City Theatrical AUTOYOKE User manual

TABLE OF CONTENTS

SECTION 1 SPECIFICATIONS

1-1 Dimensions and Weight

1-2 Compliance

1-3 Electrical

1-4 Protocol

1-5 Motors

SECTION 2 SAFETY

SECTION 3INSTALLATION AND SET-UP

3-1 Unpack and inspect the shipping container

3-2 Placing a lighting fixture in the AutoYoke

3-3 Installing the fixture power connector on the AutoYoke

3-4 Attaching a scroller

3-5 Inserting the DMX Iris

3-6 AutoFocus

3-7 Changing Lens Tubes

3-8 Securing the counterweight system

3-8 Hanging the AutoYoke

3-9 Power cable

3-10 Data cable

SECTION 4USER INTERFACE

4-1 Menu system

4-2 Address

4-3 Calibrate

4-3a Calibrate All

4-3b Calibrate a single attribute

4-3c AutoCalibrate

4-4 Invert

4-5 Resolution

4-5a 8 bit or 16 bit

4-5b DMX Smoothing values

4-6 Pan, Tilt, Iris and Focus Limits

4-7 Software release

4-8 LED Display

4-8a Timeout

4-8b Brightness

4-9 Restore factory defaults

4-10 Error messages

p. 1

p. 2

p. 2

p. 2

p. 2

p. 3

p. 4

p. 5 - 9

p. 9

p. 10

p. 11

p. 12

p. 13

p. 14

p. 15

p. 15

p. 15

p. 16

p. 17

p. 18

p. 18

p. 19

p. 19 - 20

p. 20 - 21

p. 21

p. 22

p. 22

p. 23 - 24

p. 25

p. 25

p. 26

p. 26

p. 26

p. 27

SECTION 5OPERATION

5-1 DMX channel assignments

5-2 Pan and Tilt

5-3 Default setting

5-4 Personality settings

5-5 Control channel

5-6 Encoders

SECTION 6BEAM SIZE AND COLOR CONTROL

DMXIris

AutoFocus

Scrollers

SECTION 7MAINTENANCE

Software revisions

Spare parts

Lighting fixture

SECTION 8 WARRANTY

Limited Warranty

Procedure

p. 28

p. 28

p. 29

p. 29

p. 30

p. 30

p. 31

p. 31

p. 31

p. 32

p. 32

p. 32

p. 32

p. 32

