Cimo ST. LOUIS 82 User manual

1

VACUUM INVESTMENT MIXER

ST. LOUIS 82

INSTRUCTION MANUAL

2

INDEX

CE CONFORMTY DECLARATION …………………………………………….………………………... 3

INTRODUCTION……………………………………………………………………………………………...4

WARRANTY………………………………………...…………………………………………………………4

GENERAL NOTES………………………………………...…………………………………………………..4

MACHINE FEATURES ………………………………………………………………………………………4

OPERATOR SAFETY…………………………………………………………………………………………4

TRANSPORT ………………………………………………………………………………………….………4

TECHNICAL DATA………………………………………………………………………………………..…5

VACUUM PUMP CONNECTION……………………………………………………………………………5

PRELIMINARY OPERATION……………………………………………………………………………….5

WATER CONNECTION FROM THE MAIN WATER PLANT – SEPARATE TANK………………….5

ST. LOUIS 82 REFERENCE CHART …….………………………………………………………………...6

ST.LOUIS 82 CONTROL PANEL – WATER DOSING STICKER SPECIFICATIONS……….………..7

MIXER USE ( PRELIMINARY OPERATIONS )………………………………………………………..….8

MIXER USE ( PART 2 )………………………………………….…………………………………………….9

UNIT DRAWING & PARTS LIST…………………………………………………………….……….10 - 17

3

CIMO s.r.l.

Corso Novara 171/b -27029 VIGEVANO (PV) ITALY

TEL. (+39) 0381 82193 – FAX (+39) 0381 70251

EMAIL: cimob@tin.it - www.cimosrl.it

CONFORMITY DECLARATION

St. LOUIS 82 – 6 kg.

Machine: Vacuum investment mixer for jewellery casting process

Model: ST. LOUIS 82 - 6 kg.

Serial n. 19.06.

Year made: 2019

2006/42/EC Applicable Machinery Directive

2014/30/EU Directive of electromagnetic compatibility

Applicable Harmonized Standards

EN ISO 12100:2010 Safety of machinery-General principles for design-risk assessment

and risk reduction

EN 349:1993+A1:2008

EN1037:2008

EN ISO 3744:210

EN ISO 11201:2010

EN ISO 138549-1:2008

EN 13850:2008 safety of machinery principle for design

EN 60204-1:2006+A1:2009

EN 61000-6-2:2005 electromagnetic compatibility (EMC) generic standards- immunity for

industrial environments.

EN61000-6-4:2007+A1:2011 electromagnetic compatibility (EMC) generic standards-

emission standard for industrial environments.

Vigevano,

C.I.M.O. srl -Gianluigi Barettoni

managing director

4

INTRODUCTION

These notes are provided to our Customer in order to offer the information’s necessary for the correct installation ,

operation use and maintenance of the unit purchased. Only technical staff, previously authorized by the Producer,

will guarantee a correct service of the machine and its components.

Any modification or repair made without prior CIMO authorization and agreement, will immediately cancel warrenty

conditions and this circumstance will save the producer from any kind of responsibility forward any person and things

suffering damages that might occur. Please carefully read the instructions notes before operating the machine.

CIMO is reserving the right to modify its products without previous notice.

WARRANTY

CIMO PRODUCTS ARE COVERED BY TWELVE MONTHS WARRANTY

STARTING FROM THE DELIVERY DATE TO CUSTOMER

EXCEPT ELECTRIC AND ELECTRONIC COMPONENTS THAT ARE COVERED SIX MONTHS ONLY.

WARRANTY IS LIMITED TO REPAIR OR CHANGE OF THE FAULT PARTS

UPON A PREVIOUS AUTHORIZATION AND INSPECTION BY OUR STAFF OR CIMO DELEGATE.

LABOUR, TRANSPORT, CUSTOMS AND OTHER COSTS WILL BE AT TOTAL CUSTOMER CHARGE.

THE TOTAL CHANGE OF THE COMPLETE MACHINE IS ALWAYS TO BE ESCLUDED FROM WARRANTY

CONDITIONS. PARTS REPAIRED OR CHANGED WILL NOT EXTEND THE WARRANTY PERIOD.

