CGOLDENWALL CC-300 User manual

1

CGOLDENWALL

Commercial Self-Draining

Steam Generator

USER MANUAL

2

Preface

Thanks for using CGOLDENWALL steam generator. The steam

generator has stable function and beautiful appearance, uses the

international advanced technology.

To install, operate and maintain the machine safely and correctly,

please read the instructions carefully and keep this manual for further

reference.

Please Note:

The elderly, pregnant, or patients with heart disease, high blood

pressure, diabetes or other bad health reasons cannot use this

equipment unless under the guidance of doctor.

Do not smoke, do sports and drink alcoholic drinks when do sauna.

Please leave the shower as soon as possible when feel uncomfortable,

sick or tired.

Please take good care of the children.

It is necessary to install a ventilated fan to let in the fresh air.

We will guide you online to help you solve the problem sooner

and better.

✉Email:sunflowersmile20130401@hotmail.com

3

CONTENTS

Parameters.........................................................................................4

Instructions for Installation...............................................................5

Steam Generator Location................................................................6

Water Inlet pipe.................................................................................8

Steam Outlet pipe..............................................................................9

Drain pipe and Auto drain valve......................................................10

Steam Nozzle...................................................................................10

Wiring Connection...........................................................................12

Controller Install Guide....................................................................15

Temperature Probe Install.................................................................17

Start the steam generator...................................................................18

Controller Operation Guide...............................................................18

Descaling............................................................................................20

Maintenance operation guidance........................................................20

Troubleshooting Guidance .................................................................22

4

Parameters

1.The basic parameters of the model, the outline dimensions are shown

in Table 1:

Table 1

Power/KW

Volt/Phase

Size(length*width*height)/in

3.5

220/2

13.8×7.1×9.5

4.5

220/2

17.8×7.9×12.6

6

220/2

17.8×7.9×12.6

9

220/2

17.8×7.9×12.6

10.5

220/2

19.7×8.7×15.4

12

380/3

19.7×8.7×15.4

15

380/3

19.7×8.7×15.4

18

380/3

19.7×8.7×15.4

2.The basic parameters and dimensions of the controller are shown in

Table 2:

Table 2

Model

Time/min

Temperature Range

Size(length*width*height)/in

CC-300

30~720

95 - 131℉

3.4*3.4*0.5

5

Instructions for Installation

When installing the steam generator, please note that it has been

carefully assembled and tested by our technician. The pipe installation

must be in accordance with the specifications. Or consult a professional

with local or national plumber qualification certificate for installation.

Please turn off power when installing the steam generator and confirm

whether the purchased model is suitable for your shower room.Please

refer to Table 3.

Table 3 Technical parameters

Power

(KW)

Room size

(ft3)

voltage

(V)

Phase

number

Copper

wire cable

size (mm²)

Copper wire

cable size

(AWG)

Breaker

required

(A)

3

70~105

220V

2

2.5

12

20

4.5

105~140

220V

2

4

12

32

6

175~210

220V

2

6

8

40

9

315~350

220V

2

10

8

60

10.5

315~420

220V

2

10

8

60

12

360~455

380V

3

6

10

25

15

420~560

380V

3

6

9

30

18

560~735

380V

3

6

8

40

6

Steam Generator Location

Select a location as near as practical to the shower room. Typical

locations include: closet, vanity cabinet, climate controlled attic or

basement.

1.Locate the steam bath generator within 32 feet of the shower

room.The standard length of the cable for connecting the control to the

steam generator is 32 feet. The steam generator and control must be

located accordingly

2.DO NOT install steam bath generator inside shower room.

3.DO NOT install steam bath generator outdoors or wherever

environmental conditions may affect the safety and/or performance of the

generator.

4.DO NOT install steam bath generators or pipes in an unheated

attic or any place where water may freeze.

5.DO NOT install the steam bath generator near flammable or

corrosive materials or chemicals (such as gasoline, paint thinner, etc.).

Must avoid installation in areas with high chlorine concentration (such as

swimming pool room).

6.The steam generator can be installed on the wall or on the

ground, but it must be firm. The steam generator should be installed as

close as possible to the bathtub or bathroom. To fix the machine on a

vertical wall, first loosen the 4 screws on the cover and remove the outer

cover. There is a hole in the upper left and upper right of the cover for

fixing the machine on the wall. Close the cover after fixing. In order to

provide a good maintenance service, the sign must be placed where it can

be seen, and the machine must be installed in a place that is convenient

for maintenance. Please refer to the installation diagram below.

