CHEE SIANG INDUSTRIAL GOLDEN WHEEL CS-2390 User manual

NO:CS-2390N01

金輪牌工業用縫紉機

GOLDEN WHEEL INDUSTRIAL SEWING MACHINE

CS

CSCS

CS-

--

-2390

23902390

2390/CS

/CS/CS

/CS-

--

-2391

23912391

2391

INSTRUCTION MANUAL

INSTRUCTION MANUALINSTRUCTION MANUAL

INSTRUCTION MANUAL

操作手冊

操作手冊操作手冊

操作手冊

Read safety instructions carefully before operating

Keep this Instruction Manual for future reference

為了安全地使用,請你再使用之前一定閱讀本使用說明書

請你注意保管本使用說明書,以便隨時查閱

啟 翔 股 份 有 限 公 司

CHEE SIANG INDUSTRIAL CO., LTD.

CHEE SIANG INDUSTRIAL CO., LTD.CHEE SIANG INDUSTRIAL CO., LTD.

CHEE SIANG INDUSTRIAL CO., LTD.

GOLDEN WHEEL

1

目錄索引

目錄索引目錄索引

目錄索引 CONTENTS

CONTENTS CONTENTS

CONTENTS PAGE

PAGEPAGE

PAGE

ㄧ

ㄧㄧ

ㄧ.

..

.機器使用

機器使用機器使用

機器使用 HOW TO USE MACHINE

HOW TO USE MACHINE HOW TO USE MACHINE

HOW TO USE MACHINE -----------------------------------------

2

1.部件名稱 NAMES OF MAIN PARTS ---------------------------------------

2

2.線掛 THREAD GUIDE --------------------------------------------------

3

3.轉速 SPEED ---------------------------------------------------------

3

4.給旋梭加油 OILING --------------------------------------------------

3

5.機針和面線 NEEDLE --------------------------------------------------

3

6.注油 OILING --------------------------------------------------------

4

7.調整人字寬度和送料量 ADJUSTMENT OF ZIGZAG WIDTH AND FEEDING VOLUME -

4

8.如何穿線 HOW TO THREAD THE MACHINE ---------------------------------

5

9.如何繞線 HOW TO WIND BOBBIN ----------------------------------------

6

10.將梭心裝進梭殼 INSERTING THE BOBBIN THE BOBBIN CASE --------------- 6

11.調節面線鬆緊 REGULATING THE THREAD TENSION ------------------------

7

12.倒縫 REVERSE STITCH -----------------------------------------------

7

13.調節押腳壓力大小 REGULATING PRESSURE ON MATERIAL ------------------

7

14.縫前準備 PREPARATION FOR SEWING -----------------------------------

7

15.縫後取料 TO REMOVE FABRIC AFTER SEWING ---------------------------- 7

二

二二

二.

..

.機器調節

機器調節機器調節

機器調節 ADJUSTMENT

ADJUSTMENT ADJUSTMENT

ADJUSTMENT MACHINE

MACHINEMACHINE

MACHINE -----------------------------------------

8

1.直縫調節 ADJUSTMENT FOR STRAIGHT SEWING ----------------------------

8

2.機針落點居中調節 ADJUSTMENT FOR CENTERING THE NEEDLE ---------------

8

3.人字調節 ADJUSTMENT OF ZIGZAG MOVEMENT -----------------------------

9

4.上送料機構調節 ADJUSTMENT OF UPPER FEED MECHANISM ------------------

9

5.運行至最低點時的機針差動調節

ADJUSTMENT OF NEEDLE TIMING AT ITS LOWEST POSITION ---------------

10

6.機針和旋梭差動調節(使用 DP*17 號機針)

A

DJUSTMENT OF TIMING BETWEEN NEEDLE AND HOOK (Needle being used is type

DP*17) ------------------------------------------------------------

10

三

三三

三.

..

.故障排除

故障排除故障排除

故障排除 TROUBLE SHOOT

TROUBLE SHOOT TROUBLE SHOOT

TROUBLE SHOOT ----------------------------------------------

11

斷線 Thread Breakage ------------------------------------------------

11

物料被損 Cloth Breakage ---------------------------------------------

11

跳針 Skipping of Stitch ---------------------------------------------

11

斷線(直縫時) Thread Breakage (On Straight Sewing) -------------------

11

斷針 Needle Breakage ------------------------------------------------

11

GOLDEN WHEEL

2

ㄧ

ㄧㄧ

ㄧ.