GENERAL NOTES

St. Louis vacuum mixers are machines studied and designed for the investment mixing and flask mold filling for the

lost wax casting of the jewelry making process. The main concept of the St.Louis mixing units is the total operativity

under vacuum situation.

Traditionally investment was mixed with water in open air and with this process the final blend result was not really

homogeneous and precise so the surface of the precious metal casted was not so smooth and complete.

More, the large quantity of gases incorporated in the mixing was giving such a huge percentage of porosity.

St.Louis mixer, with the vacuum total process and the timing, quantity and water dosing very precise, assures

the best quality performing results in one of the most delicate process-step by step of the lost wax casting system.

THE MACHINE FEATURES

- WATER DEGASIFICATION IN THE WATER DOSING-TANK

-TOTAL INVESTMENT POWDER DEGASIFICATION INTO THE MIXING CONTAINER

-EXACT AND PRECISE WATER QUANTITY IN THE RATIO 1:40 TO BE ADDED TO POWDER

-ADJUSTABLE MIXING SPEED AND ROTATION DIRECTION IN MIXING STEP

-CORRECT AND PRESETTED MIXING TIMING

- ADJUSTABLE INTENSITY VIBRATION FOR THE INVESTED FLASKS

OPERATOR SAFETY

PROTECTION MASK FOR OPERATOR IS COMPULSORY REQUESTED

PROTECTION HAND GLOVES FOR OPERATOR ARE SUGGESTED

THIS UNIT MUST BE OPERATED BY PROFESSIONAL STAFF

AND FOR ITS CONCEPT PURPOSE BUILT ONLY !

5

TRANSPORT

THE MACHINE SHOULD BE ALWAYS TRANSPORTED IN VERTICAL POSITION

AND HAS TO BE LIFTED FROM THE BOTTOM CHASSIS BASEMENT ONLY.

ATTENTION

PLEASE AVOID TO HOLD, LIFT OR PULLING AND PUSHING THE MACHINE FROM ITS CENTRAL

CONSTRUCTION PART ( PLEXIGLASS MIXING BOWL, FLASK CHAMBER OR MAIN MOTOR SHAFT).

TECHNICAL DATA

VOLTAGE: 220 VOLTS -50/60 HZ. SINGLEPHASE – CONSUMPTION: KW. 3.5

PROTECTION FUSE: 2 fuses x 16 AMP.

The fuses are located on the circuit board

MAX INVESTMENT DRY POWDER CAPACITY : kg. 6

ELECTRICAL POWER CONNECTION:

ATTENTION! THE UNIT MUST BE CONNECTED AND PLUGGED TO AN ELECTRICAL PLANT

WITH GROUND AND EARTH UNDER SAFETY SWITCH.

MACHINE ELECTRICAL COLOUR WIRING IDENTIFICATION:

YELLOW/GREEN:EARTH – GROUND BLUE: NEUTRAL BROWN: PHASE

VACUUM PUMP CONNECTION:

MIXER S. LOUIS 82 MUST OPERATES WITH A VACUUM PUMP CAPACITY 18 CBM/HOUR.

THE VACUUM PUMP IS SUPPLIED SEPARATELY AS INTEGRATED PART OF THE UNIT.

ON THE REAR PART OF THE MACHINE BASEMENT FIND THE VACUUM PIPE HOSE CONNECTOR

AND THE 220VOLTS PLUG ONLY FOR THE VACUUM PUMP. THE VACUUM POWER IS SUPPLIED

DIRECTLY FROM THE MIXER. DO NOT USE THIS PLUG FOR DIFFERENT PURPOSES.

WATER SUPPLY CONNECTION: FROM THE MAIN FACTORY WATER PLANT

MIXER S. LOUIS IS PROVIDED BY A SPECIAL WATER PIPE WITH RELATIVE JOINTERS TO BE

CONNECTED TO STANDARD FACTORY-WORKSHOP TAPS. WE PROVIDE THE JOINTER SEALS TOO.