7.It is strictly forbidden to install the machine in an outdoor, humid,

7

hot place or a place that may be frozen or corroded. At the same time, it is

strictly forbidden to install it near flammable and explosive places such as

paint, thinner, gasoline, etc. Should be placed in a dry and ventilated

place.

8.The steam generator can only be installed horizontally. Up in the

direction indicated by the arrow. Otherwise, it is strictly forbidden to

boot.

9.Provide a minimum of 12 inches at both ends and top of the

steam generator or as required for servicing.

attic floor(insulated)

suitable for installation

controller

closet

(suitable for installation)

basement

(suitable for installation)

steam generator

controller

steam jet

under the wash basin

(suitable for installation)

8

Pipe installation

The installation of water supply pipes and steam pipes should be

completed before sealing the wall.

1. Water inlet pipe:

the water inlet pipe is connected with the DN15 pipe (1/2 NPT). And a

DN15 metal hose is connected to the water inlet and water supply valve

of the machine.

Connect to cold water .

Provide a shut off valve in the water supply line upstream of the

steam bath generator.

Do not overheat inlet solenoid valve while welding connections.

Overheating will damage parts.

Flush inlet water line thoroughly before connection to unit.

Strainer recommended to install upstream of feed water connection

As required by local codes, install an approved backflow preventer.

Do not use PEX , PVC tubing or Aluminum-plastic tube

9

2. Steam outlet pipe(1/2’’ NPT):

The steam pipe should be installed with a metal pipe of corresponding

diameter or other materials with a high temperature resistance above

150 °C according to the steam port of the steam engine (Since the

ferrous metal and galvanized pipes will make the walls of the shower

room rusty and discolored, so they are strictly forbidden to use it). The

length of the steam pipe is no more than 3 meters. If the length exceeds 3

meters, then the pipe should be insulated.

1. Do not install any valve in steam line. Flow of steam must be

unobstructed.

2. Use 1/2” brass pipe or copper tubing from unit to steam head as

permitted by codes.

3. Insulate steam line using pipe insulation rated 250˚ F or higher.

4. Pitch steam line 1/4” per foot towards steam head or steam

generator to avoid valleys and trapping of condensation.

NOTE: Running the steam line down and then up will create a steam

trap blocking the flow of steam.

NOTE: A 1.5” hole in the shower room is required to mount the steam

head

10

3. Drain pipe and Auto drain valve ( 1 ⁄2’’ NPT)

The Auto drain System feature automatically drains the system following

each use.The auto drain is automatically turned on after the controller is

turned off for about 15 minutes, but it must be ensured that the main

power supply is not turned off.

1. Plumbing to be performed by a qualified plumber and shall be in

accordance with applicable national and local codes. Steam generator

drains by gravity. A drain line must be lower than the Auto Drain

System assembly. The Auto Drain System valve outlet is 1/2” NPT.

Check plumbing code for receptor, trap and vent requirements.

2. Use copper or brass nipple 1/2” NPT x 3 , 1 ⁄2” or longer (not

supplied) to connect Auto Drain valve. An arrow on the bottom of the

Auto Drain indicates the direction of flow

4. Steam nozzle:

Put the decorative cover on the steam nozzle in the shower room, apply

sealant and screw on the nozzle. Pay attention to avoid damaging the

decorative cover and nozzle by excessive force. Confirm that the steam

outlet of the nozzle is facing down (pointing to the ground).

11

Note: The steam nozzle should be 30cm high from the ground or 20cm

high from the edge of the bathtub. For the comfort of the shower, the

nozzle should be installed as far as possible from the seating area.

After completing the pipe installation, the electrician can carry out the

machine wiring work.

Warning:

●If the machine is installed in a place that is difficult for users to

operate, the water supply valve must be installed in a place that is easy to

operate in an emergency.

●Do not use saddle valve or needle valve to install on the water inlet

pipe. The water pipe should be unblocked and rinsed before the final

connection.

●It is strictly prohibited to install blocking valves in the steam pipe. No

obstruction or bending of the "U" channel is allowed. Otherwise,

condensed water will be generated to hinder the flow of steam. The steam

pipe should have a certain inclination when it is arranged horizontally so

that the condensed water can flow back to the steam generator or flow to

the steam nozzle.

●The steam generator cannot be installed outdoors to prevent freezing

inside. It must be installed in a place that is convenient for maintenance.

The machine should be installed horizontally with the arrow pointing up,

otherwise it cannot be turned on.