..

.機器使用

機器使用機器使用

機器使用 HOW TO USE MACHINE

HOW TO USE MACHINE HOW TO USE MACHINE

HOW TO USE MACHINE

1.

1.1.

1.部件名稱

部件名稱部件名稱

部件名稱 NAMES OF MAIN PARTS

NAMES OF MAIN PARTS NAMES OF MAIN PARTS

NAMES OF MAIN PARTS

1.手輪 Hand wheel

2.線掛 Thread guide

3.縫目調節鈕 Feed regulating dial

4.倒縫桿 Feed reverse lever

5.人字寬度調節鈕 Zigzag width indicator

6.人字寬度調節控制器 Stoppers for zigzag width indicator

7.線掛和過線孔 Thread guide with three holes

8.針棒調節螺絲 Presser bar regulator screw

9.撥線桿 Thread take-up lever

10a.上線掛 Upper arm thread guide

10b.下線掛 Lower arm thread guide

11.面線張力調節鈕 Upper thread tension regulator

12.調節座線掛 Tension post thread guide

13.針棒和針棒線掛 Needle bar and needle bar thread guide

14.押腳 Presser foot

15.針板 Throat plate

16.送料齒 Feed dog

GOLDEN WHEEL

3

2.

2.2.

2.線掛

線掛線掛

線掛 THREAD GUIDE

THREAD GUIDE THREAD GUIDE

THREAD GUIDE

為了便於包裝,線掛已被取下,包裝好後放在了附件箱裡。請根據圖 Fig.1-2 所示安裝線掛。

For the convenient sake of packing, the thread guide is removed from the machine and packed

separate in the accessory box. Put the thread guide as shown in Fig.1-2.

3.轉速

轉速轉速

轉速 SPEED

SPEEDSPEED

SPEED

機器預設速度為 2800 r.p.m.最大人字寬度 9mm。此速度需取決於電流和所使用的馬達皮帶

輪的直徑。

The machine is set to run at the speed of 2800 r.p.m. at the maximum zigzag width of 9mm.

However, this speed depends on the electric current and also the diameter of the motor pulley

being used.

為延長機器壽命,新機器剛投入使用的一段時間裡最高轉速不要超過 2300 r.p.m.。

In order to assure the durability of the machine, it is recommended that the machine will be used

at the maximum speed of 2300 r.p.m. at the beginning of use.

4.

4.4.

4.給旋梭加油

給旋梭加油給旋梭加油

給旋梭加油

OILING

OILINGOILING

OILING

請每天往旋梭裡滴幾滴油。(Fig.2)

Please supply a few drops of oil to the groove of the

rotating hook every day. (As arrow-marked in Fig.2)

5.

5.5.

5.機針和面線

機針和面線機針和面線

機針和面線 NEEDLE

NEEDLE NEEDLE

NEEDLE

機針型號應根據面線粗細及縫製物料的性質進行選擇。機針凹槽應面向操作者。(Fig.3)

The size of the needle to be used should be determined by the size of the thread as well as the

materials to be sewn. The needle should be set with its groove facing toward you, as shown in the

(Fig.3.)

機針和面線對照表

needle and Thread Chart

面線型號 Thread size 機針型號 Needle size

#120-#100 #9

#100-#80 #11

#80-#60 #14

#60-#40 #16

#40-#20 #19

#20-#16 #21

GOLDEN WHEEL

4

6.

6.6.

6.注油

注油注油

注油 OILING

OILING OILING

OILING

每天給機器加油十分重要。

It is most important the machine is properly oiled every day.

給每個加油處滴ㄧ兩滴油(Fig.4)。

One or two drops of oil would be supplied to all the spots indicated in the (Fig.4.)

7.

7.7.

