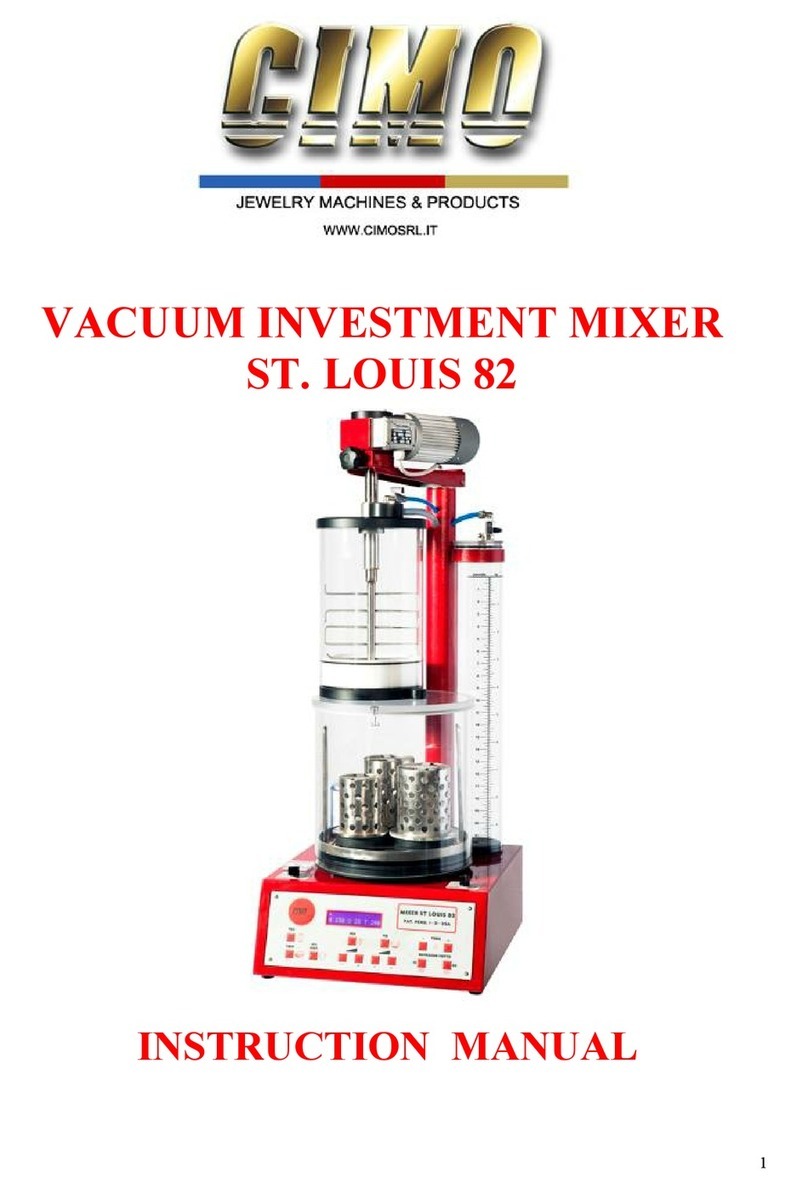

Cimo ST. LOUIS MINIMIX User manual

VACUUM INVESTMENT MIXER

ST. LOUIS MINIMIX

INSTRUCTION MANUAL

606 S Hill St, Suite 1103, Los Angeles, CA 90014 sales@romano-west.com | 310-909-7986 | romano-west.com 2

INDEX

CE CONFORMTY DECLARATION …………………………………………….………………………... 3

INTRODUCTION……………………………………………………………………………………………...4

WARRANTY………………………………………...…………………………………………………………4

GENERAL NOTES………………………………………...…………………………………………………..4

MACHINE FEATURES ………………………………………………………………………………………4

OPERATOR SAFETY…………………………………………………………………………………………4

TRANSPORT ………………………………………………………………………………………….………4

TECHNICAL DATA………………………………………………………………………………………..…5

VACUUM PUMP CONNECTION……………………………………………………………………………5

PRELIMINARY OPERATION……………………………………………………………………………….5

WATER DOSING TANK AND GRADUATE STICKER SPECIFICATIONS……………………....……5

MIXER USE ( PART 1 )………………………………………….…………………………………………….6

CONTROL PANEL…………………………………………………………………………………………….6

PARAMETER SETTING…………………………………………………………………………...…………7

MIXER USE ( PART 2 )………………………………………….…………………………………………….8

UNIT DRAWING & PARTS LIST…………………………………………………………….……….. 9 - 10

606 S Hill St, Suite 1103, Los Angeles, CA 90014 sales@romano-west.com | 310-909-7986 | romano-west.com 3

INTRODUCTION

These notes are provided to our Customer in order to offer the informations necessary for the correct installation ,

operation use and maintenance of the unit purchased. Only technical staff, previously authorized by the Producer,

will guarantee a correct service of the machine and its components.