TO FILL THE MACHINE WATER DOSING TANK PROCEED AS FOLLOWS:

OPEN AIR RELEASE VALVE ( SEE PICTURE REF. 1 ) LOCATED ON WATER DOSING TANK ( REF. 2 )

CLOSE THE TAP (SEE PICTURE REF. 3 ) NEARBY THE VALVE ( REF 1 ).

OPEN THE MAIN WATER SUPPLY TAP OF THE FACTORY AND THE MACHINE WATER TAP ( REF. 4 )

FILL THE DOSING TANK UNTIL WATER LEVEL WILL REACH THE TOP LINE ( REF. 4 ) EXACTLY.

WHEN TOP LEVEL HAS BEEN REACHED, CLOSE AGAIN THE RELEASE VALVE ( REF. 1. )

4

5

6

OPTION: WATER SUPPLY CONNECTION: FROM AN EXTERNAL WATER TANK

SWITCH ON THE MIXER BY THE REAR MAIN SWITCH. SWITCH ON THE VACUUM PUMP (VAC BUTTON

ON FRONT CONTROL PANEL). THE VACUUM RELEASE TAP ( REF. 5 ) IS CLOSED AS TAP ( REF. 6 ).

HOLD PUSHED DOWN THE ROUND CAP WHERE TAP ( REF. 6 ) IS LOCATED UNTIL VACUUM WILL KEEP

IT CLOSED. THE UNIT IS NOW TOTALLY UNDER VACUUM SITUATION:

