CLAUSING MS1318M User manual

MS1318M

Manual Miter Bandsaw

MS1318SA

Semi-Automatic Miter Bandsaw

Instruction Manual

Version 7 20210315

Clausing Industrial, Inc.

!

Safety rules

!

It’s essential to power on your bandsaw machine for at least one hour

every two years, if you seldomly use the machine.

(This period of power-on

must be without proceeding with other

operation) Otherwise the machine program may disappear due to not

strictly follow this safety rule.

**The restoration-

service fee for improper use will be extra charge.

Please note.**

Make sure your work area is cleared of uninvited

people and obstacles

every time before you start operating the machine.

Never step or stand on the roller table. Your foot may slip or trip

on the

rollers and you will fall.

Never wear gloves or loose clothing when operating the machine.

It may

lead to serious injury if they are caught in the running machine.

Wrap or

cover long hair.

Never touch the running saw blade with gloves or not. It is dangerous if

your hands, clothing or gloves are caught by the running blade.

Make sure any use of fire is prohibited in the shop and install a fire

extinguisher or other

fire control device near the machine when cutting

titanium, magnesium, or any other material that produces flammable chips.

Never leave the machine unattended when cutting flammable materials.

Use a water-soluble cutting fluid on this machine. Oil-based cutting fluids

may emit smoke or catch fire, depending on how they are used.

MS1318M / MS1318SA

!

Safety rules

Never cut carbon or any other material that may produce and disperse

explosive dust. It is possible that s

parks from motors and other machine

parts will ignite and explode the air-borne dust.

Never adjust the wire brush or remove chips while the saw blade is still

running. It is extremely

dangerous if hands or clothing are caught by the

running blade.

Stop the saw blade before you clean the machine. It is dangerous if hands or

clothing are caught by the running blade.

Never start the saw blade unless the workpiece has been clamped firmly. If

the workpiece is not securely clamped, it

will be forced out of the vise

during cutting.

Take preventive measures when cutting thin or short pieces from the work

to keep them from falling. It is dangerous if the cut pieces fall.

Use roller tables at the front and rear sides of the machine when cutting

long work. It is dangerous if the work piece falls off the machine.

Turn off the shop circuit breaker switch before

performing maintenance on

the machine. Post a sign indicating the machine is under maintenance.

MS1318M / MS1318SA

i

Table of Contents

Section 1 – Safety Information

1-1

Safety Instructions ………………………………………………………………………………………………………

1-1

Safeguard Devices ……………………………………………………………………………………………………….

1-3

Emergency Stop ………………………………………………………………………………………………………….

1-4

Illustration: Emergency Stop ………………………………………………………………………………………

1-5

Safety Labels ……………………………………………………………………………………………………………….

1-6

Illustration: Safety Labels ………………………………………………………………………………………..…

1-7

Hearing Protection ……………………………………………………………………………………………………...

1-8

CE Compliance …………………………………………………………………………………………………………….

1-8

Risk Assessment ………………………………………………………………………………………………………….

1-8

Section 2 – General Information

2-1

Specification ……………………………………..………………………………………………………………………..

2-2

Machine Parts Identification ……………………………………………………………………………………….

2-3

Floor Plan …………………………………………………………………………………………………..……………….

2-4

Section 3 – Moving & Installation

3-1

Location & Environment ………………………………..……………………………………………………………

3-1

Unpacking & Inspecting ……..……………………………………………………………………………………….

3-2

Lifting …………………………………………..………………………………………………………………….………….

3-3

Illustration: Lifting Points …………………………………………………………………….…………….

3-5

Removing Shipping Bracket …………………………..……………………………………………….……………

3-6

Cleaning …………………………………………..…………………………………………………………….……………

3-6

Installing …………………………...………………………………………………………………………….…………….

3-6

Supplying Hydraulic Oil …………………………………………………………………….…………….

3-6

Supplying Coolant ………..………………………………………………………………….……………..

3-7

Connecting Electric Power ……………………………………………………………….……………..

3-7

Leveling ……………………………………………………………………………………….…………………

3-8

Anchoring the machine …………………………………………………………………………………..

