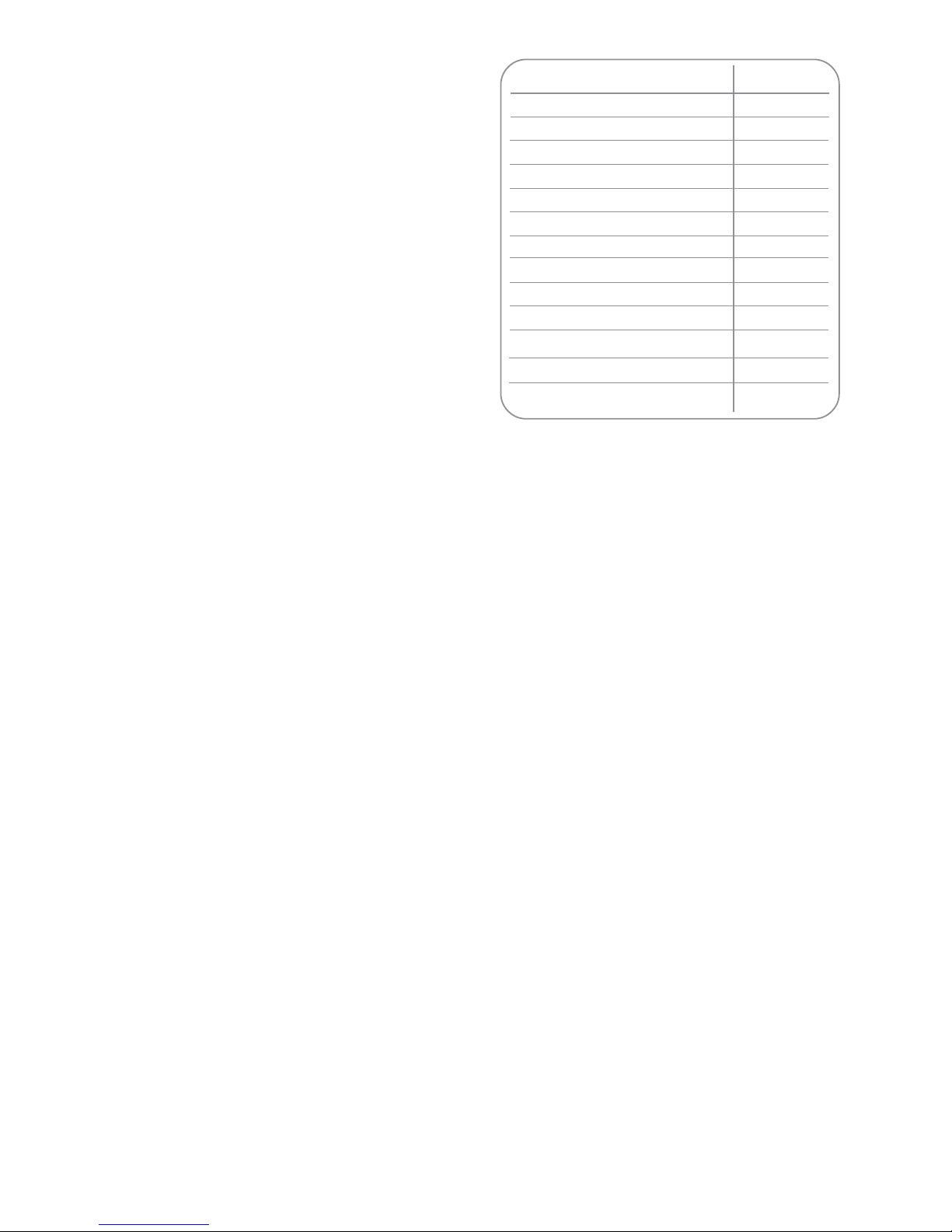

Terminal Position Minimum

\#$!C&C9>"!C&!6&I#>5 300 mm

!"#$%&'((!)%#)%*+*!, 75 mm

!"#$%!-.!, 200 mm

!"#$%/-"0#12%#)%)##3 200 mm

4)#5%-%$+16#$ 200 mm

4)#5%.!)(+0-"%*+*! 75 mm

4)#5%0#)1!), 300 mm

7/#.!%&)#'168%)##3%#)%/-"0#12 300 mm

4)#5%3-0+1&%,')3-0! 600 mm

4)#5%3-0+1&%(!)5+1-" 1200 mm

4)#5%#*!1+1&%'16!)%-%0-)%*#)( 1200 mm

9!)(+0-""2%3)#5%-%(!)5+1-" 1500 mm

:#)+;#1(-""2%3)#5%-%(!)5+1-" 300 mm

<#16!1,+1&%=##"%:!-(!) %%%%%4%%%%%%%%%%>>?@>?AB

0-11#(%/!%(#'0C!6%/2%-%*!),#1%',+1&%(C!%/-(C%#)