PROCEED NOW AS DESCRIBED IN THE PREVIOUS PARAGRAPH

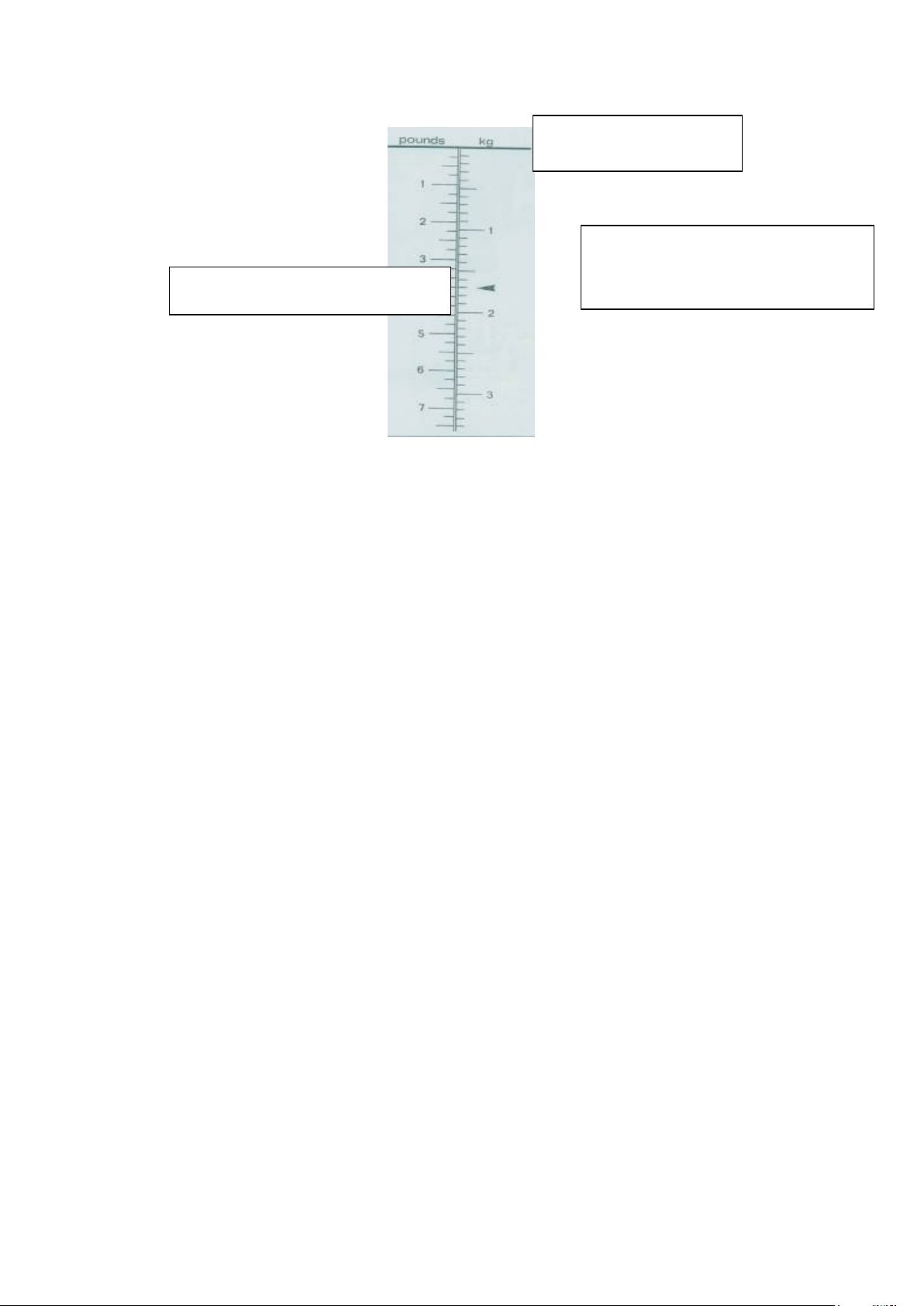

Mixer S.LOUIS 82 - REFERENCE CHART

Mixer S.LOUIS 82 -CONTROL PANEL

WATER DOSING TANK AND STICKER SPECIFICATIONS:

The sticker on the dosing water tank is indicating kg. and pounds with numbers from 0 to 9 ( kg. )

IT IS PRINTED CONSIDERING THE STANDARD RATIO: 1 KG. DRY INVESTMENT POWDER = 400 CC. WATER

THE STICKER LINES AND NUMBERS ARE INDICATING THE DRY POWDER GRAMS ( or POUNDS )

FROM TOP LINE WATER LEVEL ( under KG printed ) THE QUANTITY OF WATER CORRESPONDING

TO EACH KILOGRAM IS 400 CC

Practical example:

IF WE HAVE LOADED kg. 1,700 INVESTMENT DRY POWDER INTO THE MIXING CONTAINER, WE HAVE TO

TRANSFER INTO THE MIXING CONTAINER A QUANTITY OF WATER AS MUCH AS WE SEE MARKED ON THE

LEVEL LINE VALUE KG 1,7 ON THE DOSING COLUMN STICKER IN ORDER TO HAVE THE EXACT 40%

PROPORTION OF WATER FOR THE INVESTMENT LOADED IN THE MIXING CONTAINER.

7

MIXER USE: PRELIMINARY OPERATIONS

-SWITCH ON THE MACHINE WITH THE MAIN REAR GENERAL SWITCH.

-LIFT UP THE TOP MOTOR ( M ) WITH KNOB ( A ) AND TURN IT TO THE RIGHT SIDE OF THE UNIT.

-REMOVE THE CAP ( REF 7 ) FROM THE BLADE COVER ( B )

-REMOVE THE TOP MIXING COVER WITH ITS BLADE ( B ) FROM THE MIXING CHAMBER ( C )

-LIFT UP THE COMPLETE MIXING CHAMBER ( C ) AND PLACE IT READY FOR THE INVESTMENT

POWDER LOADING. ( MIXING CONTAINER ALWAYS DRY PLEASE )

-PLACE THE FLASKS TO BE PROCESSED ON THE ROUND FLASK PLATE ( D ): YOU COULD TAKE

OUT THE FLASK PLATE FROM ITS LOCATION FOR EASY PREPARATION OF FLASKS DISPOSITION.

BE SURE TO MATCH THE EXAGONAL PIN WHEN REPLACING THE FLASK PLATE ON ITS ORIGINAL

POSITION.