Any modication or repair made without prior CIMO authorization and agreement, will immediately cancel warrenty

conditions and this circumstance will save the producer from any kind of responsibility forward any person and things

suffering damages that might occur. Please carefully read the instructions notes before operating the machine.

CIMO is reserving the right to modify its products without previous notice.

WARRANTY

CIMO PRODUCTS ARE COVERED BY TWELVE MONTHS WARRANTY

STARTING FROM THE DELIVERY DATE TO CUSTOMER

EXCEPT ELECTRIC AND ELECTRONIC COMPONENTS THAT ARE COVERED SIX MONTHS ONLY.

WARRANTY IS LIMITED TO REPAIR OR CHANGE OF THE FAULT PARTS

UPON A PREVIOUS AUTHORIZATION AND INSPECTION BY OUR STAFF OR CIMO DELEGATE.

LABOUR, TRANSPORT, CUSTOMS AND OTHER COSTS WILL BE AT TOTAL CUSTOMER CHARGE.

THE TOTAL CHANGE OF THE COMPLETE MACHINE IS ALWAYS TO BE ESCLUDED FROM WARRANTY

CONDITIONS. PARTS REPAIRED OR CHANGED WILL NOT EXTEND THE WARRANTY PERIOD.

GENERAL NOTES

St. Louis vacuum mixers are machines studied and designed for the investment mixing and flask mold filling for the

lost wax casting of the jewelry making process. The main concept of the St.Louis mixing units is the total operativity

under vacuum situation.

Traditionally investment was mixed with water in open air and with this process the final blend result was not really

homogeneous and precise so the surface of the precious metal casted was not so smooth and complete.

More, the large quantity of gases incorporated in the mixing was giving such a huge percentage of porosity.

St.Louis mixer, with the vacuum total process and the timing, quantity and water dosing very precise, assures

the best quality performing results in one of the most delicate process-step by step of the lost wax casting system.

THE MACHINE FEATURES

- TOTAL INVESTMENT POWDER DEGASIFICATION INTO THE MIXING CONTAINER

- EXACT AND PRECISE WATER QUANTITY IN THE RATIO 1:40 TO BE ADDED TO POWDER

- ADJUSTABLE MIXING SPEED

- CORRECT AND PRESETTED MIXING TIMING

- ADJUSTABLE INTENSITY VIBRATION FOR THE INVESTED FLASKS

OPERATOR SAFETY

PROTECTION MASK FOR OPERATOR IS COMPULSORY REQUESTED

PROTECTION HAND GLOVES FOR OPERATOR ARE SUGGESTED

THIS UNIT MUST BE OPERATED BY PROFESSIONAL STAFF

AND FOR ITS CONCEPT PURPOSE BUILT ONLY !

TRANSPORT

THE MACHINE SHOULD BE ALWAYS TRANSPORTED IN VERTICAL POSITION

AND HAS TO BE LIFTED FROM THE BOTTOM CHASSIS BASEMENT ONLY.

ATTENTION

PLEASE AVOID TO HOLD, LIFT OR PULLING AND PUSHING THE MACHINE FROM ITS CENTRAL

CONSTRUCTION PART ( PLEXIGLASS MIXING BOWL, FLASK CHAMBER OR MAIN MOTOR SHAFT)

606 S Hill St, Suite 1103, Los Angeles, CA 90014 sales@romano-west.com | 310-909-7986 | romano-west.com 4

TECHNICAL DATA

VOLTAGE: 220 V. - 50/60 HZ. SINGLEPHASE – CONSUMPTION: KW. 0, 8 PROTECTION FUSE: 4 AMP.

MAX INVESTMENT CAPACITY : GRAMS 800 - MAX FLASK SIZE: DIAMETER 100 mm. X 120 mm. HIGHT

VACUUM PUMP CONNECTION

THE MIXER MUST OPERATES WITH A VACUUM PUMP OF MINIMUM CAPACITY 6 CBM/HOUR.

