3

is rotating, don’t put the work-piece in either. Do not take the process-work-piece sawed by hand when

blade is still rotating. Caution: The blade will slide a period of time after turning off the Switch.

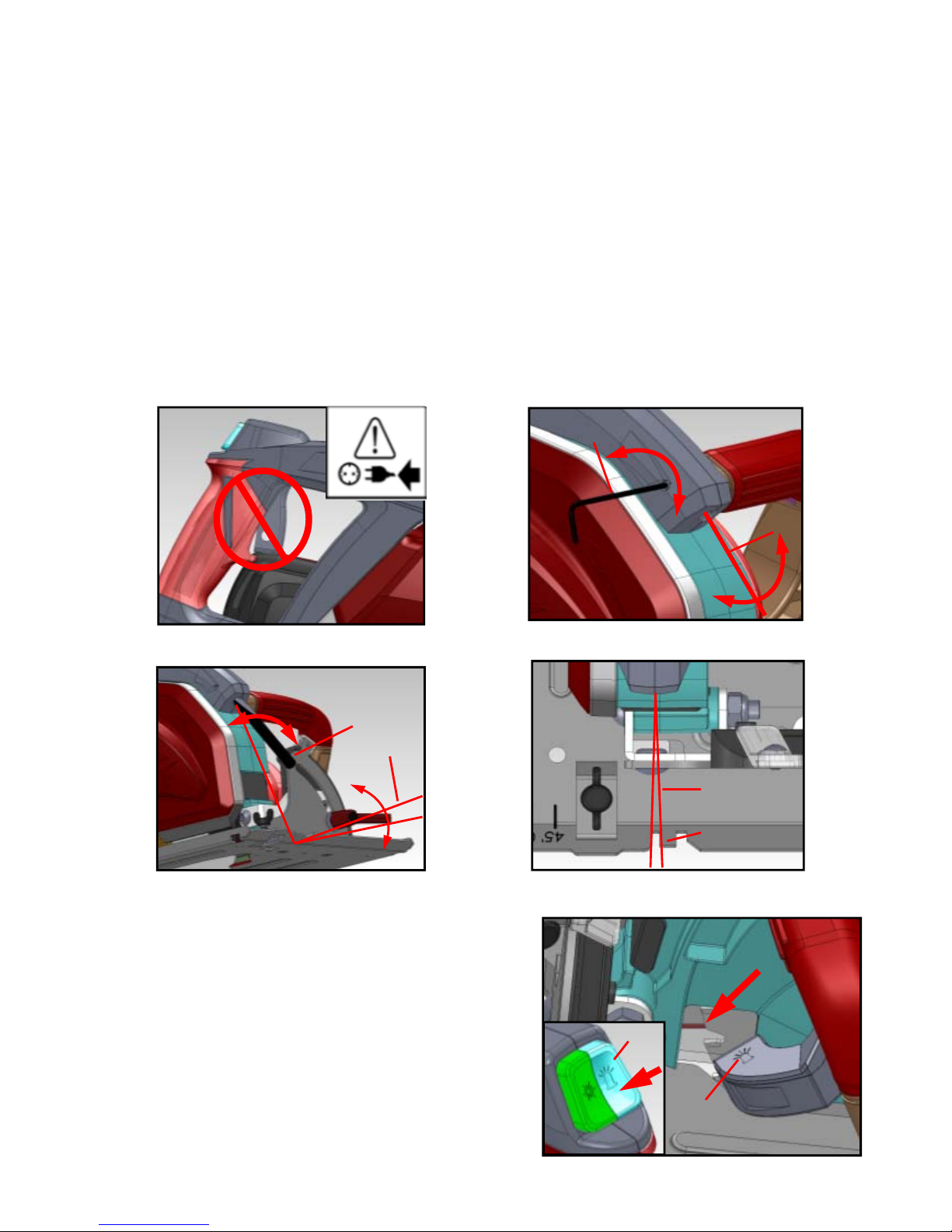

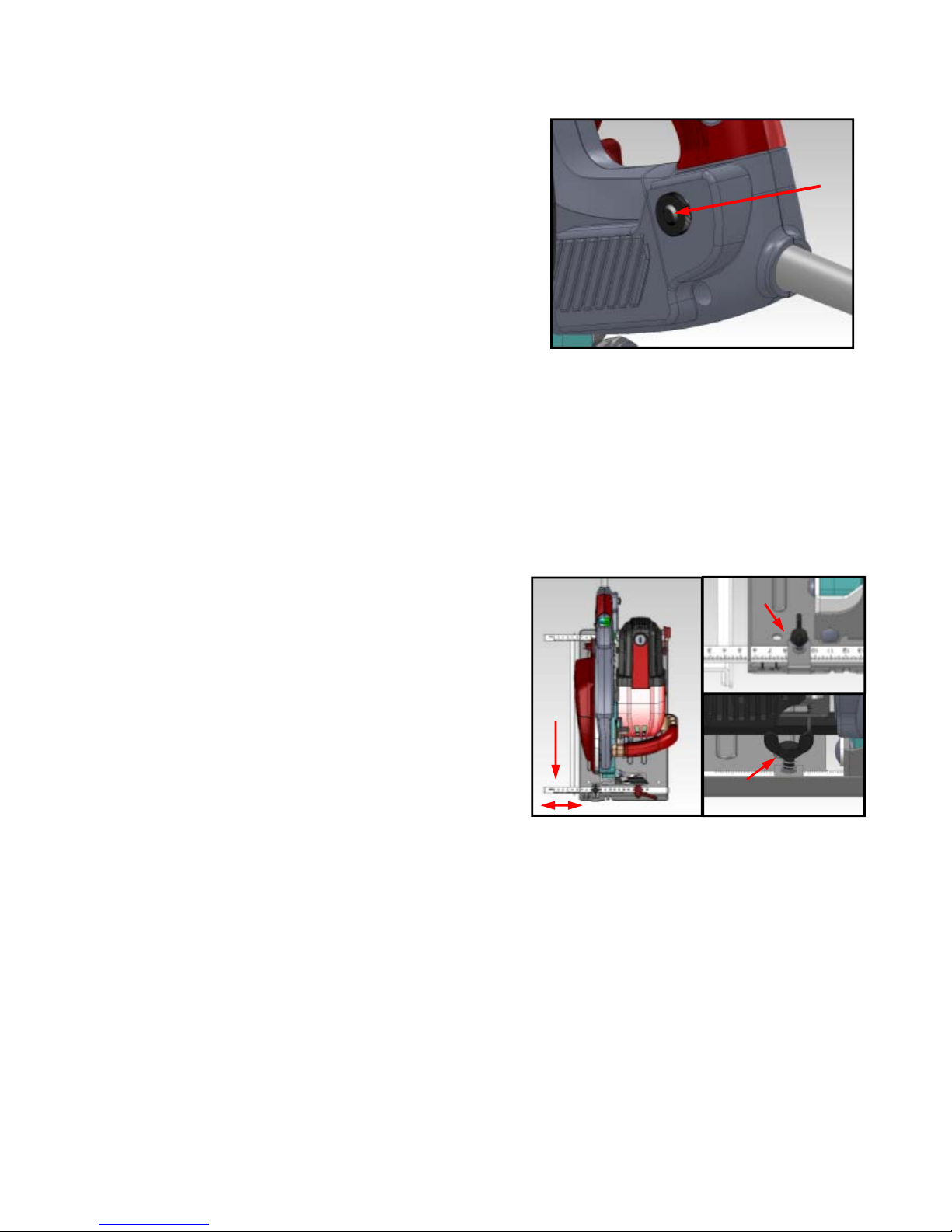

3. Adjustment. Before sawing, ascertain the adjustment of saw depth is right.

4. Must select the right blade. Use the suitable saw blade within the range shown on nameplate.

5. Guide cord should be apart from sawing place and be fixed when sawing, and ensure it can't be

twined by work-piece when sawing. The tool must be held steadily when sawing, and use the

appropriate work-piece to support, and put the guide cord far away from the work-piece.

6. Do not use cutting oil while cutting.

7. Do not use blades which are deformed or cracked.

8. Always use safety glasses. Everyday eyeglasses only have impact resistant lenses; they are not

safety glasses.

