Chiltrix CX34 User manual

Chiltrix Inc. www.chiltrix.com

DC INVERTER

AIR TO WATER HEAT PUMP

For Use with units shipped after 10-12-2018

(If unsure, contact Chiltrix technical support dept. with the serial number)

Installation and Operation Manual CX34-3

Options for Heating, Cooling and Domestic Hot Water

Version 1.9

PLEASE REVIEW ENTIRE MANUAL BEFORE PROCEEDING

PLEASE SUBMIT SYSTEM DRAWING & SCHEDULE A COMMISSIONING

CALL BEFORE STARTING THE UNIT

1

Chiltrix Inc. www.chiltrix.com

Table of Contents

Safety Precautions………………………………………………………………………………………… Page 3

CX34 Components………………………………………………………………………………………… Page 4

Hydronic Piping and Design…………………………………………………………………………… Page 5

Buffer Tanks…………………………………………………………………………………………………… Page 7

Head/Pressure Drop Calculations…………………………………………………………………… Page 8

Using Glycol……………………………………………………………………………………………………. Page 11

Heat Pump Installation………………………………………………………………………………….. Page 12

Valves G1, G2, G3…………………………………………………………………………………………… Page 20

Second Heat Source…………………………………………………………………………………….... Page 25

External T-Stat Control……………………………….………………………………………............ Page 26

System Filling/Purging.………………………………………………………………………………….. Page 28

Using The Controller/Operation.…………………………………………………………………… Page 30

P-Parameter Setting ……………………………………………………………………………………….Page 45

Status/C-Parameter Checking………………………………………………………………………... Page 50

About Screen (Software Version) …………………………………….………..………………….. Page 53

Initial Temperature Settings………………………………………………………………...………… Page 53

Error Codes……………………………………………………………………………………………………. Page 54

Dynamic Outdoor Reset Control ……………………………………………………………………. Page 57

Commissioning and Initial Test Run…………………………………………………………………………… Page 59

Footprint/Placement Dimensions --------------------------------------------------------- Page 60

2

Chiltrix Inc. www.chiltrix.com

IMPORTANT NOTE –MAKE SURE TO PROVIDE YOUR DESIGN DRAWING FOR APPROVAL BEFORE GETTING

STARTED, INCLUDING DESIRED OPERATING TEMPERATURES.

Safety Precautions

NOTE: It is required to read the Safety precautions in detail before operation. The precautions listed below

are very important for safety, please follow all safety precautions.

General

•Make sure that the ground wire in the building is securely connected to earth.

• Wiring tasks should be carried out by qualified electricians only, in addition, they should check the safety

conditions of power utilization, for example, verify that the line capacity is adequate, and the power cable

isn’t damaged.

• Users must not install, repair or relocate the unit. Improper procedures might lead to accidents e.g.

personal injury caused by fire, electrical shock or unit's falling off its base, and water leaking into the

machine. Please contact a professional service department if problems arise.

• The unit shall not be installed at a spot with the potential hazard of leaking flammable gas. If gas is leaking

near the machine, there might be the risk of explosion.

• Make sure that the foundation of the unit is stable. If the foundation is unstable, the outdoor unit may

come loose from its base and cause injury.

• Make sure that the GFCI installed at the service panel is working properly to avoid shock or fires.

• If any abnormity occurs in the unit (such as a burning smell is noticed inside the unit), cut off the power

supply immediately, and contact a professional service department.

• Please observe the follow items when cleaning the unit. Before cleaning, shut off the electric supply of the

unit first to avoid injuries caused by the fan operation.

• Do not rinse the unit with water because the rinsed unit may cause electric shock.

• Make sure to shut off the electric supply before maintaining the unit.

• Please do not insert fingers or sticks into air outlet or air inlet.

