CH Hanson PALMGREN POWERGRIND 9682090 User manual

9682090

6"

Bench Grin er

Read carefully and follow all safety rules and operating

instructions before first use of this product.

9643557.01-1118

Operating Manual & Parts List

9682090 shown.

9682090_oipm_En013_9643557.01 __ 02-08-2019 . . . . 02/08/19 3:05 PM Page 1

2

Palmgren Operating Manual & Parts List 9682090

DESCRIPTION

Palmgren Bench Grinders are equipped with a totally enclosed ball

bearing motor. Armature assembly is dynamically balanced for

smooth operation. Motor housing is compact so long pieces of

work can press against both wheels without touching the motor

frame. Removable wheel guards allow for easy changing of wheels.

Two-way tool rests are adjustable for wheel wear and angle

grinding. Grinders come complete with spark guards and safety

eyeshields.

UNPACKING

Check for shipping damage. If damage has occurred, a claim must

be filed with the carrier immediately. Check for completeness.

Immediately report missing parts to dealer.

To be certain the grinding wheels have not been damaged in ship-

ment, strike the edges slightly with a metal object. A ringing sound

indicates a good wheel, but a dull noise may signal a fracture.

WARNING: If you suspect a wheel of being fractured, replace it

immediately. Fractured wheels may shatter, causing serious injury.

S ECIFICATIONS

9682090, 6” Bench Grinder

orsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Amperes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5

ertz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Single

RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1750

Rotation (viewed from left side) . . . . . . . . . . . . . . . . . . . . . . . . Clockwise

Wheel Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6”

Wheel Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2”

SAFETY RULES

WARNING: This product can expose you to chemicals including

lead and cadmium which are known to the State of California to

cause cancer and birth defects or other reproductive harm, and

phthalates which are known to the State of California to cause birth

defects or other reproductive harm. For more information go to

http://www.p65warnings.ca.gov.

WARNING: Some dust, fumes and gases created by power sanding,

sawing, grinding, drilling, welding and other construction activities

contain chemicals known to the State of California to cause cancer

and birth defects or other reproductive harm. Some examples of

these chemicals are:

• Lead from lead based paint

• Crystalline silica from bricks, cement and other masonry

products

• Arsenic and chromium from chemically treated lumber

Your risk of exposure varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals, work in a

well-ventilated area and work with approved safety equipment,

such as dust masks that are specifically designed to filter out micro-

scopic particles. For more information go to http://www.p65warn-

ings.ca.gov/ and http://www.p65warnings.ca.gov/wood.

BE RE ARED FOR JOB

• Wear proper apparel. Do not wear loose clothing, gloves, neck-

ties, rings, bracelets or other jewelry which may get caught in

moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI Z87.1.

Everyday glasses have only impact resistant lenses. They are

NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools when tired,

intoxicated or when taking medications that cause drowsiness.

RE ARE WORK AREA FOR JOB

• Keep work area clean. Cluttered work areas and work benches

invite accidents.

• Do not use power tools in dangerous environments. Do not use

power tools in damp or wet locations. Do not expose power

tools to rain.

• Work area should be properly lighted.

• Proper electrical plug should be plugged directly into properly

grounded, three-prong receptacle.

• Extension cords should have a grounding prong and the three

wires of the extension cord should be of the correct gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of the workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to prevent

any unintentional use of power tools.

TOOL SHOULD BE MAINTAINED

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjusting

procedures.

• Keep tool clean for safest operation.

• Remove adjusting tools. Form habit of checking to see that a -

djusting tools are removed before turning machine on.

• Keep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their

intended function.

• Check for damaged parts. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting and any

other condition that may affect a tool’s operation.

• A guard or other part that is damaged should be properly re-

paired or replaced. Do not perform makeshift repairs. (Use the

parts list to order replacement parts.)

KNOW HOW TO USE TOOL

• Use right tool for job. Do not force tool or attachment to do a

job for which it was not designed.