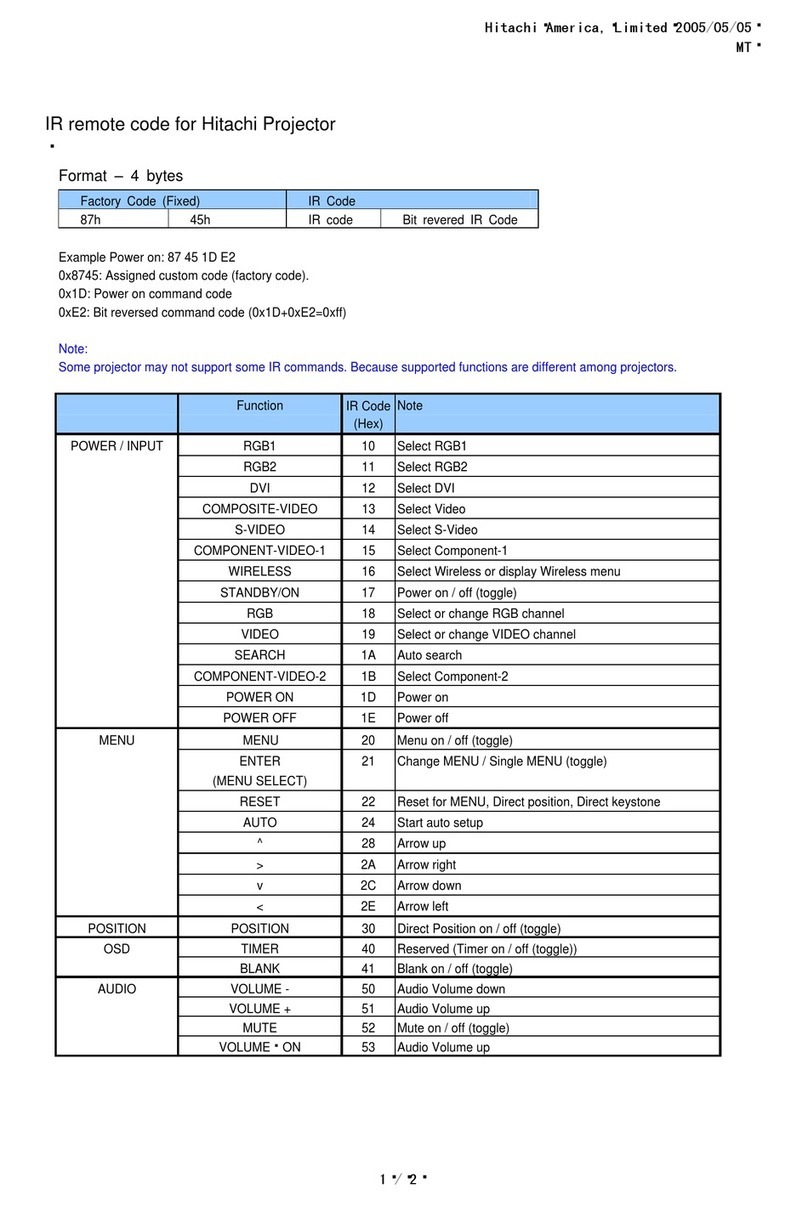

SECTION 1: SPECIFICATIONS

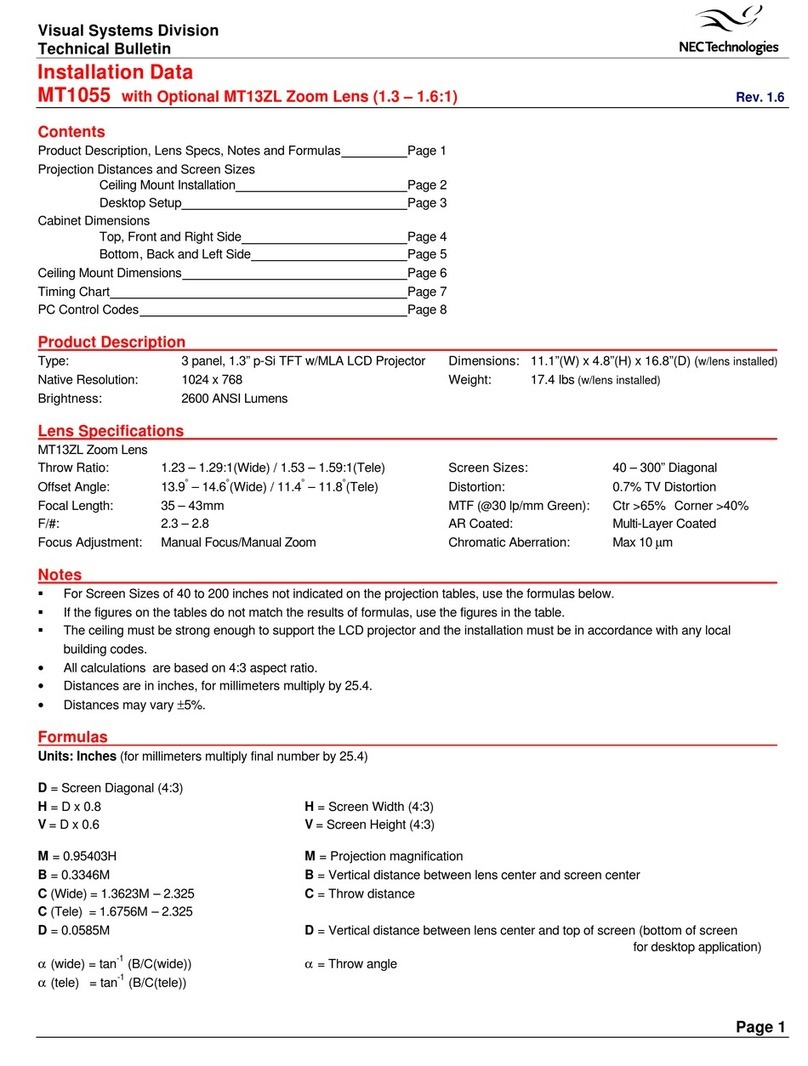

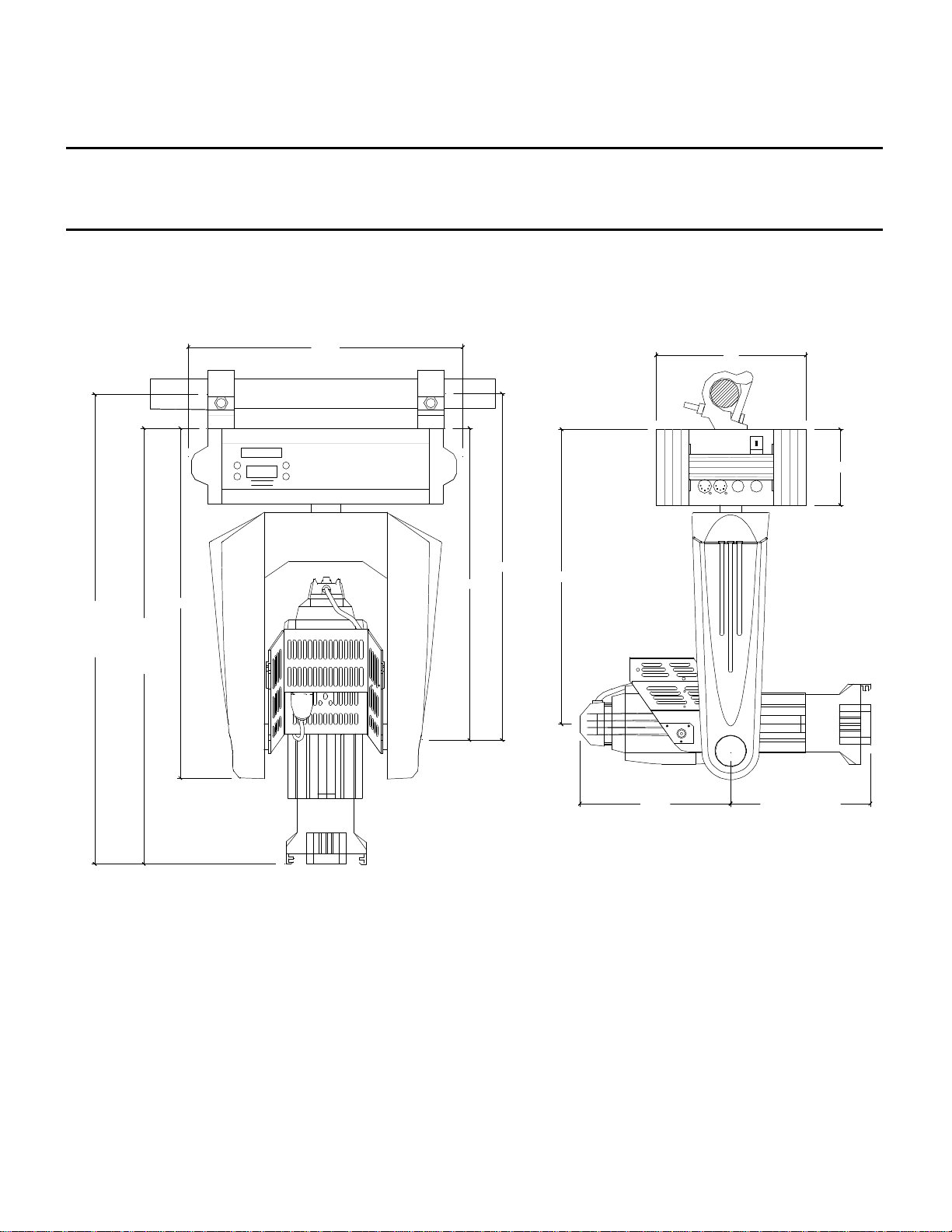

1-1DIMENSIONS & WEIGHT

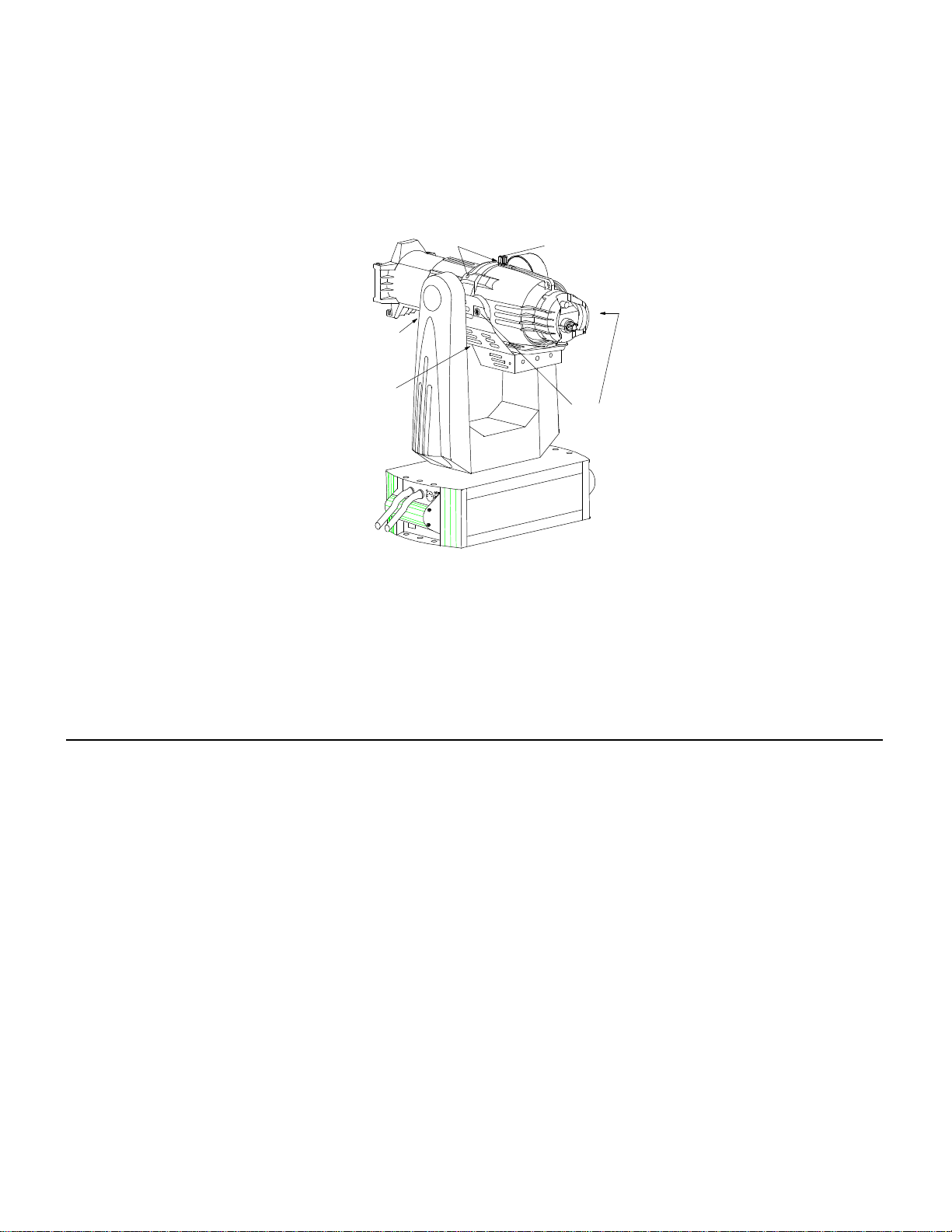

AutoYoke weight: 26 lbs (11.7 kg)

Total weight ofAutoYoke with Source Four:40 lbs (18 kg)

-1-

***Note: AutoYoke is shown with ETC Source Four and Light Source “Mega Claw” clamps

s

t

Menu

Enter

AUTOYOKE

CITY

THEATRICAL

I N C

10"

5-3/8"

9-1/8" Lens tube in

11-1/4" Lens tube out

10-1/2"

21-1/2"

20-7/8"

22"

25"

24-1/8"

29-1/4"

Lens tube in

31-3/8"

Lens tube out

32-1/4"

Lens tube in

34-3/8"

Lens tube out

1-2COMPLIANCE

Conforms to UL STD 73, Eighth Edition - Motor Operated Appliances.

Certified to CAN/CSA C22.2 NO.: 68.92

ETL# 9801635

CETL# 9801635

CE, GS,

1-3ELECTRICAL

· Working voltage: 100-240 VAC, 50/60 Hz

· Rated current: 1.3A

1-4PROTOCOL

· USITT DMX512

· Start code: (00h)

· Maximum load: 32 fixtures per DMX link (See Section 3-9, Data Cable)

· Maximum length of DMX link: 2000'(See Section 3-9, Data Cable)

· Required control channels: 7 (16-bit) or 5 (8-bit)(See Section 3-9, Data Cable)

· Termination: 120Ω(See Section 3-9, Data Cable)

1-5MOTORS

· High torque stepper motor, half stack

· Rated voltage DC: 8.7

· Step angle (degrees): 1.8

-2-

SECTION 2: SAFETY

· A moving light is a dangerous piece of equipment. It is for professional use only.

· If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly

qualified person in order to avoid a hazard.

· Follow all safety procedures that apply to the lighting fixture, per its manufacturer’s instructions.

