3

110503

MAINTENANCE

WARNING:Before doing any maintenance be sure

power is off. At the time you remove a pad frame be sure

to unplug motor and pump. This is for your safety.

SPRING START-UP

•Clean pump. Cleaning the

pump is necessary once a

year at start-up. For your

safety, turn unit off and unplug

motorandpump. Removethe

pumpfrom the mountslot. Re-

movethe base of the pump as

shown in Fig. 12. Clean the

pump and turn the impeller to

ensure free operation. Re-

move the pump spout and check for any blockage. After

cleaning,reinstallthe base onto the pump. Reattach the pump

to the mount in the cooler using the plastic retainer to ensure

that the pump will not overturn. Do not forget to replace the

spoutand water delivery tube onto the pump outlet. The pump

has an automatic reset thermal protection.

INCREASE

DECREASE

FIG.10

DEPRESSHERE

TO REMOVE

FIG.12

FAUCET

WATER

SUPPLY VALVE

SILLCOCK

FERRULE

NUT

FIG.7

DECREASE

AMPERAGE

FIG.11

FLOAT

CORNER

POST BRACKET

FIG.8

WATER CONNECTION

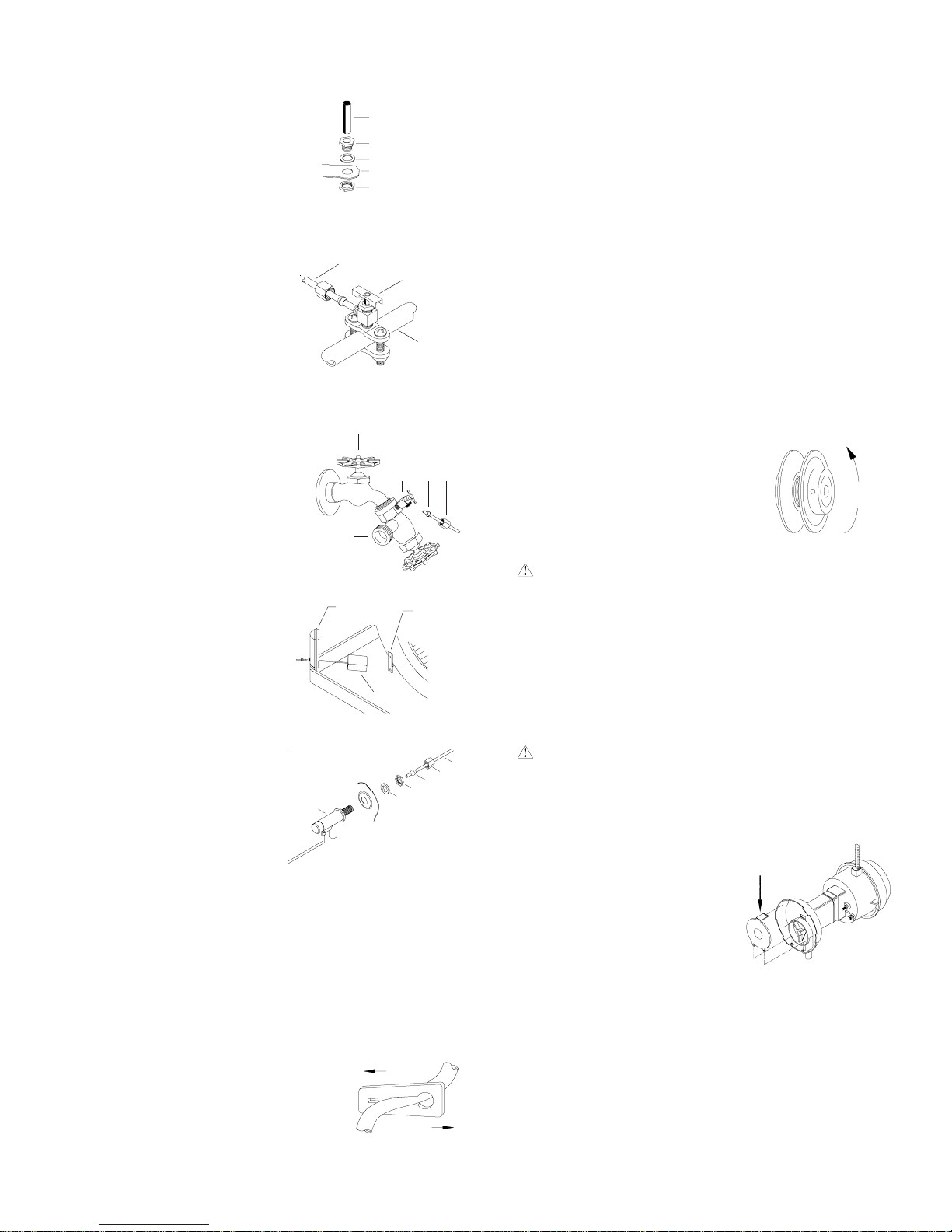

•Install overflow assembly. Re-

movenutandplace nipple through

the hole in the pan, with the rub-

ber washer between the pan and

the head of the drain nipple (Fig.

5). Screwon nut and draw uptight

againstbottomof pan. Insert over-

flow pipe in nipple to retain water.

Overflow pipe may be removed to

drain pan when necessary. Agar-

denhose may bescrewedon the

drain nipple to drain water away

from your unit.

•Connect water supply line.

Find the closest supply of water.

Use a saddle valve (Fig. 6) to

connect 1/4” tubing to the cold

water supply or use a Sillcock

andwatervalveconnectedto an

outsidefaucet (Fig. 7). Place the

nutandferruleonthetubing and

tighten the nut until water tight.

IMPORTANT: Donotconnectthe

water supply to any soft water

applications. Soft water will

cause corrosion and decrease

the life of the cooler.

•Install float and attach water

line to float. The float may be

installed in either the corner

post or bracket (see Fig. 8).

Refertofigure9for installation

instructions. Insertthefloat (1)

thruthe hole in the corner post

or bracket. Install the washer

(2) and nut (3). Tighten to

keep the float from turning.

Placethe nut (5)andferrule(4)

on the water supply line. Con-

nect to float fitting and tighten

until water tight.

•Fill pan. Allow water to fill to

within 1” of top of pan and ad-

justfloattomaintain this water

level. This can be accom-

plished by bending the float

