Chicago Pneumatic Auto Feed Drills & Tappers User manual

Other Chicago Pneumatic Drill manuals

Chicago Pneumatic

Chicago Pneumatic CP1114R Series User manual

Chicago Pneumatic

Chicago Pneumatic CP9285 Series User manual

Chicago Pneumatic

Chicago Pneumatic CP785 Series User manual

Chicago Pneumatic

Chicago Pneumatic CP7300 Series User manual

Chicago Pneumatic

Chicago Pneumatic CP873 User manual

Chicago Pneumatic

Chicago Pneumatic CP8548 User manual

Chicago Pneumatic

Chicago Pneumatic CP789R Series User manual

Chicago Pneumatic

Chicago Pneumatic CP8548K User manual

Chicago Pneumatic

Chicago Pneumatic CP7300R User manual

Chicago Pneumatic

Chicago Pneumatic CP 0315 Maintenance and service guide

Chicago Pneumatic

Chicago Pneumatic CP1117 Series User manual

Chicago Pneumatic

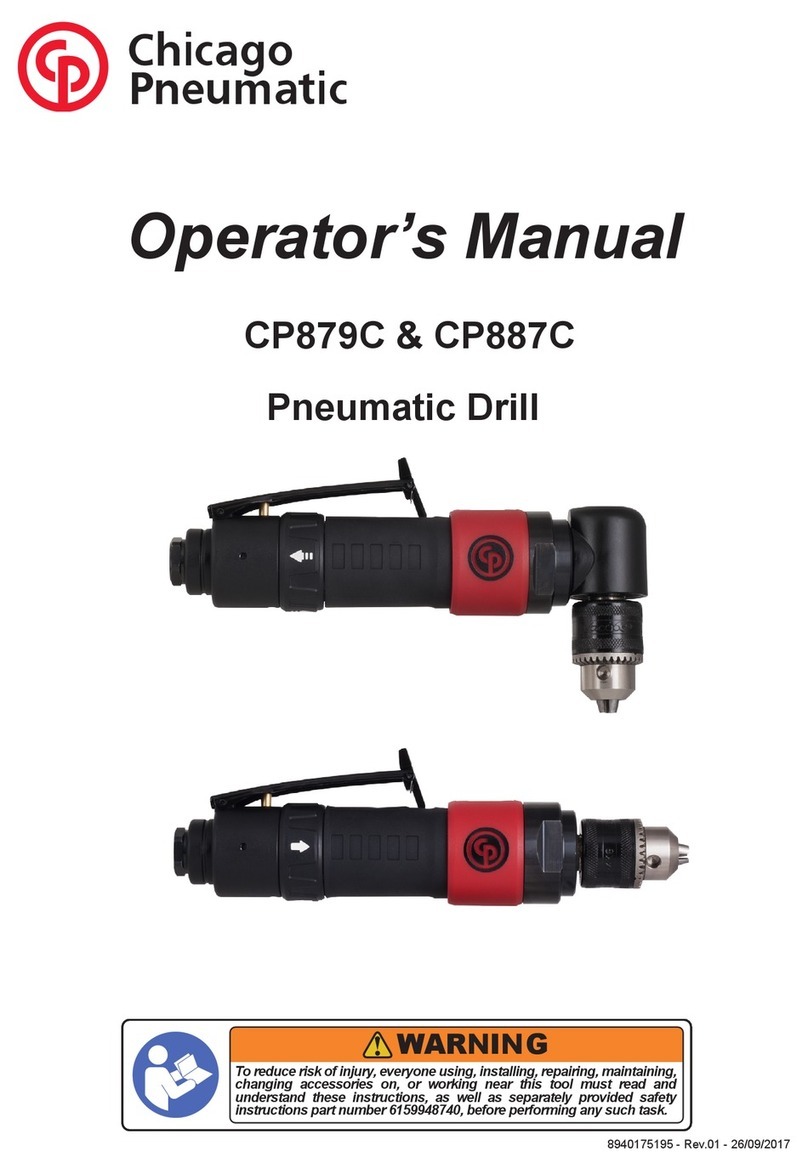

Chicago Pneumatic CP879C User manual

Chicago Pneumatic

Chicago Pneumatic CP1014 Series User manual

Chicago Pneumatic

Chicago Pneumatic CP Drill Maintenance and service guide

Chicago Pneumatic

Chicago Pneumatic CP9285C User manual

Chicago Pneumatic

Chicago Pneumatic CP7300 Series User manual

Chicago Pneumatic

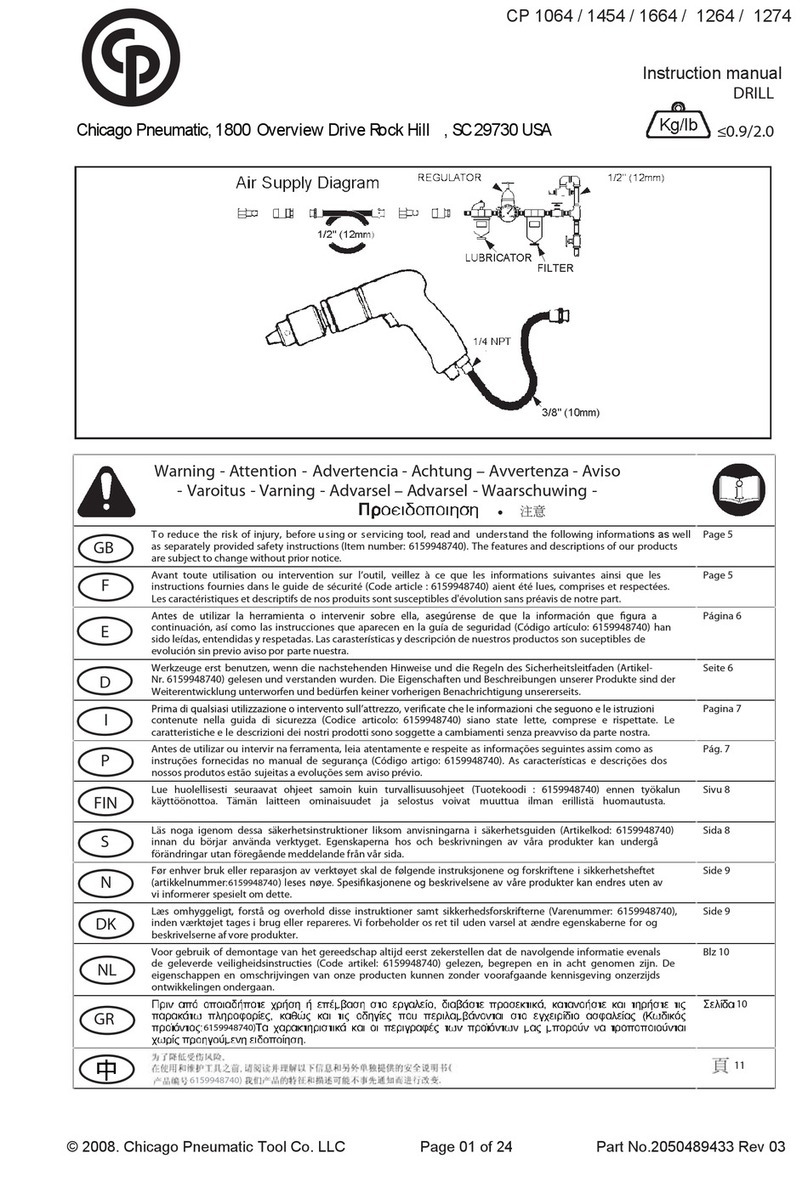

Chicago Pneumatic CP 1064 User manual

Chicago Pneumatic

Chicago Pneumatic CP879 User manual

Chicago Pneumatic

Chicago Pneumatic CP7300C User manual

Chicago Pneumatic

Chicago Pneumatic CP8528 User manual