1. Refer to the lighting fixture’s user manual for all applicable safety information.

2. Maintain minimum safe distances.

· The AutoYoke is designed for use only with the ETCSource Four 5°, 10°, 19°, 26°, 36° or 50°

Using a fixture other than the ETC Source Four 5°, 10°,19°, 26°, 36° or 50° WILL VOID THE

AUTOYOKE WARRANTY.

· Always ground (earth) the AutoYoke electrically.

· Balance of the lighting fixture as mounted in the AutoYoke is critical to proper operation of the AutoYoke.

Attempting to operate the AutoYoke while the lighting fixture is out of balance presents a significant risk

of inaccuracy, increased motor noise and component failure. See Section 3-7, Securing the

Counterweight System, for complete information.

· Never lift the AutoYoke by the lighting fixture. Always lift and carry the AutoYoke by its two

handles, located on the sides of the power supply.

· Always suspend the AutoYoke from approved clamps secured to the designated points on the AutoYoke

power supply. See Section 3-8, Hanging the AutoYoke, for further information.

· Always use an approved safety cable when hanging the AutoYoke.

· Always disconnect the AutoYoke from AC power before service.

· Do not use DMX accessories that are not cited in this manual due to possible electrical incompatibility

with the AutoYoke.

· Do not allow the AutoYoke or its accessories to come into contact with moisture.

· Do not put flammable materials on or near the AutoYoke.

-3-

SECTION 3: INSTALLATION AND SET-UP

WARNING:Using a fixture other than the ETC Source Four 5°,10°,19°, 26°, 36° or 50°

with the AutoYoke WILL VOID THE AUTOYOKE WARRANTY.

Additional hazards include the following:

