CHEE SIANG INDUSTRIAL M121 Series User manual

INSTRUCTION MANUAL

INSTRUCTION MANUAL

使用说明书

M121系列

为了安全地使用,请您在使用之前仔细阅读本使用说明书。

另外,请您注意保管本使用说明书,以便随时查阅。

Read safety Instructions carefully and understand them before using.

Retain this Instruction Manual for future reference.

No:M121A01

No:M121A01

GOLDEN WHEEL

- 1 -

M121

1

2

3

4

5

6

GOLDENWHEEL

CHEESIANGINDUSTRIALCO., LTD

24248

32

Tel886-2-22999518 Fax886-2-22999519

No.M121A01

1. Safety Precaution

Please read this manual carefully, also with related manual for the machine head before use.

For perfect operation and safety, installing and operating this product by trained personnel is required.

Turn off the power, unplug the cord and wait 10 minutes before any installing, mounting, or opening the control box cover.

This product is designed for use with specified sewing machines and must not be used for other purposes.

10%

※Attention

Only use Power Voltage indicated on the name plate of the M121 in 10 % ranges.

It becomes a cause of malfunction or failure.

20% 80%

3

M121 SERIES INSTRUCTION MANUAL

CONTENTS

1.Safety Precaution

2.Installationand Adjustment

3.Connector Diagram

4.Panel Key Function

5.General Parameter List

6.Error Code / Alarm Code

No.32, Wu Chuan 7th Road, Wu Ku Industrial Area,

Wu Ku Hsiang 24248, Taipei Hsien, Taiwan

Tel:886-2-22999518 Fax:886-2-22999519

※Appear and specification listed in this instruction

manual are subjected to change without notice.

GOLDEN WHEEL

- 2 -

Don’t operate in direct sun light, outdoors area and the room temperature is 40°C above or 5°C under.

Don’t operate near the heater, dew area and the humidity is 20 % less or 80% more.

Don’t operate in dusty, evaporate, combustible gas area, and stay away from corrosive material.

Avoid power cord being applied by heavy objects or excessive force, or over bend.

Power cord must keep 3 cm or above distance to the V-belt and the pulley.

In order to prevent the static interference and current leakage, all grounding works must be done properly.

Turning on the machine in the first time, use low speed to operate and check the correct rotation direction.

During machine operation, don’t touch any moving parts.

All moving parts must use the protective device to avoid the body contact and objects insertion.

Maintenance and repairs must be done by the specially trained personnel.

All spare parts for repair must be approved or supplied by the manufacturer.

Don’t use any objects or force to hit or ram the product.

Danger and caution signs:

Risks that may cause personal injury or risk to the machine are marked with

this symbol in the instruction manual.

This symbol indicates electrical risks and warnings.