Transporting and storage

The machine must be transported and stored vertically at all times

3

Chiltrix Inc. www.chiltrix.com

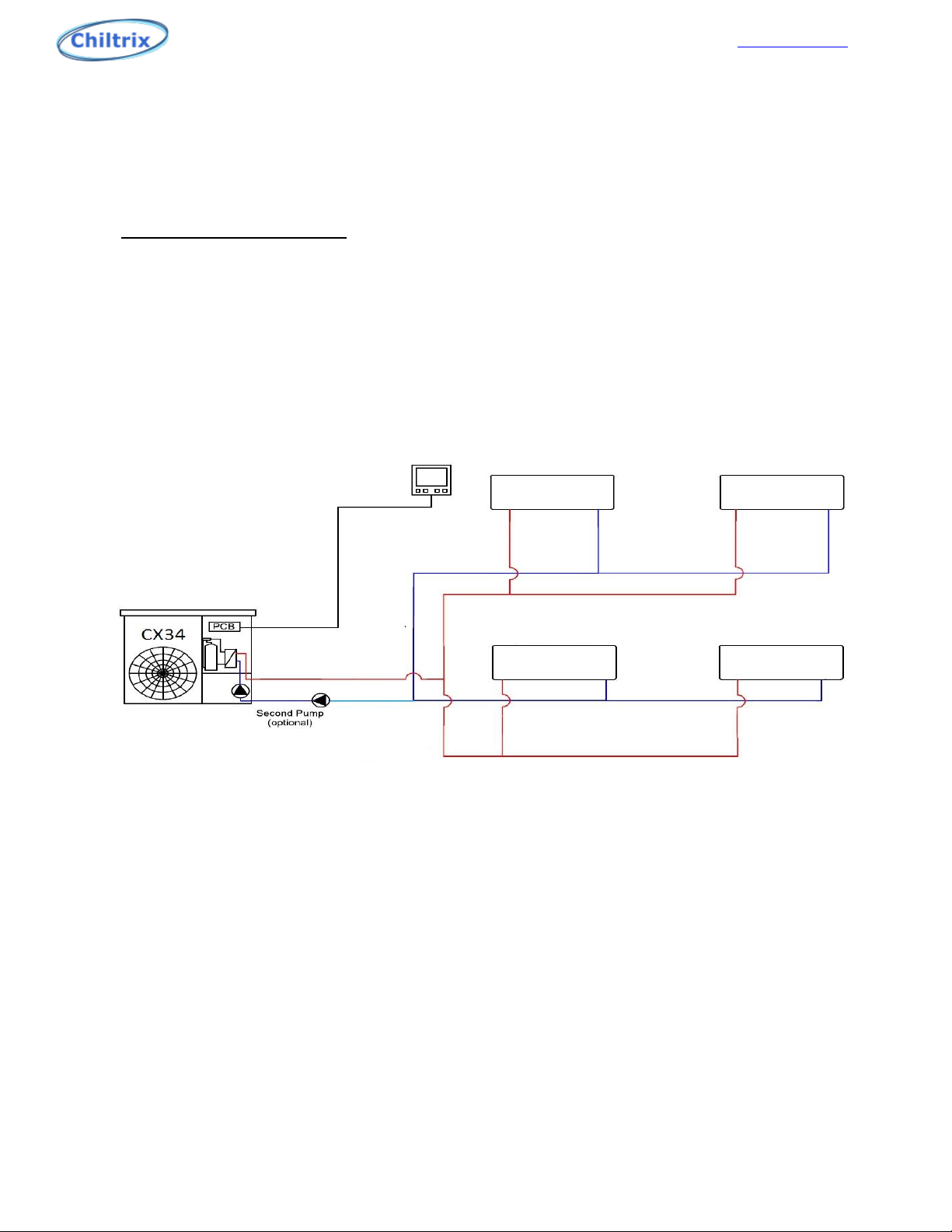

Hydronic Piping and Design Guide

Installation Methods Heating and Cooling (Heating Shown)

Note: Primary Secondary Piping or Closely Spaced Tees are NOT supported or recommended

for use with this heat pump.

A buffer tank must be used for radiant heating. A multi-port buffer tank such as VCT37 should

be used to combine multiple heat pumps.

An “additional volume” tank must be used when there is less than 15 gallons of total system

fluid volume.

Generic design shown below, not all components shown

Buffer Tank Ducted Air

Handler

Fan Coil

Fan Coil

Minimum pipe size should be no less than 1”, CPVC or Oxygen Barrier PEX, reverse return piping is preferable to

assist balancing. Reverse-return will not fully balance multiple chillers as the variable speed pumps may not

always operate at the same speed. The installer should calculate the pipe and fitting resistance to determine the

head pressure. See the examples on the following pages, maximum water flow for the CX34 is 6-7.5 gpm, design

flow is 4.8 gpm. If necessary, a second Chiltrix-provided PWM pump may be added to the loop and controlled by

the CX34. The second water pump connections are always in series with the internal pump. The loop example

above is designed with wild coils (loads). Water flows through the fan coils at all times, if there is a call for heating

or cooling the FCU controls will turn the fan on, adjust fan speed, etc. BTU leakage from a wild coil is around the

same as a light bulb, not enough to worry about. Valved options are available and Chiltrix fan coil units can

support valves, contact Chiltrix support to discuss.

An air discharge valve should be installed at the top of the circulation system, if possible, for easy air discharge. As

an alternative an automatic/manual air vent can be used inline before the pumps.

Always install a water filter or wye strainer on the supply pipe before it enter the heat pump to prevent blockage

of the heat exchanger or pump/flow meter problems.