3-9

Installing Roller Table ………………………………………………….………………………………….

3-9

Installing Fire Control Device ………………………………………………….………………………

3-9

Relocating ………………………...…………………………………………………………………….………………….

3-9

Section 4 – Operating Instructions

4-1

Safety Precautions …………………..…………………..……………………………………….…………………….

4-2

Before Operating …………………………..…………………………………………………………………………….

4-3

Control Panel (MS1318M) ……..………………..………………………………………….………………………

4-4

Control Panel ………………….………………………………………………………………………..…….

4-4

MS1318M / MS1318SA

ii

Table of Contents

Control Buttons ……………………………………………………………………………………….……..

4-4

Control Panel (MS1318SA) ……..………………..……………………………………….………………………

4-5

Control Panel ………………….………………………………………………………………………..…….

4-5

Control Buttons ……………………………………………………………………………………….……..

4-5

Standard Accessories ………….………………………..……………………………………………….……………

4-7

Unrolling & Installing the Blade …………..………..…………………………………………………………….

4-9

Adjusting Blade Speed ………..………..…………………………………………………………………………….

4-10

Adjusting Saw Arm ………..………..………………………………………………………………………………….

4-11

Adjusting Coolant Flow ………..………..…………………………………………………………………..……….

4-11

Installing Material Stop Bracket ………..………..……………………………………………………………….

4-12

Adjusting Wire Brush ………..……………………………………………………………………….……………….

4-12

Test -Running the Machine ....………..……………………………………………..…………………………….

4-13

Breaking-In the Blade ………..………..…………………………………………………………………..………….

4-13

Cutting Operation ………..………..…………………………………………………………………..……………….

4-14

Terminating a Cutting Operation ………..………..…………………………………….……………………….

4-14

Section 5 – Electrical System

5-1

Electrical Circuit Diagrams ……….…………………..……………………………………………………………..

5-1

Section 6 – Hydraulic System

6-1

Hydraulic Diagrams ……….…………………..………………………………………………………………………..

6-1

Section 7 – Bandsaw Cutting: a Practical Guide

7-1

Introduction ……………………….…….…………………..…………………………………………………………….

7-2

Saw Blade Selection ………………….…………………..……………………………………………………………

7-2

Vise Loading….…………….…………………..………………………………………….………………………………

7-3

Blade Break -In …………….………………….………………………………………….………………………………

7-3

Section 8 – Maintenance & Service

8-1

Introduction ……………………….…….…………………..…………………………………………………………….

8-1

Basic Maintenance ………………….…………………..…………………………………………….……………….

8-1

Maintenance Schedule …………….…………………..…………………………………………………………….

8-2

Before Beginning a Day’s Work ……………………………………………………………………….

8-2

After Ending a Day’s Work …………………………………………………….………………………..

8-2

Every 2 weeks ……………………………………………………………………….……………………….

8-2

First 600hrs for new machine,then every 1200h…………………….……………………….

8-4

Every Six Months ……………….………………………………………………….……………………….

8-5

Storage Conditions …………………………....………..……………………………………………………………..

8-5

Terminating the Use of Machine ……..…………..……………………………………………………………..

8-5

Oil Recommendation for Maintenance ……………………………………………………………………….

8-6

MS1318M / MS1318SA

iii

Table of Contents

Section 9 – Troubleshooting

9-1

Introduction ……………………….…….…………………..…………………………………………………………….

9-1

Precautions ………………….…………………..…………………………………………………………………….....

9-2

General Troubles & Solutions ………………………..…………………………………………………………….

9-2

Minor Troubles & Solutions ………………………..………………………………………………..…………….

9-3

Motor Troubles & Solutions ………………………..…………………………………………………..………….

9-3

Blade Troubles & Solutions ………………………..………………………………………………………………..

9-4

Sawing Problems & Solutions ………………………..……………………………………………………………

9-5

Re-Adjusting the Roller Table ………………………..…………………………………………………………….

9-12

Section 10 – Parts

10-1

Spare Parts Recommendations …………………..……………………………………………………………….

10-1

Part List ……………………………………………………………………………………………………………………….