GOLDEN WHEEL

- 3 -

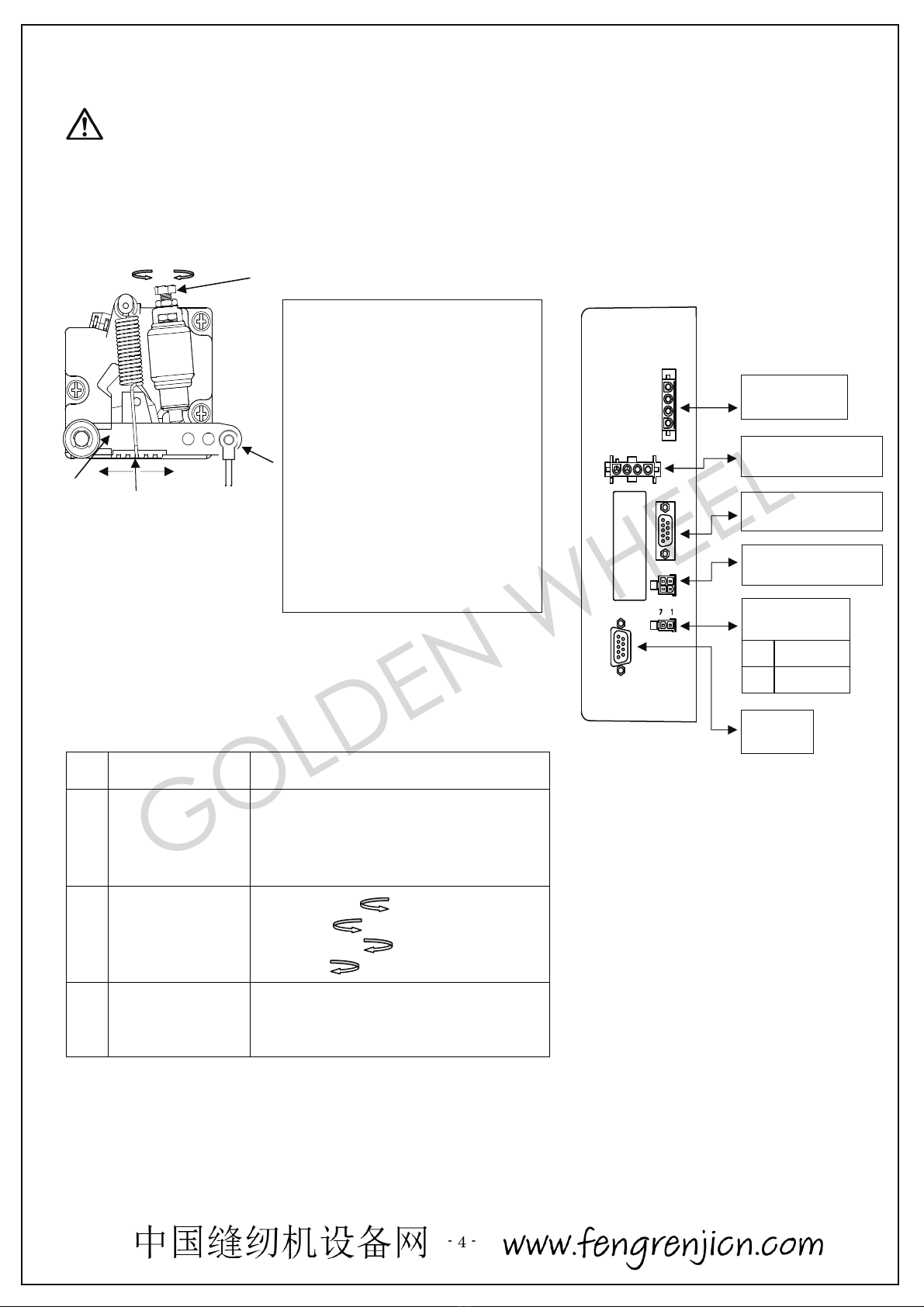

2.

2. Installation and Adjustment

.. M121

2.1. M121 Installation

a)M121

a). Install the M121 controller under

the table.

b)

b) Install the pedal to the speed

controlunit of M121 controller.

c)

M121

3

c). The cable of a pedal unit, a motor output,

and a motor encoder is surely

connected to

M121controller.

For details, refer to "3. Connector Diagram".

..

2.2. Install and Adjust The Synchronizer(sensor)

Attention:

When tightening the fixing screws,

release the foot from the pedal.

2

a) Synchronizer Installation:

Mounting the Synchronizer onto the flange of machine

pulley,and match the stopper with a stop groove of the

synchronizer.

With then tighten and secure 2 screws of the synchronizer.

2

b) Synchronizer Adjustment :

Adjust this position with the synchronizer installed onto

the sewing machine and while stopping at the UP

position.

Adjustment of UP Position

Loosen the two screws on the synchronizer joint, and set

thestop position by turning the synchronizer joint.

After adjustment, please fix it by tightening the screws.

sewing machine

motor

p

edal

M121

M121 controlle

r

p

edal

Sewing machine pulley

Flan

g

e

Synchronizer

joint

Synchronizer

Stop

groove

Stopper

(Backside of the sewing machine)

GOLDEN WHEEL

- 4 -

..

