Page 7 of 40

Bulletin 441G

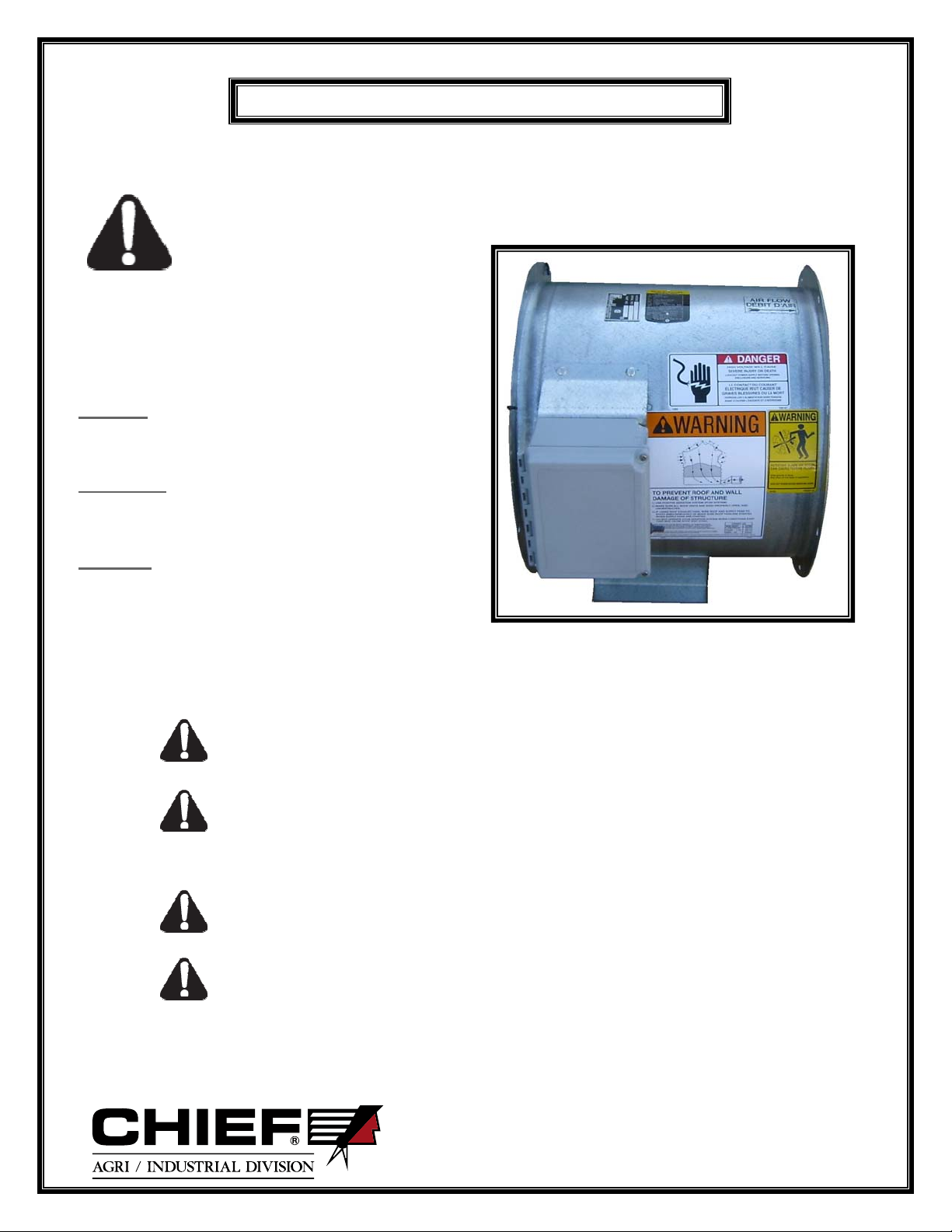

Fi

ure 1 . Warnin

Label Locations

Safety Notice - Important - Read This!

Safety Alert Symbol

This symbol means ATTENTION! BE ALERT! YOUR SAFETY IS AT STAKE!

The Safety Alert Symbol identifies

important safety messages in this document

and on your fan. Make yourself familiar

with the messages identified for you with

the Safety Alert Symbol. When you see this symbol, be alert to

the possibility of serious injury or death. Follow the safety

instructions given in this manual and on your fan.

Signal Words

Danger:Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury.

Warning: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury and property damage.

Caution:Indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Fan Information:

A.) The unit utilizes electricity as the source of energy. When the power is installed

properly, and protective covers are in place, the unit poses no direct hazard.

WHEN INSTALLING OR SERVICING THE ELECTRICAL COMPONENTS, ALWAYS

SHUT THE POWER OFF AT THE FAN DISCONNECT, AND LOCK THE FAN

DISCONNECT IN THE OFF POSITION, SO NO POWER CAN BE DELIVERED TO THE

FAN WHILE YOU ARE SERVICING THE UNIT.

IN PERFORMING ELECTRICAL CHECKS WITH THE POWER ON, USE A VOLTMETER

AND BE CAREFUL NOT TO CONTACT LIVE PARTS.

B.) The unit, when operating, has a fan blade turning at high speed, and when guarded

with the screen guard, poses no direct hazard.

MAKE SURE THE SCREEN GUARD IS SECURELY FASTENED IN PLACE.

WHEN SERVICING THE FAN BLADE, MAKE SURE THE ELECTRICAL POWER IS

SHUT OFF AT THE FAN DISCONNECT, AND LOCK THE FAN DISCONNECT IN THE

OFF POSITION.