10-2

MS1318M / MS1318SA

MS1318M / MS1318SA

1-1

Section 1

SAFETY

INFORMATION

SAFETY INSTRUCTIONS

SAFEGUARD DEVICES

EMERGENCY STOP

SAFETY LABELS

HEARING PROTECTION

CE COMPLIANCE

RISK ASSESSMENT

Safety is a combination of a well-designed machine, operator’s knowledge about the machine and

alertness at all times. Our band machine has incorporated many safety measures during the design

process and used protective devices to prevent personal injuries and potential risks. Warning labels

also serve as a reminder to the operator.

Throughout this manual, you will also see various safety-related symbols indicating important

information that you should take note of prior to use of the machine or part of its functions. These

important safety instructions do not cover all possible situations that might occur. It is your

responsibility to take caution and follow procedures stated in this manual when installing,

maintaining and operating your machine. We will not be liable for damages resulting from improper

use.

SAFETY INSTRUCTIONS

What the icons and signs in this user manual mean:

This icon marks

WARNING; hazards or unsafe practices that may result in

personal injury or damage to the machine.

Supplementary information to the procedures described in this manual.

Call your local agent or our service center

for help.

MS1318M / MS1318SA

1-2

This manual has important safety

information. Read through it carefully

before operating this machine to

prevent pe

rsonal injury or machine

damage. Learn the operation, limitation

and the specific potential hazards

peculiar to this band saw. All users must

read it before performing any activity on

the machine, such as replacing the saw

band or doing regular maintenance

.

Disconnect the power cord before

making adjustment, maintenance or

blade changes.

Do not operate this machine unless it is

completely assembled.

Make sure the power switch is off before

plugging in power cord.

Always remember to switch off the

machine when the work is completed.

Use recommended accessories.

Improper accessories may be hazardous.

Never hold the material by hand for

cutting. Always use the vise and make

sure the material is clamped securely

before cutting

.

When a workpiece is too long or heavy,

make sure it is supported with a roller

table (recommended).

Keep your work area well illuminated at

minimum

500 lumen.

Remove adjusting keys, wrenches or any

loose parts or items from the machine

before tu

rning on power.

Use a sharp saw blade and keep the

machine in its best and safest

performance by following a periodical

maintenance schedule.

!

!

Wear proper apparel during operation

and when ser

vicing the machine.

Some

personal protective equipment is

required for the safe use of the machine,

e.g. protection goggles.

Moving parts should be kept in proper

alignment and connection with the

machine. Check for breakage, mounting

and any other cond

itions that may

affect its operation. Any damaged part

or guard should be properly repaired or

replaced.

It is dangerous to operate the machine

when the floor is slippery. Keep the floor

clean and dry. Check for ice, moisture, or

grease before entering

.

Do not use the machine to cut explosive

material or high pressure vessels as it

will generate great amount of heat

during the sawing process and may

ignite an explosion.

Keep your work area clean. Cluttered

and slippery floors in

vite accidents.

Keep blade protection cover and wheel

covers in place and in working order.

Never operate while under the influence

of drugs, alcohol or medication.

Do not reach over or stand on any part

of the machine.

Keep the work environment safe. Do not

use band saw in a damp or wet location.

Keep all guards and shields in place

before installing or starting up the

machine.

Keep

unauthorized personnel away.

MS1318M / MS1318SA

MS1318M / MS1318SA

1-3!

SAFEGUARD DEVICES

The safeguard devices incorporated in this machine include the following two main parts:

1. Protection covers & guards

2. Safety-related switches

Protection Covers & Guards

1. Idle wheel housing cover

2. Drive wheel housing cover

3. Gear reducer cover

4. Wire brush belt cover

5. Blade guard cover (left & right)

6. Safety fence (left & right)(CE model only, as shown in Illustration: Safety Fence)

7. Chip conveyor cover (CE model only)

The protection devices should always be mounted on the machine whenever the machine is running.

Do not remove any of these safeguard devices under any circumstances except when servicing the

machine. Even skilled service technicians should still take cautions when performing repairs or service

on the machine with any of these protectors removed. It is the responsibility of the user to make sure all

these elements are not lost and damaged.

