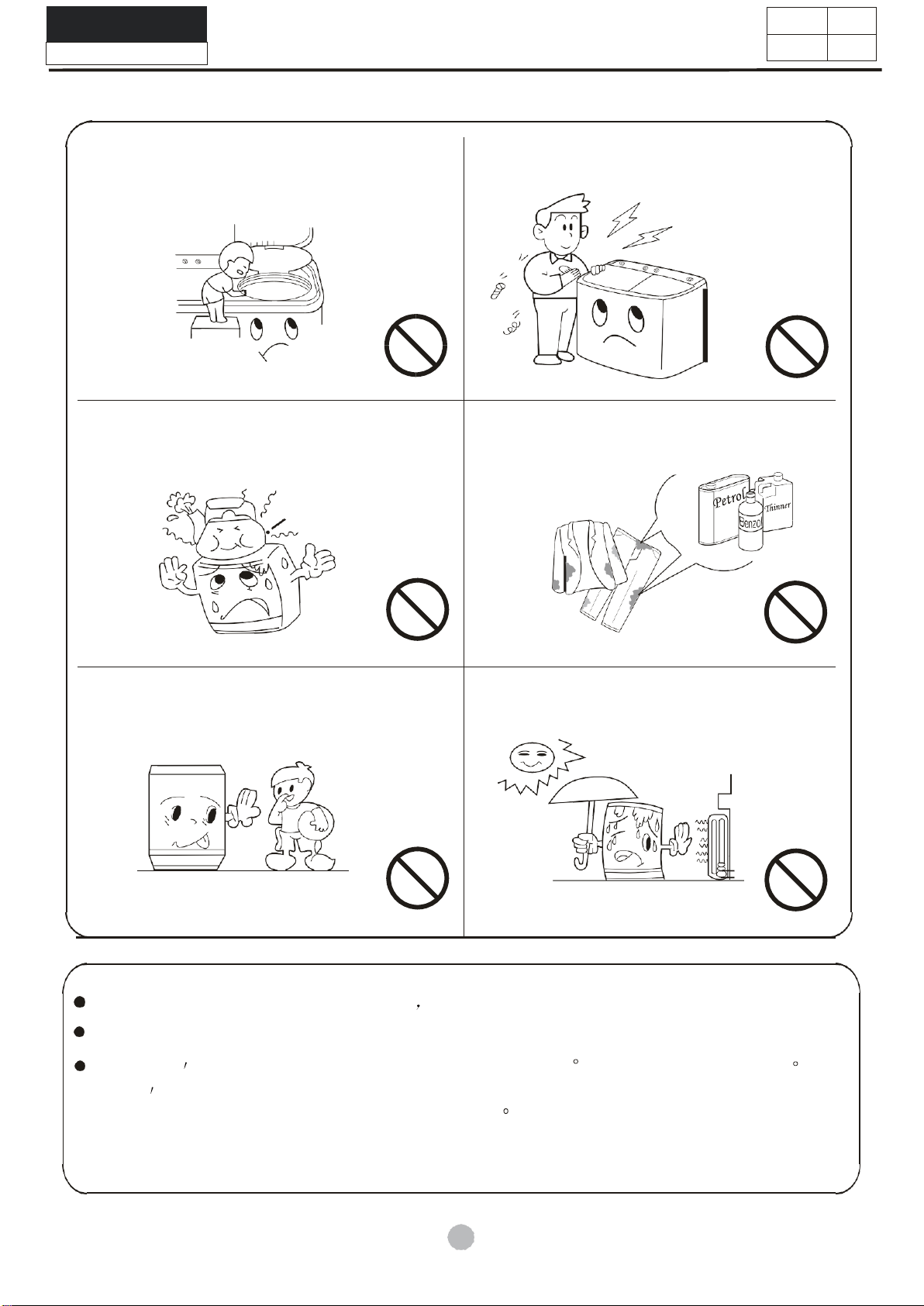

Dismantling and installation of the bearing seat

Once the bearing seat is taken off, it can not be utilized again. Therefore do not dismantle

it as far as possible. In case that it has to be replaced, please dismantle it as per following

sequence, then install a new bearing seat.