· Damaging both the AutoYoke and the lighting fixture

· Fixture detaching from the AutoYoke

· Fire hazard

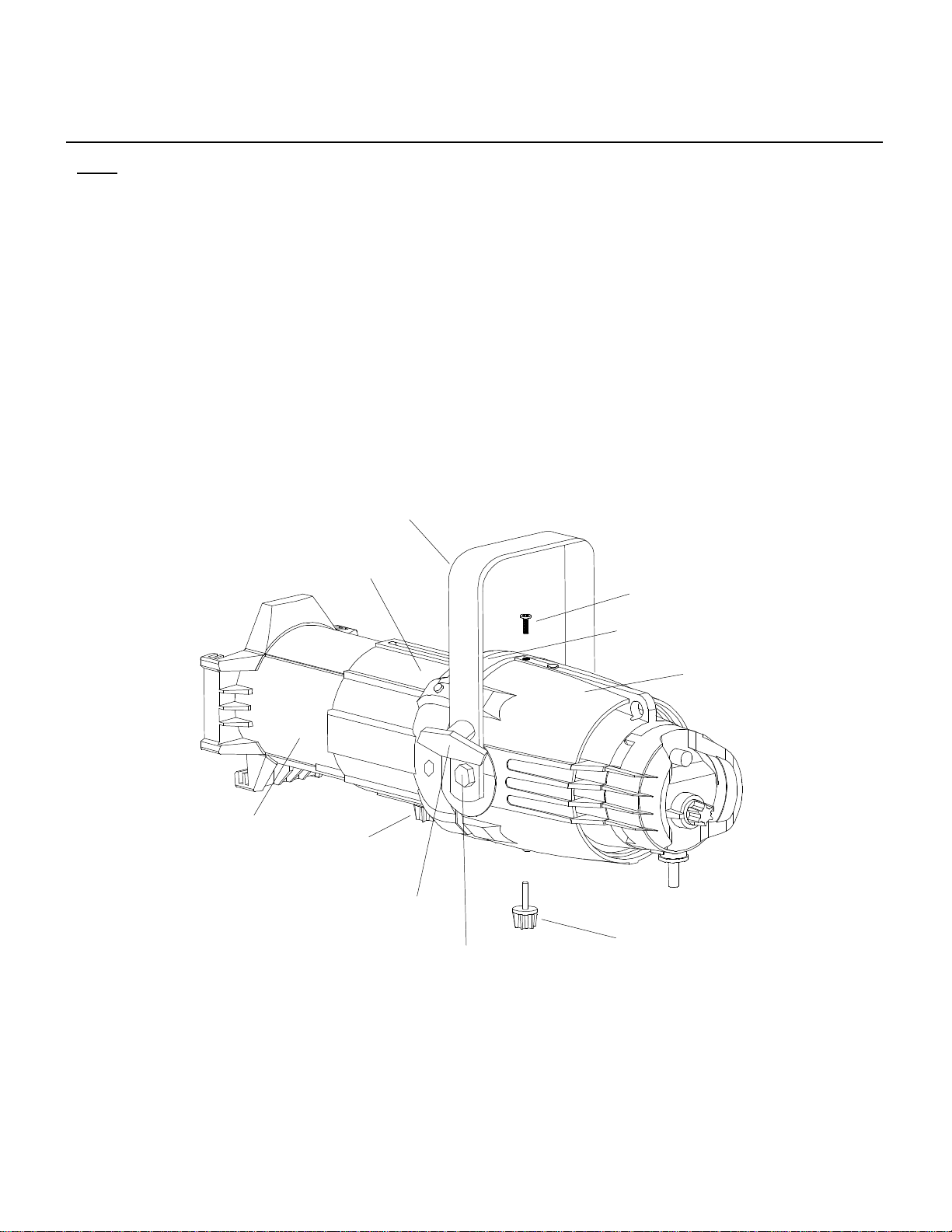

3-1UNPACK AND INSPECT THE SHIPPING CONTAINER

Verify that the AutoYoke has arrived complete and undamaged. The shipping container will contain the

following items:

· (1) AutoYoke w/ User’s Manual

· (1) counterweight halo

· (10) counterweight rings [8 lead, 2 steel]

· (2) lighting fixture mounting screws [5/16 - 18 x 1/2” flanged button head screws]

· (2) Counterweight halo mounting screws [1/4 - 20 - 3/4” socket head cap screws]

· (3) Counterweight ring mounting screws [1/4 - 20 - 1” socket head cap screws]

· (3) Counterweight ring mounting screws [1/4 - 20 - 2” socket head cap screws]

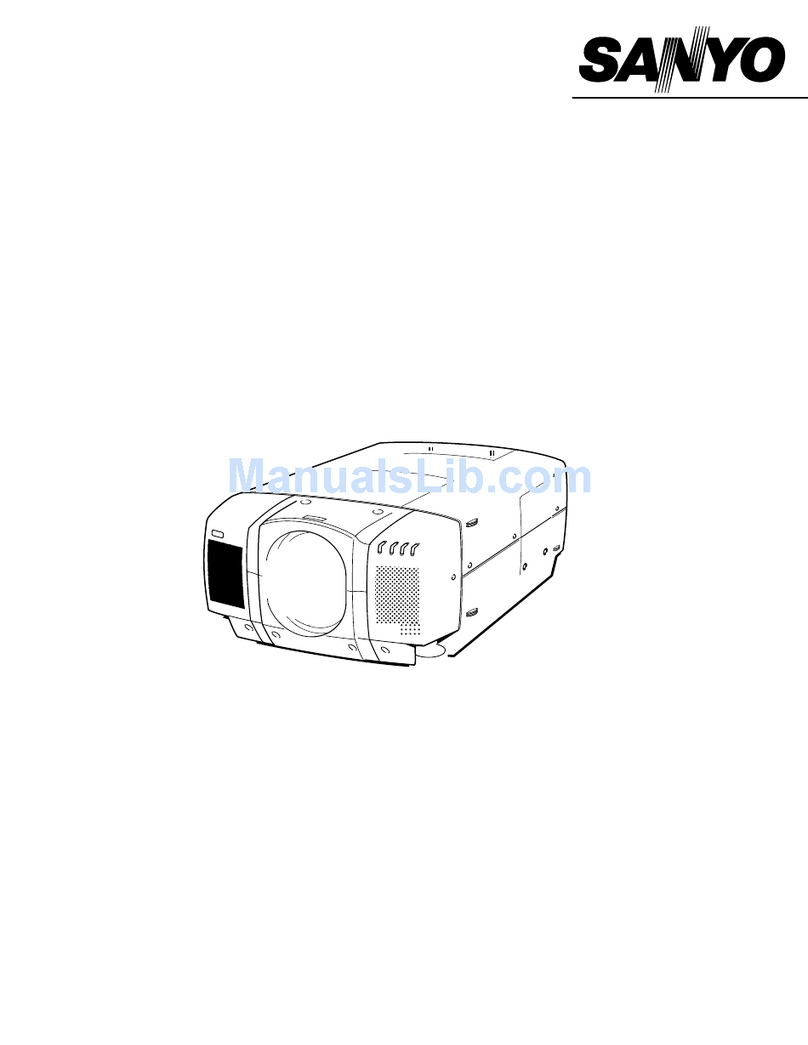

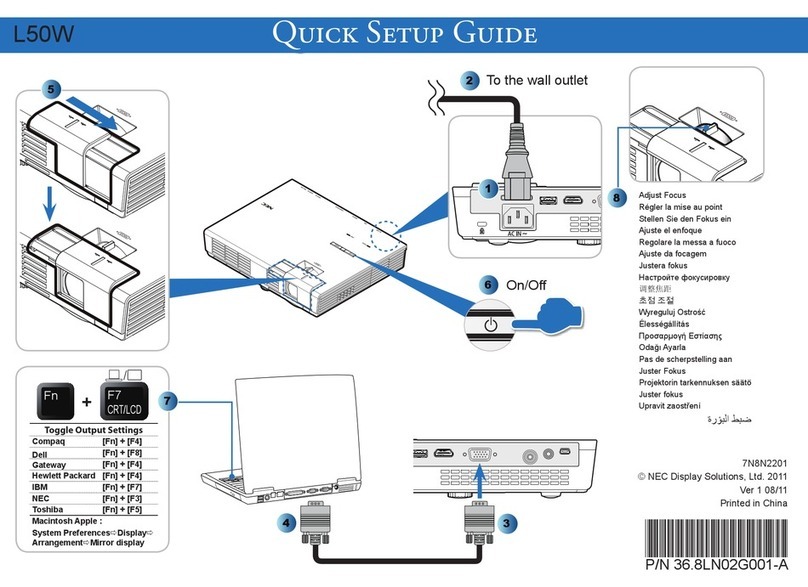

CITY

THEATRICAL

I N C

s

A U T O Y O K E

t

Enter

Menu

Lumen

-4-

Source Four

cradle

connector box

counterweight halo

yoke

control panel

handle

power supply

3-2PLACING A LIGHTING FIXTURE IN THE AUTOYOKE

*NOTE: SOURCE FOUR FIXTURES THAT WERE MANUFACTURED BEFORE JULY 1995 DO NOT HAVE A

THREADED HOLE FOR THE “RETAINER BOLT” AS IN EXAMPLE 1 BELOW. THEY ONLY HAVE A

“BARREL ROTATION KNOB”, INSTALLATION OF THESE UNITS WILL REQUIRE MODIFICATION FOR

PROPER MOUNTING TO THE AUTOYOKE. CONTACT CITY THEATRICAL, INC. FOR A MODIFICATION KIT.

1. Remove all accessories from the lighting fixture (scroller, gel frame, top hat, etc.)

2. On the lighting fixture, remove the yoke by removing the yoke locking knob and the two hex bolts that

are on either side of the lighting fixture.