INVESTMENT POWDER LOADING AND MIXER PREPARATION:

BE SURE THAT BOTTOM POURING VALVE TAP ( REF 8 ) IS CLOSED.

WE SUGGEST TO PLACE THE MIXING CONTAINER ON A DIGITAL SCALE AND MAKE THE TARE

BEFORE LOADING THE INVESTMENT POWDER IN THE QUANTITY NEEDED.

OTHERWISE MAKE THE EXACT WEIGHT OF THE POWDER AND POUR IT INTO THE CHAMBER

AVOIDING BREATHING THE INVESTMENT DUST. USE ALWAYS MASK AND GLOVES PROTECTION !

ONCE LOADED, PLACE THE MIXING CONTAINER ON ITS LOCATION CARING:

-A) CORRECT MATCHING FOR THE MIXING CONTAINER ON THE FLASK CHAMBER (REF. F )

-B) CORRECT MATCHING OF THE STICKER LINE REFERENCE BETWEEN THE LOWER MIXING

CONTAINER BASE AND THE FLASK PLEXIGLASS CHAMBER. (REF. E) – TWO VERTICAL

REFERENCES LINES

-INSERT THE MIXING BLADE (REF. G) INTO THE MIXING CHAMBER CARING THAT COVER WILL

SEAL PERFECTLY THE CHAMBER TOP.

-LOCATE THE TOP MOTOR IN THE ORIGINAL POSITION CARING TO INSERT THE TRANSMISSION

SHAFT CORRECTLY. ( if the operation get DIFFICULT and not matching: SIMPLY START AND STOP

THE MIX BUTTON ON THE CONTROL PANEL.

-PLACE AGAIN THE CAP (REF. 7 ) IN THE ORIGINAL POSITION

-VERIFY THAT ITS TAP (REF. 6 ) IS CLOSED ( CROSSING PERPENDICULARLY THE PIPE DIRECTION )

Example: as described above

(KG. 1,7 POWDER )

TOP LEVEL LINE

----- OF WATER

1

MEANS THAT WE HAVE LOADED

KG. 1 OF DRY POWDER

The quantity of water from top line until

line indicating 1 is the 40% ratio (400 cc. )

8

PROCESS START:

BEFORE PROCEEDING THR MIXING OPERATION PLEASE VERIFY:

a) PRESETTED MIXING TIME ( SECONDS ON EXTREME RIGHT SIDE OF THE LED DISPLAY )

To set the value that will be kept always in memory until an eventual change: push + or – ( TIMER )

ATTENTION: ONCE TIME HAS BEEN SETTED, IT WILL WORKS AUTOMATICALLY AND WHEN

MIXER WILL START UNTIL THE MIXING END. AT THE END OF MIXING, THE VALUE WILL COME BACK

TO THE ORIGINAL SETTED TIME FOR THE NEXT OPERATION.

AT THE END OF THE MIXING TIME ONE BUZZER WILL SOUND TO INFORM THE OPERATOR THAT THE

MIXTURE IS NOW READY FOR THE POURING STEP.

DURING THE MIXING PROCESS, IF EVENTUALLY THE MACHINE WILL BE STOPPED, THE TIMER

WILL START AGAIN FROM THE INITIAL PRESETTED TOTAL TIME.

b) BLADE ROTATION DIRECTION : ( LEFT TOP PART ARROW ON LED DISPLAY )

WE SUGGEST TO START MIXING ALWAYS FROM LEFT TO RIGHT SIDE.

BY PUSHING INV. MOT BUTTON IT IS POSSIBLE TO CHANGE THE BLADE DIRECTION

( AN OPTION THAT OCCASIONALLY COULD BE USEFUL ).

BY PUSHING + OR - UNDER MIX BUTTON LOCATION, IT IS POSSIBLE TO ADJUST THE BLADE

SPEED ROTATION.

ONCE CHECKED THE ABOVE PARAMETERS, CHECK IF THE VACUUM TAP (REF. 5) IS CLOSED.