rod.

•Level water troughs. Operate pump until pads are satu-

rated. Checkeach trough to see if water is evenly dispersed in

the trough. If they are not, loosen adjustment bolts and level

trough. Retighten bolts. Check to see that all pads are satu-

rated with water and that there are no dry spots or openings in

the pads.

•Adjust water amount. Your cooler is equipped with a unique

water metering valve (Fig. 10). The amount of water delivered

to the pads may be decreased by press-

ing the plastic valve as the arrows

indicate. If water is splashing out of wa-

ter troughs, you may need to decrease

the amount of water delivery. Check to

see that all pads are saturated with wa-

ter and that there are no dry spots or

openings in the pads.

AMPERAGE DRAWAND BELT TENSION

This unit is equipped with an adjustable motor drive sheave for

adjustingthe blower wheel speed to the proper loading on differ-

ent duct systems. It is important that the motor drive pulley is

adjusted to correct size to assure maximum air delivery without

damage to the motor. Be sure to follow these instructions care-

fully.

•Adjust drive pulley. After the unit is completely installed, ad-

justthedrive pulley totheleast diameter andadjustbelttension.

See the maintenance section for adjusting belt tension.

•Start cooler. Install all pad frames, start pump, and allow to

operate until pads are wet.

•Check amperage. With pads wet and unit started, check am-

perage draw with an amperage meter.

•Adjust pulley if necessary. If amperage draw is less than

motor rating, turn off electrical power and remove pad frame.

Unplug motor inside cooler, this will protect you from someone

turning on unit while you are working inside. This should be

done for your safety. Adjust pulley to a larger diameter and

readjustbelttension, plug motor in,in-

stall pad frame, and retest amperage

draw. Repeat this process until cor-

rect amperage draw is attained.

Increasing motor pulley diameter in-

creasesamperagedraw. Decreasing

motorpulley diameter decreases am-

perage draw (see Fig. 11).

CAUTION: Do not operate cooler with larger amper-

age draw than specified on motor plate.

NOTE: Noattemptshouldbemadetocompletelyinstallthisunit

without the aid of an electrician or someone familiar with testing

amperage draw. Failure to comply with these instructions may

void your warranty.

COLD

WATER

PIPE

SADDLE

VALVE

1/4” TUBING

FIG. 6

RUBBERWASHER

OVERFLOW PIPE

NIPPLE

BOTTOM PAN

NUT

FIG. 5

FIG.9

123

56

4