7.調整人字寬度和送料量

調整人字寬度和送料量調整人字寬度和送料量

調整人字寬度和送料量 ADJUSTMENT OF ZIGZAG WIDTH AND FEEDING VOLUME

ADJUSTMENT OF ZIGZAG WIDTH AND FEEDING VOLUMEADJUSTMENT OF ZIGZAG WIDTH AND FEEDING VOLUME

ADJUSTMENT OF ZIGZAG WIDTH AND FEEDING VOLUME

1)通常由人字刻度盤來調節人字寬度。當需要縫

製直線時,將刻度盤調為”0”,數字越大,人

字寬度越大,直至 10mm。

Adjustment of zigzag width can be made by zigzag

regulator dial. When straight sewing is required,

please place the dial to “0” and gradually raising

numbers, zigzag width will be widened up to the

maximum width of 10mm.

2)送料量可通過送料調節鈕來調節。當刻度調

為”0”時,停止送料。數字越大,送料量越大,

直到 5mm。

Feeding volume can be adjusted by feed regulation

dial and when it is placed to “0”, feeding is

stopped. By raising the numbers upward, the

required volume is obtained and the maximum

feeding volume is 5mm.

GOLDEN WHEEL

5

8.如何穿線

如何穿線如何穿線

如何穿線 HOW TO THREAD THE MACHINE

HOW TO THREAD THE MACHINEHOW TO THREAD THE MACHINE

HOW TO THREAD THE MACHINE

從線掛(1)開始穿起,按序穿過下列過到

Starting from the thread guide (1), please lead the thread as per the following manner.

(2)三孔過線器 There hole thread eyelet.

(3)面線張力調節鈕 Tension disc.

(4)鬆緊彈簧 Tension spring.

(5)調節座線掛 Tension post thread guide.

(6)上線掛 Upper arm thread guide.

(7)撥線桿 Take up lever.

(8)調節座線掛 Tension post thread guide.

(9)下線掛 Lower arm thread guide.

(10)針棒線掛 Needle bar thread guide.

(11)機針 Needle.

GOLDEN WHEEL

6

9.

9.9.

9.如何繞線

如何繞線如何繞線

如何繞線

HOW TO WIND BOBBIN

HOW TO WIND BOBBINHOW TO WIND BOBBIN

HOW TO WIND BOBBIN

如果繞在梭心上的底線不均勻,就會影響縫製效果。請根據下列步驟認真繞線。

If the bobbin thread does not wind evenly on the bobbin, this will affect the stitch and please be

careful to wind the thread to bobbin as per the following:

1)將梭心套上繞線軸。

Push the bobbin on the bobbin winder spindle

as far as it will go.

2)將線頭從梭心下面繞上,順時針方向繞幾

圈到梭心上。

Bring the thread forward towed the bobbin

and wind from below in clockwise direction

several times around the bobbin.

3)按下繞線桿,直到梭心輪抵到皮帶上,啟

動機器。

Push the bobbin winder lever downward until the wheel contacts the drive belt, and then start the

machine.

4)通過調節螺絲可增加或減少繞線量。

Adjustment screw can be turned in or out increase or decrease the amount of thread to be wound

on the bobbin.

如果繞線不均勻,向左(或右)調節線緊調節板,直至調到理想狀態。

If the thread does not wind evenly on the bobbin, adjust the tension thread guard by moving to

right or left as may be required.

10.

10.10.

10.將梭心裝進梭殼

將梭心裝進梭殼將梭心裝進梭殼

將梭心裝進梭殼

INSERTING THE BOBBIN IN TH

INSERTING THE BOBBIN IN THINSERTING THE BOBBIN IN TH

INSERTING THE BOBBIN IN THE BOBBIN CASE

E BOBBIN CASEE BOBBIN CASE

E BOBBIN CASE

將梭子(1)放入梭殼(2)內。再將縫線穿過梭殼溝

槽(3),並繞過彈簧夾線片(4)的型槽。

注意

注意注意

注意:梭子安裝好後,拉動底線時,梭子轉動方向

須如圖示之箭頭方向。

Put the bobbin (1) into the bobbin case (2). Pass the

thread through the threading groove (3) and the

notch (4) of tension spring in the bobbin case.

CAUTION: Fit the bobbin in the bobbin case so that

the bobbin turns in the direction of the

arrow when the bobbin thread is pulled.

GOLDEN WHEEL

7

11.

11.11.