Take note of the following main moving parts on the machine prior to and during machine operation:

ySaw bow assembly

yDrive and idle wheels

yBlade guide arm

ySaw blade guide rollers

yQuick approach device

yWire brush

yChip conveyor (optional)

yWorkpiece clamping vises

yShuttle vises and workbed rollers

yTop clamps (optional)

yGear reducer

!

MS1318M / MS1318SA

1-4

Safety Related Switches

To protect the operator, the following safety related switches on the machine are actuated when the

machine is in operation.

Wheel motion detector

This is a proximity sensor used to detect the motion

of the drive wheel. Once the saw blade is broken

or

as soo

n as it starts slipping, the sensor will detect

and stop the drive wheel and the machine.

Power switch

Located on the cover of electrical cabinet, the power

switch controls the main power of the machine.

Emergency stop button

Located on the control panel, the button when

pressed will stop the machine completely.

Vise clamp switch

(depends on machine model)

This switch assures firm clamping of the workpiece. If

the workpiece is not cl

amped properly, the saw

blade

should not be allowed to run.

Wheel cover interlock switches

(CE model only

)

Located on the two wheel housings, these switches

are used to assure that the machine will stop

whenever the wheel covers are open. This device is

to protect users from being cut by the running saw

blades.

Among all these safety switches, some of them are used to protect the users and some of them are

used to prevent damage to saw blades, the workpiece and the machine itself, etc. We have taken

every precaution to prevent injury or damage and to provide safe and economical operation of the

machine.

EMERGENCY STOP

Designed to be easily accessible, the emergency stop button is located on the left (or right) bottom

corner of the control panel and is made in red color and rubber material. For CE models,

supplementary emergency stop button may be available at other area(s) of the machine depending

on machine type. Please refer to Illustration: Emergency Stop.

When you press the button, the machine will immediately come to a full stop to avoid injury or

damage when an accident occurs. The button will be locked when you press it. To unlock it, pull it

upward.

You should press it immediately without any hesitation when observing:

zAn emergency situation that would cause any injury or damage

zAn abnormal situation or problem such as fire, smoke, abnormal noise and etc.

MS1318M / MS1318SA

MS1318M / MS1318SA

1-5!

Illustration: Emergency Stop

!

MS1318M

!

!

MS1318SA

Emergency Stop

Emergency Stop

MS1318M / MS1318SA

1-6

SAFETY LABELS

Please read through and understand these safety labels before operating the machine. Refer to

Illustration: Safety Labels.

Label

Meaning

Label

Meaning

Impact Hazard

WEAR SAFETY SHOES. Do

not approach dropping area

during operation.

!

Read Operator’s Manual

This manual has important safety

information. Read through it

carefully before operating this

machine to prevent personal injury

or machine damage.

Keep Unauthorized

Personnel Away

Do not step.

Do not stand on the machine or on

the accessories!

DANGER: Running Blade

Blade runs through this

area. Keep your hands away

from a running blade to

avoid severe inj

ury. The

arrow indicates direction of

the blade.

Cutting Hazard

KEEP COVER CLOSED / KEEP HAND

OFF while the blade is running.

T

urn power off before opening

cover. Failure to follow the warning

can result in severe injury.

Hazardous Voltage

TURN POWER OFF before

servicing. Failure to

following the warning can

result in

severe injury.

Burn Hazard/Hot Surface

Hand Crush/Force from

Above

Crush hazard by vise

Loose Hand Hazard

KEEP HAND OFF. Do not

touch chip

conveyor. Failure

to follow the warning can

result in severe injury.

Pinch Point/Hand Entanglement

!

CAUTION : Class I invisible

Laser Radiation Present.

Avoid direct exposure to

beam.

MS1318M / MS1318SA

MS1318M / MS1318SA

1-7!

Illustration: Safety Labels

MS1318M/SA

MS1318M / MS1318SA

1-8

HEARING PROTECTION

Always use ear protection!

