Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

4

ASSEMBLY AND PREPERATION FOR USE

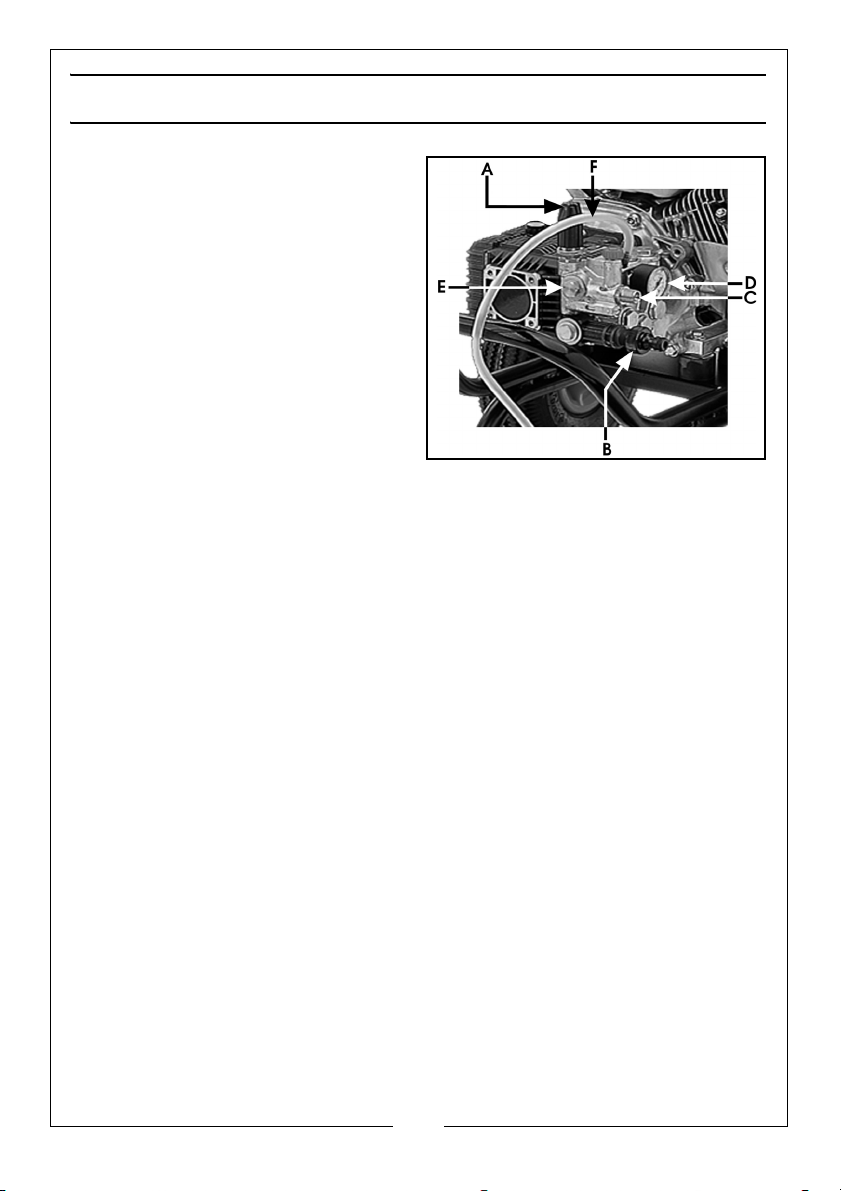

• A - Pressure Regulator Knob

• B - Low Pressure Water Inlet

• C - High Pressure Water Outlet

• D - Pressure Guage

• E - Unloader Valve

• F - Detergent Hose

1. Attach the handle to the frame,

using the plastic screws supplied.