11.調節面線鬆緊

調節面線鬆緊調節面線鬆緊

調節面線鬆緊

REGULATING THE THREAD TENSION

REGULATING THE THREAD TENSIONREGULATING THE THREAD TENSION

REGULATING THE THREAD TENSION

面線和底線的鬆緊應調節ㄧ致,以便縫製的時候將兩根線鎖在面料中間。

For ordinary stitching, the tension of the upper and lower thread should be equal so as to lock both

threads in the center of the fabric.

底線的鬆緊雖可通過鬆緊螺絲來進行調節,但最好讓期保持較鬆的狀態。面通過增減面線

的鬆緊直至達到滿意的縫製效果。

The tension of the bobbin thread is regulated by the tension screw, but it is preferable to keep it

rather weak. Once it is regulated, the perfect stitch can be obtained by adjusting the tension of

upper thread by increasing the tension.

12.

12.12.

12.倒縫

倒縫倒縫

倒縫

REVERSE STITCH

REVERSE STITCHREVERSE STITCH

REVERSE STITCH

若需倒縫時,縫製時按下倒縫桿直至作業完成即可。鬆開倒縫桿,即會自動恢復至正常縫

製狀態(正常順縫時,倒縫桿會自動停留在上側停靠點)。

For reversing the feed of the machine, keep the feed reverse lever #4 (In Fig.1) depressed as long

as required and if release the lever, ordinary forward stitch will be done. (For all other forward

stitching the lever remains in up position.)

13.

13.13.

13.調節押腳壓力

調節押腳壓力調節押腳壓力

調節押腳壓力 REGULATING PRESSURE ON MATERIAL

REGULATING PRESSURE ON MATERIALREGULATING PRESSURE ON MATERIAL

REGULATING PRESSURE ON MATERIAL

通常應保持盡可能鬆的押腳壓力,以保證流暢送料。可通過

調節螺絲(A)向右旋轉增加押腳壓力,向左旋轉減少壓力。

Always use the lightest pressure possible to allow the smooth

feed of material. It can be adjusted by turning the regulating

screw (A). To increase the pressure, turn the screw to the right

and to decrease it to the left.

14.

14.14.

14.縫前準備

縫前準備縫前準備

縫前準備 PREPARATION FOR SEWING

PREPARATION FOR SEWING PREPARATION FOR SEWING

PREPARATION FOR SEWING

1)用右手轉動手輪,至機針上下運行ㄧ次後回復至最高處,從而將底線帶出。

Turn the balance wheel toward you with the right hand until the needle moves down and up again

to its highest point thus catching the lower (bobbin) thread.

2)拉動面線、底線的線頭,從押腳下面向後拉出。

Now pull the end of the upper thread you are holding and the bobbin thread will be brought up

with it through the needle hole in the throat plate and place both ends of the thread back under the

presser foot.

3)將物料送至押腳下,放下押腳,開始縫紉。

Place the fabric to be sewn beneath the presser foot, lower the foot upon it and then start sewing

the machine.

15.

15.15.

15.縫後取料

縫後取料縫後取料

縫後取料

TO REMOVE FABRIC AFTER SEWING

TO REMOVE FABRIC AFTER SEWINGTO REMOVE FABRIC AFTER SEWING

TO REMOVE FABRIC AFTER SEWING

將針棒運行至最高處,抬起押腳,將物料向後拉出後從左手側取出,剪斷多餘線頭。

Raise the needle bar to its highest point, lift the presser foot and draw the fabric back to the left.

Cut the ends of the thread a few inches long from the needle.

GOLDEN WHEEL

8

二

二二

二.

..

.機器調節

機器調節機器調節

機器調節 ADJUSTMENT

ADJUSTMENT ADJUSTMENT

ADJUSTMENT

1.

1.1.

1.直線調節

直線調節直線調節

直線調節 ADJUSTMENT FOR STRAIGHT SEWING

ADJUSTMENT FOR STRAIGHT SEWINGADJUSTMENT FOR STRAIGHT SEWING

ADJUSTMENT FOR STRAIGHT SEWING

機器出廠時人字調節鈕都是設置在”0”位

置。

At the time of dispatch from the factory, the

machine is so adjusted that the zigzag regulator

is fixed at “0”.