BY HOLDING WITH ONE HAND THE TAP CLOSED ( REF. 7 ) START THE VACUUM PUMP

BY PUSHING VAC BUTTON AND RELEASE THE HAND FROM THE CAP ONCE THE VACUUM LEVEL

IS KEEPING IT WITH ENOUGH SUCTION. CHECK THE VALUE ON VACUUM GAUGE ( REF. 9 )

AND BE SURE THAT A GOOD VACUUM SITUATION IS BETWEEN - 60 AND – 76 ( DEPENDING OF

THE ALTITUDE FROM SEA LEVEL ).

MIXER USE: DELICATE AND PRECISE OPERATIONS

ONCE THE VACUUM LEVEL HAS BEEN REACHED

SWITCH OFF THE VACUUM PUMP !

ALWAYS OPERATES IN THIS PROCESS STEP UNDER VACUUM BUT WITH THE PUMP OFF

TO AVOID ECCESSIVE BUBBLING ON THE MIXTURE.

TO TRANSFER THE EXACT WATER QUANTITY FROM THE DOSING TANK

TO THE MIXING CONTAINER PROCEED AS FOLLOW:

JUST REMEMBERING THE DRY POWDER QUANTITY LOADED,

KEEP ONE FINGER TO THE EXACT CORRESPONDANT LEVEL LINE ON THE STICKER

OF THE WATER DOSING TANK IN ORDER TO AVOID MISTAKES AND LOAD TOO MUCH WATER

OR LESS WATER IN THE MIXING CONTAINER.

a) OPEN TAP ( REF. 6 ) AND CLOSE IT IMMEDIATELY AS WATER LEVEL LINE ON DOSING

TANK WILL LOWERED TO THE FINGER INDICATING THE CORRESPONDENT VALUE OF

THE POWDER PREVIOUSLY LOADED. ( REFER TO PAGE 7 )

b) Start mixing operation ( PUSH MIX BUTTON ) we suggest to start initially slow and

adjust speed according to the density condition of the mixture.

c) Keep the vacuum level on the vacuum meter controlled not lower than - 55 / -60

d) During mixing operation, check the flask correspondence to the pouring hole and

eventually adjust the flask position by pushing SX or DX where ROTAZIONE

PIATTO is written on control panel.

e) Blade speed and rotation could be adjusted without problems during the machine

functions.

9

WHEN MIXING END:

a) Open pouring valve ( REF. 8 ) and check the correct flask filling.

b) We suggest to switch on the VIB button to have a slight vibration during the mixture

pouring for a better flask filling. To adjust intensity push + or– where is VIB button on

the control panel.

c) After the first flask has been filled, close valve ( REF. 8 ) and turn the flask plate until

next flask will reach correct positioning. Open again the valve for the flask filling.

d) If the vacuum value on the vacuum meter gauge has not been lowered,

IT IS NOT NECESSARY TO START THE VACUUM PUMP AGAIN.

switch on the pump just if the vacuum gauge has gone below – 60

WHEN FLASK HAS BEEN TOTALLY FILLED:

a) Start the vibration process ( max 3 minutes ) by pushing VIB on the control panel.

b) Adjust the vibration intensity according to flask size and quantity.

c) Switch off the vibration

d) Release vacuum by opening vacuum tap ( REF. 5 ) until vacuum gauge will reach zero.

e)

FINAL OPERATIONS:

f) Leave flasks into the unit for the mixture hardening.

g) Remove the mixing chamber and the mixing blade and care to wash and rinse all their

parts, specially the bottom part of the mixing container where it is located the pouring

valve and its spring.

h) Dry the container and the blade before using them for a new operation

i) Clean the internal part of the top cover and cap especially where the blade shaft

connection.

j) take the flask plate completely off the machine.

k) This particular process phase is very delicate: be careful in the flask moving because

this is the most delicate moment for the accurate mould reproduction and copy during

the mixture hardening .That’s why we deliver with the unit a spare extra flask plate.

l) Load again water level into the dosing tank

m) The unit is now ready for another investment preparation process.

Table of contents

Other Cimo Mixer manuals