Do not use CPVC if glycol percentage will be above 25%. Do not use PVC. 5

Chiltrix Inc. www.chiltrix.com

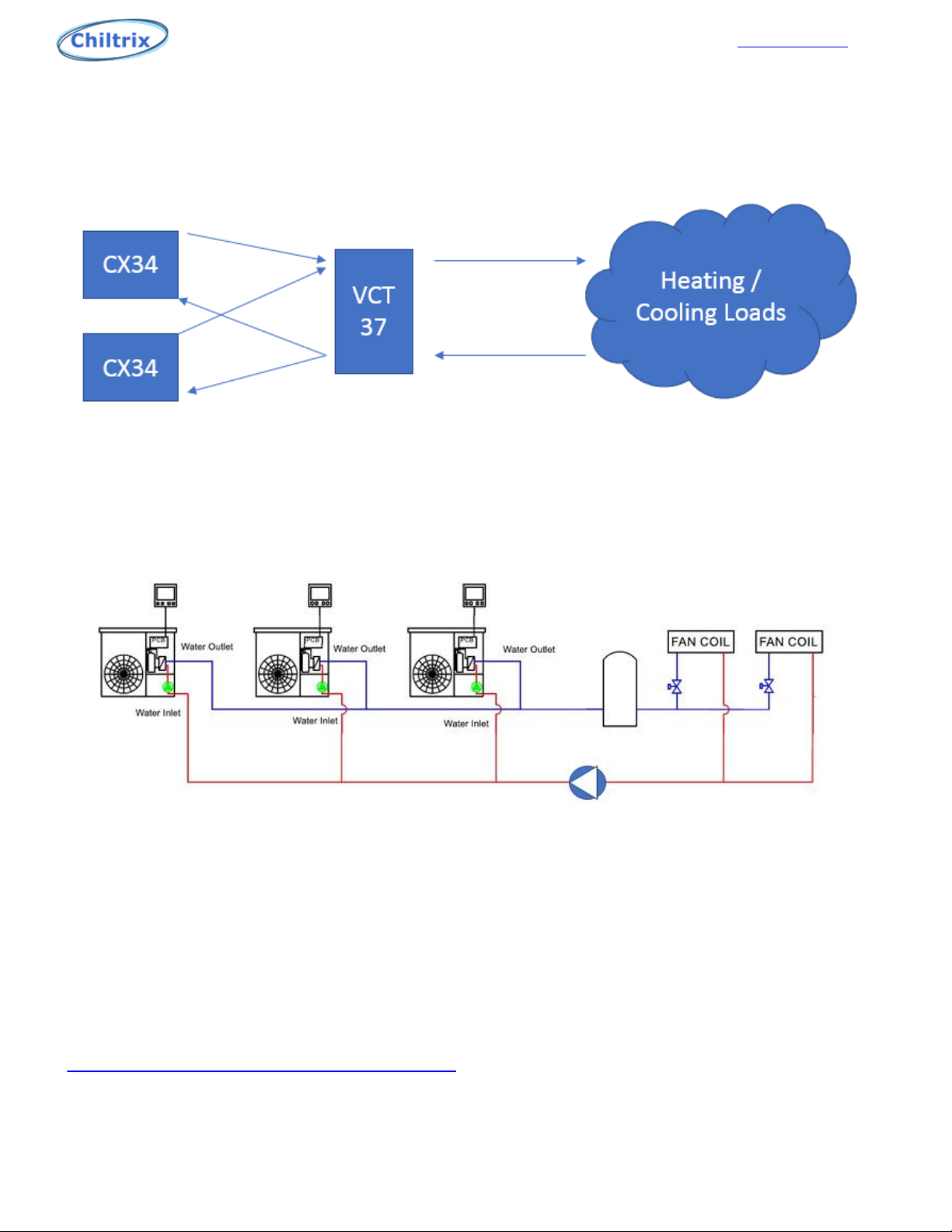

Piping Examples: Stacked Heat Pumps

Preferred Method For 2 or 3 Units:

Optional Method, multiple heat pumps piped in parallel:

(Requires additional loop pump supplied by installer)

PLEASE SEND YOUR PROPOSED FINAL DESIGN TO CHILTRIX SUPPORT DEPARTMENT FOR

APPROVAL, COMMENTS, AND SUGGESTIONS

Pipe Insulation

All loop piping must be insulated per local and national mechanical codes. Any piping in a

system with chilled water (used for cooling) must also be sealed vapor tight to prevent