如果不是,重設調節鈕至”0”刻度,然後運

行機器即可縫製出直線效果。若沒有縫出直

線效果,請鬆開調節螺絲(A),然後輕微調節

人字縫調節鈕(B),直到獲得直線縫的效果。

調節好後,將螺絲(A)(B)擰緊並設置在”0”

刻度位置。(Fig.9)

If not, please reset the indicator dial at “0” and run machine to assure that accurate straight stitches

be obtained. Should you fail to obtain accurate straight stitches by the above, please loosen

regulator screw (A), then adjustment is made correctly, set the screws (A) and (B) tight with

indicator points “0”.(Fig.9)

2.

2.2.

2.機針落點居中調節

機針落點居中調節機針落點居中調節

機針落點居中調節

ADJUSTMENT F

ADJUSTMENT FADJUSTMENT F

ADJUSTMENT FOR CENTERING THE NEEDLE

OR CENTERING THE NEEDLEOR CENTERING THE NEEDLE

OR CENTERING THE NEEDLE

將人字調節鈕設置為直線縫模式,轉動手輪使機針運行至最低處。觀察機針是否正好落在針

板上的針孔中間位置。同時觀察旋梭尖是否扣合機針垂直的中部。若不是,鬆開螺絲(C),調

整針棒座連桿上的調節鈕(D)即可。(Fig.10)

Set the zigzag regulating dial for straight stitch sewing and turn hand wheel towards you until the

needle reaches its lowest point of its downward stroke. See that needle enters the needle slot in the

throat (needle) plate at the very center. And also see that the hook point meets the vertical center of

needle, at this position. If it does not, adjust the needle bar frame pitman eccentric stud (D) (Fig.10)

by loosening the set screw (C).

GOLDEN WHEEL

9

3.

3.3.

3.人字調節

人字調節人字調節

人字調節

ADJUSTMENT OF ZIGZAG MOVEMENT

ADJUSTMENT OF ZIGZAG MOVEMENT ADJUSTMENT OF ZIGZAG MOVEMENT

ADJUSTMENT OF ZIGZAG MOVEMENT

如果人字凸輪運行錯誤,可將機針運行至最低點,然後擰緊凸

輪上的調節螺絲(E)至最高點。(Fig.11)

In case the zigzag drive cam is found wrongly situated, make the

needle to reach its lowest point and tighten the set screw “E” of the

cam to come to the top, as shown in the (Fig.11).

4.

4.4.

4.上送料機構調節

上送料機構調節上送料機構調節

上送料機構調節 ADJUSTMENT

ADJUSTMENT ADJUSTMENT

ADJUSTMENT OF UPPER FEED MECHANISM

OF UPPER FEED MECHANISM OF UPPER FEED MECHANISM

OF UPPER FEED MECHANISM

A 欲增加外押腳的抬高幅度:

To increase the lifting volume of outer foot.

1)鬆開調節螺絲(A)。

Loosen the adjusting belt (A).

2)提高搖桿曲柄至適合位置。

Raise the position of rock shaft crank as you

desire.

3)調整好後將螺絲擰緊。

Set the bolt tightly, after adjustment.

B 欲進ㄧ步增加外押腳的抬高幅度:

To obtain more lifting volume of outer foot.

1)鬆開調節螺絲(B)。

Loosen the adjusting belt (B).

2)提高提升曲柄連接桿至合適位置。

Raise the position of lifting crank connecting

line as you desire.

3)調整好後將螺絲擰緊。

Reset the belt tightly, after adjustment.

C 欲增加外押腳的送料量:

To increase the feeding volume of order foot.

1)鬆開調節螺絲(C)。

Loosen the adjusting belt.

2)提高送料連接桿至合適位置。

Raise the position of feed connecting line as

you desires.

3)調整好後將螺絲擰緊。

Reset the belt, after adjustment.

GOLDEN WHEEL

10

5.

5.5.

5.運行至最低點時的機針差動調節

運行至最低點時的機針差動調節運行至最低點時的機針差動調節

運行至最低點時的機針差動調節

ADJUSTMENT OF NEEDLE TIMING AT ITS LOW

ADJUSTMENT OF NEEDLE TIMING AT ITS LOWADJUSTMENT OF NEEDLE TIMING AT ITS LOW

ADJUSTMENT OF NEEDLE TIMING AT ITS LOWEST POSITION

EST POSITIONEST POSITION

EST POSITION

移開面蓋,鬆開針棒座上的螺絲。慢速轉動手

輪直到針棒(F)和針棒搖桿曲桿上的螺絲平

行。此點即為機針最低落點。(Fig.13)

Remove face plate and loosen the screw of

needle bar bracket. Turn the hand wheel slowly

towards you until the needle bar is aligned with

the screw of needle bar crank rod. This is

considered the lowest position of needle.(Fig.13)

6.