2.3. Speed Control Unit Adjustment

Term of ad

j

ustment

Ad

j

ustment result

Toeing forward

force adjustment

Spring A move to right = force increased

Spring A move to left = force decreased

Heeling backward

force adjustment

Bolt B turn= force decreased

Bolt B turn= force increased

Treadle stroke

adjustment

Rod D secure at right = stroke is longer

Rod D secure at left = stroke is shorter

Components of speed control unit :

see figure

A: Spring for toeing forwardforce

adjustment

B: Bolt for heeling backward force

adjustment

C: Treadle / Pedal arm

D: Pitman rod for Treadle / Pedal

B

D

CA

重

Caution :

For person safety, turn off the power switch and remove

the power plug from outlet before any adjustment.

decrease increase

3. Connector Dia

g

ram

MOTOR

AC

AC POWERSUPPLY

SYNCHRONIZER

ENCODER

LIGHT

1 0V

2 +12V

PEDAL

decrease increase

GOLDEN WHEEL

- 5 -

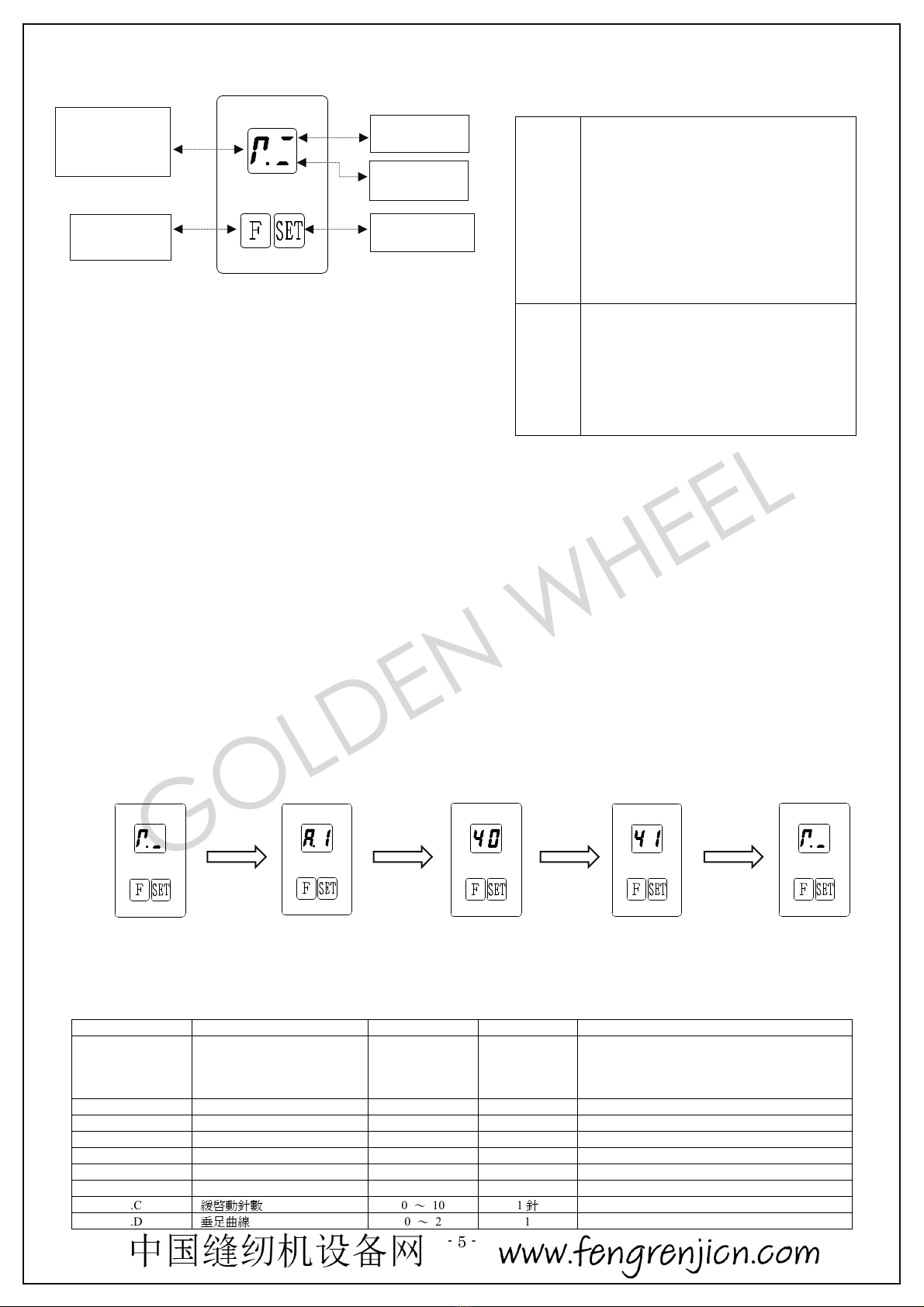

4. PanelKey Function

..