-5-

yoke

hex bolt

yoke locking knob

beam focus knob

lens tube

front barrel assembly

barrel rotation knob

reflector housing assembly

iris slot

retainer bolt

EXAMPLE 1

3.Remove the Source Four shutters with the following instructions:

a. Remove the lens tube from the front barrel assembly by

removing the beam focus knob.

b.Untwist and remove the Source Four front barrel

assembly from the reflector housing assembly by loosening

the barrel rotation knob and removing the retainer bolt.

c.Lay the front barrel assembly on its side, with the iris slot

pointing up.

d.Remove the four pan head 8-32 x 3/4” screws and 8-32

Ny-lok nuts that fasten the top and bottom barrel casting.

Remove the four shutter springs. Always wear protective

eyewear during this procedure, as the springs may pop

out of place.

e.Separate the top and bottom barrel casting, and remove the

four shutter blades. Keep the three divider plates in the

same position relative to each other and the SourceFour

(refer to Source Four user manual for further details).

f.Rejoin the top and bottom barrel casting. Starting at the

holes closest to the shutters, use the four pan head screws

and Ny-lok nuts to fasten the front barrel casting halves

together. Hold the Ny-lok nuts tight against the casting while

tightening the screws. Torque the screws to 25 inch/pounds

[From Source Four Parts and Assembly Instructions

published by ETC].

g.Insert the four shutter springs between the four dimples in

the shutter plate and the tabs in the lip of the casting.

Always wear protective eyewear during this procedure, as

the springs may pop out of place [From Source Four Parts

and Assembly Instructionspublished by ETC].

h.Twist and re-insert the front barrel assembly into the

reflector housing assembly, and fasten by inserting the

barrel rotation knob into the hole from which you previously

removed the retainer bolt (Example 2). Do not re-insert

the retainer bolt at this time. It will be used shortly.

i. Re-insert the lens tube into the front barrel assembly, and

fasten by tightening the beam focus knob.

-6-

4. Tighten the barrel rotation knob into the hole from which you previously removed the retainer bolt. The

barrel rotation knob should now be on the same side as the iris slot. (Example 2)

5. With its iris slot on top, rest the lens tube of the lighting fixture inside the cradle of the AutoYoke. The

lighting fixture’s cable with the stage pin connector should lie between the cradle and the lighting fixture

(NOT directly beneath the lighting fixture), on the same side of the cradle as the female stage pin

connector on the connector box.

6. Using a flat head screwdriver for leverage between the

lighting fixture and the AutoYoke cradle, GENTLYmaneuver

the lighting fixture into the cradle. When the lighting fixture

is in the correct position, the holes on the sides of the

lighting fixture from which you removed the hex bolts will

line up with the matching holes on the cradle.(Example 3)

***Note: If the lighting fixture will be permanently installed

in the AutoYoke, City Theatrical Inc. suggests

cutting the lighting fixture cable to 22” to eliminate

interference with the movement of the fixture in the yoke.

***Note: The lighting fixture must have a three pin stage

connector to plug directly into the AutoYoke.

New position of

barrel rotation knob

Old position of

barrel rotation knob

-7-

EXAMPLE 2

Slide lighting

fixture in from

rear of cradle.

screwdriver

These holes must

match up.

EXAMPLE 3

7. Secure the lighting fixture into the cradle with the (2) 5/16 - 18 x 1/2” flanged button head screws

provided (Example 4).

8. Rotate the lighting fixture and cradle 90 degrees so you have access to the bottom of the cradle.

Use the retainer bolt that you originally removed to secure the lighting fixture into the bottom of the

cradle through the hole in the cradle (Example 5)

CITY

THEATRICAL

INC

s

AUTO YO KE

t

Enter

Menu

-8-

EXAMPLE 4

EXAMPLE 5

9.TIGHTEN ALL HARDWARE.Tighten the side hex screws, the bottom retaining bolt, iris slot cover

screws and both the beam focus knob and the barrel rotation knob. This step is of the utmost

importance. IF THE HARDWARE IS NOT TIGHT, YOU RISK INACCURACY, NOISE, AND THE

POSSIBILITY OF THE LIGHTING FIXTURE DETACHING FROM THE AUTOYOKE. (Example 6)

10.Plug the lighting fixture cable with the male stage pin connector into the female stage pin connector

on the cradle connector box.

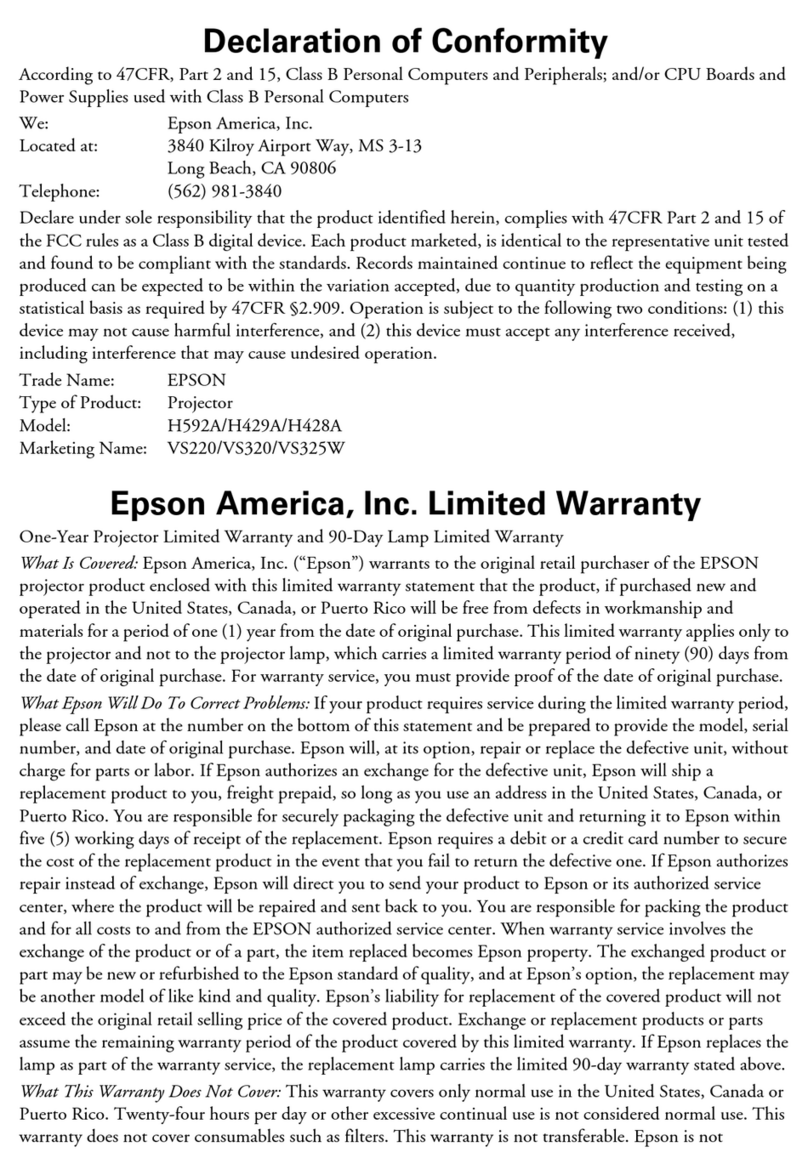

3-3INSTALLING THE LIGHTINGFIXTURE POWERCONNECTOR ON THE AUTOYOKE

When AutoYoke is ordered without a lighting fixture power connector (standard factory configuration is

three pin stage connector), use the following instructions to install the connector:

1.Strip cable jacket back 1 - 1/4”.