,C#$!)D

EC!)!%+1,(-""-(+#1%$+""%/!%+1%-1%'1','-"%"#0-(+#1%(C!1

,*!0+-"%*)#0!6')!,%5-2%/!%1!0!,,-)2%-16% FDGHIB

&+.!,%6!(-+"!6%&'+6-10!%#1%(C+,%-,*!0(D

7%0#5*-)(5!1(%',!6%(#%!10"#,!%(C!%:!-(!)%JKFL

/!%6!,+&1!6%-16%0#1,()'0(!6%,*!0+-""2%3#)%(C+,

*')*#,!D%71%!M+,(+1&%0'*/#-)68%#)%0#5*-)(5!1(8

5-2%/!%',!6%*)#.+6!6%+(%+,%5#6+3+!6%3#)%(C!%*')*#,!D

N!(-+",%#3%!,,!1(+-"%3!-(')!,%#3%0'*/#-)6%0#5*-)(O

5!1(%6!,+&18%+10"'6+1&%-+)+1&%0'*/#-)6%+1,(-""-(+#1,

-)!%&+.!1%+1% FDGHIBD

P1%,+(+1&%(C!%:!-(!)8%(C!%3#""#$+1&%"+5+(-(+#1,%JKFL

/!%#/,!).!6Q

1. LC!%*#,+(+#1%,!"!0(!6%3#)%+1,(-""-(+#1%JKFL%-""#$

-6!R'-(!%,*-0!%3#)%,!).+0+1&%+1%3)#1(%#3%(C!%/#+"!)

-16%3#)%-+)%0+)0'"-(+#1%-)#'16%(C!%/#+"!)D

2. LC+,%*#,+(+#1%JKFL%-",#%*!)5+(%(C!%*)#.+,+#1%#3%-

,-(+,3-0(#)2%/-"-10!6%3"'!%(!)5+1-(+#1D

3. LC+,%*#,+(+#1%JKFL%-",#%*!)5+(%(C!%*)#.+,+#1%#3%-

,-(+,3-0(#)2%0#11!0(+#1%(#%(C!%0#16!1,-(!%6)-+1D

Gas Supply

71%!M+,(+1&%5!(!)%-16%*+*!$#)S%,C#'"6%/!%0C!0S!68

*)!3!)-/"2%/2%(C!%T-,%F'**"+!)8%(#%!1,')!%(C-(%(C!2

-)!%-6!R'-(!%(#%6!-"%$+(C%(C!%)-(!%#3%&-,%,'**"2

)!R'+)!6D

F'**"2%*+*!,%,C#'"6%/!%,+;!6%(#%,'+(%+1,(-""-(+#1%-16

#/(-+1%-%$#)S+1&%*)!,,')!%#3%>A%5/-)%UVTW8%XH%5/-)

U=)#*-1!W%>I%5/-)%U '(-1!WD%P1,(-""-(+#1%*+*!,

,C#'"6%/!%3+((!6%+1%-00#)6-10!%$+(C% FDGBI@D

7%V-(')-"%T-,%:!-(!)%5',(%/!%0#11!0(!6%(#%-

&#.!)1!6%5!(!)D

Conversion

4#)%0#'1()+!,%*!)5+((!6%(#%',!%6+33!)!1(%&-,,!,%(C!

-**"+-10!%+,%,'**"+!6%,!('*%3#)%(C!%*)+5-)2%&-,D%P(

0-1%/!%0#1.!)(!6%(#%(C!%-"(!)1-(+.!%/2%(C!%-66+(+#1%#3

-1%Y)+3+0!%$C+0C%+,%,'**"+!6%$+(C%(C!%C!-(!)D%F!!

*-&!%(C!%+1,+6!%0#.!)%3#)%(C!%6-(-%-16%=-&!@>%3#)

0#1.!),+#1%+1,()'0(+#1,D

Flueing

Y1"2%3"'!%0#5*#1!1(,%,*!0+3+!6%/2%(C!%J-1'3-0(')!)