6.6.

6.機針和旋梭差動調節

機針和旋梭差動調節機針和旋梭差動調節

機針和旋梭差動調節(

((

(使用

使用使用

使用 DP*17

DP*17DP*17

DP*17 號機針

號機針號機針

號機針)

))

)

ADJUSTMENT OF TIMING BETWEEN NEEDLE AND HOOK (Needle being used is

ADJUSTMENT OF TIMING BETWEEN NEEDLE AND HOOK (Needle being used is ADJUSTMENT OF TIMING BETWEEN NEEDLE AND HOOK (Needle being used is

ADJUSTMENT OF TIMING BETWEEN NEEDLE AND HOOK (Needle being used is type DP*17)

type DP*17)type DP*17)

type DP*17)

1.將人字調節鈕調至最大人字寬度 9mm,並使機針

上下運行ㄧ個來回。

Turn the zigzag dial right to the largest width of

9mm and have the needle reach at its rightist and

lowest point.

2.調整旋梭使得旋梭尾部位於機針(L)右側

0.5mm。(Fig.14)

Then set the hook so that the end of hook gib

comes 05mm right of needle (L). (Fig.14)

3.轉動手輪,使旋梭運行至最左,最低點,使得

旋梭尖位於機針穿線孔上側 1mm 。(Fig.15)

Turn the hand wheel to the leftist and lowest

position. See that the hook point travels 1mm

above the thread hole of the needle. (Fig.15)

4.縫制不同物料時,差動太大可能造成一定的遲

延。

When sewing the different materials, it is

recommended that the timing explained above is a

little delayed.

GOLDEN WHEEL

11

三

三三

三.

..

.故障排除

故障排除故障排除

故障排除 TROUBLE SHOOT

TROUBLE SHOOT TROUBLE SHOOT

TROUBLE SHOOT

發生下列故障,請參照說明的方法予於排除。(*重要,**十分重要)

If following problems be occurred, please check the points as suggested below. (*marked be

checked carefully, **marked be most carefully checked)

斷線 Thread breakage

**

檢查旋梭尖是否斷裂或損壞? (仔細檢查旋梭尖部)

Any damage on the hook? (Please carefully check on the hook point)

機針和旋梭尖的差動調節是否正確? Is timing between needle and hook correct?

* 旋梭尖是否磨損殆盡? Isn’t hook point worn out?

* 面線質量是否合格? Is quality of thread good?

線掛是否有刮痕、毛刺? Any scratch on thread guides?

**

旋梭座是否有損壞或擦痕? Any damage or scratch on hook retainer?

機針是否正確? Is needle all right?

* 針板及其落針孔附近是否有損壞?Any damage on needle, particularly around needle hole?

* 彈簧安裝是否正確?彈性是否太硬? Is check spring correct, not too hard?

梭殼裡是否有異物? No lint’s in bobbin case?

物料被損 Cloth breakage

* 是否因機器陳舊,導致運行部件帶動其它零件一起活動?

Isn’t the machine too old to cause excessive play on all moving parts?

* 機針是否落在針板上的落針孔中央?

Does needle penetrate center of needle hole on needle plate?

* 使用的機針是否已彎? No bent needle used?

* 人字叉是否過度? No too much play on zigzag drive fork?

* 面線鬆緊是否合適? Is thread tension correct?

跳針 Skipping of stitch

* 機針與旋梭尖的時間差動是否正確?

Is the timing of needle to hook correct? Not too early, not too late?

使用的機針是否已彎? No bent needle used?

旋梭尖是否磨損殆盡? No won out on hook point?

* 針棒是否運行過度? No excessive play on needle bar?

* 機針和旋梭尖距離是否太大? No excessive clearance between needle and hook point?

* 針板上的落針孔對於在用的機針來說是否太大?