9. To avoid possible hearing damage, wear ear plugs when using power tool.

Motor Specifications and Electrical Requirements

Power Supply and Motor Specifications

The AC motor used in this saw is a universal. Nonreversible type having the following specifications:

Model No. 60250

Maximum

Developed H.P 2.4

Voltage 120

Amperes 15

Hertz (Cycles) 60

Phase Single

RPM 2300

Rotation of Shaft Counter-clockwise

Power Connections

A separate electrical circuit should be used for your tools. This circuit should not be less #12 wire and

should be protected with a 20 Amp fuse. Have a certified electrician replace or repair a worn cord

immediately and connect the motor as nameplate mentions. Running low voltage will damage the

motor.

WARNING: DO NOT EXPOSE THE TOOL TO RAIN OR OPERATE THE TOOL IN DAMP AREAS.

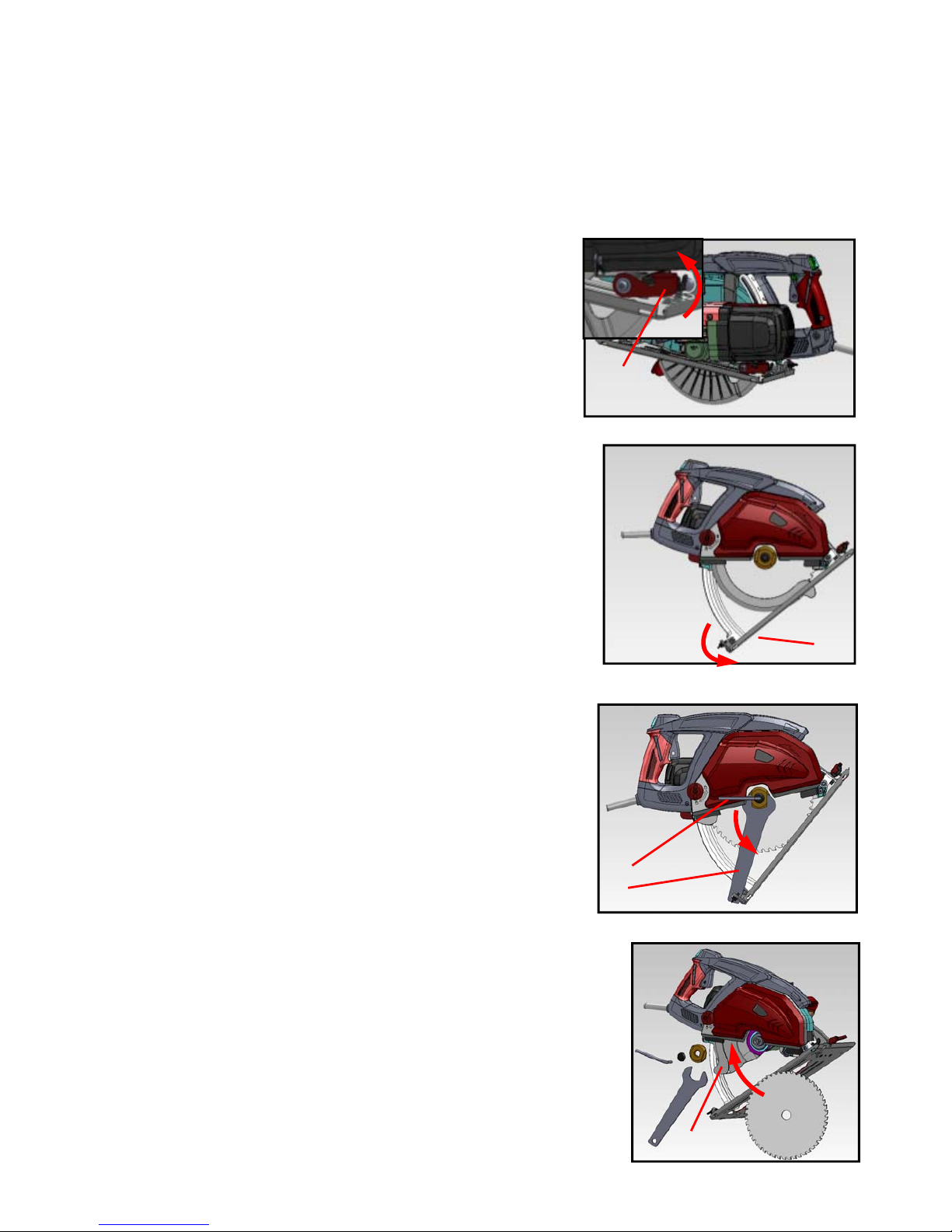

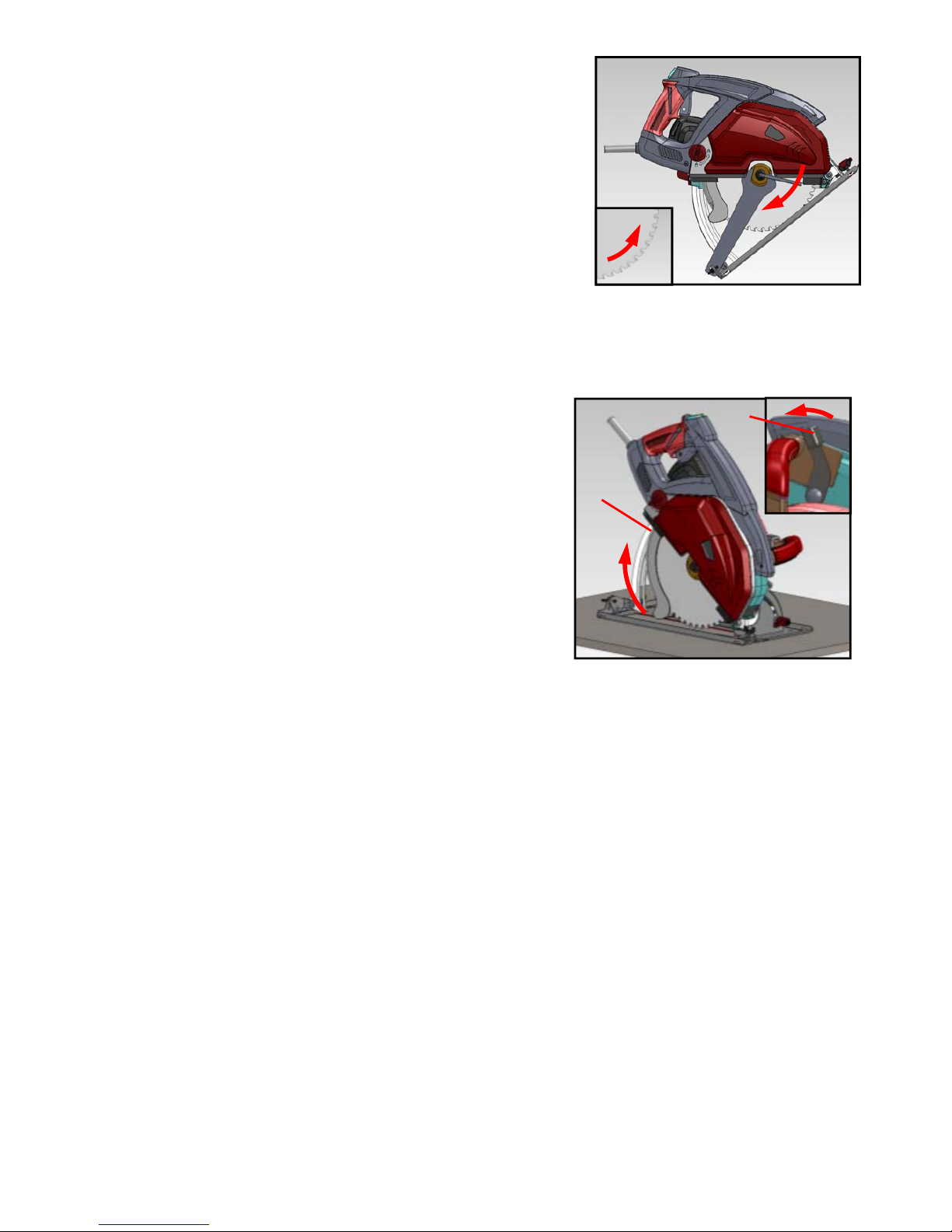

ASSEMBLY AND ADJUSTMENT INSTRUCTIONS

WARNING:

For your own safety, never connect the plug to a power source outlet until all assembly steps are

complete and you have read and understood the safety and operating instructions. The safety cover is

attached to the saw for your protection. Should the safety cover become damaged, do not use the saw

until damaged cover has been replaced. If the safety cover becomes dirty, or chip adheres to it. Clean

the safety cover carefully with a damp cloth.