●The pipe installation must use red copper pipe material, stainless steel

pipe. It is strictly forbidden to use plastic, acrylic, aluminum-plastic tubes

or other similar materials as steam pipes. The temperature allowed by

these materials cannot reach 150°C and higher.

12

●The steam pipe entrance, all other entrances and gaps should be

sealed to prevent steam seepage and damage the machine and other

objects.

●Draining the water in the water tank into the shower room may cause

scalding accidents and damage the building materials used in the shower

room.

Wiring Connection

When installing and operating the steam generator, it should be noted

that the machines manufactured by our company have been carefully

assembled and tested. The wiring connection must be carried out in

accordance with national regulations and by professionals who have

obtained local or national professional electrician qualification

certificates. The power must be turned off before making any wiring

connections.Please refer to the following wiring diagram for complete

wiring information

TO AVOID EQUIPMENT DAMAGE, DO NOT CONNECT POWER

SUPPLY DIRECTLY TO ELEMENTS!!!

Wiring diagram

If you are in 110V countries, like America, you need to connect to

TWO DIFFERENT 110V live wires(L1 and L2). NO neutral wire is

required. L1, L2, Ground to be field wired

13

If you are in other 220V countries, you need to connect to one 220V

live wire and one neutral wire (L and N). For both, a ground wire is

needed. L1, N1, Ground to be field wired

14

When installing the steam generator, please note that it has been

carefully assembled and tested by our technician. The pipe installation

must be in accordance with the specifications. Or consult a professional

with local or national plumber qualification certificate for installation.

Please turn off power when installing the steam generator and confirm

whether the purchased model is suitable for your shower room. Please

refer to Table 3.

Steam generator power supply installation:

1. Confirm the correct power supply voltage (220V or 380V, see label),

please refer to the label on the machine or the information in Table 1 in

the manual.

2. Requirements for installing a circuit breaker in the circuit: The circuit

breaker must be installed in strict accordance with Table

3. The machine must be grounded reliably. Install CFI (Floor Leakage

Appliance) (International Electrotechnical Code 210-8).

4. Choose the power wire routing that matches the local requirements. If

you need to install a socket, please install it near the steam generator.

Note that the plug and socket must not be less than 250V and the required

current load. After the wall is sealed, the machine and the controller can

be connected.

5. Loosen the cover screws and remove the cover. Connect the left wire

hole of the power cord to the wiring block inside the machine. Connect in

strict accordance with the wiring method on the power wiring diagram

label (the wiring diagram label is on the chassis cover). After the

controller is installed, the machine can be started and debugged

Before using, please check according to the following terms:

1. The machine is properly grounded, and the diameter of the grounding

wire is greater than 4mm2.

2. Whether the machine model is selected properly. If not, the shower

room may not reach the preset temperature.

15

3. Choose the voltage connected to the steam generator (i.e. 220V or

380V). The neutral wire of the 380V steam generator and the live wire

cannot be connected wrongly, that is, the neutral wire cannot be

connected to the live wire. Otherwise it will damage the circuit board and

the heating tube.

4. The steam generator must be installed vertically and horizontally.

5. Select the correct wire number cable and circuit breaker.

Warning:

● All power switches must be turned off before installing and maintaining

the machine.

● It is strictly prohibited to connect any additional wires or supply power

to the machine and controller. Make sure that the neutral wire is not

connected to a live wire. In the process of installation, operation,

maintenance, and repair, in order to use the machine for continuous and

safe operation, please only use the original authorized replacement

components.

Controller installation guide

1. Controller installation location:

The controller must be installed can be installed inside and outside the

shower room and sealed with silicone adhesive.

For controller power supply connection,the white connection line is one

head connect to the controller, another head connect to the control

panel.The standard length of the cable for connecting the control to the

steam generator is 32 feet. The steam generator and control must be

located accordingly.

16

2. Installation of controller:

The controller can be installed inside and outside the shower room. For

ease of use, it is recommended that the controller be installed at a height

of 1500 mm above the ground. Locate controller where it will sense

general room temperature and NOT direct steam emission from the steam

head.

An 86 switch bottom box should be embedded on the wall so that the

back of the controller can be inserted and installed. The control wires

behind the controller should be respectively inserted into the

corresponding ports and connected firmly. Peel off the double-sided

adhesive film on the back of the controller and stick it on the wall, and

seal it with silica gel around.

(Note: 1. The control line must be installed in the line pipe for easy

maintenance. 2. The double-sided tape on the back of the controller

cannot be used for fixing and needs to be fixed with silica gel.)