,C#'"6%/!%',!6%$+(C%(C!,!%-**"+-10!,D%N!(-+"!6

)!0#55!16-(+#1,%3#)%3"'!+1&%-)!%&+.!1%+1% FDZ[[AQ

LC!%3#""#$+1&%1#(!,%-)!%+1(!16!6%3#)%&!1!)-"%&'+6O

-10!D

1. !%-$-)!%#3%(C!%*"'5!%3)#5%(C!%3"'!%-16%(C!

$!((+1&%!33!0(%+(%0-1%C-.!%(#%-6\-0!1(%*)#*!)(2D

2. LC!%3"'!%0-1%/!%(-S!1%'*$-)6,8%"!3(8%)+&C(%#)%(#

(C!%)!-)%#3%(C!%-**"+-10!8%/'(%never 6#$1$-)6,D

3. LC!%:!-(!)%+,%,'**"+!6%,!*-)-(!%(#%(C!%0C#,!1

3"'!%,!(D%P(%0-1%/!%3+((!6%$+(C%'*%(#%>A%5!()!,

!R'+.-"-1(%"!1&(C%#3%<#10!1()+0%3"'!8%,!!%(C!%4"'!

F!0(+#1%#1%*-&!%B8%I%]%@A%3#)%!M-5*"!,%-16

*-)(,%,!"!0(+#1D

Fig. 1.0

IMPORTANT.

P(%+,%-/,#"'(!"2%^FF^VLP7_%(#%!1,')!%+1%*)-0(+0!8

(C-(%*)#6'0(,%#3%0#5/',(+#1%6+,0C-)&+1&%3)#5%(C!

(!)5+1-"%0-11#(%)!O!1(!)%(C!%/'+"6+1&8%#)%-12%#(C!)

-6\-0!1(%/'+"6+1&8%(C)#'&C%.!1(+"-(#),8%$+16#$,8

6##),8%#(C!)%,#')0!,%#3%1-(')-"%-+)%+13+"()-(+#1%#)

3#)0!6%.!1(+"-(+#1?-+)%0#16+(+#1+1&D

If this should occur, the appliance MUST be turned

OFF IMMEDIATELY and the Local Supplier con-

sulted.

Air Supply

P(%+,%VYL%1!0!,,-)2%(#%C-.!%-%*')*#,! *)#.+6!6%-+)

.!1(%+1%(C!%)##5%#)%+1(!)1-"%,*-0!%+1%$C+0C%(C!%/#+"!)

+,%+1,(-""!6D

EC!)!%(C!%/#+"!)%+,%+1,(-""!6%+1%-%0'*/#-)6%#)

0#5*-)(5!1(%no -+)%.!1(,%-)!%)!R'+)!6D

:#$!.!)%(C!%',!)%5-2%$+,C%(#%!1,')!%(C-(%+(%+,

.!1(+"-(!6%(#%*)#.+6!%-+)%0+)0'"-(+#1D

Outdoor Heaters

LC!,!%:!-(!),%-)!%0!)(+3+!6%3#)%#'(6##)%+1,(-""-(+#18

$C!1%!R'+**!6%$+(C%(C!%-**)#.!6%(!)5+1-"D

WARNING: LC!%C!-(!)%,C-""%1#(%/!%"#0-(!6%+1%-1%-)!-

$C!)!%$-(!)%,*)+1S"!),8%#)%#(C!)%6!.+0!,8%5-2%0-',!

$-(!)%(#%,*)-2%(C)#'&C%(C!%0-/+1!(%#*!1+1&,%-16%+1(#

(C!%C!-(!)D%%LC+,%0#'"6%0-',!%C!-.2%+1(!)1-"%)',(+1&%#)

6-5-&!%,#5!%!"!0()+0-"%0#5*#1!1(,8%-16%(C+,%$#'"6

.#+6%(C!%$-))-1(2D

P(%+,%)!0#55!16!6%(C-(%*!)+#6+0-""2%(C!%0-,+1&%+,

0"!-1!6%-16%,*)-2!6%$+(C%EN[A%#)%,+5+"-)%"+R'+68%-16

-12%!M*#,!6%(C)!-6,%-)!%"+&C("2%0#-(!6%+1%&)!-,!D