condensate issues. For design tips and a thickness calculator please visit

http://www.armacell.us/knowledge-center/

6

Chiltrix Inc. www.chiltrix.com

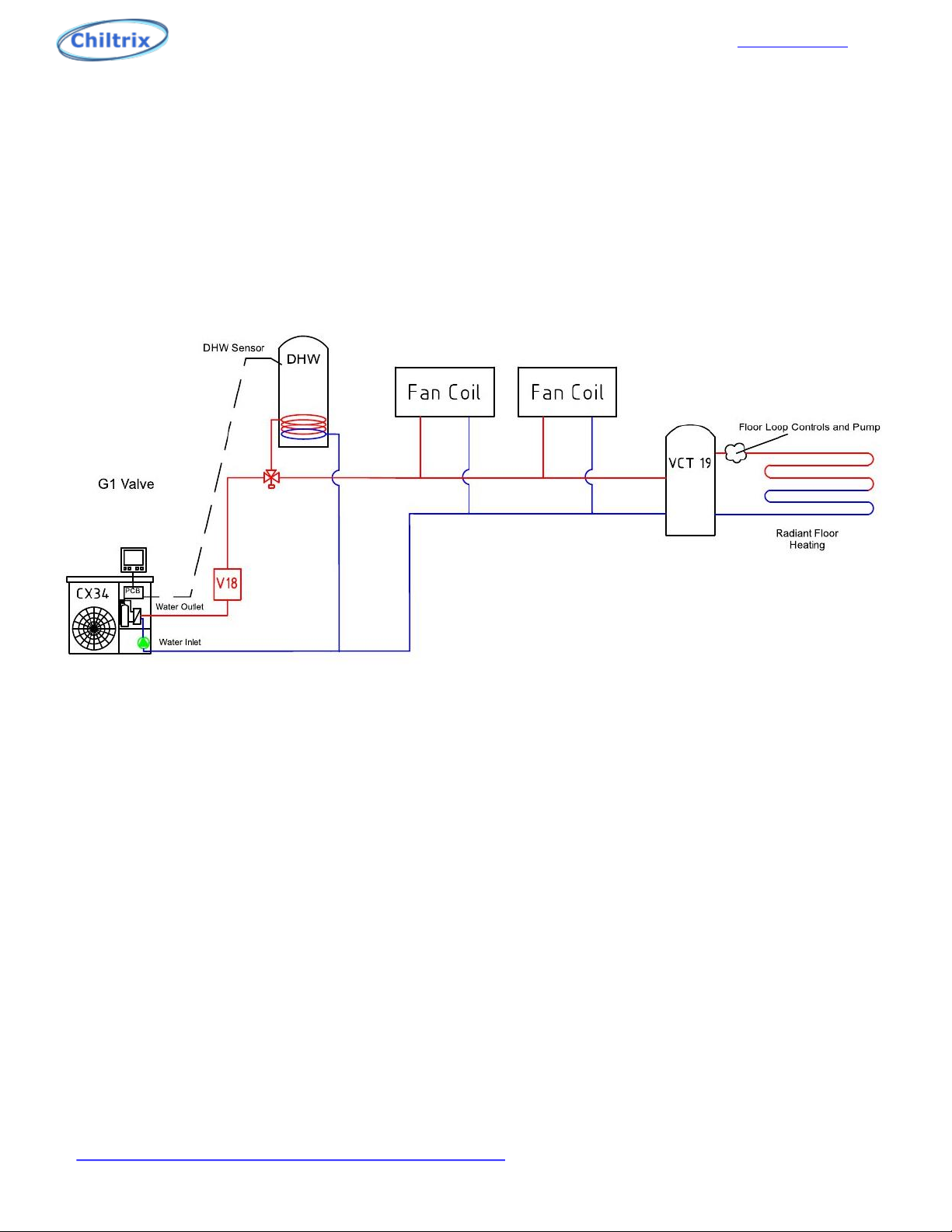

Using a Buffer Tank w/ Radiant

Example below shows optional DHW, optional V18 backup heater, fan coils, and radiant. The radiant is attached

to the load side of a buffer tank.

For V18 information please see the V18 Manual available on the Chiltrix website documents page.

For DHW or buffer tank installation information see the Chiltrix Tank Manual.

Primary / secondary piping is not supported, when connecting to a floor heating loop always use a buffer

tank. Buffer tanks are generally needed only with floor heating with the Chiltrix system, or to combine

multiple CX34 units.

IMPORTANT NOTE ABOUT BACKUP HEAT

Do not ever use buffer tanks for backup heat. The element capabilities of the buffer tank are provided for

emergency heat only. Contact Chiltrix with any questions about emergency or backup heat options. See

Chiltrix DHW & Tank Manual.

The radiant loop pump in the buffer tank drawing is controlled by the customer’s floor loop controls, pump,

etc. The buffer tank isolates the pumps from each other providing hydraulic separation and thermal

buffering.

A 15-20 gallon buffer tank is used generally for best performance with a single CX34. 30-45 gallons is used

for systems of two or three CX34s, and used when multiple CX34s are to be combined. A G3 seasonal valve

may be used to isolate the tank in cooling mode, if applicable, note that isolating the buffer tank in this

manner may cause the need for an additional volume tank to be added.