Temperature Sensor

Installed at the height of

1.5 m of shower room

Controller can be installed inside

and outside the shower room

17

Installation of temperature probe

The temperature probe senses the temperature in the shower room. Its

installation height is about 1.5 meters and should be fixed in the shower

room with screws.

One head of the temperature probe line connect to the control

panel.Another head of the temperature probe with sensor must be fixed

inside the shower room by screws,and on a vertical surface, 4-5 inch

above the floor and should be exposed to the air.

Drill a 1/4” hole in the wall. The hole should not be too large or too

small. Clean the area thoroughly.

Route the end of the temperature probe cable with the temperature

probe through the wall into the shower room as picture.

18

Do not locate the probe above or near the steam head or direct steam

emissions. The probe is 10ft cable. Ensure that the probe and controller

are located accordingly.

IMPORTANT NOTE: Do not strain, staple, pinch, otherwise damage the

probe cable.

Start the steam generator

After confirming that the pipes and circuits are installed correctly, you

could open the water valve and turn on the power switch. Press the

ON/OFF and the machine will start to work. After heating for minutes,

the machine starts to emit steam, and stops steaming until the room

reaches the set temperature.

Press the ON/OFF button again to turn off the machine. The controller

will display the current temperature in the shower room when it is

working. The temperature setting range of the controller is between

95-131℉.

Warning:

The machine and controller are strictly prohibited to be installed in

places prone to moisture and corrosion. The installation site should be

dry and ventilated. If the machine is damaged in a damp or corrosive

environment, our after-sales service warranty will not take effect.

The double-sided tape on the back of the controller cannot be used for

fixing. The installer needs to use silica gel to seal it.

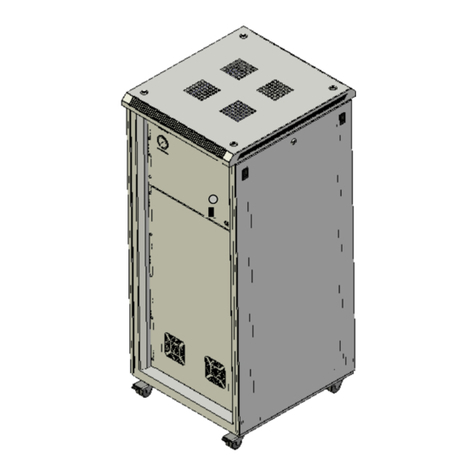

Controller operation guide

1. Display screen: display time and temperature when the steam

generator is working;

2. Light button: used for lighting in the shower room. Output 220V,

maximum power 100W.

19

3. On/Off: Press this key to start working and steam will be generated

after a few minutes. Press this key again to stop working. The machine's

internal working time is set to 60 minutes, and it will automatically shut

down after the set time;

4. Time/temperature setting key: After turning on the machine, press the

temperature setting key to set the temperature, and then press Up/down

button to adjust the temperature. The set temperature will be shown on

the display screen. Press the temperature setting button again or wait for

15 seconds to exit the temperature setting state. The set temperature range

of the steam generator is between 95 - 131℉;

• The time setting range is 30 minutes to 12 hours.

• Timing function adopts countdown working mode.

5. Up/down button: increase and decrease the temperature.

Warning:

The machine and controller are strictly prohibited to be installed in

places prone to moisture and corrosion. The installation site should be

dry and ventilated. If the machine is damaged in a damp or corrosive

environment, our after-sales service warranty will not take effect.

The double-sided tape on the back of the controller cannot be used for

fixing. The installer needs to use silica gel to seal it.

Time / temperature

setting button

Light

Digital Up/down button

On/off

button

display screen

20

Descaling

1. The equipment is equipped with automatic drain valve to clean the

incrustation scale in the steam generator.

Clean process: Add 50g citric acid, turn off the power for about 2 hours,

and let the citric acid dissolve. Turn the power back on after 2 hours.

Finally, turn off the controller to start self-draining. Clean up every six

months or a year.

2. This process can also be done depending local water quality and

operating frequency of generator

3, or more frequent cleaning according to the local water quality and the

use of the steam generator.

Maintenance operation guidance

1. Replace the electric heating tube:

Turn off the power, drain the water in the water tank, open the front cover

and the outer cover of the electric heating tube passage, mark and remove

the wires, and then take out the electric heating tube. If you need to

replace a new electric heating tube, first put a rubber ring on the wire

mouth of the tube and clean the scale in the water tank. Put the electric

heating tube into and tighten it. (The sealing gasket should be pressed

tightly, but it cannot be turned outward.) Reconnect the wires, check

Table of contents