THE VACUUM PUMP IS SUPPLIED SEPARATELY AS OPTIONAL ACCESSORY.

ON THE REAR PART OF THE MACHINE BASE FIND THE VACUUM PIPE HOSE CONNECTOR.

VACUUM PUMP MUST BE CONNECTED DIRECTLY TO A SEPARATE 220 VOLTS PLUG.

PRELIMINARY OPERATIONS

Connect the vacuum hose from the rear part of the machine to an external vacuum pump (6 cbm/h.).

WHENEVER THE UNIT IS SUPPLIED WITH OUR VACUUM PUMP,

REMIND TO FILL THE PUMP OIL TANK WITH ITS SPECIFIC OIL

BEFORE SWITCHING ON THE PUMP MOTOR.

Connect the unit to an electrical plug that must have ground.

Fill the open dosing tank ( located on the right part of the motor column of the unit )

with clean water ( temperature between 20° and 24° C. ) correctly to the top level line

of the sticker indicating the water proportion quantity. ( ratio: 1 kg. powder = 400 cc. water )

606 S Hill St, Suite 1103, Los Angeles, CA 90014 sales@romano-west.com | 310-909-7986 | romano-west.com 5

WATER DOSING TANK AND STICKER SPECIFICATIONS:

The sticker on the dosing water tank is indicating kg. and pounds with numbers from 0 to 2 ( kg. )

IT IS PRINTED CONSIDERING THE STANDARD RATIO: 1 KG. DRY INVESTMENT

POWDER = 400 CC. WATER

THE STICKER LINES AND NUMBERS ARE INDICATING THE DRY POWDER GRAMS ( or

POUNDS )

FROM TOP LINE WATER LEVEL ( under KG printed ) THE QUANTITY OF WATER

CORRESPONDING TO EACH KILOGRAM IS 400 CC.

Practical example:

IF WE HAVE LOADED kg. ,700 INVESTMENT DRY POWDER INTO THE MIXING

CONTAINER, WE HAVE TO TRANSFER INTO THE MIXING CONTAINER A QUANTITY

OF WATER AS MUCH AS WE SEE MARKED ON THE LEVEL LINE VALUE KG 1,7 ON

THE DOSING COLUMN STICKER IN ORDER TO HAVE THE EXACT 40% PROPORTION

OF WATER

FOR THE INVESTMENT LOADED IN THE MIXING CONTAINER.

Please be informed that the STICKER shows just 40% RATIO IN THE RIGHT SIDE and

38% RATIO IN THE LEFT SIDE

Attention: in presence of special Platinum Investment powder sometimes the requirement is

to add a different water percentage. We supply with PT version sticker with 30 % ratio.

ATTENTION: in the water dosing tank is possible to put water and binder together, for PT

investment that need. But is important when job is finish put only water inside the water

dosing tank and using the vacuum transfer the water to mixing chamber to clean the water

piping from the acid of the binder.

----- MAX

WATER LEVEL

←

ARROW INDICATING

INVESTMENT

LOADED: KG. 0,7

606 S Hill St, Suite 1103, Los Angeles, CA 90014 sales@romano-west.com | 310-909-7986 | romano-west.com 6

MIXER USE ( part one ):

FRONT CONTROL PANEL

VIB vibration control

MIXER mixing control

1

2

3

4

5

6

7

A SELF AUTOMATIC SWITCH-OFF HAS BEEN INSTALLED IN THE MACHINE

Whenever the unit will remain for more than one minute without operation it will switch off automatically

Lift up the top motor ( 1) located on the unit column and turn it

to the right side of the mixer.

DISCONNECT THE FAST JOINTER ( REF. 5 )

Remove the top black cover with the mixing blade from the clear

mixing chamber ( 2 )

Place the flask (with wax tree on its rubber base) on the central

part of the lower black plate base ( 3 ) of the MIXER.

Load the investment powder (after its weighting ) into the mixing

chamber . Check that the pouring valve ( 4 ) of mixing chamber

is logically closed .

BE SURE THAT THE MIXING CHAMBER IS DRY

Replace the mixing chamber on its original location and insert

the mixing blade on it. Place the top cover on it and connect pipe

for tap ( ref 5 ). Be sure that vacuum release valve (6) is closed.

