6

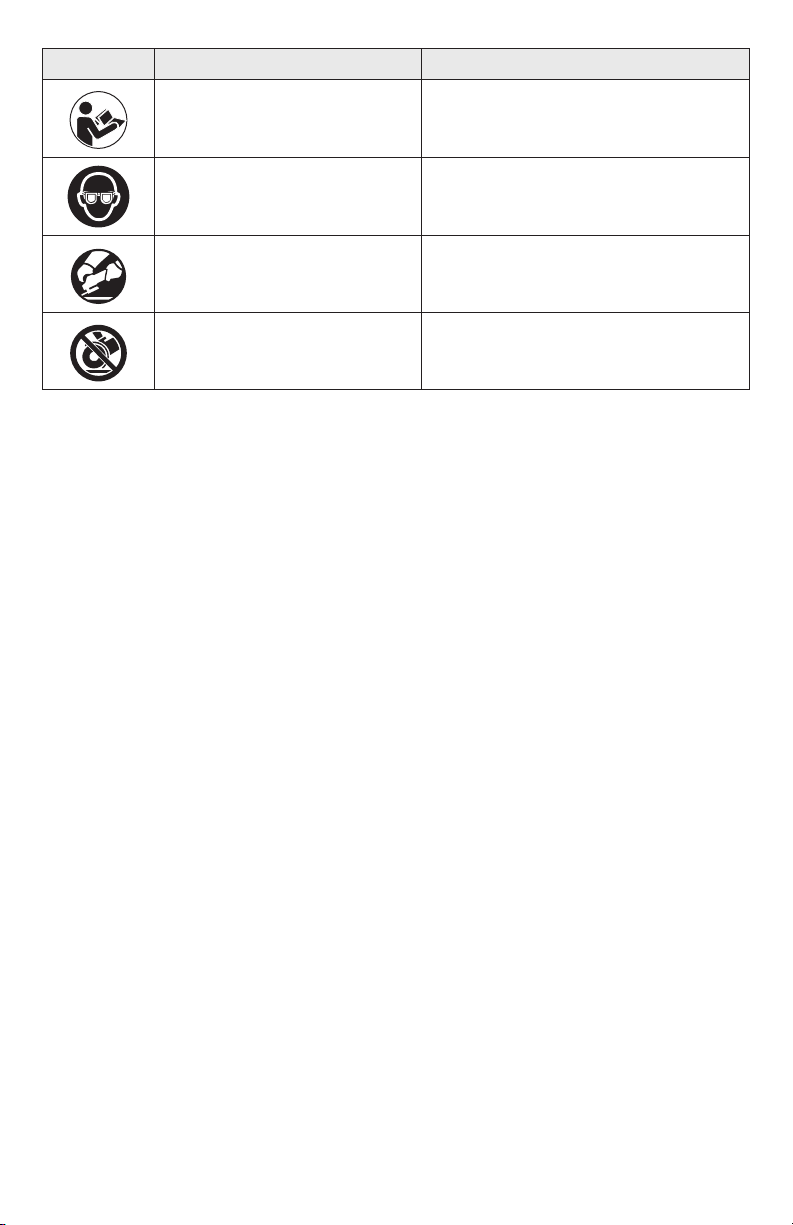

b. If you are not completely familiar with operating a grinder, consult your instructor,

supervisor, or other qualied individual.

c. Only use 8” (200 mm) diameter grinding wheels with a bore exactly equal to that of the

grinder arbor (shaft). Your tool is equipped with a 5/8” (16 mm) arbor. Never machine an

undersized wheel to t an arbor. Maximum thickness of the grinding wheel is 3/4'' (20 mm).

d. Examine grinding wheels for cracks or other damage before using grinder. Replace

cracked, damaged or vibrating wheels immediately.

e. Use only wheel anges furnished with grinder. Use of other anges may cause damage or

breakage to the grinding wheel and result in injury to the operator.

f. Never operate grinder near ammable fumes or liquids. Sparks from grinding wheel or

motor could ignite ammable material.

g. Do not overtighten wheel nuts.

h. Always use all guards and eye shields, making sure they are properly adjusted and

secured. Keep spark guards close to the wheel and readjust inward as the wheel wears.

Always use wheel guards and covers when using a bufng wheel or standard grinding

wheel.

i. Always use grinding wheels that are rated for safe use on this grinder. Never use a wheel

rated lower than 3450 RPM.

j. Always stop grinder before making any adjustments.

k. Do not move grinder until it comes to a full stop.

l. Do not force work against the grinding wheel. Excessive pressure may damage or break

the wheel, resulting in injury to operator or bystander.

m. When turning ON the power, stand to the side of the wheel and allow the grinder to come

up to speed and operate for one full minute before applying work to the wheel.

n. Never grind on the side of the wheel. Always grind on the face of the wheel only.

o. Dress the face of the wheel only. Dressing the side of the wheel may make it too thin for

safe use.

p. Never apply coolant directly to the grinding wheel. Coolant may deteriorate the bonding

strength of the wheel and cause it to fail.

q. Grinding creates HEAT. Never touch the workpiece until you are sure it has cooled

sufciently.

Note and follow the safety warnings and instructions that appear on the grinder.

Think safety: Safety is a combination of operator common sense and alertness at all times

when the grinder is being used. Do not allow familiarity (gained from frequent use of your

grinder) to become commonplace. Always remember that a careless fraction of a second is

sufcient to inict severe injury.

Connection to a Power Source

This machine must be grounded while in use to protect the operator from electric shock.

Plug power cord into a 110-120V properly grounded type outlet protected by a 15-amp dual

element time delay fuse or circuit breaker.

Not all outlets are properly grounded. If you are not sure that your outlet, as pictured, is

properly grounded; have it checked by a qualied electrician.

DANGER To avoid electric shock, do not touch the metal prongs on the plug when

installing or removing the plug to or from the outlet.

DANGER Failure to properly ground this power tool can cause electrocution or serious

shock, particularly when used near metal plumbing or other metal objects. If

shocked, your reaction could cause your hands to hit the tool.