4.1. Parameter Setting Mode

①F

②F

③SET

F

④SET

In parameter setting mode, check and change of each preset value is possible by "Parameter code".

Operation at the parameter setting mode

(1) Press "F" key to enter parameter setting mode.

Display the "Parameter code".

(2) Press "F" key, select "Parameter code" you want to adjust.

(3) Press "SET" key will display selected parameter preset value.

Press "F" key to change the value.

(4) Press "SET" key again, parameter setting mode will be ended and it will return to thenormalmode.

e.g

5. General Parameter List

..

5.1. Parameter A

F

"F" Key

Change to the parameter

setting mode/

Increment "Parameter code"/

Increment parameter value/

Return to normal mode

SET

"SET"

Key

Select "Parameter code"/

Save parameter value/

Changing the needle position

A.1

2 [B.1] 100r/min

B.1

A.2

10

12

A.2 20 A0 10r/min 2

A.5 20 50 10r/min ()

A.6 15 30 10r/min ()

A.8 UP / DN - UP:DN:

A.A ON / OF -

A.B 2 30 100r/min 1

A.C 0 10 1

A.D 0 2 1

Motor rotation

direction icon

Needle

u

p

Needle down

F

Function key

SET

Needle down

Normalmode

「F 」

"F"key 「SET 」

"SET"key

「F 」

"F"key

「SET 」

"SET"key

Normalmode

N

ormalmode

『』

Parameter code

select

Paramete

r

Parameter

settingschange

The function of each key

GOLDEN WHEEL

- 6 -

..

5.2. Parameter B

1 10r/min

21015

10A11B12C13D14E15F

100A0

※1Depending on thesewing machinemodels, the unitof the displayis "10r/min".

2Thenumbersof10-15 is displayed in the alphabet as follows.

10 : A, 11 : B, 12 : C, 13 : D, 14 : E, 15 : F

For example,"100"is"A0".

Paramete

r

code Parameter function Range / Selection Unit Remarks

A.1

Maximum sewing speed

2 [B.1] 100r/min

The value of [B.1] is a maximum.

The value of [A.2] is a minimum.

(Digit of 10 of the low-speed setting is not

displayed)1,※2

A.2 Low speed 20 A0 10r/min 2

A.5 The needle up speed by the

backward pedaling 20 50 10r/min (Before thread trimming speed)

A.6 The needle up pre-speed by

the backward pedaling 15 30 10r/min (Thread trimming speed)

A.8 Needle position at

machine stop UP / DN - UP : Up position

DN : Down position

A.A Slow start function selection ON / OF -

A.B Slow start speed 2 30 100r/min 1

A.C Stitch numbers for slow start 0 10 1stitches

A.D Pedal curve 0 21

B.1 2 100r/min 1

B.2 0 / 1 - 0:CCW1:CW

B.3 ON / OF -

B.4 0 / 1 - 0:1:

B.5 0 F0 1 B.3= ON

2

B.6 20 30 10r/min B.3= ON

B.D TS / TK - TS:

TK:

Parameter

code Parameter function Range / Selection Unit Remarks

B.1 Upper limit of maximum

speed

2 Limit of the

machine 100r/min 1

B.2 Direction of motor rotation 0 / 1 - 0:CCW / 1:CW

B.3

Motor stops with a rotation

angle after the needle up by

the backward pedaling

ON / OF -

When it turns ON, machine rotates

automatically after the needle up by the

backward pedaling.

B.4 Direction of rotation of[B.3] 0 / 1 - 0:Reverse rotation / 1:Forward rotation

B.5 Angle of rotation of [B.3] 0 F0 1degree Valid only when [B.3] = ON2

B.6 Speed of rotation of [B.3] 20 30 10r/min Valid only when [B.3] = ON

B.D

Motor running mode at

trimming sequence TS / TK -

TS:Standard operation.

TK:Rotation is not carried outat up stop

position.

GOLDEN WHEEL

- 7 -

6. Error Code /Alarm Code

..

6.1.Error Code List (The error which forced stop of the operation)

When the control box detects an error, forced stop of the motor is carried out.

"Errorcode" is displayed on the panel display.