2. Strip 1/2” of insulation from end of each connector.

3.Attach conductors to pins per connector manufacturers instructions. The body of the connector

should be marked with a “N”, “G”, and “H”. This corresponds to:

N:Neutral(white wire)

G:Ground(green wire)

H:Hot(black wire)

Wire pins in the following order: “N” first, “G” second, “H” third.

-9-

barrel rotation knob

iris slot cover screws

lighting fixture mounting screws

retainer bolt

beam focus knob

EXAMPLE 6

3-4ATTACHING A SCROLLER

A color scroller is an optional accessory, and is not supplied by City Theatrical Inc. See

Section 6 for further information.

THE AUTOYOKE SUPPORTS THE WYBRON FORERUNNER, WYBRON CXI (See cable note below),

WYBRON COLORAM II (See cable note below), RAINBOW PRO SERIES, AND CHROMA Q BROADWAY

COLOR SCROLLERS. THE AUTOYOKE SUPPLIES POWER TO THE SCROLLER; OTHER

MANUFACTURER’S SCROLLERS ARE NOT ELECTRICALLY COMPATIBLE. ATTEMPTING TO USE A

SCROLLER OTHER THAN THOSE LISTED ABOVE WILL POTENTIALLY DESTROY THE SCROLLER.All

AutoYoke-compatible scrollers that are not a Wybron CXI or a Wybron Coloram II are referred to in this

manual as direct DMX scrollers.

See Section 4-2 for addressing.

1.Insert the scroller into the lighting fixture gel frame holder.

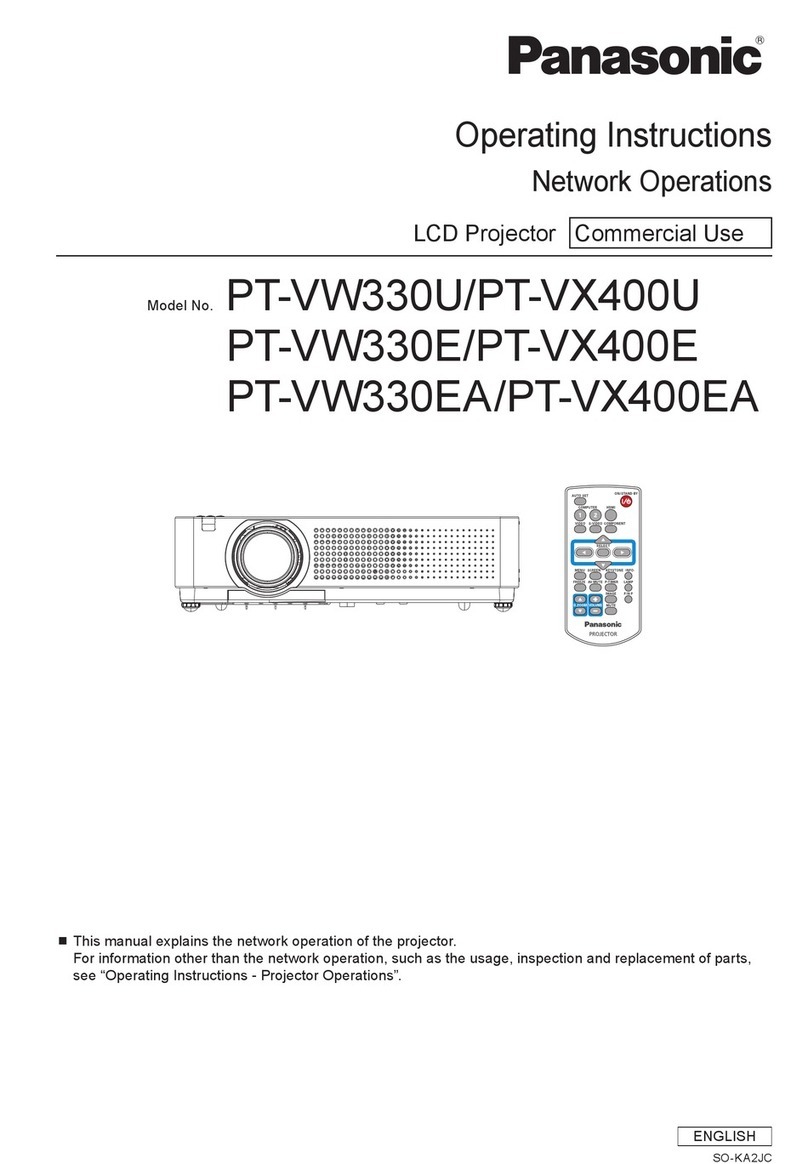

2.Plug a 15” 4-Pin XLR cable into the scroller and into the cradle connector box on the AutoYoke. (See

Example 7 for front view of cradle connector box)

***Note: City Theatrical does not recommend using a cable that is longer than 15”. Using a scroller

cable that is longer than 15” runs the significant risk of interfering with the AutoYoke’s range

of motion.

***Note: When using a Wybron CXI or a Coloram II, the scroller cable must be wired in the following

way: Male pin 1 to Female pin 4

Male pin 2 to Female pin 2

Male pin 3 to Female pin 3

Male pin 4 to Female pin 1

Using a cable that is not wired this way will destroy the scroller. Always consult the color

scroller manufacturer’s signal cable requirements before connecting a scroller to the AutoYoke.

-10-

XLR 4 pin

connector

(Scroller)

XLR 7 pin

connector

(Iris)

Stage Pin

connector

(lighting fixture)

EXAMPLE 7

3.Use at least one wire tie to secure

the scroller to the lighting fixture

(Example 8). The scroller must

not be able to shift in the gel

frame holder; Shifting may result

in AutoYoke inaccuracy and the scroller

falling from the fixture.

3-5INSERTING THE AUTOIRIS

The AutoIris is an optional accessory. See Section 6 for further information.

***Note: It is extremely important to avoid damaging the AutoIris with the end of the lens tube while it

is in the fixture. This can occur while focusing the lighting fixture if the lens tube is forced all

the way in. Damage can also occur if the AutoYoke is shipped with a loose lens tube allowing

the tube to slam into the AutoIris.

1.Remove iris slot cover from lighting

fixture and keep the screws.

2.Rotate iris slot cover 180 degrees and

hold in place.

3.Insert the AutoIris into the drop-in iris

slot on the lighting fixture.

4. Replace screws through holes to retain

AutoIris and reversed iris slot cover.

5.Plug the DMX Iris signal cable into the

7-Pin female XLR on the AutoYoke

cradle connector box.

-11-

iris slot cover screws

Old position of iris slot cover

New position of iris slot cover

AutoIris

EXAMPLE 8

3-6AUTOFOCUS

AutoFocus is an optional accessory. It is a factory installation. It will be necessary to perform simple

field maintenance wth the following tools:

· #1 Phillips head screwdriver

· #2 Phillips head screwdriver

· (2) 7/16 open end wrenches (optimally with offset heads).

CRITICAL MAINTENANCE POINTS:

· Tighten all Phillips head screws as much as possible.

· Tighten the front guide bolt as much as possible.