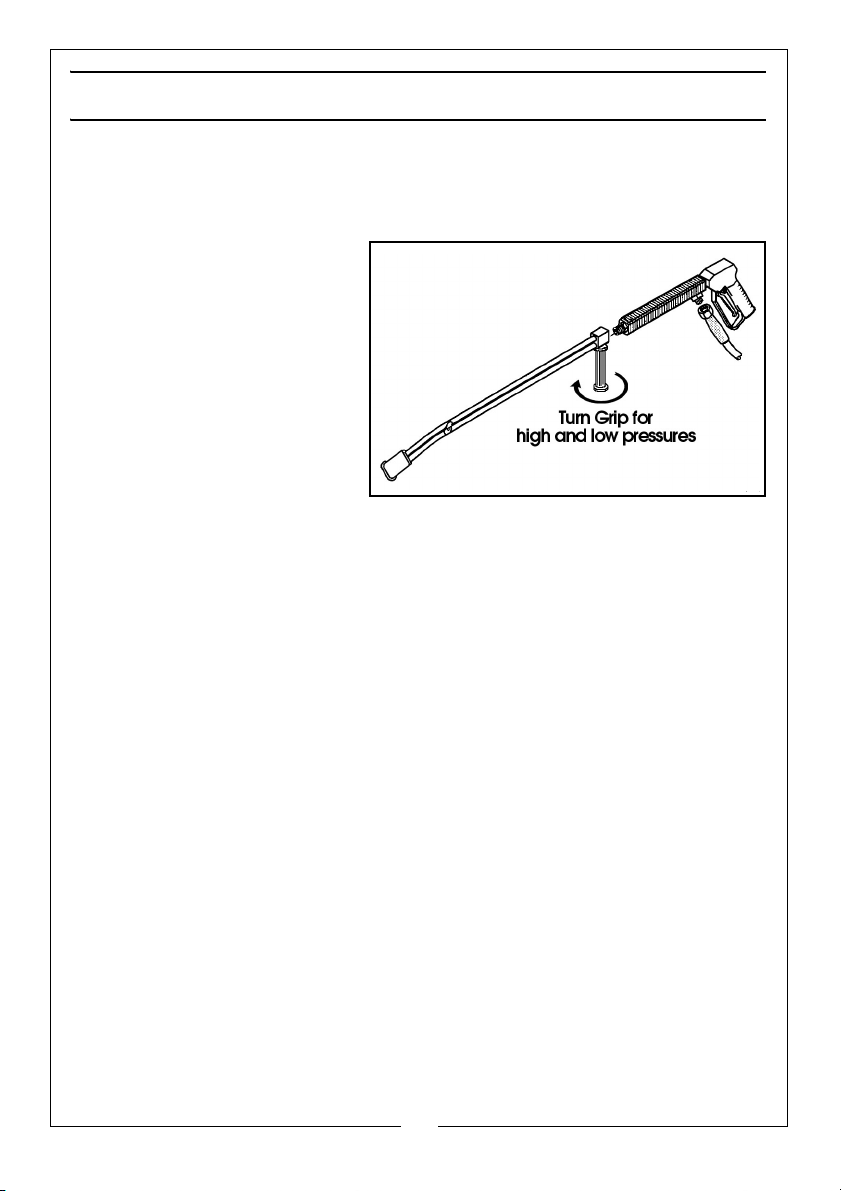

2. Assemble the lance, by screwing

the two halves together securely,

with the hand grip in any position convenient to the operator.

3. Two nipple sizes are supplied. That with the larger bore, is the low pressure

nipple, and should be screwed in to the tube nearest to the hand grip,

using a suitable socket.

The smaller bore nipple, is therefore screwed into the tube furthest from the

hand grip.

4. Connect the high pressure hose to the upper connection (C) on the

unloader valve,

• Fit the dowty washer between the hose and upper connection (C).

5. Connect the other end of ther hose to the connection at the lance,

ensuring the seals are correctly in place.

6. The hose from the mains supply is connected to the lower connection (B).

• A good quality hose of at least 1/2" should be used, and is available

from DIY, hardware and gardening supply stores. ALL connections

must be tight to prevent leaks.

7. Check the pump oil level using the sight glass, but be aware that if the level

is not visible, it may be as a result of over-filling, and should be checked by

removing the filler plug, and checking. Top up where necessary with the

recommended oil.

8. Refer to the handbook supplied for the engine, and check the engine oil

level, topping up where necessary with the recommended oil.