E01

1 2

E02 IC

1C

E03

E04

E05

AB

E06

E07

E12

E13

E16 uvw

E99

PF

OFF

GOLDEN WHEEL

- 8 -

Erro

r

code Error name Cause of the problem Status and Measurement

E01

Moto

r

over-current

Wiring on the motor short-circuited.

The load torque of the sewing machine istoo

large.

Wiring of the motor has disconnected one or two.

Please check wiring on the motor.

Please check the sewing machine.

E02

Motor control IC

over-current

Motor control IC detects Motor ove

r

-current.

Wiring on the motor short-circuited.

The load torque of the sewing machine istoo

large.

Please check wiring on the motor.

Please check the sewing machine.

E03 Rise of power

supply voltage

When Power ON, detected high voltage.

Connect the wrong voltage, too high.

Please check the AC power. (Too high)

Please check the main board.

E04 Drop of power

supply voltage

When Power ON, detected low voltage.

Connect the wrong voltage, too low.

Please check the AC power. (Too low)

Please check the main board.

E05

Abnormalities in

the encoder signal

The connector of the encoder is not inserted

completely.

The signal wire of the encoder is disconnected.

Please check the encode

r

or encode

r

connectors

and its connection.

Make surethat there is noabnormality in the

encodersignal.

E06

Motor

disconnection

Bad connection at the motor connector.

The connector of the motor is not inserted

completely.

Please check the motor or motor connectors and

its connection.

E07

Synchronize

r

(sensor) signal

error

Can not detect synchronizer signal.

Machine locked or object stuck in the motor

pulley.

Sewing material is too thick.

The connector of the synchronizer is not

Inserted completely.

Please check the synchronizer(sensor) or

synchronizer connectors and its connection.

Please check the synchronizer (sensor) and its

signal.

Please check the machine head to see if objects

stuck in the motor pulley, or rotate not smoothly.

E12

Initial magnetic

pole detection

error

When magnetic pole detection signals are

abnormalities at the time of the Power ON.

The connector of the encoder is not inserted

completely.

Wiring of an encoder is disconnected.

Please check the encode

r

or encoder connectors

and its connection.

Please check that there are no abnormalities in

the magnetic pole detection signal.

E13

pulley ratio

calculation error

Calculation of the pulley ratio is not completed

normally.

The upper position signal has abnormalities.

The upper position signal was disconnected.

Please check the upper position signal connection.

Please check that there are no abnormalities in

the upper position signal.

E16

UVW magnetic

pole detection

signal error

The magnetic pole detection signal has

abnormalities.

The magnetic pole detection signal was

disconnected.

Please check the encode

r

or encoder connectors

and its connection.

Please check that there are no abnormalities in

the magnetic pole detection signal.

E99

Memory erro

r

When the read-out values of memoryare

abnormalities at Power ON.

After Power OFF,Power ON again the error will

disappear, but all parameter setup values return to

the initial value.

When the abnormalities in a repetition occur, the

component replacement of a main board is

needed.

PF

Power OFF When Power ON OFF [ Switch OFF ].

When power supply voltage is too low.

Please check whether it is the value with right

AC power supply voltage.

Displaying, when Power OFF is not Abnormal.

When Power OFF at the time of parameter

change is required, it may display (not unusual).

GOLDEN WHEEL

- 9 -

..

6.2.Alarm Code list(Alarm:Release is possible.)

When the control box detects an alarm, "Alarmcode" is displayed on the panel display.

If you want to continue to operate, you need to pay attention to the cause of the alarm.

E50

E54

Alarm

code Alarmname Contents Status How to release alarm

E50 Pedal position

alarm

When the pedal unit is not neutral position

at Power ON.

Cannot operate

during the alarm.

Please return the pedal to neutral

position.

E54

Overload alarm The load of the sewing machine islarge to

the drive capability of themotor.

Please change into a high outputmotor.

Operation is

continuable under

the alarm.

Please stop operation.

If the detected motor currentfalls,

the alarm will be released

automatically.

:

memo:

GOLDEN WHEEL

启翔股份有限公司

CHEE SIANG INDUSTRIAL CO., LTD.

No.32, Wu Chuan 7th Road, Wu Ku, Wu Ku District 24890,

New Taipei City, Taiwan.

GOLDEN WHEEL

This manual suits for next models

1

Other CHEE SIANG INDUSTRIAL Sewing Machine manuals