• Disconnect tool from power when changing accessories such as

grinding wheels, buffing wheels and the like.

• Avoid accidental start-up. Make sure that the switch is in the off

position before plugging in.

• Do not force tool. It will work most efficiently at the rate for

which it was designed.

• Keep hands away from moving parts and grinding surfaces.

• Never leave a tool running unattended. Turn the power off and

do not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is tipped

over.

• Know your tool. Learn the tool’s operation, application and

specific limitations.

• Use recommended accessories. Understand and obey all safety

instructions supplied with accessories. The use of improper

accessories may cause risk of injury to persons.

• Do not over tighten wheel nut. Replace cracked wheel immedi-

ately. Use only flanges supplied with the grinder.

9682090_oipm_En013_9643557.01 __ 02-08-2019 . . . . 02/08/19 3:05 PM Page 2

3

Palmgren Operating Manual & Parts List 9682090

SAFETY RULES (CONTINUED)

• Adjust distance between wheel and tool rest to maintain 1/16”

or less gap.

• andle the workpiece correctly. Whenever possible, use tool

rest to support workpiece during grinding operation. Turn tool

off if it jams.

• Always use guards and eyeshields.

• Clean grinding dust from beneath tool frequently.

ASSEMBLY

Parts to be fastened to the unit should be located and accounted

for before assembly.

IM ORTANT: Do not attempt assembly if parts are missing. Use this

manual to order replacement parts.

A Knob (2)

B Flat washer, M8 (6)

C Tool rest bracket (2)

D Tool rest (2)

E M10 Flat washer (2)

F Knob (2)

G Pan head screw, M5 x 10 (4)

Upper eyeshield bracket (2)

I Eyeshield (2)

J Lower eyeshield bracket (2)

K Knob (2)

L Spark Deflector (2)

M Knob (2)

N Spring Washer, M10 (8)

TOOL REST ASSEMBLY

1) Place tool rest (D) over tool rest bracket (C) and secure in posi-

tion with knob (F) and flat washer (E).

2) Attach tool rest bracket (C) to the bottom of the wheel guard

(O) using knob (A) and flat washer (B). Make sure that the slot of

the bracket is located over the raised boss on the wheel guard.

Secure in position with knob.

3) Position tool rest (D) so that distance between tool rest (D) and

wheel (P) is less than 1/16”. Reposition angle of tool rest if nec-

essary. Secure all knobs.

• Mount right tool rest in a similar manner.

EYESHIELD ASSEMBLY

• Attach spark guard (L) to left wheel guard (O) using knob (M),

spring washer (N) and flat washer (B).

• Mount left upper eyeshield bracket ( ) to eyeshield (I) and

lower eyeshield bracket (J) using two pan head screws (G).

NOTE: Left upper eyeshield bracket is stamped “L” for identification.

• Slide knob (K) through hole at top of left spark deflector (L) into

upper eyeshield bracket ( ) and secure in position.

• Locate eyeshield in desired position for protecting operator and

secure all knobs and bolts.

• Mount right eyeshield assembly in a similar manner.

DUST COLLECTION HOSE

• A dust collector hose has been provided with grinder. Slide

hoses onto sides of T-connector and flanges. Mount the hose by

sliding the flanges at each end over the exhaust ports on the

left and right wheel guards. Attach 2½” shop vacuum hose to

collector hose. Be sure hose is mounted securely.

DANGER: Be sure to empty shop vacuum of all flammable mate-

rial (flammable liquids and vapors, paper, wood, plastic, etc.) before

connecting vacuum to grinder. ot sparks from grinder may ignite

flammable materials in shop vacuum.

INSTALLATION

MOUNT BUFFER (FASTENERS NOT INCLUDED)

• Mount buffer to a solid horizontal surface.

• To mount buffer to metal pedestal, align mounting holes with

corresponding holes in pedestal. Insert a 1/4-20 x 1¼” hex head

bolt with flat washer through base of buffer. From bottom of

pedestal, place a 1/4” flat washer and 1/4”-20 hex nut onto the

bolt. Tighten only until space between buffer base and pedestal

is 1/8”. Using second nut on each bolt, jam tighten against the

first to prevent loosening by vibration.

