UNHITCHING PROCEDURE:

PERFORM THE FOLLOWING IN THIS ORDER:

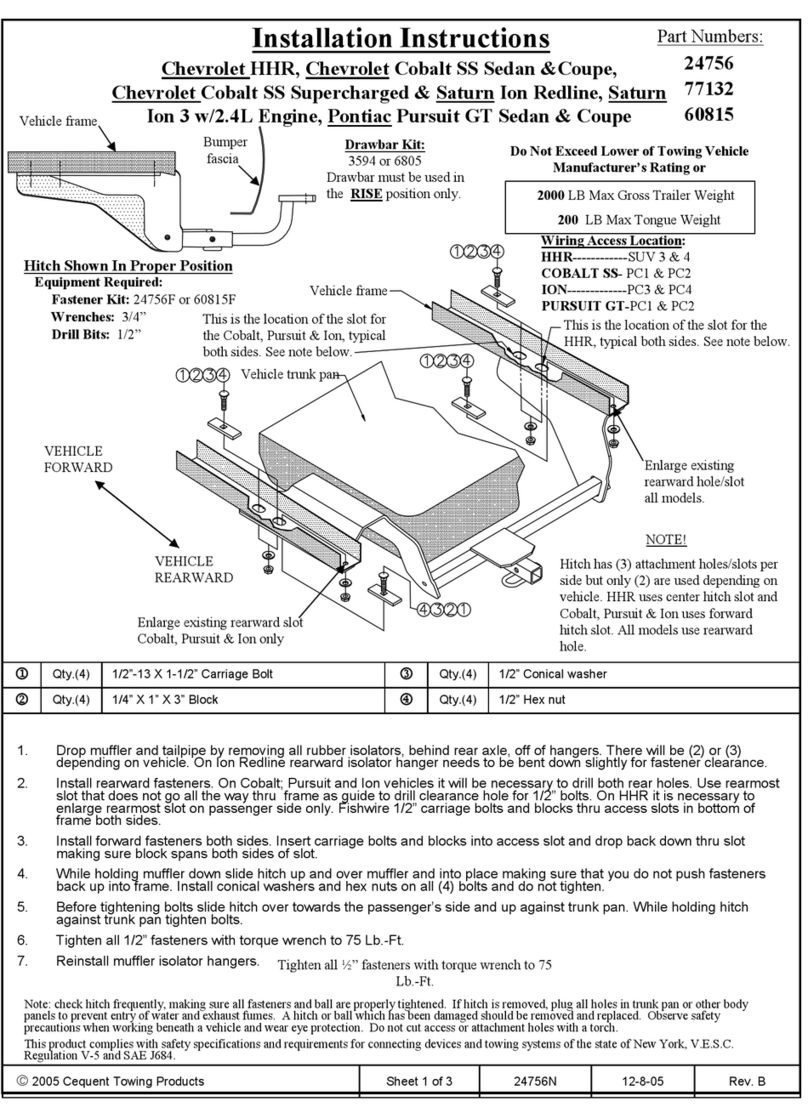

1. Make sure truck is in park with emergency brake on.

2. Place blocks firmly against front and rear of each trailer wheel to prevent any possible forward or rearward motion.

3. Using trailer jacks, lower trailer landing gear following the directions in the Trailer Manual until feet of landing gear are

resting on firm ground.