Isn’t needle hole of needle plate too large to the size of needle used?

斷線(直線時) Thread Breakage (On straight sewing )

* 機針和旋梭尖距離是否太大? No excessive clearance between needle and hook point?

* 旋梭尖的動作時間是否正確? 是否太早? Is hook timing correct? Not too early?

* 檢查彈簧是否太硬? Isn’t check spring too hard?

* 彈簧是否收放自如? Does check spring moves freely?

斷針 Needle Breakage

* 機針是否撞擊針板? Doesn’t needle hit needle plate?

* 機針和旋梭尖距離是否正確? Is the clearance between needle and hook point correct?

**

針棒是否運行過度? No excessive play on needle bar frame?

**

旋梭推力軸套是否運動過度? No excessive play on hook shaft thrust collar?

GOLDEN WHEEL

This manual suits for next models

1

Table of contents

Other CHEE SIANG INDUSTRIAL Sewing Machine manuals

Popular Sewing Machine manuals by other brands

Merrow

Merrow 60AD Instructions for setting up and operating

TZS First AUSTRIA

TZS First AUSTRIA FA-5700-2 instruction manual

Baby Lock

Baby Lock A-LINE Grace BL40 Instruction and reference guide

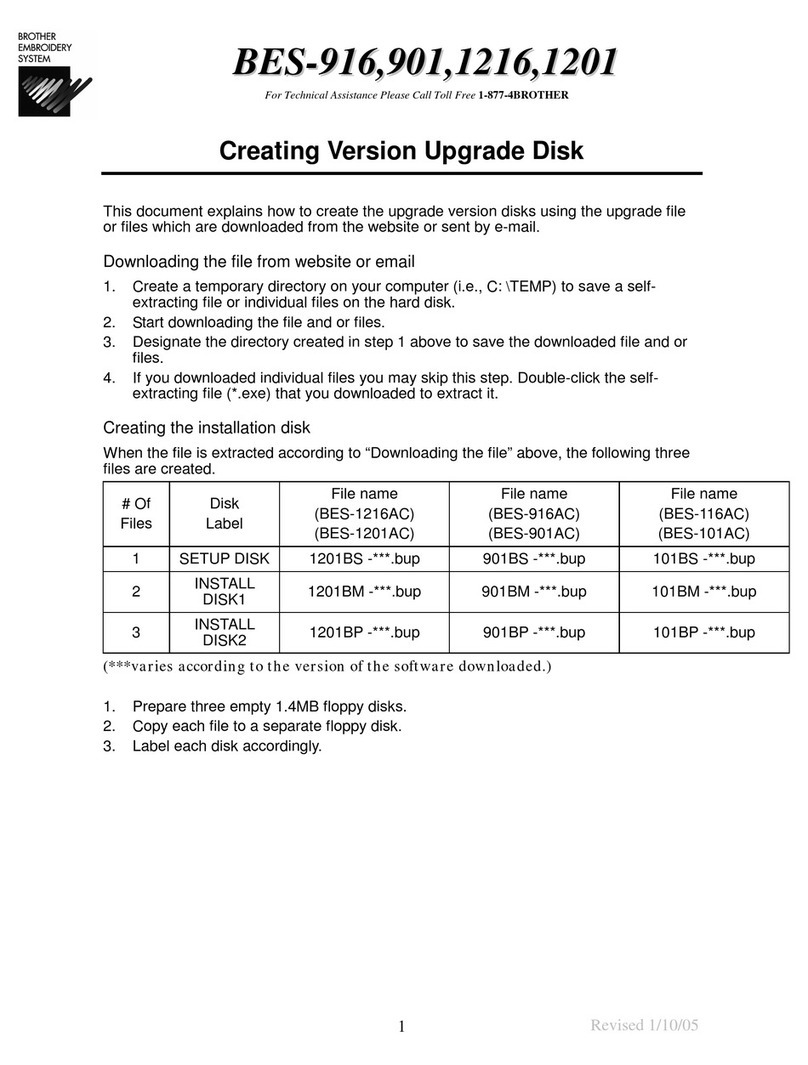

Brother

Brother BE-0901E PC Software guide

Riccar

Riccar 9160 instruction manual

Singer

Singer 114-32 Instructions for using and adjusting