• To mount buffer to wooden bench top, use 1/4 x 1¼” wood

screws with flat washers beneath heads. Tighten screws until

space between buffer base and bench top is 1/8”.

GROUNDING INSTRUCTIONS

WARNING: Improper connection of equipment grounding con-

ductor can result in the risk of electrical shock. Equipment should

be grounded while in use to protect operator from electrical shock.

• Check with a qualified electrician if grounding instructions are

not understood or if in doubt as to whether the tool is properly

grounded.

• This grinder is equipped with an approved 3-conductor cord

rated at 300V and a 3-prong, grounding type plug (See Figure 2)

for your protection against shock hazards.

• Grounding plug should be plugged directly into a properly in-

stalled and grounded 3- prong grounding-type receptacle (See

Figure 2).

J

G

O

P

C

B

N

B

D

EF

A

K

L

M

I

Figure 1 – Left Tool Rest and Eyeshield Assembly

Figure 2 – 3- rong Receptacle

Properly Grounded Outlet

Grounding Prong

3-Prong Plug

9682090_oipm_En013_9643557.01 __ 02-08-2019 . . . . 02/08/19 3:05 PM Page 3

4

Palmgren Operating Manual & Parts List 9682090

INSTALLATION (CONTINUED)

• Do not remove or alter grounding prong in any manner. In the

event of a malfunction or breakdown, grounding provides a

path of least resistance for electrical shock.

WARNING: Do not permit fingers to touch the terminals of plug

when installing or removing from outlet.

• Plug must be plugged into matching outlet that is properly in-

stalled and grounded in accordance with all local codes and or-

dinances. Do not modify plug provided. If it will not fit in outlet,

have proper outlet installed by a qualified electrician.

• Inspect tool cords periodically, and, if damaged, have repaired

by an authorized service facility.

• Green (or green and yellow) conductor in cord is the grounding

wire. If repair or replacement of the electric cord or plug is nec-

essary, do not connect the green (or green and yellow) wire to a

live terminal.

• Where a 2-prong wall receptacle is encountered, it must be re-

placed with a properly grounded 3-prong receptacle installed

in accordance with National Electric Code and local codes and

ordinances.

WARNING: This work should be performed by a qualified

electrician.

• A temporary 3-prong to 2-prong grounding adapter (See Figure

3) is available for connecting plugs to a two pole outlet if it is

properly grounded.

• Do not use a 3-prong to 2-prong grounding adapter unless per-

mitted by local and national codes and ordinances.

(A 3-prong to 2-prong grounding adapter is not permitted in

Canada.) Where permitted, the rigid green tab or terminal on the

side of the adapter must be securely connected to a permanent

electrical ground such as a properly grounded water pipe, a prop-

erly grounded outlet box or a properly grounded wire system.

• Many cover plate screws, water pipes and outlet boxes are not

properly grounded. To ensure proper ground, grounding means

must be tested by a qualified electrician.

EXTENSION CORDS

• The use of any extension cord will cause some drop in voltage

and loss of power.

• Wires of the extension cord must be of sufficient size to carry

the current and maintain adequate voltage.

• Running the unit on voltages which are not within ±10% of the

specified voltage may cause overheating and motor burn-out.

• Use the table to determine the minimum wire size (A.W.G.) ex-

tension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

• If the extension cord is worn, cut or damaged in any way, re-

place it immediately.

ELECTRICAL CONNECTIONS

WARNING: All electrical connections must be performed by a

qualified electrician. Make sure tool is off and disconnected from

power source while motor is mounted, connected, reconnected or

anytime wiring is inspected.

• Motor and wires are installed as shown in wiring diagram (See

Figure 4). Motor is assembled with approved, 3-conductor cord to

be used at 120 volts. Motor is prewired at the factory for 120 volts.