4. Lower truck tail gate.

5. Disconnect power cable and breakaway switch cable between truck and trailer.

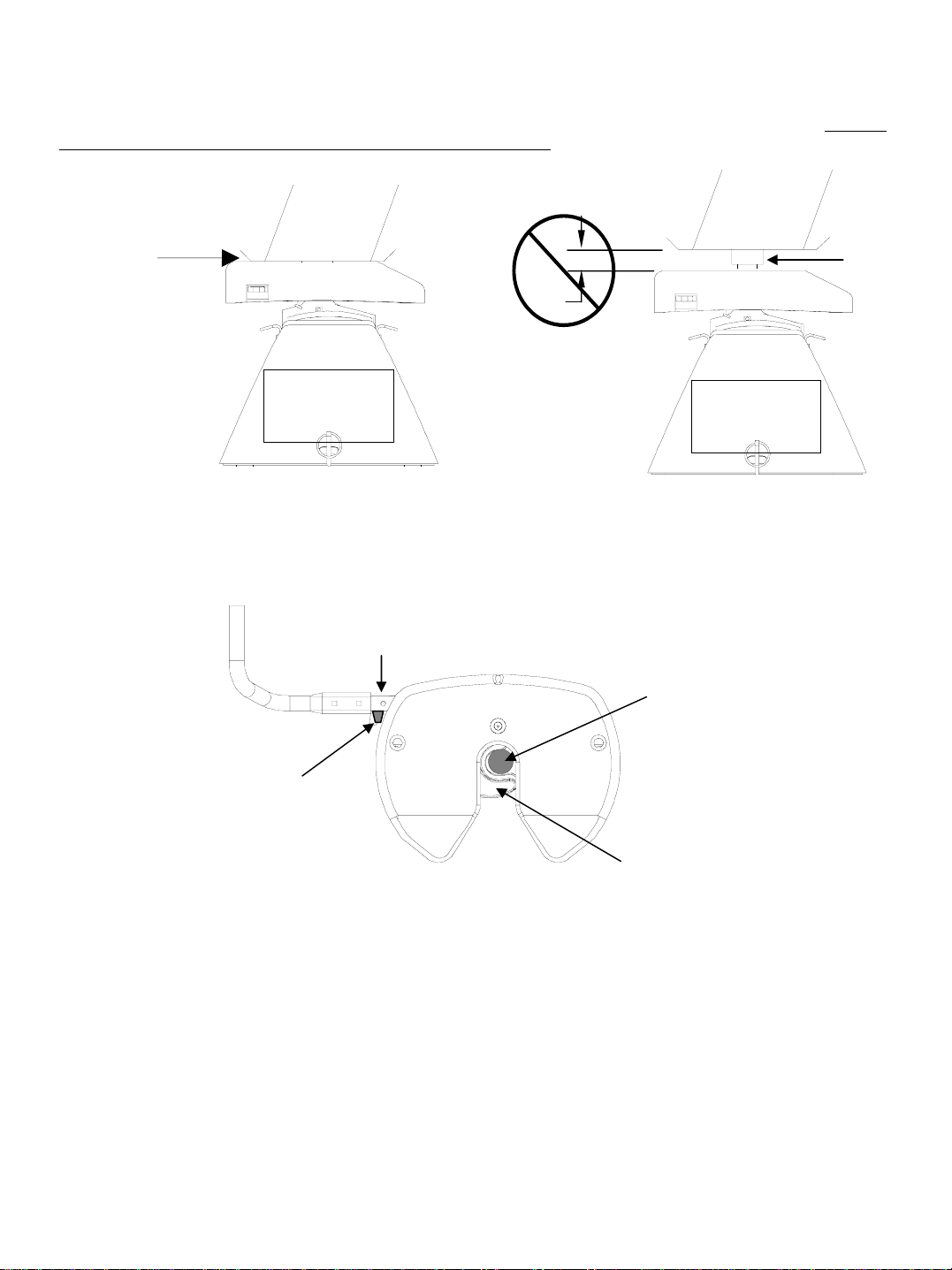

6. Remove bail pin from hole in handle.

7. Pull hitch handle out completely until it latches in open position so that king pin is no longer

securely grasped by hitch jaws (see Figure 4). Trailer is now free from hitch and truck. If handle does not pull out,

there is probably pressure against the jaw. To relieve this pressure, back the truck slightly. Reset truck emergency

brake. Then pull hitch handle out completely until it latches in open position.

8. AFTER MAKING CERTAIN NO ONE IS STANDING BETWEEN TRUCK AND TRAILER OR IN FRONT OF TRUCK,

drive truck slowly away from trailer.

9. Hitch jaw will automatically close as the king pin is removed from the jaw.

10. KEEP WHEEL BLOCKS IN PLACE. This will keep trailer from moving unexpectedly

WARNING:

Trailers that are not stable or properly hitched can fall and cause death or serious injury!

To avoid death or serious injury:

• All trailer tires MUST be blocked in front and behind each tire AND

• Trailer landing gear MUST be resting on firm ground AND

•TruckMUSTbe stationary, in park, with emergency brake on!

WARNING

Whenever possible, avoid putting body under trailer or between truck and trailer

If you need to place any part of our body under trailer or between truck and trailer:

•All trailer tires MUST be blocked in front and behind each tire AND

•Trailer landing gear MUST be resting on firm ground AND

•Truck MUST be stationary, in park, with emergency brake on!