REPLACE THE TOP MOTOR ON ITS POSITION

( shaft into the blade-gear )

1

2

3

4

5

6

1 vacuum gauge

2 increase value

3 decrease value

4 on – off mixing motor

5 motor speed

6 on – off vibrator

7 vibrator intensity

606 S Hill St, Suite 1103, Los Angeles, CA 90014 sales@romano-west.com | 310-909-7986 | romano-west.com 7

PARAMETER SETTING:

WHEN SWITCHING ON THE MACHINE, THE DISPLAY SHOWS THE MIXING TIME PRESETTED:

Example: 4.5 means 4 minutes and 30 seconds / 3.0 means 3 minutes zero seconds.

To modify the mixing time ( operation possible only when mixing motor is OFF )

increase or decrease time by pushing “ 2 “ or “ 3 “ button.

The value is automatically memorized.

MIXING MOTOR SPEED:

This value has been pre settled already by CIMO srl.

To set a different mixing motor speed ( operation possible when mixing motor is ON or OFF ):

a) push button “5” until led is ashing

b) increase or decrease motor speed by pushing “2” or “3”

c) after 5 seconds from the last pushing on 2 or 3 the setting procedure is over.

d) WHEN SWITCHING OFF THE MACHINE the parameter will go back again to the initial

CIMO value.

VIBRATION INTENSITY:

To set the vibration intensity ( operation possible when vibration is ON or OFF ):

a) push button “7” until led is ashing

b) increase or decrease vibration intensity by pushing “2” or “3”

c) after 5 seconds from the last pushing on 2 or 3 the setting procedure is over.

d) WHEN SWITCHING OFF THE MACHINE the parameter will go back again to the initial

CIMO value.

LEAVE THE FLASK SOME MINUTES TO DRY ON THE FLASK PLATE

MEANWHILE THE OPERATOR IS WASHING AND RINSING THE BLADE AND THE

MIXING CONTAINER.

DRY ALL BEFORE A NEW OPERATION.

ALARMS ON DISPLAY

A 1 : ELECTRICAL SHORT – CONTROL BOARD DAMAGED

A 2 : MIXING MOTOR OVERHEATING

A 3 : MIXING MOTOR MECHANICAL FAULT ( too much powder loaded )

( internal blade bearing dirty )

( mixture too much dry )

A 4 : LOW TENSION AT THE UNIT

To reset the alarms: switch off and switch on the unit

606 S Hill St, Suite 1103, Los Angeles, CA 90014 sales@romano-west.com | 310-909-7986 | romano-west.com 8

MIXER USE ( second part )

ONCE THE INVESTMENT POWDER HAS BEEN LOADED INTO

THE TOP PART OF THE MIXING CHAMBER (A ) AND ALL THE

MACHINE COMPONENTS HAVE BEEN PLACED IN THEIR

ORIGINAL POSITION,

CHECK THE TIME SETTED ON THE DISPLAY

( WE SUGGEST 4 MINUTES: 4. 0 )

START THE VACUUM PUMP MOTOR ( SEPARATE SWITCH

EXTERNAL FROM THE UNIT ) AND LEAVE THE VACUUM

PUMP RUNNING UNTIL THE VACUUM LEVEL GAUGE IS

REACHING THE VACUUM CONDITION.

( MINIMUM VALUE OF “ 60 ” ) THEN, SWITCH OFF THE PUMP.

OPEN THE TOP WATER TAP (B) AND WATER WILL FLOW

DIRECTLY INTO THE MIXING CHAMBER.

CLOSE IMMEDIATELY THE TAP WHEN THE WATER LEVEL

OF THE DOSING TANK WILL REACH THE CORRESPONDENT

LINE OF THE INVESTMENT QUANTITY LOADED.

( AS FOR INSTRUCTIONS ON PREVIOUS PAGE ).

START THE MIXING BY PUSHING BUTTON “4”

WHEN THE MIXING TIME PRESETTED WILL BE ZERO,

THE MOTOR OF THE MIXING BLADE WILL STOP AND

A BUZZER WILL SOUND TO WARN THE OPERATOR FOR THE

IMMEDIATE POURING OF THE MIXTURE INTO THE FLASK.

OPEN THE SIDE POURING VALVE KNOB (E)

( PULL TOWARD EXTERIOR) IN ORDER TO FILL THE FLASK

WITH THE MIXTURE.

CLOSE THE VALVE ( E ) WHEN FLASK IS TOTALLY FILLED

START VIBRATION BY PUSHING BUTTON “ 6 ”

AND KEEP THE VIBRATION INTENSITY SMOOTH

FOR A COUPLE OF MINUTES.