OPERATION

CAUTION: Always follow proper operating procedures as defined

in this manual even if you are familiar with use of this or similar

tools. Remember that being careless for even a fraction of a second

can result in severe personal injury.

WARNING: Always wear safety glasses complying with United

States ANSI Z87.1 (shown on package) before commencing power

tool operation.

• Keep a steady, moderate pressure on the work and keep it mov-

ing at an even pace for smooth grinding.

• Pressing too hard overheats the motor and prematurely wears

down the grinding wheels.

• Note the original bevel angle on the item to be sharpened and

try to maintain that angle. Sharpening a cutting edge requires

removing burrs from edge.

• Deburring edge is done best by using the grinder to pull burr

from edge across the bevel angle.

• The grinding wheel should rotate into object being sharpened.

• Dip work into a coolant regularly to prevent overheating. Over-

heating can weaken metals.

MAINTENANCE

• As wheels wear, tool rests should be positioned closer to the

face of the wheels.

• The gap between the wheel and the tool rest should not be

greater than 1/16”. When the wheels are worn to the extent that

the 1/16” maximum gap cannot be maintained, the wheels

should be replaced.

• Replacement wheels for model 9682090 must have a minimum

rated speed of at least 1800 RPM and a maximum wheel diame-

ter of 6” .

• To loosen nuts holding the wheels, disconnect power and push

a wood wedge between the tool rest and the wheel to keep the

shaft from turning. The threads on the right side of the grinder

(facing unit) are right hand; threads on the left side are left

hand. Tighten nuts securely before operating the grinder.

• For grinding efficiency, wheels should be dressed periodically,

especially if they become clogged from grinding soft metals.

Figure 3 – 2- rong Receptacle with Adapter

Grounding Lug

Adapter

3-Prong Plug

2-Prong Receptacle

Make sure this is

connected to a known

grounded receptacle.

Figure 4 – Wiring Diagram

Blue White

Brown

Red

120V

Volts

120 25 50 100

240 50 100 200

06 18 16 16

6 10 18 16 14

10 12 16 16 14

12 16 14 12

More Not

Than More Than Minimum Gage for Cord

Total Length of Cord in Feet

Not Recommended

Ampere Rating

Extension Cord Table

9682090_oipm_En013_9643557.01 __ 02-08-2019 . . . . 02/08/19 3:05 PM Page 4

5

Palmgren Operating Manual & Parts List 9682090

SYM TOM

Grinder won’t start

Excessive vibration

Motor overheating

Fuses are being blown or

circuit breakers are being tripped

OSSIBLE CAUSE(S)