See more designs here:

https://www.chiltrix.com/documents/chiller-options.pdf

7

IMPORTANT

Check all tank ports including under any element covers

to make sure any unused ports are plugged. Pre-plugged

ports may be only finger-tight. Check ALL ports and plugs

for water tight fit.

Chiltrix Inc. www.chiltrix.com

Head Calculation Example:

To calculate the head pressure for the correct water flow, the pipe length must be measured and all fittings

counted. It is advisable to use flexible red oxygen barrier PEX piping and route it so as to avoid as many elbows as

possible.

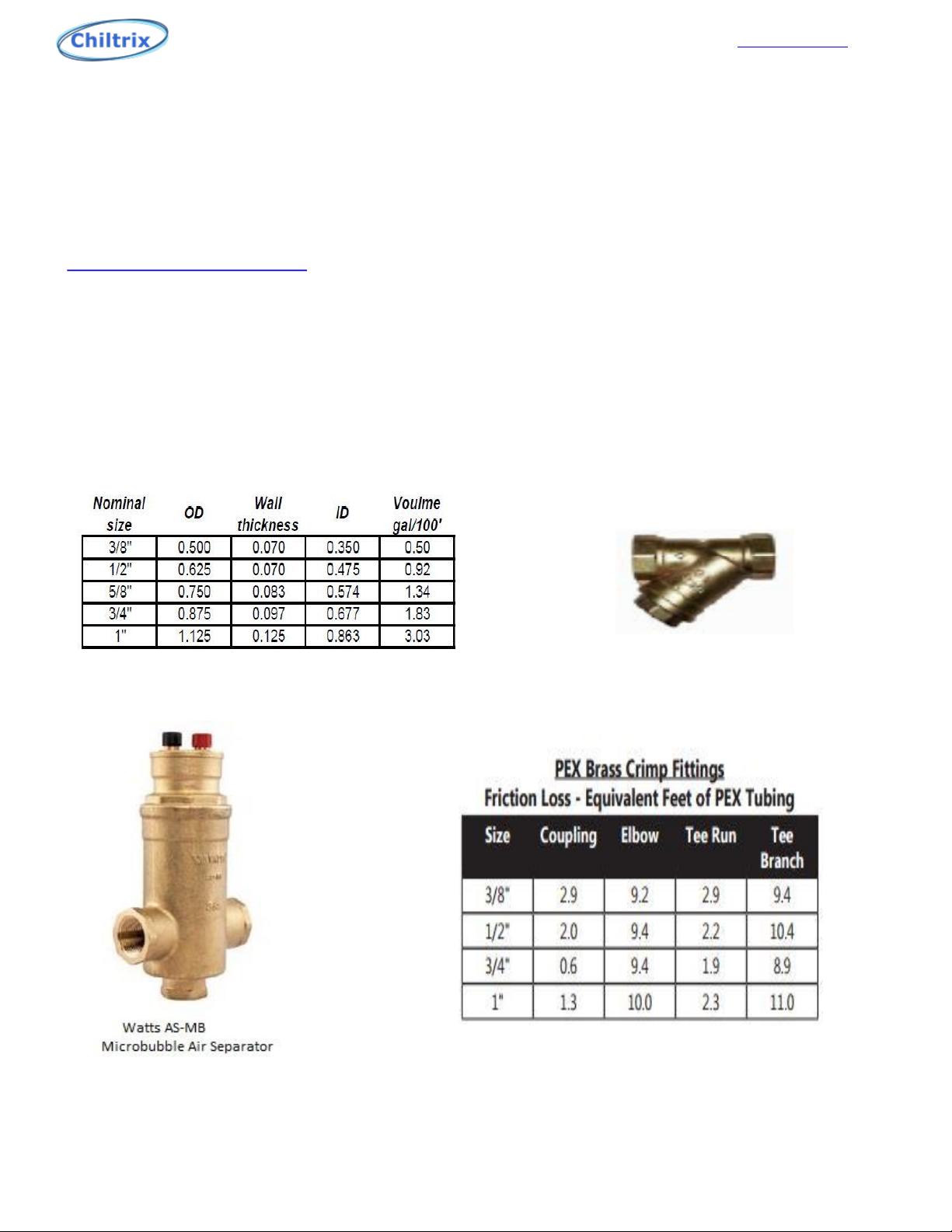

All fittings have an equivalent length of pipe already calculated, available on the next page under PEX Fittings

Pressure Drops. Add up the equivalent length of pipe for the fittings, 13.8’ + 11.7’ =25.5’. Then, add this to the

actual pipe, 25.5’+115” = 140.5’ of 1” pipe. Once you know the total length of pipe, use a (1” PEX 10% Glycol, feet

of head per 100 feet of tubing chart), to get the head for 1’ of pipe, at 40°F and 4.76 GPM. This comes to (.0500)

feet of head per foot. 140.5 x .0500=7.02 ft. of head.