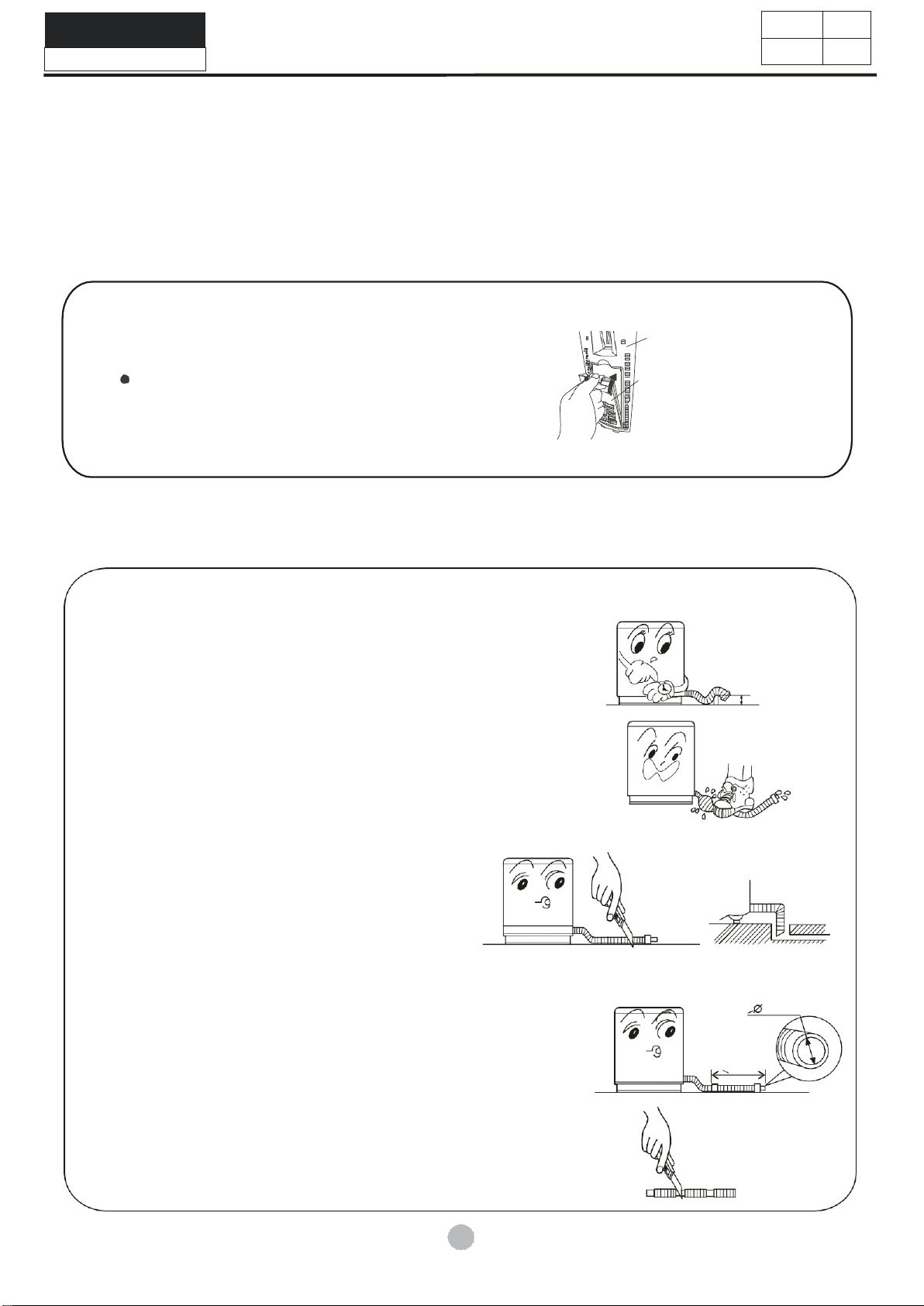

Dismantle the spin tub . Then pull out the bearing seat.

Cut off the inner lining claw inside the bearing seat with cutting pliers and take it out.

Install the new bearing seat and inner lining.

The bearing seat is an inlay component. Be sure to aim the claw of the inner lining at the

hole of the tub then push it in. Please use suitable tools and add even pressure around

the tub.