When your machine is running, noise generated by the machine may come from the following:

ySaw blade during cutting or material feed mechanism

yWire brush unit

yChip conveyor unit

ySpeed reducer

yHydraulic motor/pump

yBelt transmissions variable speed motors

yBlade motor

yCoolant pump

yDrive wheel

yParts not assembled tightly causing mechanical vibration

Our products pass noise testing less than 78 dBA. Noise level vary according to working conditions

and we recommend ear plugs or other hearing protection at all time. If your machine produces an

undesirable noise while it is running, you should:

1. Make sure all maintenance tasks have been performed following the prescribed maintenance

schedule (Refer to Section 8).

2. If maintenance does not seem to solve the problem, follow the troubleshooting procedures

under Section 9.

CE COMPLIANCE

Our CE model is designed to satisfy regulations of the Council Directive on the approximation of the

laws of the Member States relating to machinery (2006/42/EC) - Annex I Essential health and safety

requirements relating to the design and construction of machinery.

RISK ASSESSMENT

Risk assessment generally takes account of intended use and foreseeable misuse, including process

control and maintenance requirements. We made every effort to avoid any personal injury or

equipment damage during the machine design stage. However, the operator (or other people) still

needs to take precautions when handling any part of the machine that is unfamiliar and anywhere on

the machine that has potential hazards (e.g. the electrical control box).

MS1318M / MS1318SA

2-1

Section 2

GENERAL

INFORMATION

SPECIFICATION

MACHINE PARTS IDENTIFICATION

FLOOR PLAN

This band saw machine is designed by our R&D engineers to provide you the following features and

advantages:

Safety

yThis machine is designed to fully protect the operator from its moving parts during cutting

operation.

yThe machine and each compoment has passed strict testing (Council Directive on the

approximation of the laws of the Member States relating to Machinery).

yThe machine will shut off automatically when the saw blade is broken, protecting both the

operator and the machine.

Convenience & High-Performance

yThe machine is designed in the way that the operation and adjustment can be easily

performed.

yThe machine will stop automatically when out of stock.

yDual valve system is designed to achieve optimal cutting performance with the simple

setting of feed rate and perspective cutting pressure for different material.

MS1318M / MS1318SA

2-2

SPECIFICATION

Model

/ Name of Equipment

MS1318M/MS1318SA

Capacity

Angle

0±

45±

60±

Round

13” (330 mm)

11.8” (300 mm)

8.6” (220 mm)

Square

11.0” (280 mm)

9.4” (240 mm)

8.6” (220 mm)

Rectangular

(H x W)

280 x 440 mm

(11 x 17.3 in.)

OR 140 x 500

mm (5.5 x 19.7

in.)

11” x 9.4”

(

280 x 240 mm)

11” x 8.6”

(

280 x 220 mm)

Saw Blade

Speed

98~328 fpm (30~100 m/min)

Size (L x W x T)

163” x 1.06” x 0.035” (4,140 x 27 x 0.9mm)

Pressure

19~20 kgs/ cm² (Tolerance: +1~+2 kgs / cm² )!

Tension

Manual / 1900~2000 kgs / cm²

(Tolerance: +100~+150 kgs / cm² )!

Guide

Interchangeable tungsten carbide

Cleaning

Steel wire brush

Motor

Output

Saw Blade

3 HP (2.2 kW)

Hydraulic

*(MS1318SA only)

1/2 HP (0.37 kW)

Coolant Pump

1/8 HP (0.09 kW)

Other Components

-------------------------------

Tank

Capacity

Hydraulic

*(MS1318SA only)

2.1 gal (8 L)

Coolant

7.9 gal (30 L)

Remnant Length

-------------------------------

Vise

Clamping

Control Method

-------------------------------

Min. Clamping Capacity

0 mm

Clamping Pressure

-------------------------------

Workbed

Height

32.3” (820 mm)

Weight

Ne

t

MS1318M: 1,320 lb (600 kg)

MS1318SA: 1,408 lb (640 kg)

Gross

MS1318M: 1,760 lb (800 kg)

MS1318SA: 1,848 lb (840 kg)

Floor Space (

L x W x H)

MS1318M: 84.7” x 51.93” x 57.8” (2,152 x 1,319 x 1,469 mm)

MS1318SA:87.44” x 43.38” x 57.8” (2,221 x 1,102 x 1,469 mm)

Operating

Environment

Temperature (煌C)

5~40 煌C (41~104 煌F)

Humidity (%)

30~85% (without condensation)

*Please refer to the formula "Watt/Voltage = Amperage" with the information above.