Add up all head calculations, 7.02 + 9.18 + 4.01 = 20.21 ft. of head. Next, we will look at the Wilo Pump curve on

page 13. Maximum head at 4.76 GPM is 23.67 ft.

If using the CX30SE (Free Cooling option) the CX30SE’s pressure drop is 4.5 PSI when active.

8

Chiltrix Inc. www.chiltrix.com

Head Calculations - Continued:

The previously shown example loop has a volume of 4.5 gallons. The internal thermal expansion tank is 2 liters

or .52 Gallons. The volume of the CX34 is 4.5 liters. An additional thermal expansion tank may be required for

larger loops. There are many thermal expansion calculators on the internet, the following is an example.

http://westank.com/calculator/

Minimum loop pressure is 14.5 psi, maximum pressure is 43.5 psi, and ideal pressure is 29 psi. The lowest

temperature is 44°F, the highest temperature is 131°F, the Initial pressure is 14.5 psi, and the final pressure is

29 psi.

A microbubble air separator should be installed in the loop preferably in the higher part of the loop to remove

any air in the circulation loop. Always install a water filter or wye strainer on the supply pipe to the chiller to

prevent blockage of the heat exchanger or damage to flow meter.

WYE STRAINER (from supplyHouse.com)

9

Chiltrix Inc. www.chiltrix.com

Chiltrix CX34 Internal Pump:

Wilo Yonos PARA RS 25/7.5 PWM1 Ku

Head/Ft.

GPM

26.2

22.9

19.6

16.4

13.1

9.8

6.5

3.2

2.2 4.4 6.6 8.8 11 13.2 15.4

Dark Black Line = Chiltrix Pump (25/7.5)

Examples:

If required flow is 4.4 GPM, the maximum allowed head would be 22.9 Ft.

If required flow is 6.6 GPM, the maximum allowed head would be 22.9 Ft.

If required flow is 8.8 GPM, the maximum allowed head would be 18.0 Ft.

Note: The CX34 unit adds max 6 ft. head. A booster pump may be needed for non-optimal

designs, longer piping distances, dual or triple CX34s, other complex or larger systems.

10

Chiltrix Inc. www.chiltrix.com

Glycol

While not always required, customers in colder climates that are subject to occasional freezing should add an

appropriate percentage of food-grade propylene glycol to the system. NEVER USE ETHYLENE GLYCOL.

Ethylene Glycol is a poison. Propylene Glycol is a non-toxic anti-freeze also used in food, cosmetics, etc. and

can safely be used.

Food-Grade Glycol is available at Home Depot and other retailers. You may also consider HSE Corn Glycol

(Biodegradable Food-Grade Glycol made From Corn

https://www.hotspotenergy.com/corn-glycol/

Below is a Freezing Point Chart For Propylene Glycol Mixed w/ Water

NOTE:

When using CPVC piping it is highly recommended

that you do not exceed a 25% glycol to water ratio.

Environmental Stress Cracking, also referred to as

ESC, may occur. Do NOT use PVC piping.

Flow Rates

Required flow rate changes with the glycol %.

Note the “500” formula water factors are adjusted as follows (based on 2,3 tons capacity):

Example:

Based on load calculations a given system need to deliver

a maximum of 31,000 BTU with 30% glycol:

BTU/31,000/480=6.45 GPM

(BTU/water factor=required flow rate)

Use the required flow rate to calculate head based on the Head Flow Curve on the following page.

Minimum pump speed can be set at P53, minimum speed should not produce a flow rate in your system of

less than 6 L/min and generally should not be set lower than 40%. Pump speed can be monitored at C48, 1 is

lowest and 10 is highest speed. Actual water flow can now be monitored on the desktop and at C13, liters

per minute. Test at full pump speed. 1 L/min = .264 GPM // 1 GPM = 3.78 L/min

00% glycol use 500 24,000/500/10=4.8 GPM

10% glycol use 494 24,000/494/10=4.85 GPM

20% glycol use 488 24,000/488/10=4.91 GPM

30% glycol use 480 24,000/480/10=5.00 GPM

40% glycol use 463 24,000/463/10=5.18 GPM

50% glycol use 442 24,000/442/10=5.43 GPM

00% glycol use 500 36,000/500/10=7.42 GPM

10% glycol use 494 36,000/494/10=7.28 GPM

20% glycol use 488 36,000/488/10=7.37 GPM

30% glycol use 480 36,000/480/10=7.50 GPM

40% glycol use 463 36,000/463/10=7.77 GPM

50% glycol use 442 36,000/442/10=8.14 GPM

11

Chiltrix Inc. www.chiltrix.com

Chiltrix Heat Pump Installation

Heat Pump Installation

Installation position

Note: Installation must be carried out by professional personnel.