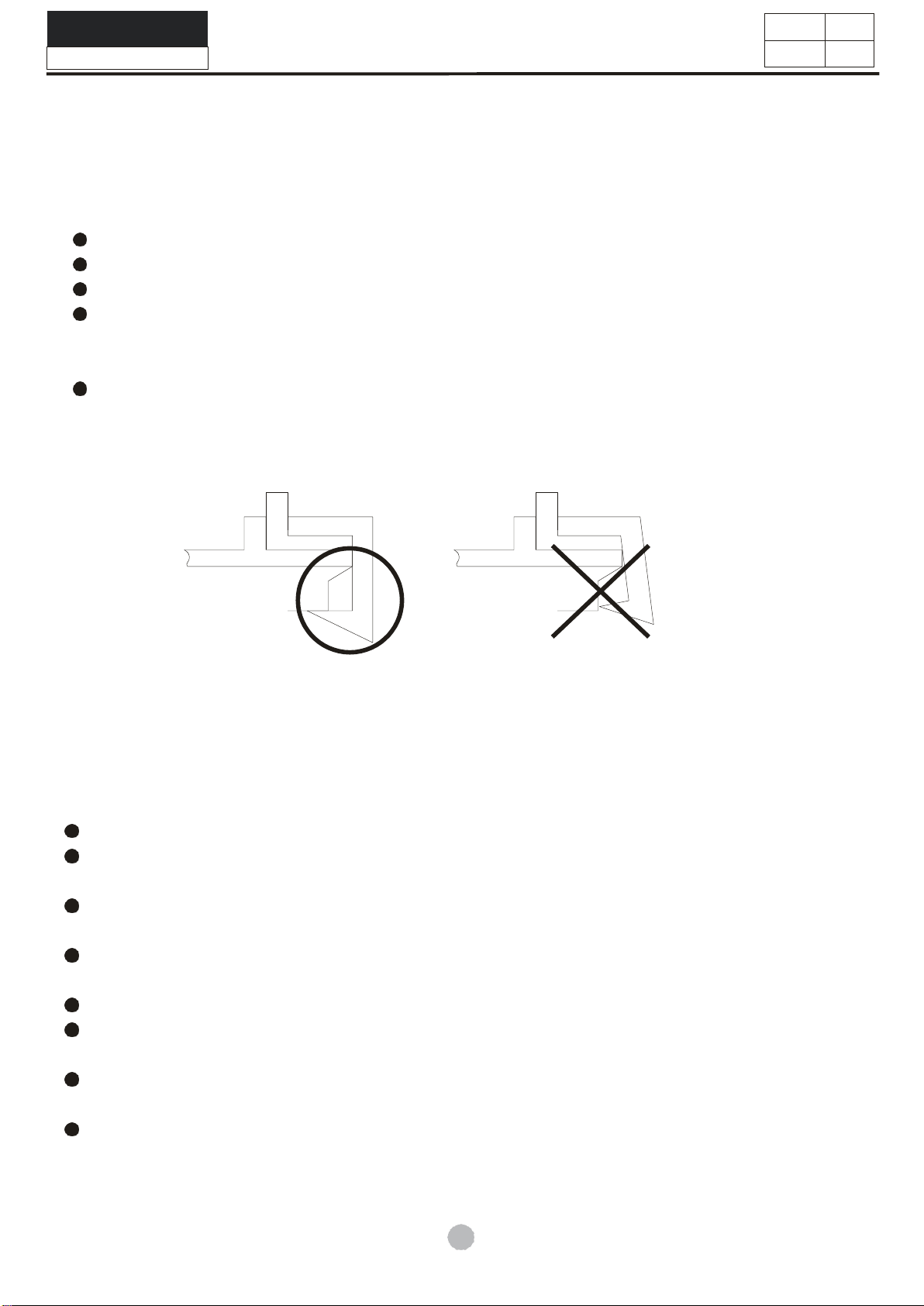

After inlay the bearing seat, check if the claw is installed to proper position from the outside

of the twin-tub (Figure 7).

Right Wrong Figure 7

6.2

Points of Attention in After-salesService

Be sure to switch off the power during dismantling or repair.

Be sure to use insulated wiring terminals and insulation box in connection of the wires, and

crimp and fix to proper position with suitable tools.

In welding connections with electric iron, be sure to twist the wires before welding, and insulate

with insulation tapes.

In welding the wires with electric iron, be sure not to touch the resin part and insulation part of

each switch.

The inlay connection wires and terminals shall not be loose or drop.

Do not make the wires touch the moving parts like the belt, pulley of the motor, brake bar etc.

Do not make the wires touch the sharp edges and high-temperature area.

In case that there are metal parts with the wires, do not make the wires touch the metal parts.

Insulation materials are needed between them.

After assembly, the washing machine shall act normally. Check if it leaks and if the sound and

vibration are normal.