1. Blown line fuse or tripped circuit breaker

2. Low line voltage

3. Material wedged between wheel

and guard

4. Defective switch

5. Defective, blown capacitor

1. Improper mounting of grinder or

accessories

2. Grinding wheel out of balance

3. Improper wheel mounting

1. Excess pressure required to grind material

2. Grinding on side of wheel

3. Motor not turning freely (without power)

1. Overloading due to binding

2. Defective plug

3. Defective cord

4. Defective switch

5. Faulty internal wiring

CORRECTIVE ACTION

1. If fuse is blown, replace with fuse of

proper size. If breaker tripped, reset it

2. Check power supply for voltage and

correct as needed

3. Turn grinder off and remove material

4. Replace switch

5. Replace capacitor

1. Remount

2. Dress wheels or replace wheels

3. Remount wheels, but rotate one wheel 90º

with respect to its previous position. Other

wheel should remain in its original

position

1. Dress wheel or replace wheel with one of

proper grit

2. Grind only on face of wheel

3. Clean around wheels and shaft and/or

replace bearings

1. Clean around wheels and shaft and/or

replace bearings

2. Replace plug

3. Replace cord

4. Replace switch

5. Contact your Palmgren distributor

TROUBLESHOOTING

9682090_oipm_En013_9643557.01 __ 02-08-2019 . . . . 02/08/19 3:05 PM Page 5

6

Palmgren Operating Manual & Parts List 9682090

1

2

44

4

43

28

23

17

48

16

15

46

18

14

13

26

7

12

11

10

9

8

6

5

4

2

1

24

16

27

447

3

39

40

33

34

32

38

35

22

20

21

19

10

9

8

7

30

12

11

25

15 13

16

48

17

24 26

14

37

36

33

20

41

42

4

6

31

16

28

Figure 5 – Repair arts Illustration for 9682090, 6” Bench Grinder

9682090_oipm_En013_9643557.01 __ 02-08-2019 . . . . 02/08/19 3:05 PM Page 6

7

Palmgren Operating Manual & Parts List 9682090

1 Philips Screw, Flat Washer, Spring Washer, M4×10 * 10

2 Wheel Guard Cover 9624464.01 2

3 ex Nut, M12, L Thread 9600064.01 1

4 Flange 9618904.00 4

5 Wire Wheel, 6” x 1/2" Bore 9636468.00 1

6 Philips ex Bolt, Spring Washer, M6×14 * 6

7 Wheel Guard 9624465.01 2

8 Spark Deflector (Set of 2) 9616841.01 1

9 Eyeshield Plate N/A 2

10 Eyeshield Kit (Includes 9, 10, 12) Set of 2 9632290.01 1

11 Upper Eyeshield Bracket (Set of 2) 9625177.01 1

12 Philips Screw, Spring Washer, M5×10 * 4

13 Flat Washer, M6 * 2

14 Spring Washer, M6 * 2

15 Eyeshield Knob 9625816.01 2

16 Flat Washer, M10 * 4

17 Spark Deflector Knob 9625817.01 2

18 Motor N/A 1

19 Clip Plate 9608099.01 1

20 Philips Screw, M5×8 * 4

21 Cord Clip * 1

22 Power Cord 9600067.01 1

23 Left Tool Rest 9625813.01 1

24 Locking Knob 9625812.01 2

25 Base N/A 1

26 Flat Washer, M8 * 2

27 Tool Rest Bracket, Left 9625810.01 1

28 Locking Knob 9625817.01 2

30 Tool Rest, Right 9625825.01 1

31 Tool Rest Bracket, Right 9625826.01 1

32 Philips Screw, Spring Washer, M6×20 * 2

33 Philips Screw, Spring Washer, Flat Washer, M4×8 * 2

34 Star Lock Washer, M4 * 1

35 Capacitor 9616908.01 1

36 Capacitor Support 9616655.01 1

37 ex Nut, M8 * 1

38 Base Plate 9623758.01 1

39 Rubber Foot 9623991.00 4

40 Philips Screw, Flat Washer, M4×12 * 4

41 Switch Plate 9636282.01 1

42 Switch 9608066.01 1

43 Grinding Wheel, 60 Grit, 1/2" Bore 9602033.00 1

44 ex Nut, M12 9600548.01 1

46 Dust Port Assembly 9608070.05 1

47 Wire Wheel Spacer 9643559.01 1

48 Spring Washer, M10 * 2

Ref. art

No. Description Number Qty.

Ref. art

No. Description Number Qty.

REPAIR PARTS LIST FOR 9682090, 6˝ BENCH GRINDER

(∆) Not shown.

(N/A) Not available as repair part.

(*) Standard hardware item, available locally.

9682090_oipm_En013_9643557.01 __ 02-08-2019 . . . . 02/08/19 3:05 PM Page 7

PALMGREN WARRANTY

C. . anson / Palmgren warrants their products to be free of defects in material or workmanship. This

warranty does not cover defects due directly or indirectly to misuse, abuse, normal wear and tear, failure to

properly maintain the product, heated, ground or otherwise altered, or used for a purpose other than that

for which it was intended.

The warranty does not cover expendable and/or wear part (i.e. v-belts, screws, abrasives, jaws), damage to

tools arising from alteration, abuse or use other than their intended purpose, packing and freight. The

duration of this warranty is expressly limited to the terms noted below beginning from the date of

delivery to the original user.