The recommended mounting pad should be at least 1 ½” above ground level. If you are in an area where snow

occurs, mount the unit high enough above grade to avoid blockage by drifting snow. You can consider a

properly rated wall mount if desired.

Proper drainage is required at the heat pump unit to avoid flooding the outdoor unit with water or ice. Make

sure condensate has a way to rapidly and completely drain away from the unit.

To install the unit on a balcony or on top of a building, the installation site must meet the allowable load

bearing capacity of the building structure without affecting the structural safety. Ensure the unit is well

ventilated; the direction of air exhaust should be kept away from the windows of neighboring buildings.

Adequate service clearance should be kept around the unit. The unit should not be installed in places

accompanied with oil, inflammable gases; corrosive components e.g. sulfur compound, or high-frequency

equipment.

Outdoor Unit Placement / Clearances

(Unit: mm) 200mm = 8” , 350mm =14 “,

400=16”, 500=20”,1000=40”

12

Chiltrix Inc. www.chiltrix.com

Chiltrix Heat Pump Installation

NOTE: The CX34 is shipped with the pump in a separate box attached to the top of the chiller. Please follow

the directions below to install the “C4” Wilo Yonos PARA internal pump.

Internal Pump Installation

(Remove Top, Front, and Right Side Covers) DO NOT BEND OR STRESS

THE PIPING, this may case a broken joint or leak where it joins the heat

exchanger. Cut the insulation and peel it back out of the way of the

flange nuts. This will allow installation of the pump without bending

either of the pipes. The pump will slide in between the pipes with the

washers.

Peel back the insulation Removing the shipping spacer Verify flow direction (UP) Installed properly

13

Chiltrix Inc. www.chiltrix.com

Internal Pump Wiring

If the Wilo RS 25/7.5 PWM pump does not have the required flow rate, a second Wilo RS

25/7.5 may be added to increase the total pump pressure and flow. This will double the

head pressure capability at the targeted flow rate. When adding a booster pump, wire

both power and control wires in parallel with the internal Wilo pump wiring. Use the

same terminals. See diagrams next page.