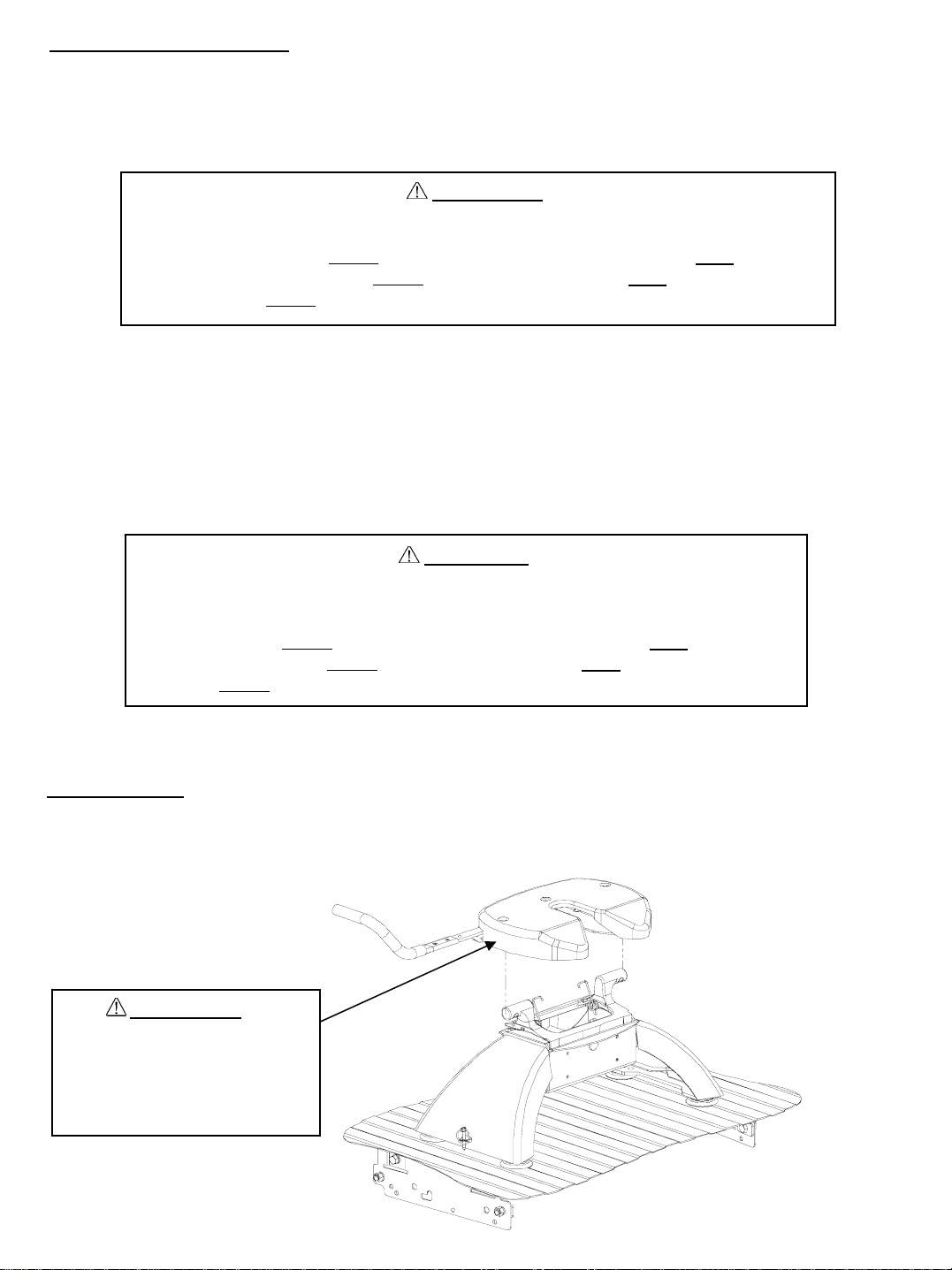

1. Recheck tightness of all hardware every 1000 miles of use. All 5/8” bolts have a torque specification of 170ft.lbs.,

and 1” jam nuts should be box wrench snug plus1/4 turn(see assembly instruction, 30058IN, for more detail).

2. See “Before each trip” section in this manual.

3. Anchor assemblies should be lubed every 6 months with lithium grease to keep assemblies moving freely.

MAINTENANCE:

Figure 10 : Head Placement

WARNING:

Tilting 5th Wheel head can

crush and cut. Keep hands and

fingers clear from this area at

all times (including

placement/removal of head).

30059OP - 15MAR05D PCN7735 ©2005 CEQUENT TOWING PRODUCTS, INC LITHO IN USA

FOR KITS 30059, 40259 & 50259