Clarke® Operator's Manual LV-30 Page 3

OPERATOR SAFETY INSTRUCTIONS

DANGERmeans: Severe bodily injury or deathcan occur to you or otherpersonnel if the DAN-

GER statementsfoundonyourmachineorinyourOwner'sManualareignored

orarenotadheredto. Read andobserveallDANGER statementsfoundin

yourOwner'sManualandonyourmachine.

WARNINGmeans: Injury can occur to you and to other personnel if the WARNING statements

foundonyour machineorin yourOwner'sManualareignored orarenot

adheredto. ReadandobserveallWARNING statementsfoundinyour

Owner'sManualandonyourmachine.

CAUTIONmeans: Damage can occur to the machine or to other property if the CAUTION state-

mentsfound onyour machineor in yourOwner's Manualare ignored orare not

adheredto. ReadandobserveallCAUTIONstatementsfoundinyourOwner's

Manualandonyour machine.

DANGER: Failure to read the Operator's Manual prior to using this machine could result in injury to

you or to other personnel; damage to the machine or to other property could occur as well.

Youmust have training in the operation ofthismachine before using it. If your operator(s)

cannotread this manual,have it explained fullybefore attempting to operatethis machine

DANGER: Machinescancauseanexplosionwhenoperatednearflammablematerialsandvapors. Do

not use this machine with or near fuels, grain dust, solvents, thinners, or other flammable

materials.

DANGER: Operating a machine that is not completely or fully assembled could result in injury or

property damage. Do not operate this machine until it is completely assembled.

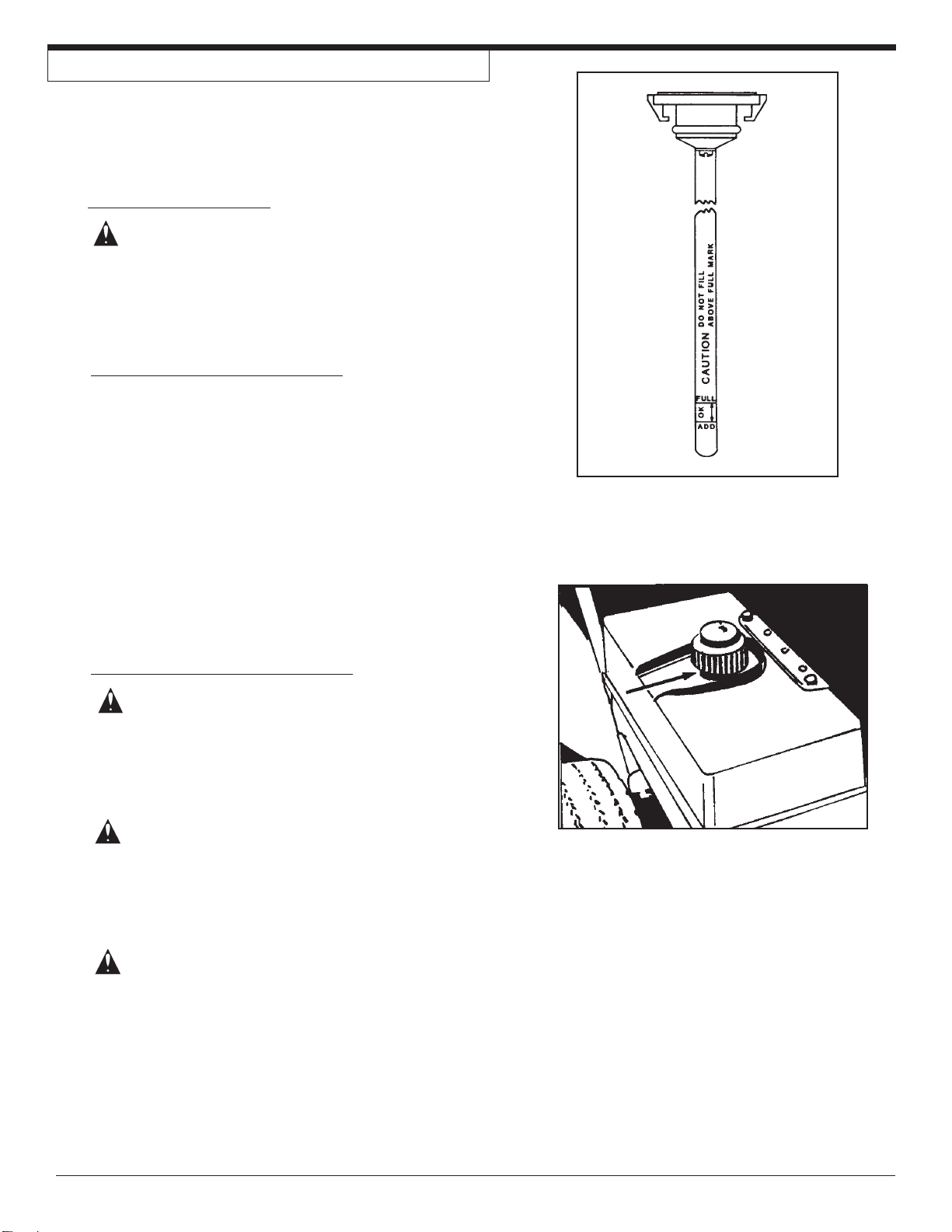

DANGER: Fillinga machinewith fuel inan explosive orpoorly-ventilated areacancause anexplosion.

Only fill the fuel tank in an open area. Do not fill the tank near open flames or while the

machine is running. Do not smoke while filling the tank. Do not over-fill the tank. Wipe up

any spills. Tighten the cap on the tank when finished.

WARNING: Removaloftheimpellercoverorothermaterialsfromthemachine,withoutdisconnecting

the spark plug, could result in serious injury to the operator.

WARNING: Failure to read and observe all safety statements found on your machine or in this

Operator'sManual can resultin serious injuryordamage. Read and observeall safety

statements. Make sure that all labels, decals, warnings, cautions, and instructions are

fastenedtothe machine. Get new labels from your authorized Clarke distributor.

WARNING: Toavoidinhaling exhaustfumes,operatemachinein awell ventilatedareaonly. Engine

exhaustfumesare dangerousto yourhealth.

CAUTION: Maintenanceandrepairsperformedbyunauthorizedpersonnelcouldresultindamageor

injury. Maintenanceandrepairsperformedbyunauthorizedpersonnelwillvoidyourwar-

ranty. Servicing of this unit must always be referred to an authorized Clarke distributor.

CAUTION: Use of this machine to move other objects or to climb on could result in injury or damage.

Do not use this machine as a step or furniture. Do not ride on this machine.

WARNING AVERTISSEMENT ADVERTENCIA