· Verify that the lead screw is exiting the motor opening at center. Observe this with the scroller

attached and the lead screw positioned either all the way out or all the way in.

If the lead screw is not at the exact center of the motor opening, loosen the two jam nuts.

Then tighten or loosen the rear guide bolt so that the lead screw is centered in the motor

opening. Once positioned correctly, use one crescent wrench to hold the rear guide bolt in

place, and use the other one to tighten the two jam nuts.

· Verify that the home flag is perpendicular to the drive shaft and flat so that it passes through the

home sensor correctly. Carefully adjust as needed.

home sensor

jam nuts (2)

lead screw

rear guide bolt

home flag

front guide bolt

motor opening

-12-

3-7CHANGING LENS TUBES (FOR UNITS WITH AUTOFOCUS)

If the Autoyoke is installed with AutoFocus and you wish to change or replace the Source Four lens tube, follow

these conversion procedures:

REMOVING EXISTING LENSTUBE FROM AUTOYOKE WITH AUTOFOCUS:

·Remove Autofocus cover

·Remove the 1-inch screw holding the front of the lenstube and the autofocus shaft.

·Loosen the 2 jam nuts on the 2-inch screw located just above the focus motor.

·Loosen the 2-inch screw (it is not necessary to remove the screw from the shaft).

·Lens tube may now be removed from the barrel.

MODIFICATION OF THE LENS TUBE:

·Remove plastic knob, ¼" screw and brass ferrule, they are not used. Remove all eight plastic guides,

they are not used.

·Cut strips of "BLACKTAK" 5 ¾" long and cover the slots where the plastic guides were removed in the

previous step. Smoothen "BLACKTAK" carefully to remove creases.

·Disassemble two halves of lens by removing three 8-32 screws with nuts and one 8-32 screw (at the

lower gel clip) which is tapped into the lens tube/ or may be also have a nut in some versions.

·Look at the inside front of the lens. One side of the lens tube has three lens holders and the other side

has two. Lay the side of the lens with the three lens holders down on the bench and carefully separate

the two halves of the lens, leaving the side with the three lens holders on the bench. For European lenses

with the safety screen, keep the screen in the half of the lens with the three lens holders.

·Insert one (1) ¼" x 1/32" flat washer as a shim under the nut opposite the gel frame retaining clip in the

lens casting.

·Put the two halves of the lens back together again. Be careful that the spring clip goes into the hole

properly.

·Reinstall the two 8-32 screws with nylock nuts at the rear of the lens to hold the two lens halves togeth

er. Reinstall one 8-32 screw with nylock nut near the spring clip (use needle-nose pliers or modified nut-

driver to hold the nut)

·Install Front Lens Mount Bracket at the lower gel clip with the one screw which is tapped into the casting.

The clip goes adjacent to the clearance hole. Use the same screw which was in there originally.

-13 -

3-8SECURING THE COUNTERWEIGHT SYSTEM

1.This step must be done after attaching the scroller and DMX Iris to ensure proper balance.

2.Facing the back of the lighting fixture, line up the holes on the bottom of the counterweight halo with

the matching holes on the rear of the connector box. Use two of the counterweight screws (1/4 - 20

x 3/4” socket head cap screws) to secure the counterweight halo into place.

3.The 10 counterweight rings provided with the AutoYoke should be added one at a time until the lighting

fixture is in balance. Facing the back of the lighting fixture, position the Leadrings on the back of the

counterweight halo, lining up the holes. Add Lead weights until the AutoYoke is close to the point of

balance and then add a Steel ring last to sandwich the lead weights. Use the remaining two counter

weight screws (1/4-20 x 2” socket head screws) to secure the rings into place.

***Note: If you are operating the AutoYoke with a Chroma Q scroller you may not need to add the

lead counterweight rings.

TIGHTENALLHARDWARE.

4. The lighting fixture will be in balance when it freely drifts to a horizontal position (perpendicular to the

AutoYoke). Operating the AutoYoke with the lighting fixture out of balance will result in inaccuracy.

***Note: If you are operating the AutoYoke without a scroller or with the lens tube of the lighting

fixture run all the way in, you may not need to add the counterweight rings or the counterweight

halo. In addition, the counterweight quantity may have to be adjusted once the lens tube position is

established. Operating the AutoYoke without a scroller will create an out of balance condition that

will not effect the accuracy or repeatability of the AutoYoke. Though not critical, this out of balance

condition can be improved with the addition of a color extender. Remember to safety all gel slot

accessories.

-14 -

3-9HANGING THE AUTOYOKE

The AutoYoke must be securely attached to the hanging position with hanging clamps. The Power Supply must be

placed either directly above or directly below the lighting fixture for proper operation. A secondary means of

suspension - a safety cable - must be used to prevent the AutoYoke from falling in the event of hanging clamp

failure.

Pan direction is CLOCKWISE from 0% to 100% when the AutoYoke is hanging Power Supply up, facing the Front

Panel, looking at the AutoYoke hanging from below. Keep this in mind when choosing hanging

orientation for optimal travel.

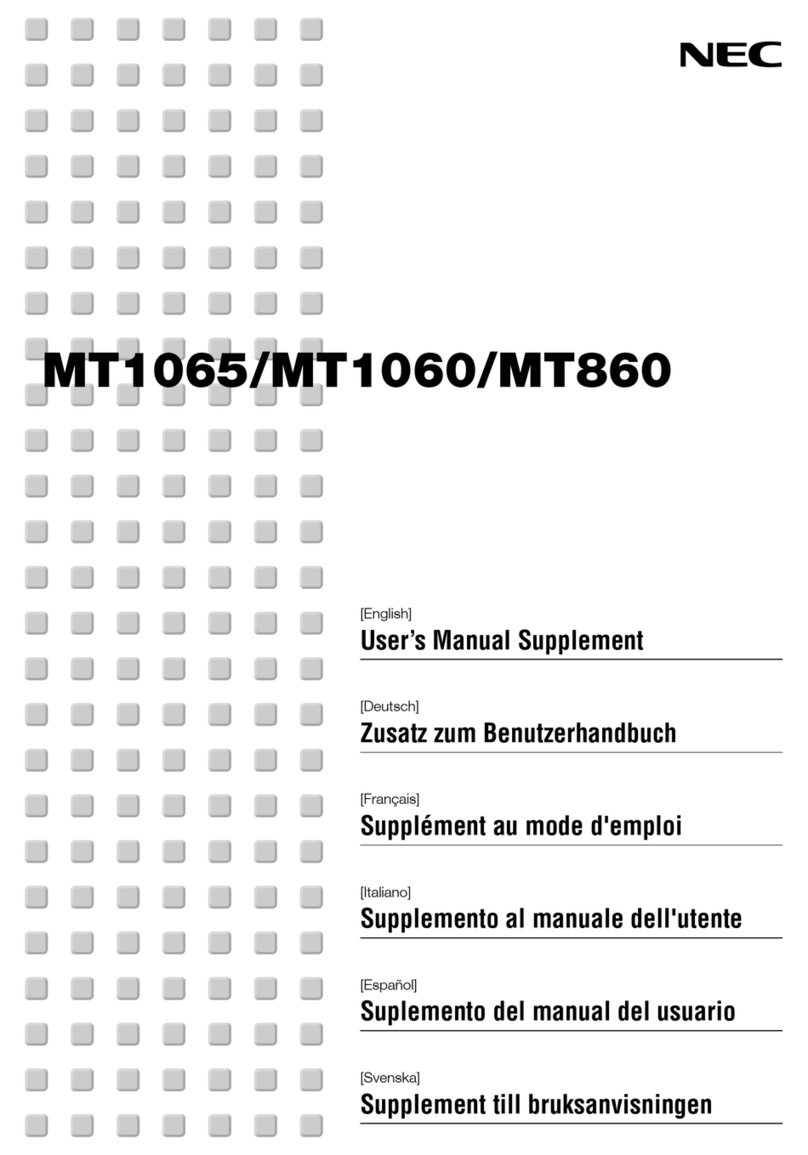

1.Attach hanging clamps to the specified holes on the top of the

Power Supply.