STOP THE VIBRATION AND RELEASE VACUUM BY OPENING

THE TOP ROUND SMALL VALVE OVER THE TOP COVER OF

THE UNIT (F)

PLEASE CONSIDER THAT ALL THE PROCESS IS DONE UNDER

VACUUM SO DO NOT EXPECT TO SEE “BOILING-BUBBLING”

FROM THE INVESTED FLASK. IN ORDER TO GET AN EXACT

VIBRATION INTENSITY PLACE YOUR HAND ON TOP MIXER

COVER TO PRACTICALLY FEEL THE VIBRATION INTENSITY.

AT THE END OF THE OPERATIONS PLEASE NOTE THAT IT IS

BETTER TO LEAVE THE FLASK ON THE FLASK PLATE

OF THE MIXER AND QUICKLY WASH AND RINSE PROPERLY

THE MIXING CHAMBER ( CARE TO CLEAN THE INTERNAL

PART OF THE POURING VALVE, THE BLADE SHAFT AND

THE INTERNAL PART OF THE TOP COVER )

A

B

E

F

606 S Hill St, Suite 1103, Los Angeles, CA 90014 sales@romano-west.com | 310-909-7986 | romano-west.com 9

ELETTRONIC

BOARD

N. CODE N. CODE N

1 92LT2A 21 MIX92LT2A21 42 MIX92LT2A42

2 92LT2A 22 MIX92LT2A22 43 MIX92LT2A43

3 92LT2A 23 MIX92LT2A23 44 MIX92LT2A44

4 MIX92LT2A4 24 MIX92LT2A24 45 MIX92LT2A45

5 MIX92LT2A5 25 MIX92LT2A25 46 MIX92LT2A46

6 MIX92LT2A6 26 MIX92LT2A26 47 MIX92LT2A47

7 MIX92LT2A7 27 MIX92LT2A27 53 MIX92LT2A53

8 MIX92LT2A8 28 MIX92LT2A28 59 MIX92LT2A59

9 MIX92LT2A9 29 MIX92LT2A29 60 MIX92LT2A60

10 MIX92LT2A10 30 MIX92LT2A30 61 MIX92LT2A61

11 MIX92LT2A11 31 MIX92LT2A31 62 MIX92LT2A62

12 MIX92LT2A12 32 MIX92LT2A32 63 MIX92LT2A63

13 MIX92LT2A13 33 MIX92LT2A33

14 MIX92LT2A14 34 MIX92LT2A34

15 MIX92LT2A15 35 MIX92LT2A35

16 MIX92LT2A16 36 MIX92LT2A36

17 MIX92LT2A17 37 MIX92LT2A37

17 MIX92LT2A17 38 MIX92LT2A38

18 MIX92LT2A18 39 MIX92LT2A39

19 MIX92LT2A19 40 MIX92LT2A40

20 MIX92LT2A20 41 MIX92LT2A41

606 S Hill St, Suite 1103, Los Angeles, CA 90014 sales@romano-west.com | 310-909-7986 | romano-west.com 10

N. CODE N. CODE

1 MIX92LT2B1 23 MIX92LT2B23

2 MIX92LT2B2 24 MIX92LT2B24

3 MIX92LT2B3 25 MIX92LT2B25

4 MIX92LT2B4 26 MIX92LT2B26

5 MIX92LT2B5 27 MIX92LT2B27

6 MIX92LT2B6 28 MIX92LT2B28

7 MIX92LT2B7 30 MIX92LT2B30

8 MIX92LT2B8 31 MIX92LT2B31

9 MIX92LT2B9 32 MIX92LT2B32

10 MIX92LT2B10 33 MIX92LT2B33

11 MIX92LT2B11 34 MIX92LT2B34

12 MIX92LT2B12 35 MIX92LT2B35

13 MIX92LT2B13 36 MIX92LT2B36

14 MIX92LT2B14 37 MIX92LT2B37

15 MIX92LT2B15 38 MIX92LT2B38

16 MIX92LT2B16 40 MIX92LT2B40

17 MIX92LT2B17 41 MIX92LT2B41

18 MIX92LT2B18 42 MIX92LT2B42

19 MIX92LT2B19 43 MIX92LT2B43

20 MIX92LT2B20 44 MIX92LT2B44

21 MIX92LT2B21 45 MIX92LT2B45

22 MIX92LT2B22 46 MIX92LT2B46

Table of contents

Other Cimo Mixer manuals