Electronics Cabinet

14

Chiltrix Inc. www.chiltrix.com

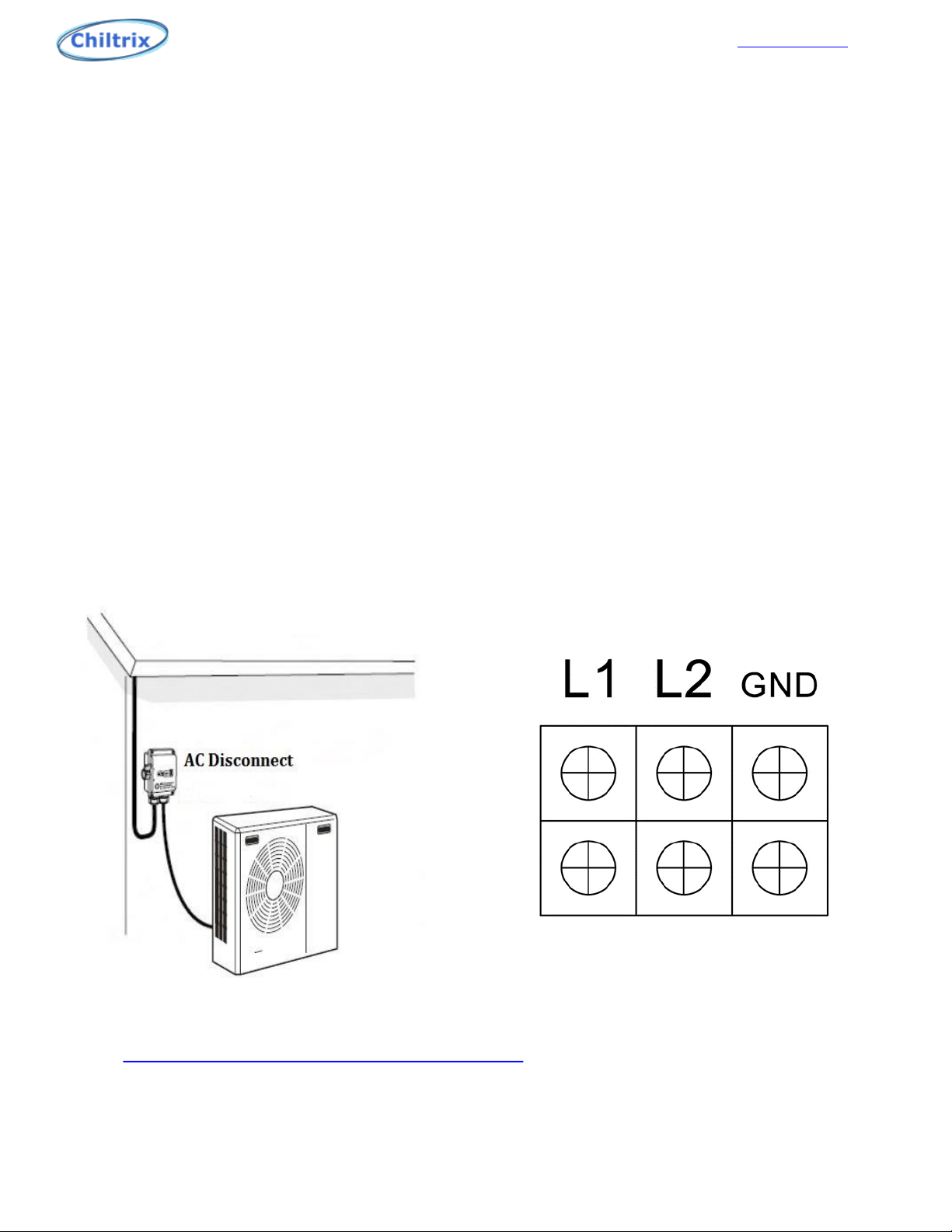

Electrical Connection

General

Note!

Electrical installation and service must be carried out under the

supervision of a qualified electrician. Electrical installation and wiring

must be carried out in accordance with the NEC.

The heat pump must be connected under the supervision of a qualified electrician. Wires, spare parts and

materials etc. must satisfy the relevant standards and codes issued by the host country or region.

The heat pump does not include an AC disconnect or switch on the incoming electrical supply which will be

required. The power supply cable must be connected to a circuit-breaker with at least a 3 mm breaking gap.

Incoming supply must comply with the technical requirements, with a frame ground wire (neutral is not

used), via a distribution box with breakers. Allowed Voltage range is 208-240vac. Maximum current draw is

13 amps, minimum wire size is 12 AWG, minimum breaker size is 20 AMP. It is advisable to add surge

suppression with transient voltage protection to the circuit powering the chiller.

Main terminal block inside electronics box

Example MOV transient voltage suppressor

https://www.mouser.com/_/?Keyword=V300LA40AP

16

Chiltrix Inc. www.chiltrix.com

When using a second NON-PWM water pump

When using a second NON-PWM water pump, use terminals L2 and C6L for relay coil

power only. Do not connect a pump directly to L2 and C6L, always use a relay with a 240

vac coil. This pump will only run when the PWM pump is running. Setting P54=0 and

P52=1, will shut C6 off when the chiller reaches its set point.

19

Chiltrix Inc. www.chiltrix.com

DHW (Domestic Hot Water)

G1 Valve

G1: DHW/AC / Heating 3-Way Valve

In DHW mode, the G1 valve is powered off. In AC/heating mode, G1 is powered on.

Parameter P08 must be “0” to enable DHW, C19 will show the switch status.

G1 and G3 valves use 220v Primary from the CX34. Use conduit and install per local code.

DHW target setting temperature is the tank water temperature measured with the DHW sensor, not the

CX34 inlet water temperature. If the target temperature is 122°F, (refer to page 43 to set the DHW temp),

and the differential is 2°c, it means, when the DHW tank reaches 122°F, the compressor will stop. When

the DHW tank temperature is lower than 119°F, the compressor will start. See the Chiltrix Tank Manual

before proceeding to install or connect any DHW or buffer tank.

See the Chiltrix Tank Manual for important details and options for using CX34 with DHW, including

backup heat options, and anti-legionella function. READ THE CHILTRIX TANK MANUAL BEFORE

DESIGNING, CONNECTING, CONFIGURING, OR USING DHW.

Note*

There is one sensor taped to the outer CX34 plastic wrapper with the rubber feet, it is for the DHW tank.

The indoor ambient air temp is not used at this time, however, do not disconnect this sensor. Leave all

unused sensors plugged in and wrapped in the bundle above the compressor.

20

IMPORTANT

Check all tank ports including under any element covers

to make sure any unused ports are plugged. Pre-plugged

ports may be only finger-tight. Check ALL ports and plugs

for water tight fit.

Other manuals for CX34

2

Table of contents

Other Chiltrix Heat Pump manuals

Chiltrix

Chiltrix CX34-4 User manual

Chiltrix

Chiltrix CX34 User manual

Chiltrix

Chiltrix CX30FC User manual

Chiltrix

Chiltrix CX50 User manual

Chiltrix

Chiltrix AC series Heating & Cooling series CX30 User manual

Chiltrix

Chiltrix CX45 User manual

Chiltrix

Chiltrix AC series Heating & Cooling series CX30 User manual