2. Hang the AutoYoke on a minimum of 2’3” centers and with a clearance

of 3’ from the top of the Power Supply to a fully extended lens tube

and scroller.

3.Fasten a safety cable through one of the handles of the AutoYoke, and

secure it to the hanging position.

3-10POWER CABLE

AutoYoke:The cable with the three pin Edison connector supplies power to the AutoYoke. Plug to a

NON DIMpower supply that is configured for a switchable PSUor a hot circuit that does

not pass through a dimmer rack.

Lamp:The cable with the three pin stage or twist lock connector (or without connector) supplies

power to the lighting fixture. Plug it to a dimmer.

3-11DATACABLE

Plug a DMXcable to the male 5-pin XLR on the AutoYoke Power Supply.

· Cable must be twisted pair, 120Ω, shielded EIA485 cable (Belden 9829, 9842 or equivalent),

minimum 22 AWG.

· Recommended maximum cable length is 1640’ (500m). [Recommended Practice for DMX512,

Adam Bennette 1994] Maximum cable length is 2000’ (610m).

· A maximum of 32 DMX receiving devices can be present on a single DMX line.

· The last DMX device on the line must be terminated with a resistor with a value of 120Ω.

-15 -

Hook Clamps

SECTION 4: USER INTERFACE

4-1MENU SYSTEM

Several of the routines (marked with a * below) that are performed at the front panel are also

accessible from the control channel (See Section 5-4, Control Channel, for further operation).

The menu on the front panel of the AutoYoke allows you to do the following:

· Set DMX address

· Calibrate*

· Invert Pan, Tilt, Iris and Focus travel direction

· Select 8- or 16-bit operation

· Select DMX smoothing value

· Set Pan, Tilt, Iris and Focus Limits*

· Display software version

· Invert display

· Change LED display properties

· Restore Factory Defaults

· Display Error messages

Throughout this manual, the following conventions will be used to explain menu navigation:

· Menu:The Menubutton allows you to enter the menu item or return to the

upper level menu items.

· Enter: The Enterbutton allows you to select a function.

· st: The arrow keys allow you to navigate into and out of the

menu system.

· AddrAddr:Menu items that appears on the LED display on the front

panel will be presented in this format.

-16-

4-2AddrAddr- ADDRESS

The AutoYoke requires 7 channels (16-bit) or 5 channels (8-bit) per fixture to operate. The scroller

requires an address other than those addresses occupied by the AutoYoke. When using a Wybron CXI

scroller, the scroller must be addressed at 001001, and it will occupy 3 control channels - the 8th, 9th, and

10th in the sequence when operating in 16-bit and the 6th, 7th, and 8th when operating in 8-bit. When

using a Coloram II scroller, the address at the head (rotary switch) is inconsequential, but the scroller will

always occupythe 8th channel in the sequence (in 16-bit) and the 6th channel in the sequence (in 8-bit).

All other specified scrollers can be set at a user selected DMX address as long as it is not occupied by an

AutoYoke attribute. It is only necessary to select the first DMX address for the AutoYoke.

*NOTE:WHEN USING COLORAM II SCROLLERS, SET THE DIP SWITCHES AS FOLLOWS:

Switch 1 - OFF (Motor Speed - Normal)

Switch 2 - ON (Operation - 24-Chan)

Switch 3 - OFF (Chan Range - 1~12)

Switch 4 - OFF (Fan Speed - Remote Xtrol)

DMX CHANNEL ASSIGNMENTS

16-bit8-bit

1 - Pan Course 1 - Pan

2 - Pan Fine 2 - Tilt

3 - Tilt Course 3 - Iris(occupied if not used)

4 - Tilt Fine 4 - Focus (occupied if not used)

5 - Iris(occupied if not used)5 - Control Channel

6 - Focus(occupied if not used)**Address scroller independently

7 - Control Channel

**Address scroller independently

1.Turn on the AutoYoke. Pan, Tilt, Iris and Focus will AutoCalibrate as the word GoGotravels across the

LED display (This will only occur if the AutoYoke is still configured with Factory Defaults. See Section

4-9 for Factory Default settings). If the AutoYoke is receiving DMX, it will travel to the DMX values

once it has calibrated. If the AutoYoke is not receiving DMX, it will move to a 50/50 position on

the Pan and Tilt axes upon the completion of calibration. The 50/50 position is at the halfway

point of the attributes' travel range. See Section 5-2 for further information about the 50/50 position

.***Note: If the AutoYoke is not receiving DMX, a series of dashes will continuously travel across the

LED display

***Note: The scroller is not part of the AutoCalibrate or Calibrate routine, but will autodetect and

self - test at Power Up.

2.Press Menu:AddrAddr(Address)AddrAddrwill appear on the display.

-17-

3.Press Enter:Default (or previously programmed)

address will appear on the

display.

4. Press st:0 - 5040 - 504Select DMX address from 0 -0 -

504504.

5.Press Enter:Address is recorded.

4-3CALCAL-CALIBRATE

Calibration is necessary to insure accurate operation at both power up and following an error

state. In the event that an AutoYoke is forced off of its recorded position, it should be recalibrated. See

Section 5-6, Encoders, for further information about recovering recorded position after the AutoYoke has

been hit. If the AutoYoke is not Calibrated at power up, it will not operate.

In the Calibrate sub-menu, the options are as follows:

· ALLALLCalibrate Pan, Tilt, Iris and Focus

· CALPCALPCalibrate Pan and Tilt (Tilt always Calibrates with Pan)

· CALtCALtCalibrate Tilt

· CALICALICalibrate Iris

· CALFCALFCalibrate Focus

· ACPACPAutoCalibrate Pan and Tilt at power up

· ACtACtAutoCalibrate Tilt at power up

· ACIACIAutoCalibrate Iris at power up

· ACFACFAutoCalibrate Focus at power up

· The default Calibrate setting is AutoCalibrate Pan, Tilt, Iris and Focus at power up. You may

choose to turn off the AutoCalibrate option or you may choose to AutoCalibrate only some of the

attributes. However, every attribute MUSTbe Calibrated before you operate the AutoYoke. See

Section 5-3, Factory Defaults, for further information.

4-3aCALIBRATE ALL (Pan, Tilt, Iris and Focus):

1.Press Menu:AddrAddr(Address)AddrAddrwill appear on the display.

2.Press st:CALCAL(Calibrate)Advance to CALCAL.

3.Press Enter:ALLALLALLALLwill appear on the display.

4.Press Enter:Pan, Tilt, Iris and Focus will

Calibrate.

-18-

Other manuals for AUTOYOKE

2

Table of contents