* Design and specification are subjected to change without notice.

*The saw blade pressure and tension standard above are the general values. For special saw blade,

please contact to the saw blade manufacturer for the applicable values.

MS1318M / MS1318SA

2-3!

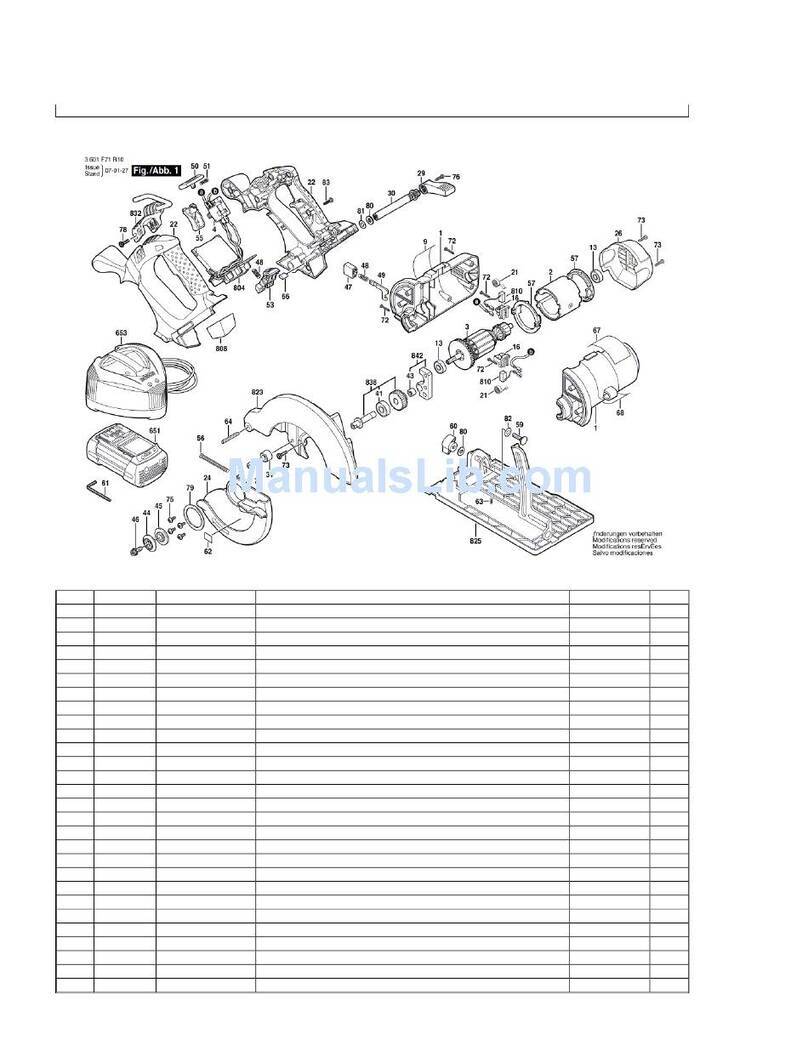

MS1318M

!

!

MS1318SA

!

Electrical Compartment

Slide Plate

Idle Wheel Cover

Saw Bow

Left Guide Arm

Base

Rotating Pivot Seat

Drive Wheel

Cover

Control Panel

Work Bed

Right Guide Arm

Pulley Cover

Blade Motor

Electrical Compartment

Slide Plate

Idle Wheel Cover

Saw Bow

Left Guide Arm

Base

Rotating Pivot Seat

Drive Wheel

Cover

Control Panel

Work Bed

Right Guide Arm

Pulley Cover

Blade Motor

MS1318M / MS1318SA

2-4

FLOOR PLAN

MS1318M

Machine top view

Machine front view

MS1318M / MS1318SA

This manual suits for next models

1

Table of contents