The Palmgren branded items carry the following warranties on parts:

All vises, clamps, positioning tables, tombstones, jack screws and vise accessories - LIFETIME.

All bench grinders, drill presses, tapping machines, band saws, lathes, milling machines, arbor presses,

abrasive finishing machines and work stands - 3 YEARS.

The obligation of C. . anson / Palmgren is limited solely to the repair or replacement, at our option, at its

factory or authorized repair agent of any part that should prove inoperable. Purchaser must lubricate and

maintain the product under normal operating conditions at all times. Prior to operation become familiar

with product and the included materials, i.e. warnings, cautions and manuals.

Failure to follow these instructions will void the warranty.

This warranty is the purchaser's exclusive remedy against C. . anson for any inoperable parts in its

product. Under no circumstances is C. . anson liable for any direct, indirect, incidental , special or

consequential damages including loss of profits in any way related to the use or inability to use our

products. This warranty gives you specific legal rights which may vary from state to state.

Palmgren - a C. . anson company

2000 N. Aurora Rd., Naperville, IL 60563 U.S.A.

or call: 1-800-827-3398

Palmgren Operating Manual & Parts List 9682090

180301

9682090_oipm_En013_9643557.01 __ 02-08-2019 . . . . 02/08/19 3:05 PM Page 8

Table of contents

Other CH Hanson Grinder manuals

Popular Grinder manuals by other brands

Dynabrade

Dynabrade 52224 Important operating, maintenance and safety instructions

Collomix

Collomix CMG 1700 operating manual

Makita

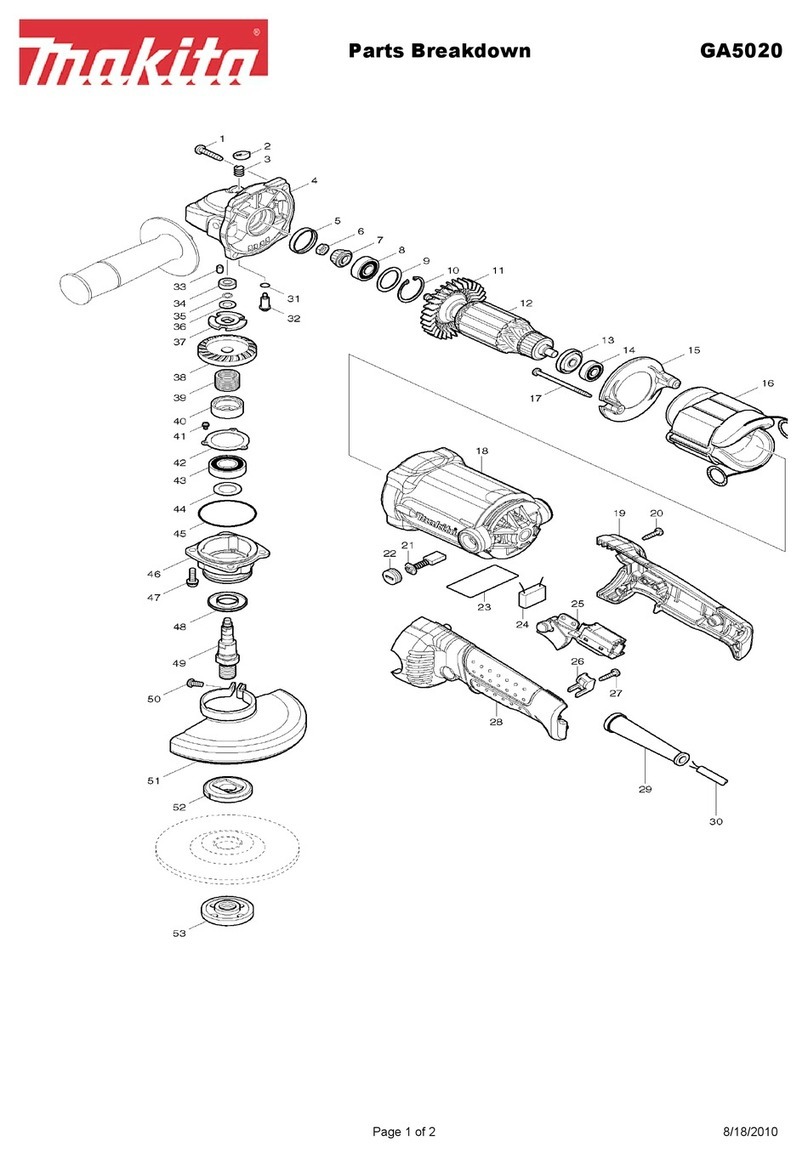

Makita GA5020 Parts Breakdown

Hitachi

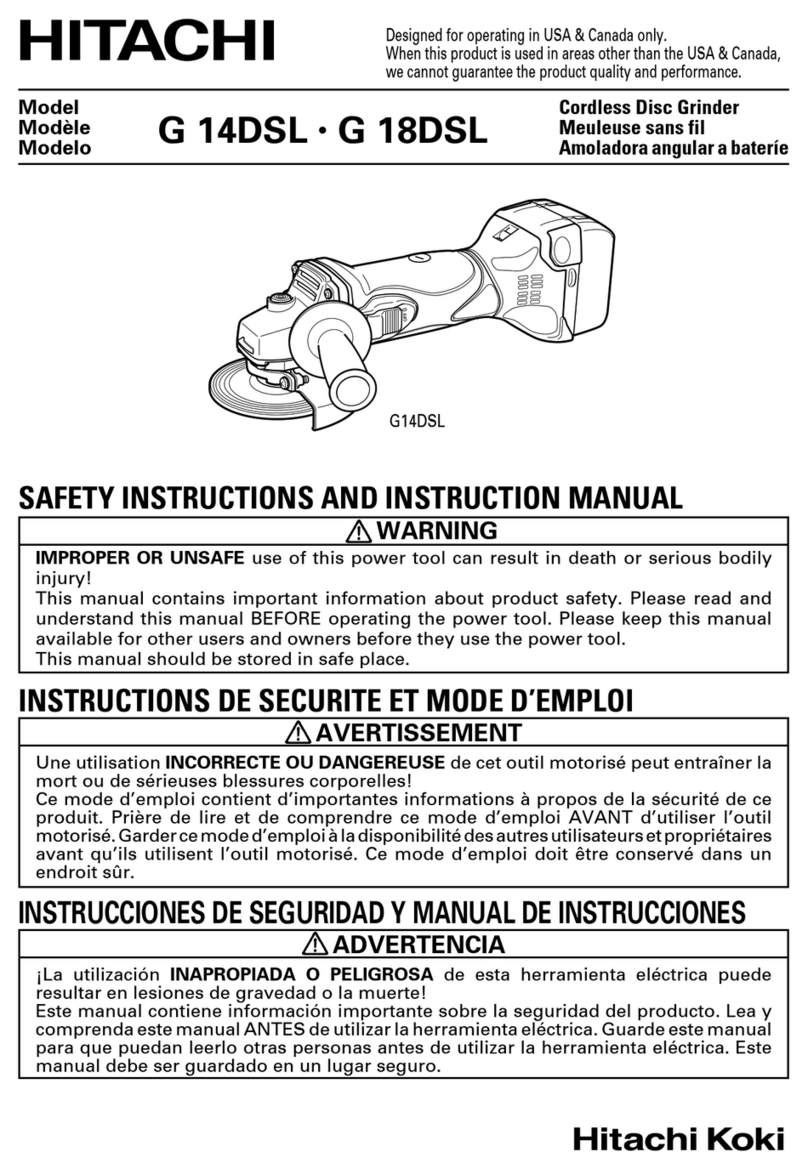

Hitachi G 18DSL Safety instructions and instruction manual

Westfalia

Westfalia 843612 Original instructions

Skil

Skil BI9502-00 owner's manual